They are super simple to apply. Simply align, lay down, give it a good rub and pull off the backing film. Keep us posted!oh okay gotcha.. That reduces a few steps , that would be ideal. I will reach out to a maker and see if they are willing to do a run for me. will report back

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a true gilt dial on the cheap - Tropical or Black

- Thread starter chrome72

- Start date

Just want to say that @chrome72 and @WatchN3RD your results look very encouraging. This is fantastic!

Well I should have googled more. It’s not only possible but common method

www.wickedwatch.ch

www.wickedwatch.ch

Luckily I know a screen printer!

A micro comparison of different lume applications

We are an independ Swiss Watch Brand focusing on dive watches. Our target is to offer most affordable watches without losing their quality. We ensure the quality of every single timepiece.

Luckily I know a screen printer!

The whole point of this thread is to think out of the box and make stuff. As we don't have access to the same level of tech manufacturers do. Luckily we have ingenuity. As I think about another project that is gilt related I am wondering how I could get a smooth, consistent finish on a dial without spray painting. In my research in this project I have learned a lot about photolithography and micro photolithography and how they smoothly coat silicone wafers with a consistent layer of film and they do that by spin coating. Essentially apply some coating in the center, spin it and let centripital force pull the coating outwards.

Any reason why this wouldn't work for say attaching the dial to a dremel and put paint on and spin? I realize it would probably not be plug n play as there would be a little screw in the way, however I am assuming you could probably figure out some sort of jig. I want to get away from spray painting and having any mess ups which would require rejecting the dial.

Any reason why this wouldn't work for say attaching the dial to a dremel and put paint on and spin? I realize it would probably not be plug n play as there would be a little screw in the way, however I am assuming you could probably figure out some sort of jig. I want to get away from spray painting and having any mess ups which would require rejecting the dial.

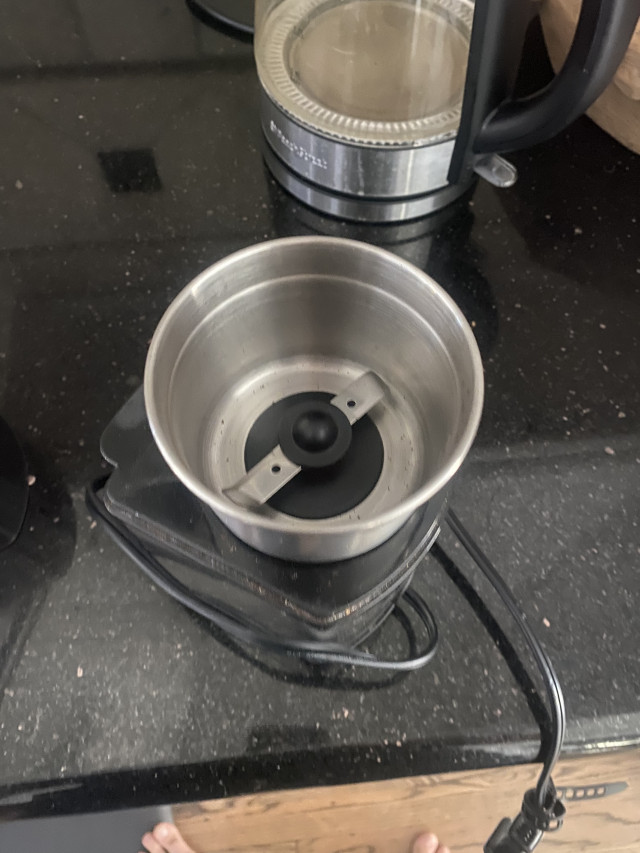

I wonder if an old coffee grinder would work too? Those have pretty high RPMS and im sure a jig could easily be put in in place of the blades.

https://clickpix.org/image/hlP8JF] [/url]

[/url]

https://clickpix.org/image/hlP8JF]

[/url]

[/url]I'm not sure that would work well for all paints, but it's seems possible with the right RPMs and the right paint consistency. It seems like another project that would take some experimenting, but there are probably better alternatives since it's rarely used in paint systems. What about dipping the dial and letting it hang dry? It would work for most coatings that don't evaporate too fast. You just want to be sure it's something that can properly cure as a thicker coat.The whole point of this thread is to think out of the box and make stuff. As we don't have access to the same level of tech manufacturers do. Luckily we have ingenuity. As I think about another project that is gilt related I am wondering how I could get a smooth, consistent finish on a dial without spray painting. In my research in this project I have learned a lot about photolithography and micro photolithography and how they smoothly coat silicone wafers with a consistent layer of film and they do that by spin coating. Essentially apply some coating in the center, spin it and let centripital force pull the coating outwards.

Any reason why this wouldn't work for say attaching the dial to a dremel and put paint on and spin? I realize it would probably not be plug n play as there would be a little screw in the way, however I am assuming you could probably figure out some sort of jig. I want to get away from spray painting and having any mess ups which would require rejecting the dial.

