Just go on AliExpress and search for whatever size you need. There’s lots on there for $3-4 each.

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a true gilt dial on the cheap - Tropical or Black

- Thread starter chrome72

- Start date

Thanks. I’ve messaged a few sellers to make sure they are really brass and not just gold colored aluminum (that a lot seem to be.)Just go on AliExpress and search for whatever size you need. There’s lots on there for $3-4 each.

The ones I got were 100% brass. If you are going for a gilt dial, the gold would work too as long as you don't sand it off! You can get away with just polishing it most likelyThanks. I’ve messaged a few sellers to make sure they are really brass and not just gold colored aluminum (that a lot seem to be.)

Try Inkscape it's a free bit of software and pretty useful if you don't already have it.Final stupid question. I’ve found the black and white decal designs (Jpeg) in various threads. There seemed to be some Illustrator and Photoshop files with dead links now. How is everyone scaling the dials properly for printing?

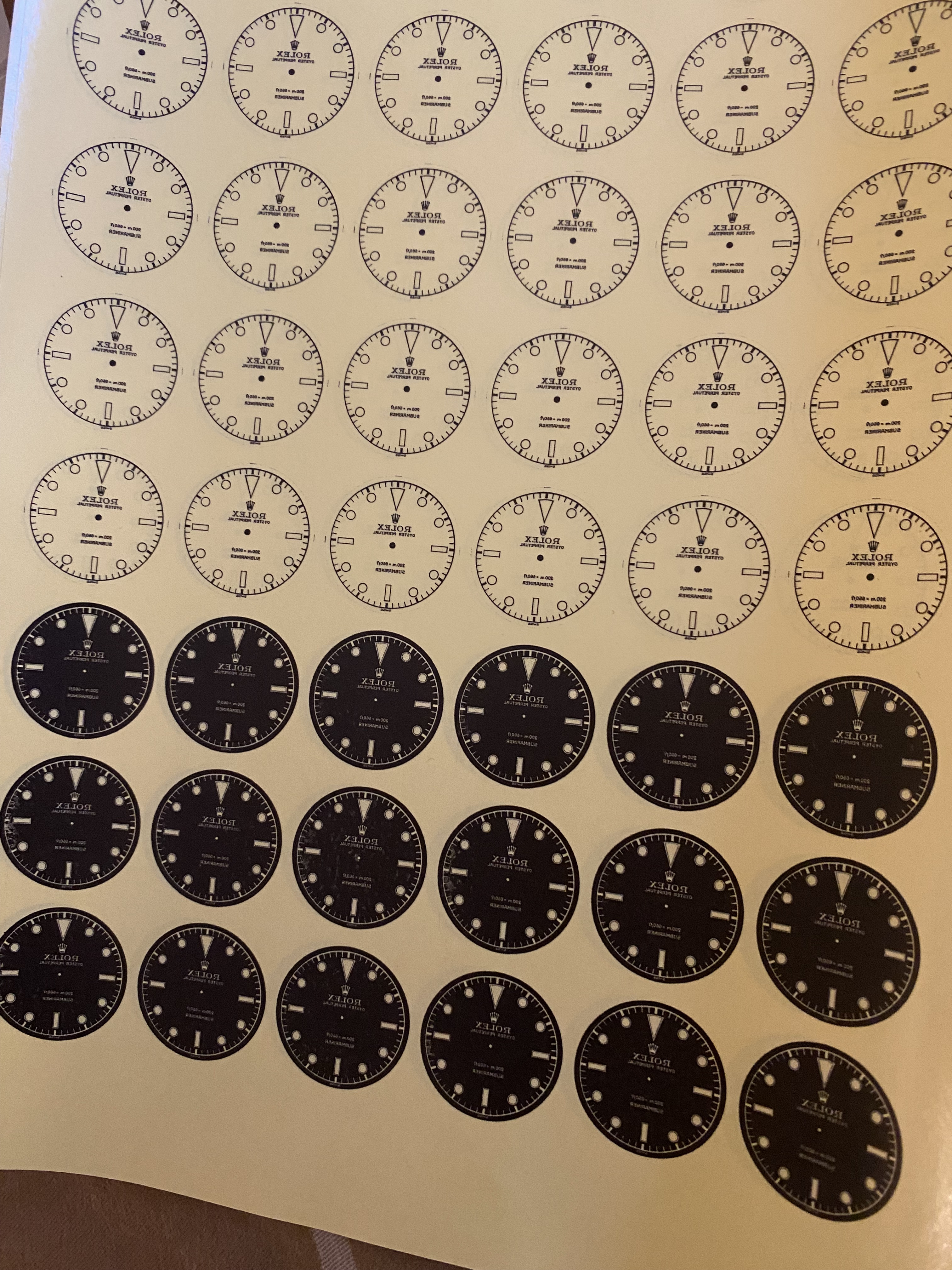

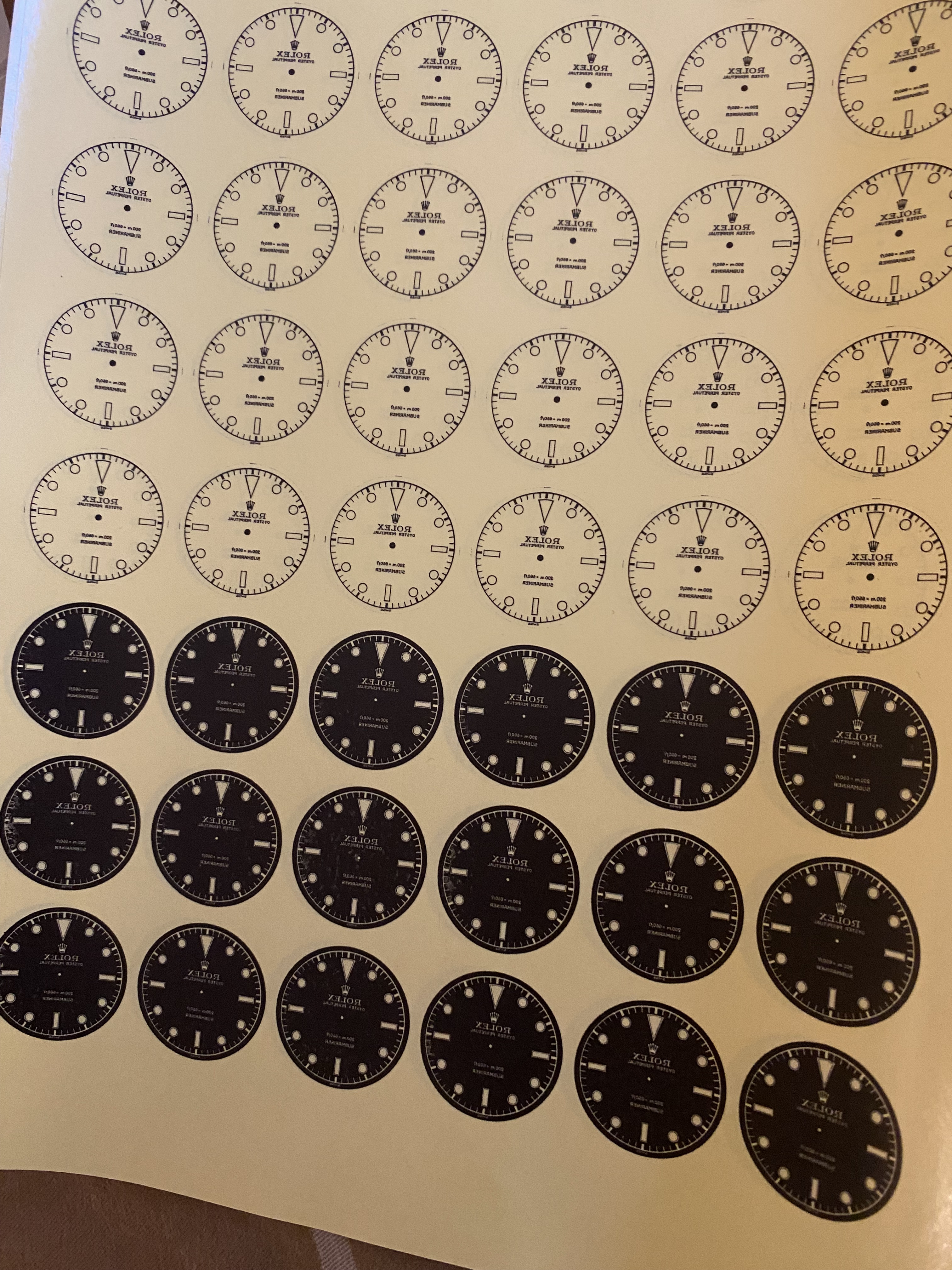

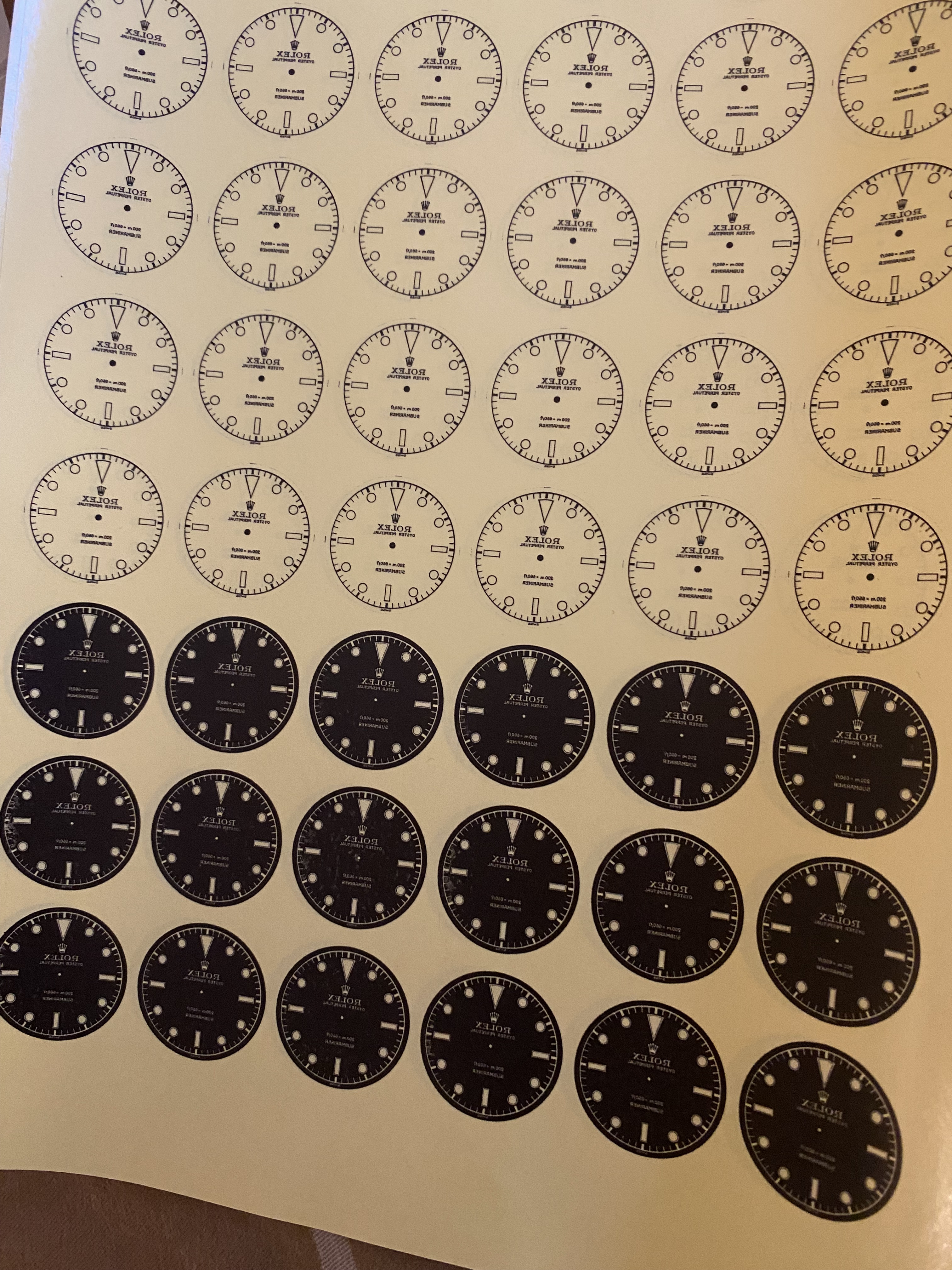

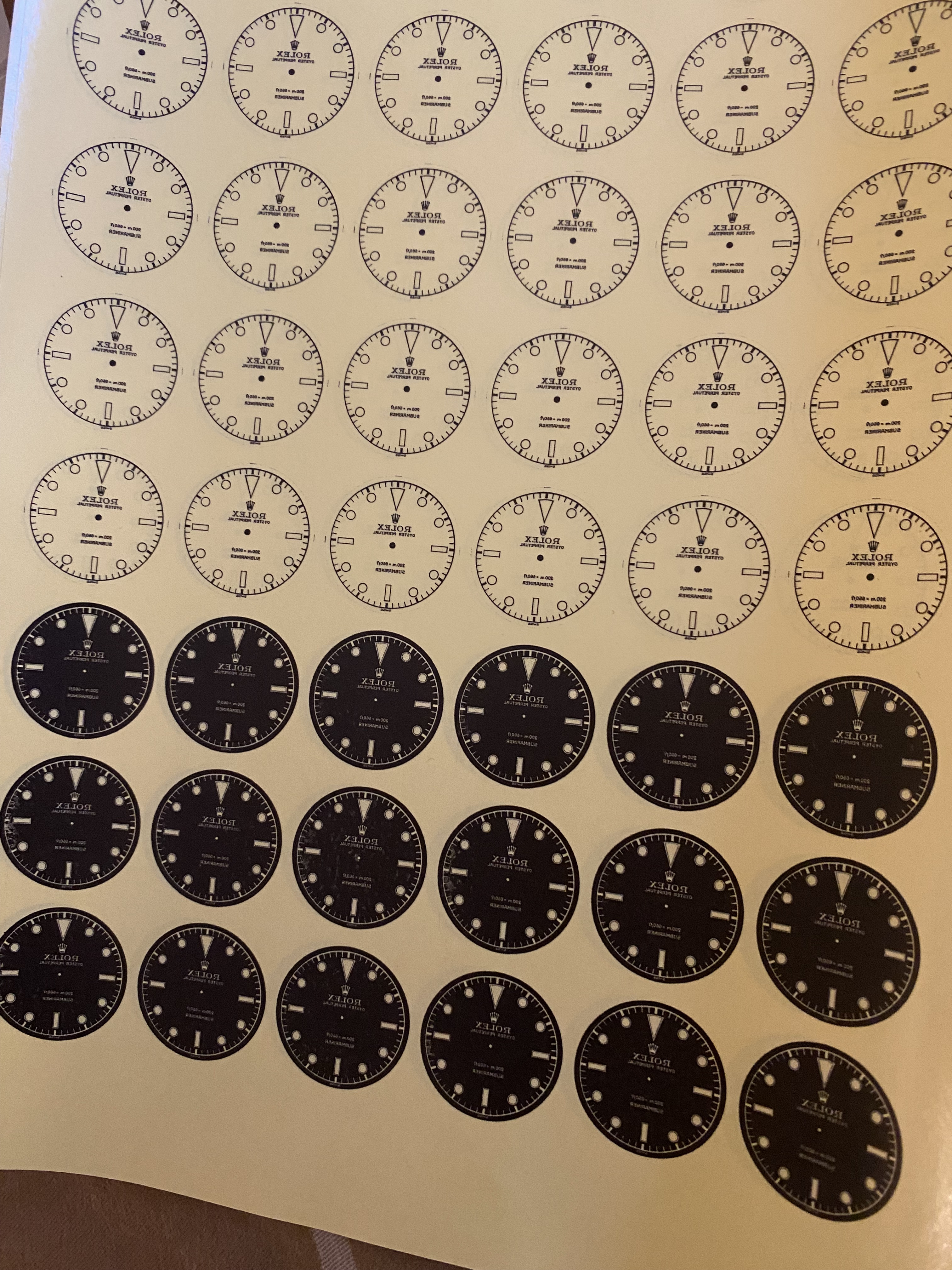

Got my transfers scaled and printed! Excited to experiment when my blank dials arrive this week.

A little tip for the reverse negative ones. You don’t really have much alignment built in (ie a circle just barely bigger than the actual dial or cross hairs for 3 o’clock alignment) you can use a really bright light to shine onto the paper and you can kind of see the artwork through the paper and see where it will be on the brassGot my transfers scaled and printed! Excited to experiment when my blank dials arrive this week.

Those look pretty good transfer wiseThis was far more difficult than I expected! Many tries to get the ink to fully transfer to the dial, and I wasn’t happy with the outcome after I used Brass Black. I’m going to give a water slide decal a try instead and might come back to this method later on.

