- 12/3/18

- 37,415

- 79,563

- 113

Update concerning SEL

We've all experienced SEL issues and many of us have tried some various techniques to improve a look. I'd like to share a few things I learned over the years that might help others improve their look.

I'm making a 16713 with my case and finally have all the parts now but the bracelet I was going to use was a Noob TT and the gold didn't look so great. I had tried an ARF 116613 TT bracelet previously (a real beauty) but didn't get a good fit straight away.

So today I had another go at it and after trying a bunch of different springbars and some tape and bending and sanding mods, I was able to achieve a nice result.

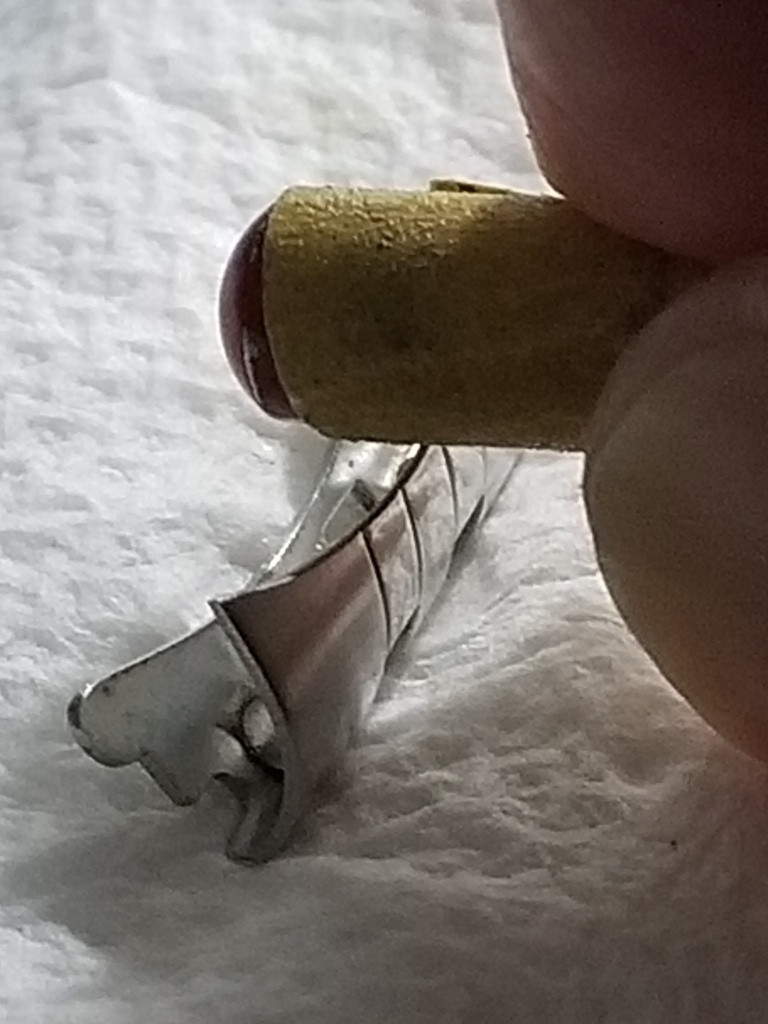

The ARF bracelet will take a 2.0mm springbar but on the shoulderless bars the tips are too big to both fit in the lug holes and extend fully. I had used a 1.5mm bar with about 6 layers of narrow bracelet tape on one long axis for the Noob and it was a reasonably decent fit. This technique allows you to force the bar to one side of the SEL hole (raising the SEL up), and makes the fit solid. It also provides smaller diameter tips that can fit into the lug holes without having to be centered.