Not only doable, it's probably the best way to apply it. This is one of the items on my never ending list of projects.Totally random but would screen printing lume be a viable option for applying lume to dials? I assume it wouldn’t be very raised.

I hope this would work as it would save quite a bit of time and should be easy to align a screen to an already made dial.

Like hydrodipping? Or literally just dipping it in paint and taking it out?I'm not sure that would work well for all paints, but it's seems possible with the right RPMs and the right paint consistency. It seems like another project that would take some experimenting, but there are probably better alternatives since it's rarely used in paint systems. What about dipping the dial and letting it hang dry? It would work for most coatings that don't evaporate too fast. You just want to be sure it's something that can properly cure as a thicker coat.

Like dipping it in a clear varnish, lacquer, etc.Like hydrodipping? Or literally just dipping it in paint and taking it out?

Ill note my progress on another project too.

I want to make a version of the MKII Key West albino gilt dial:

It requires a slightly different order of things. This is my best guess of how its probably done:

-Polish brass disc

-Apply resist mask

-Plate with zinc

-Paint white

-Remove resist mask

I don't know how they would remove the resist mask with paint over it so i will do the following:

-Polish

-Plate with zinc

-paint white

-Apply REVERSE image of resist mask

I will essentially be left with a stencil of parts to be removed. Then its remove the paint and use an acid (hydrochloric acid, vinegar etc) to remove the zinc. Since it would be a thin layer of zinc it should be removed quite quickly and not mess with the polished brass. I would then dissolve the resist mask with washing soda/water. This should leave me with a nice looking white, negative relief gilt dial.

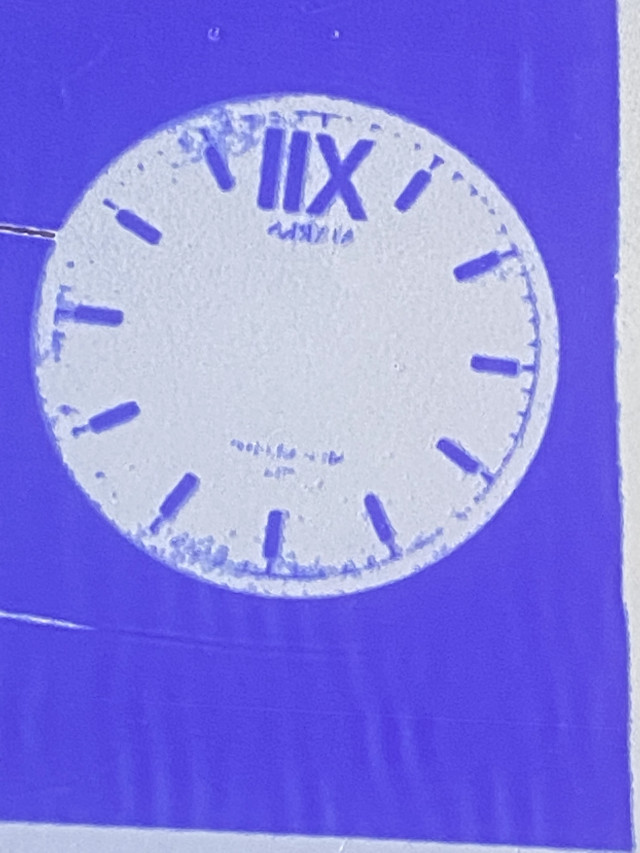

Here is a first tinkering. Its a start. I wanted to see if I could get the resist mask to develop onto a painted surface. I can. My photosensitive film needs to be replaced as its 3 years old. My mask needs to be inverted too so I only have to remove the numbers, minute track etc. I tried wiping away the painted area with acetone but was worried it would remove the photofilm as well. I might need to find an ink/paint that is dissolvable in alcohol or find a better way to remove spray painted acrylic paint.

https://clickpix.org/image/hlbwp2] [/url]

[/url]

I want to make a version of the MKII Key West albino gilt dial:

It requires a slightly different order of things. This is my best guess of how its probably done:

-Polish brass disc

-Apply resist mask

-Plate with zinc

-Paint white

-Remove resist mask

I don't know how they would remove the resist mask with paint over it so i will do the following:

-Polish

-Plate with zinc

-paint white

-Apply REVERSE image of resist mask

I will essentially be left with a stencil of parts to be removed. Then its remove the paint and use an acid (hydrochloric acid, vinegar etc) to remove the zinc. Since it would be a thin layer of zinc it should be removed quite quickly and not mess with the polished brass. I would then dissolve the resist mask with washing soda/water. This should leave me with a nice looking white, negative relief gilt dial.