I thought so too, but then everything went south. Haha. I spent many hours trying to get a good one.Those look pretty good transfer wise

The one on the left looks like it wasn’t fully grease/dirt free. The one on the right has issues I sometimes get and I can’t figure out why. It has the grid of brass colored dots evenly spaced out. part of me thinks that it’s the way the brass was made since it’s typically copper/zinc alloy I find that if I sand the problem doesn’t repeat itself for that dial.I thought so too, but then everything went south. Haha. I spent many hours trying to get a good one.

I thought so too, but then everything went south. Haha. I spent many hours trying to get a good one.

You need to zinc plate the dial after you've masked it that's how you get the depth, once it's plated then dip it in black zinc passivate to blacken it.

Remove the masking and you've got yourself a negative relief dial.

Satin Black Passivate - ePlating

Black Passivate is a process for creating a black chromate on zinc plate, and is suitable for use with acid, cyanide and alkaline non-cyanide zinc plating. The kit includes enough chemicals to make 5 litres of black passivate. This works with zinc plating producing an attractive satin black...

Thanks for the tip. If I’m not happy with my water slide decal attempt next week, I’ll give this a shot.You need to zinc plate the dial after you've masked it that's how you get the depth, once it's plated then dip it in black zinc passivate to blacken it.

Remove the masking and you've got yourself a negative relief dial.

Satin Black Passivate - ePlating

Black Passivate is a process for creating a black chromate on zinc plate, and is suitable for use with acid, cyanide and alkaline non-cyanide zinc plating. The kit includes enough chemicals to make 5 litres of black passivate. This works with zinc plating producing an attractive satin black...eplating.co.uk

I used to have stacks & stacks of decal paper, trip down memory laneGot my transfers scaled and printed! Excited to experiment when my blank dials arrive this week.