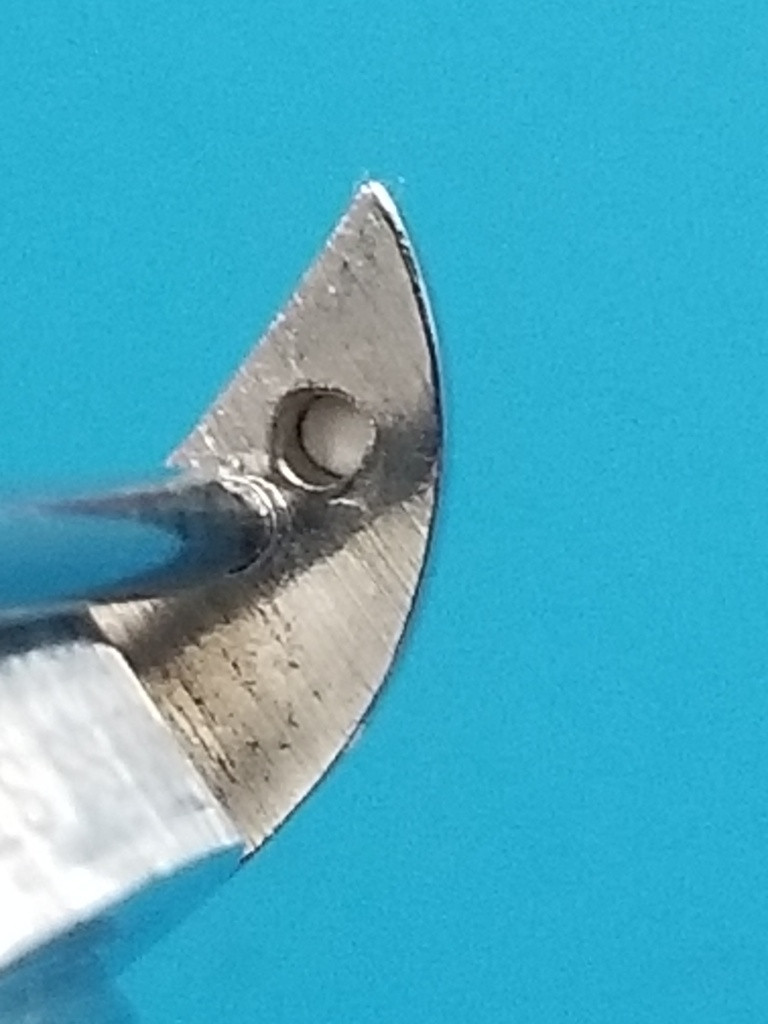

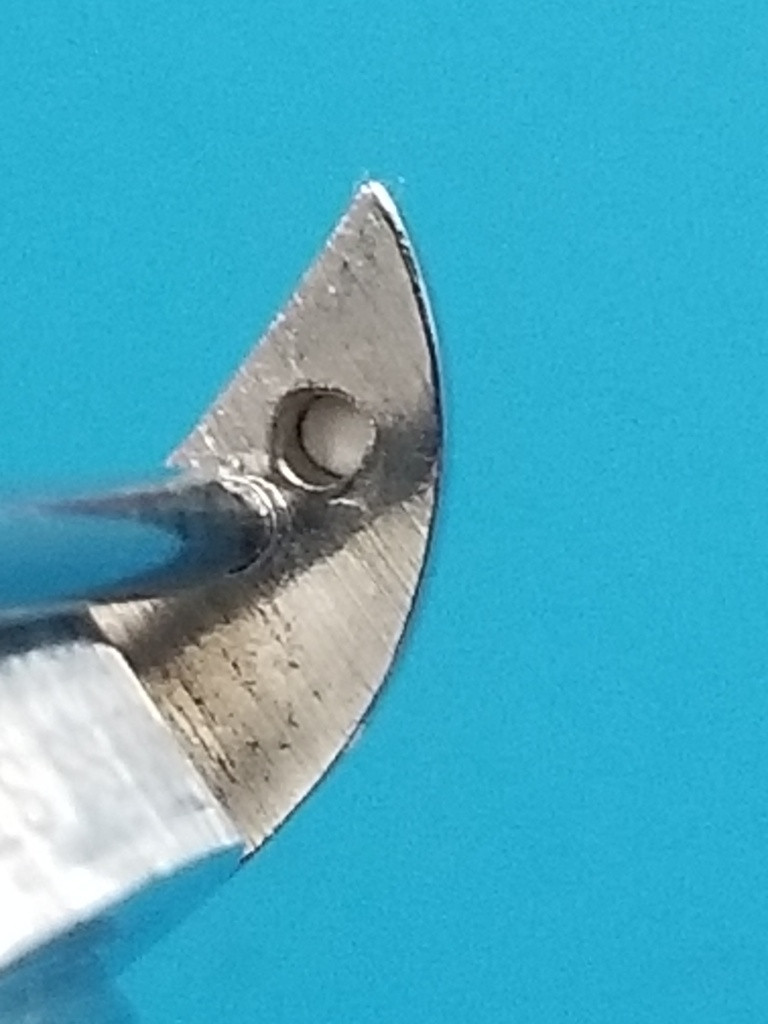

So with that in mind, I wondered if a 2.0mm springbar with shoulders and a smaller diameter tip would at all be feasible. The ARF SEL hole was big enough to also fit one layer of tape which would serve the two purposes mentioned above.