Here is a first tinkering. Its a start. I wanted to see if I could get the resist mask to develop onto a painted surface. I can. My photosensitive film needs to be replaced as its 3 years old. My mask needs to be inverted too so I only have to remove the numbers, minute track etc. I tried wiping away the painted area with acetone but was worried it would remove the photofilm as well. I might need to find an ink/paint that is dissolvable in alcohol or find a better way to remove spray painted acrylic paint.

https://clickpix.org/image/hlbwp2]

[/url]

[/url]Coming in a bit late, but the incredible reference site "Rolex Haven" has a section on lume and how Rolex switched from hand application to silk screening lume in 1968:

https://rolexhaven.com/luminous-material.html

Scroll down to the section titled "Dead" Tritium 1968-1998. The first image in that section shows what it looks like.

https://rolexhaven.com/luminous-material.html

Scroll down to the section titled "Dead" Tritium 1968-1998. The first image in that section shows what it looks like.

thanks! I have read that site many times before but under a different lens for learning. You can see the mesh marks in that one photo!Coming in a bit late, but the incredible reference site "Rolex Haven" has a section on lume and how Rolex switched from hand application to silk screening lume in 1968:

https://rolexhaven.com/luminous-material.html

Scroll down to the section titled "Dead" Tritium 1968-1998. The first image in that section shows what it looks like.

From my extremely limited experience this far with this film, it washes away with washing soda with no issues when it's fresh. Once it's exposed and allowed to really cure, I'm not sure how easy washing soda will take it off.Ill note my progress on another project too.

I want to make a version of the MKII Key West albino gilt dial:

It requires a slightly different order of things. This is my best guess of how its probably done:

-Polish brass disc

-Apply resist mask

-Plate with zinc

-Paint white

-Remove resist mask

I don't know how they would remove the resist mask with paint over it so i will do the following:

-Polish

-Plate with zinc

-paint white

-Apply REVERSE image of resist mask

I will essentially be left with a stencil of parts to be removed. Then its remove the paint and use an acid (hydrochloric acid, vinegar etc) to remove the zinc. Since it would be a thin layer of zinc it should be removed quite quickly and not mess with the polished brass. I would then dissolve the resist mask with washing soda/water. This should leave me with a nice looking white, negative relief gilt dial.

Here is a first tinkering. Its a start. I wanted to see if I could get the resist mask to develop onto a painted surface. I can. My photosensitive film needs to be replaced as its 3 years old. My mask needs to be inverted too so I only have to remove the numbers, minute track etc. I tried wiping away the painted area with acetone but was worried it would remove the photofilm as well. I might need to find an ink/paint that is dissolvable in alcohol or find a better way to remove spray painted acrylic paint.

https://clickpix.org/image/hlbwp2][/url]

It sounds like your ideas/process can work, but you might need to adjust the order of coatings.

Also, I may be reading your post wrong, but why coat in zinc if you are using paint?

From my extremely limited experience this far with this film, it washes away with washing soda with no issues when it's fresh. Once it's exposed and allowed to really cure, I'm not sure how easy washing soda will take it off.

It sounds like your ideas/process can work, but you might need to adjust the order of coatings.

Also, I may be reading your post wrong, but why coat in zinc if you are using paint?

The zinc is for depth so it’s. Negative relief once I eat away the paint and zinc.From my extremely limited experience this far with this film, it washes away with washing soda with no issues when it's fresh. Once it's exposed and allowed to really cure, I'm not sure how easy washing soda will take it off.

It sounds like your ideas/process can work, but you might need to adjust the order of coatings.

Also, I may be reading your post wrong, but why coat in zinc if you are using paint?

That makes sense, but I think you could also skip the zinc and just etch longer for more depth.The zinc is for depth so it’s. Negative relief once I eat away the paint and zinc.

But then I’d lose my polish of the brass right?That makes sense, but I think you could also skip the zinc and just etch longer for more depth.

Went to go pick up that dial I had digitally printed. It actually looked very nice. Got caught up in the whole zoomed in texture. Applied nitrocellulose lacquer and acetone fumes and it destroyed the dial. If my method doesn’t pan out well I’ll circle back to this and will have to fatten the text and minute track in order for the gilt to show up. If my way works I shouldn’t have to do that.

It's possible, but I'm not sure it would be as rough as you are assuming since you're starting your etch on a smooth surface with little texture.But then I’d lose my polish of the brass right?

But now I see your point of wanting to use zinc to preserve the brass finish much as possible since it would probably etch the zinc at a faster rate.

Sounds like a smart idea. I missed the part about you wanting to do as little as possible to the polished brass.

I have no idea if it will make a noticeable difference, but logically, it makes perfect sense. Definitely worth giving it a shot.

I have been tinkering for a few years aiming to perfect the vintage Tudor rose logo. Its small, its intricate. I figured if I can perfect that, anything else would be peanuts next to it. Confirmed my settings today with my resin printer as the UV light source. Check out this mask! The text even has the serifs. Will do this on an actual dial, zinc plate, and apply acids and have a quality dial.

https://clickpix.org/image/hCFBqo] [/url]

[/url]

https://clickpix.org/image/hCFBqo]

[/url]

[/url]