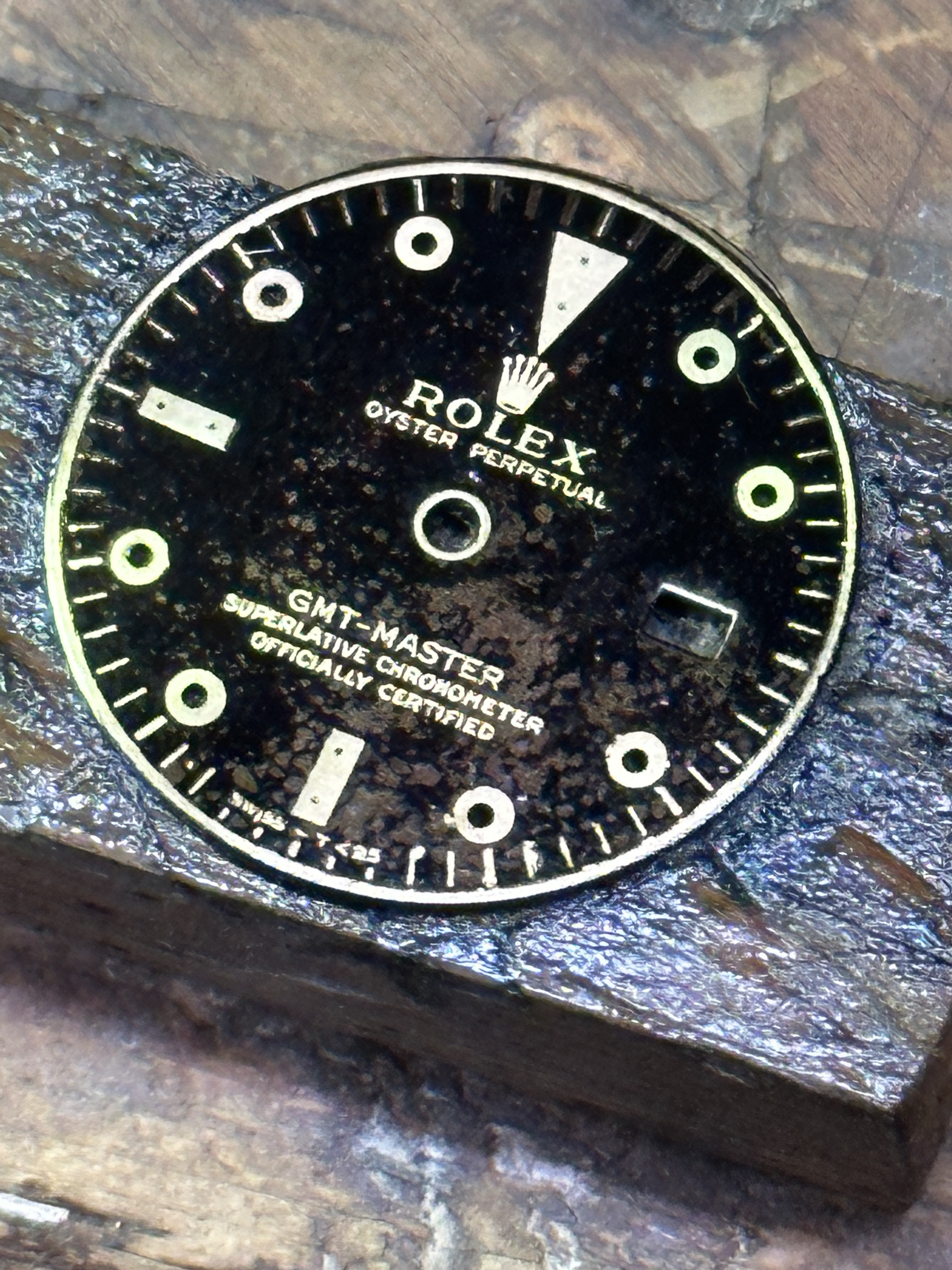

Also, I'd like to thank @matzemedia for the inspiration by proving an amazing clearcoat is possible with rattlecans doing a final thin coat without sanding and polishing the last coat.

I was able to achieve the same, but I did have to cheat a little by putting the dial under a glass with solvents inside for a few minutes.

Just enough to slow the drying -- which helped the gases escape and also let the coat level itself.

I was able to achieve the same, but I did have to cheat a little by putting the dial under a glass with solvents inside for a few minutes.

Just enough to slow the drying -- which helped the gases escape and also let the coat level itself.