The springbars I used were from ST, the part number is on the bag. These are very nice, solid and strong.

You can stick tape on the bar right from the roll and cut off the excess.

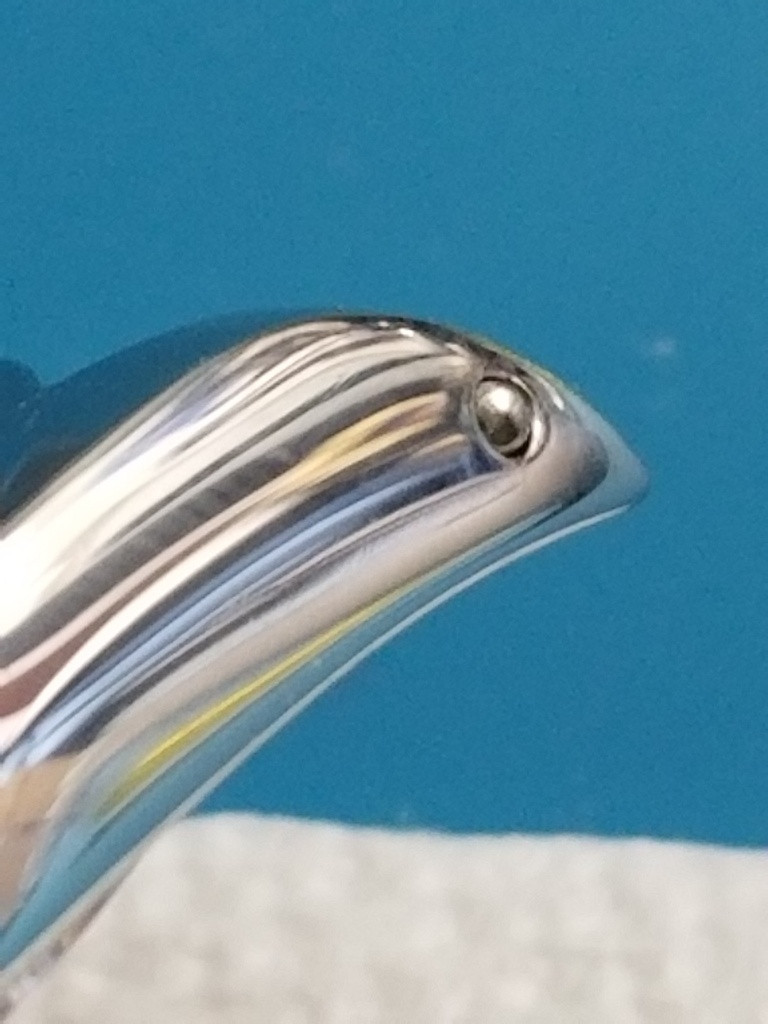

So on the initial fit attempt there was some rotational play in the SEL that created a little gap to the case if the bracelet was pulled down. Two layers of narrow tape on this vertical part of the case lip fixed that.

Then both sides of the bar tips wouldn't go in the holes because the bottom of the SEL was pushed back a little. So I bent the tip a little but even that wasn't enough.

So I began sanding a little of the tip off from the backside to let that tip extend into the hole. After a few attempts, it worked.

