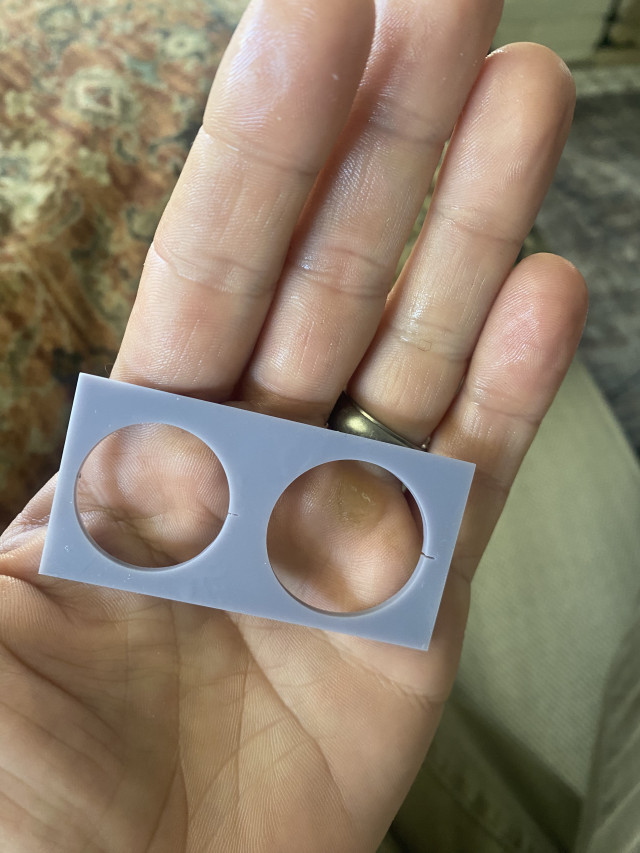

That's very promising! Is that after removing the unexposed portion with soda ash?I have been tinkering for a few years aiming to perfect the vintage Tudor rose logo. Its small, its intricate. I figured if I can perfect that, anything else would be peanuts next to it. Confirmed my settings today with my resin printer as the UV light source. Check out this mask! The text even has the serifs. Will do this on an actual dial, zinc plate, and apply acids and have a quality dial.

https://clickpix.org/image/hCFBqo][/url]

BTW, I've read that some films work better after letting the film develop another 10-30 minutes after exposure, but prior to removing the unexposed portion. I've noticed it goes from a softer film to a darker, harder plastic the longer it sits. I haven't calculated the exposure times I'll need or the best ratio of soda ash yet. Only mentioning in case you come across any issues where that information might help.