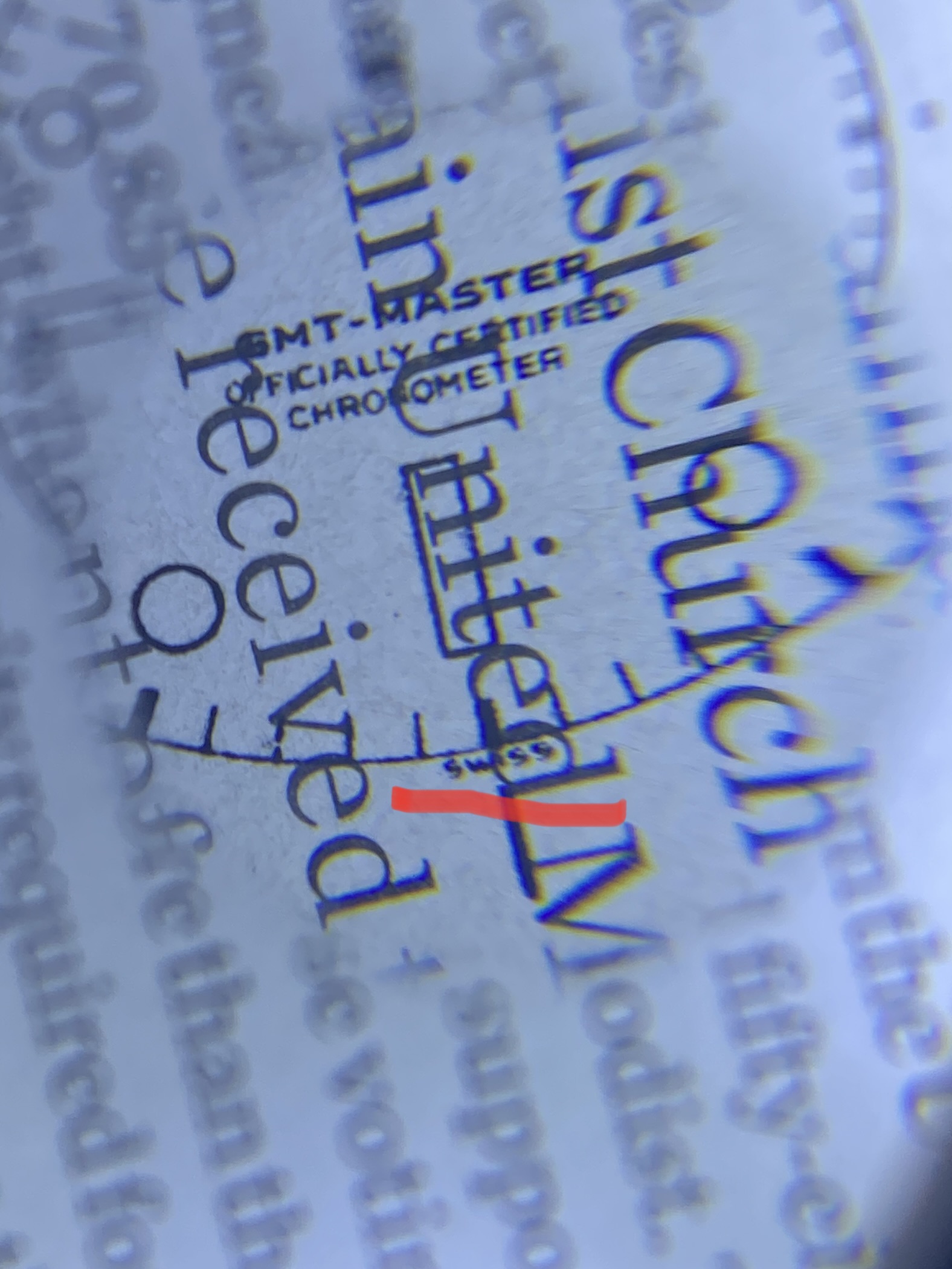

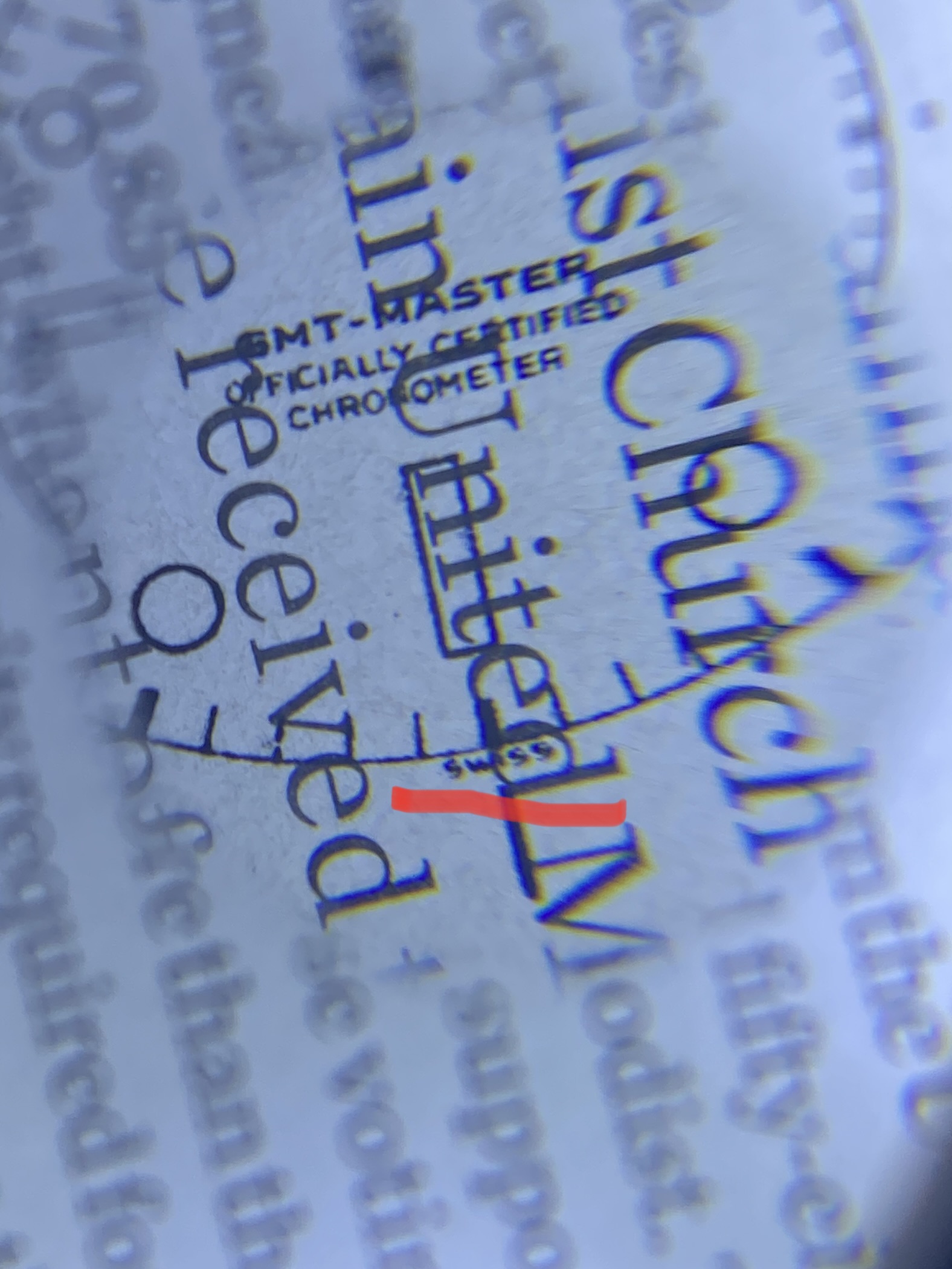

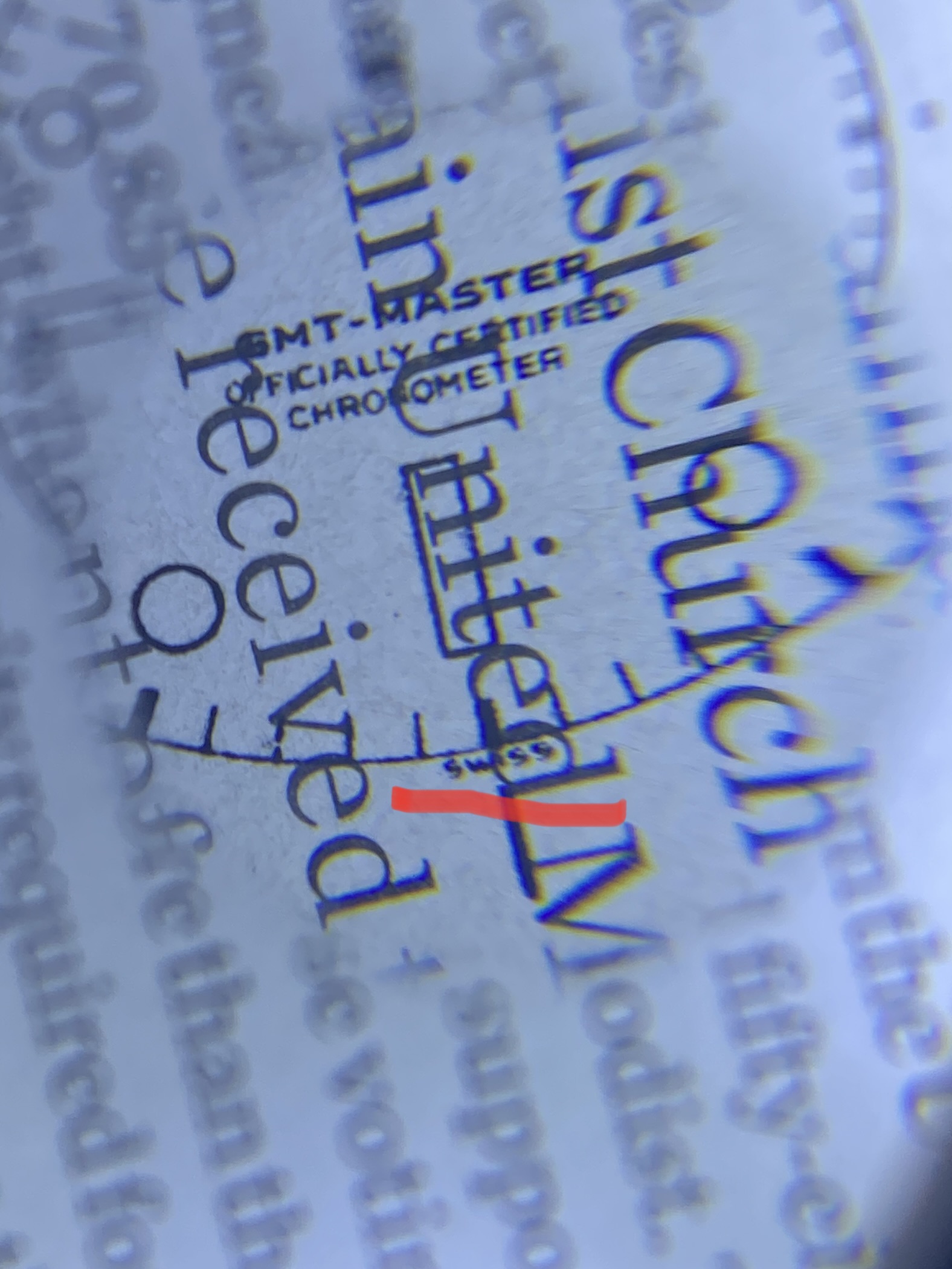

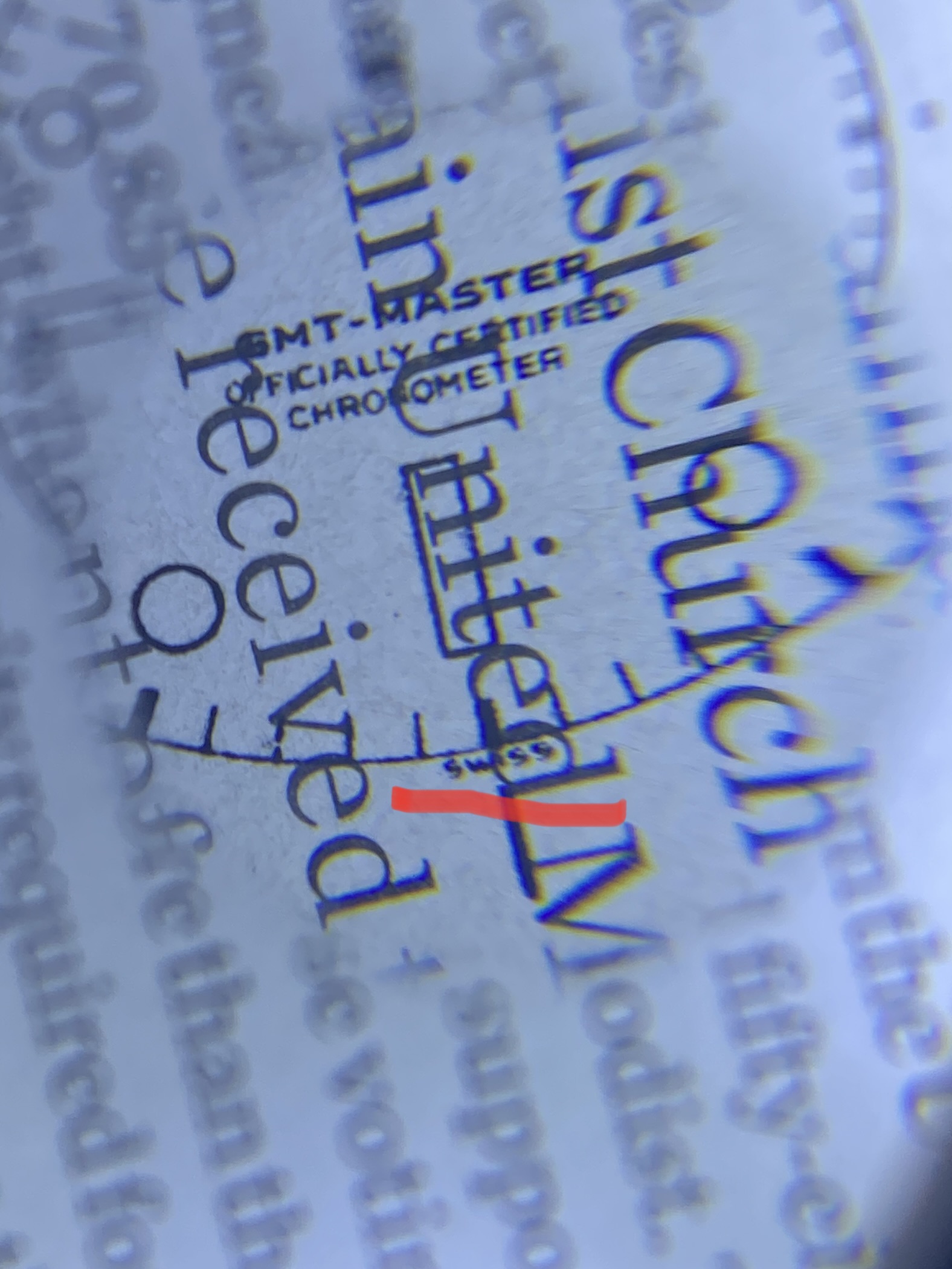

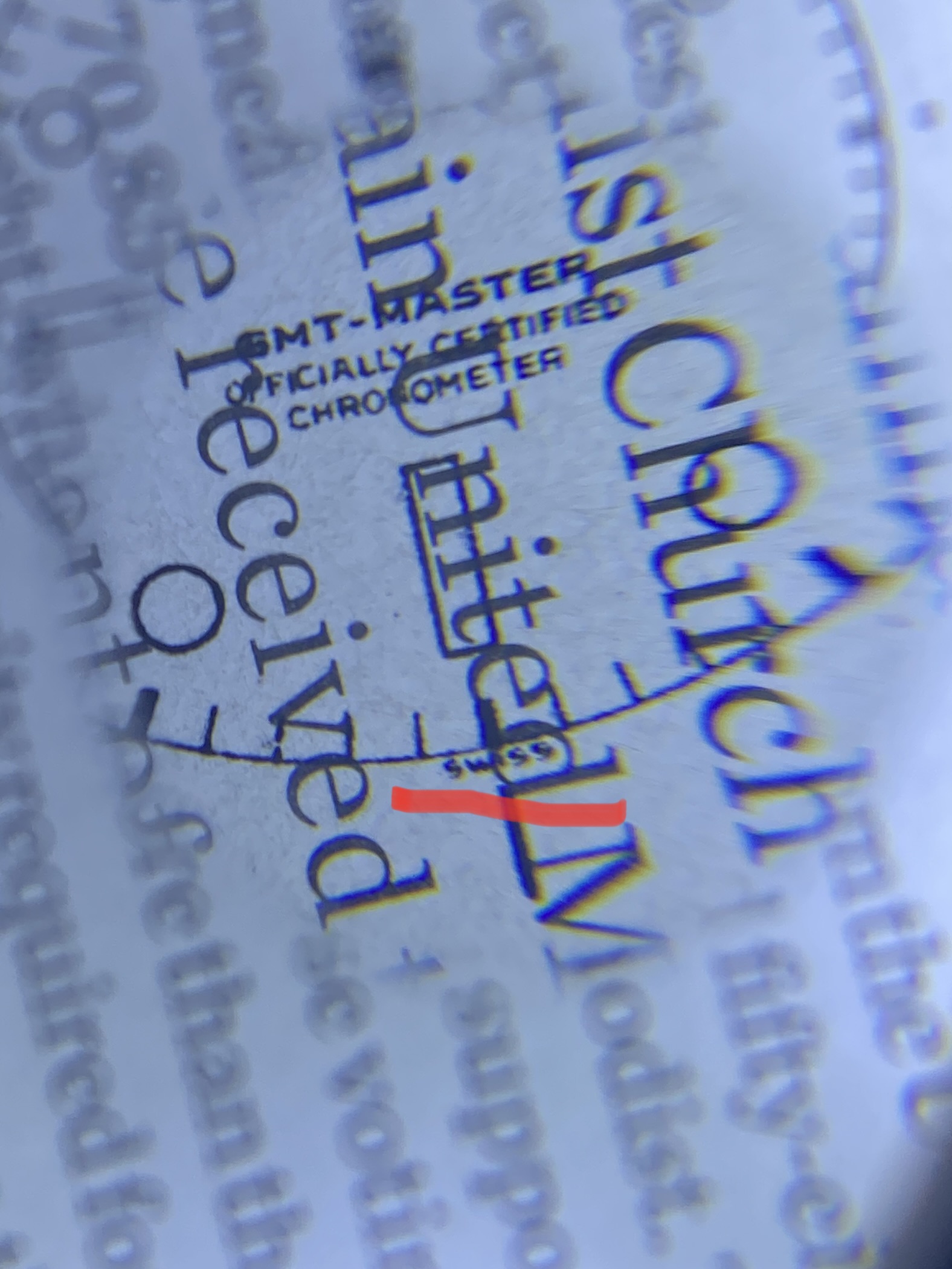

I have been tinkering with printers trying to get even more out of prints so haven’t really made dials lately. Trying to find a printer that would print high res and didn’t cost a lot. Really excited for my new printer. It prints 1200x1200 dpi and I believe the setting on the “professional” print setting slows down the printer head allowing for super fine lines. Just did a test print on magazine paper and really excited to see how the well the “SWISS” text came out. It’s like a 50% increase in legibility which is awesome given it’s a .45mm tall letters. I would honestly say this rivals pad printing quality. I’m at the point now if I can’t print it. I can transfer it as is.

Off to Staples to buy the thin glossy brochure paper which has worked very well!

Off to Staples to buy the thin glossy brochure paper which has worked very well!

- 21/3/16

- 419

- 71

- 28

Looking forward to seeing the results!I have been tinkering with printers trying to get even more out of prints so haven’t really made dials lately. Trying to find a printer that would print high res and didn’t cost a lot. Really excited for my new printer. It prints 1200x1200 dpi and I believe the setting on the “professional” print setting slows down the printer head allowing for super fine lines. Just did a test print on magazine paper and really excited to see how the well the “SWISS” text came out. It’s like a 50% increase in legibility which is awesome given it’s a .45mm tall letters. I would honestly say this rivals pad printing quality. I’m at the point now if I can’t print it. I can transfer it as is.

Off to Staples to buy the thin glossy brochure paper which has worked very well!

- 21/3/16

- 419

- 71

- 28

Looking forward to seeing the results!I have been tinkering with printers trying to get even more out of prints so haven’t really made dials lately. Trying to find a printer that would print high res and didn’t cost a lot. Really excited for my new printer. It prints 1200x1200 dpi and I believe the setting on the “professional” print setting slows down the printer head allowing for super fine lines. Just did a test print on magazine paper and really excited to see how the well the “SWISS” text came out. It’s like a 50% increase in legibility which is awesome given it’s a .45mm tall letters. I would honestly say this rivals pad printing quality. I’m at the point now if I can’t print it. I can transfer it as is.

Off to Staples to buy the thin glossy brochure paper which has worked very well!

- 21/3/16

- 419

- 71

- 28

Here is a close up of my whoopy dial. The "Swiss t25" is not so legible as wellLooking forward to seeing the results!

Nice! Which printer are you using?I have been tinkering with printers trying to get even more out of prints so haven’t really made dials lately. Trying to find a printer that would print high res and didn’t cost a lot. Really excited for my new printer. It prints 1200x1200 dpi and I believe the setting on the “professional” print setting slows down the printer head allowing for super fine lines. Just did a test print on magazine paper and really excited to see how the well the “SWISS” text came out. It’s like a 50% increase in legibility which is awesome given it’s a .45mm tall letters. I would honestly say this rivals pad printing quality. I’m at the point now if I can’t print it. I can transfer it as is.

Off to Staples to buy the thin glossy brochure paper which has worked very well!

HP 3001DW. its capable of 1200 x 1200 dpi. i was using a samsung ml-2525 which was 1200 x 600 dpi and it was pretty legible. Just couldn't quite get the details on the Tudor rose logo. I really got the new printer to get the Tudor rose logo to print well (its very detailed and small) as I am kind of stuck on "i want to make a 7928 dial" and if I can get that level of detail i can do anything.Nice! Which printer are you using?