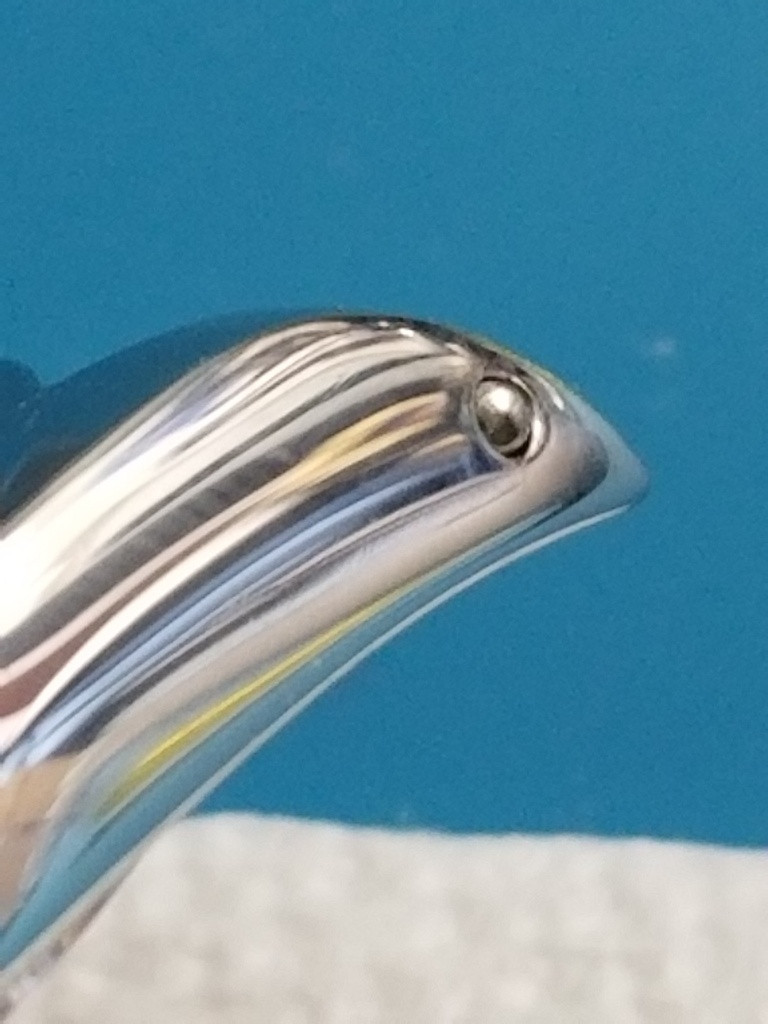

Now everything fits tightly and the SEL recess is OK.

The view from the bottom isn't the prettiest sight around but I know it's not going to bother me any.

I'll take this look every time.

With a little tinkering and some simple mods you can often make some substantial improvements. Ofc this result really needs the fake springbar tip mod to finish it properly. Ah the joys of repping, haha.

BTW if you are wondering I am going to use the ARF Glidelock clasp on this build. I've used a Glidelock on my gen 16710 for years, what an awesome improvement.

We've all experienced SEL issues and many of us have tried some various techniques to improve a look. I'd like to share a few things I learned over the years that might help others improve their look.

I'm making a 16713 with my case and finally have all the parts now but the bracelet I was going to use was a Noob TT and the gold didn't look so great. I had tried an ARF 116613 TT bracelet previously (a real beauty) but didn't get a good fit straight away.

So today I had another go at it and after trying a bunch of different springbars and some tape and bending and sanding mods, I was able to achieve a nice result.

The ARF bracelet will take a 2.0mm springbar but on the shoulderless bars the tips are too big to both fit in the lug holes and extend fully. I had used a 1.5mm bar with about 6 layers of narrow bracelet tape on one long axis for the Noob and it was a reasonably decent fit. This technique allows you to force the bar to one side of the SEL hole (raising the SEL up), and makes the fit solid. It also provides smaller diameter tips that can fit into the lug holes without having to be centered.

So with that in mind, I wondered if a 2.0mm springbar with shoulders and a smaller diameter tip would at all be feasible. The ARF SEL hole was big enough to also fit one layer of tape which would serve the two purposes mentioned above.

The springbars I used were from ST, the part number is on the bag. These are very nice, solid and strong.

You can stick tape on the bar right from the roll and cut off the excess.

So on the initial fit attempt there was some rotational play in the SEL that created a little gap to the case if the bracelet was pulled down. Two layers of narrow tape on this vertical part of the case lip fixed that.

Then both sides of the bar tips wouldn't go in the holes because the bottom of the SEL was pushed back a little. So I bent the tip a little but even that wasn't enough.

So I began sanding a little of the tip off from the backside to let that tip extend into the hole. After a few attempts, it worked.

Now everything fits tightly and the SEL recess is OK.

The view from the bottom isn't the prettiest sight around but I know it's not going to bother me any.

I'll take this look every time.

With a little tinkering and some simple mods you can often make some substantial improvements. Ofc this result really needs the fake springbar tip mod to finish it properly. Ah the joys of repping, haha.

BTW if you are wondering I am going to use the ARF Glidelock clasp on this build. I've used a Glidelock on my gen 16710 for years, what an awesome improvement.

Last edited: