I should add the company's name is EPI and the product is E-Chrome 861. Its not listed on their website but just ask nicely!

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to make a true gilt dial on the cheap - Tropical or Black

- Thread starter chrome72

- Start date

bigtiddygothgf

Active Member

- 7/10/18

- 323

- 149

- 43

Hexavalent chromium is not something i would recommend any DIYer to fuck around with especially if the goal here is an easy at home process anyone can do to make a gilt dial, at that point just go with literally any other method. If someones dumb enough or doesnt care enough about their own health and wellbeing thats one thing, but you dont want some random moron to start dumping that shit down their sink drain.

Yea I should have mentioned this. The plating industry has moved to trivalent chromates that are less hazardous. My post was more meant to be a “this is what they used and this is why dials turned brown”. The cost for the item mentioned above is $500 and I don’t want to do that.Hexavalent chromium is not something i would recommend any DIYer to fuck around with especially if the goal here is an easy at home process anyone can do to make a gilt dial, at that point just go with literally any other method. If someones dumb enough or doesnt care enough about their own health and wellbeing thats one thing, but you dont want some random moron to start dumping that shit down their sink drain.

Plenty of companies offer zinc blackening and browning that are friendlier to the user.

i think zinc baths use to use cyanide salts. Chromium 6 is what makes it bad is my understanding.Is there cyanide involved? What makes that so dangerous to a knowledgeable person without a laboratory setting. Personally, cyanide is one of the few chemicals I won't "play" with.

I've been thinking quite a bit about how gilt dials look brownish in certain lights. Mq's dials do the same thing from being new, part of the process used in making the dials is 'burning off' the ink that's used as a mask during plating and then blackening. If the ink is burned off then exposing the dials to high temperatures could result in the light browning we see.

bigtiddygothgf

Active Member

- 7/10/18

- 323

- 149

- 43

I'm not an expert or anything, just read about it online a recently as the EU enacted further restrictions on it not too long ago, but chromium-6 is highly carcinogenic and a respiratory toxicant. Plating in general is incredibly toxic. A lot of superfund sites here in the U.S. are former plating facilities.Is there cyanide involved? What makes that so dangerous to a knowledgeable person without a laboratory setting. Personally, cyanide is one of the few chemicals I won't "play" with.

Appreciate the additional information, as I hadn't heard of it before this thread. The minor searches I've done don't make it make it sound safe, that's for sure.

I certainly don't want to downplay something I know nothing about, but at the same time, carrying an asbestos roof shingle is not the same as working or living somewhere with asbestos walls. It's definitely not the same as working in an asbestos factory either.

I'll be sure to triple research the details if I consider using it. Just wanted to make sure it wasn't an "instant death" chemical! Like to rule those out at square one.

I certainly don't want to downplay something I know nothing about, but at the same time, carrying an asbestos roof shingle is not the same as working or living somewhere with asbestos walls. It's definitely not the same as working in an asbestos factory either.

I'll be sure to triple research the details if I consider using it. Just wanted to make sure it wasn't an "instant death" chemical! Like to rule those out at square one.

For what it’s worth. The zinc plating I am doing is just vinegar, sugar,epsom salt and zinc. The vinegar is acidic and dissolves the zinc. The salt provides the means for conductivity. The sugar is meant to help brighten the zinc and not be as dull. After that it’s just using the zinc solution I created and a piece of zinc and a battery charger. So it’s stuff that is safe and you use probably multiple times a week other than the zinc.

bigtiddygothgf

Active Member

- 7/10/18

- 323

- 149

- 43

Theres really no reason to use chromium-6 when alternatives exist such as what @chrome72 suggested. Hell you're better off just doing film free decals at that point. Its still toxic through skin contact and the plating process can cause mist and such in the air. Nickel and zinc are much safer although proper ventilation and disposal are still needed.

Custom Watch Dial Decals | DIY Watch Face Logo Stickers - 4Customize

Shop metal decals stickers for DIY watch dials, Make custom watch face with your own metal logo stickers. Free design, rush order available.

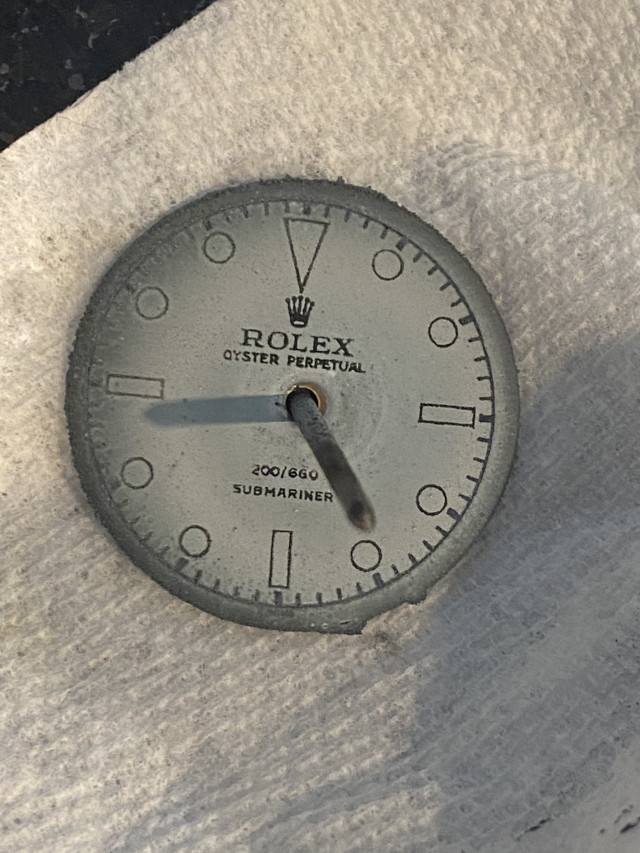

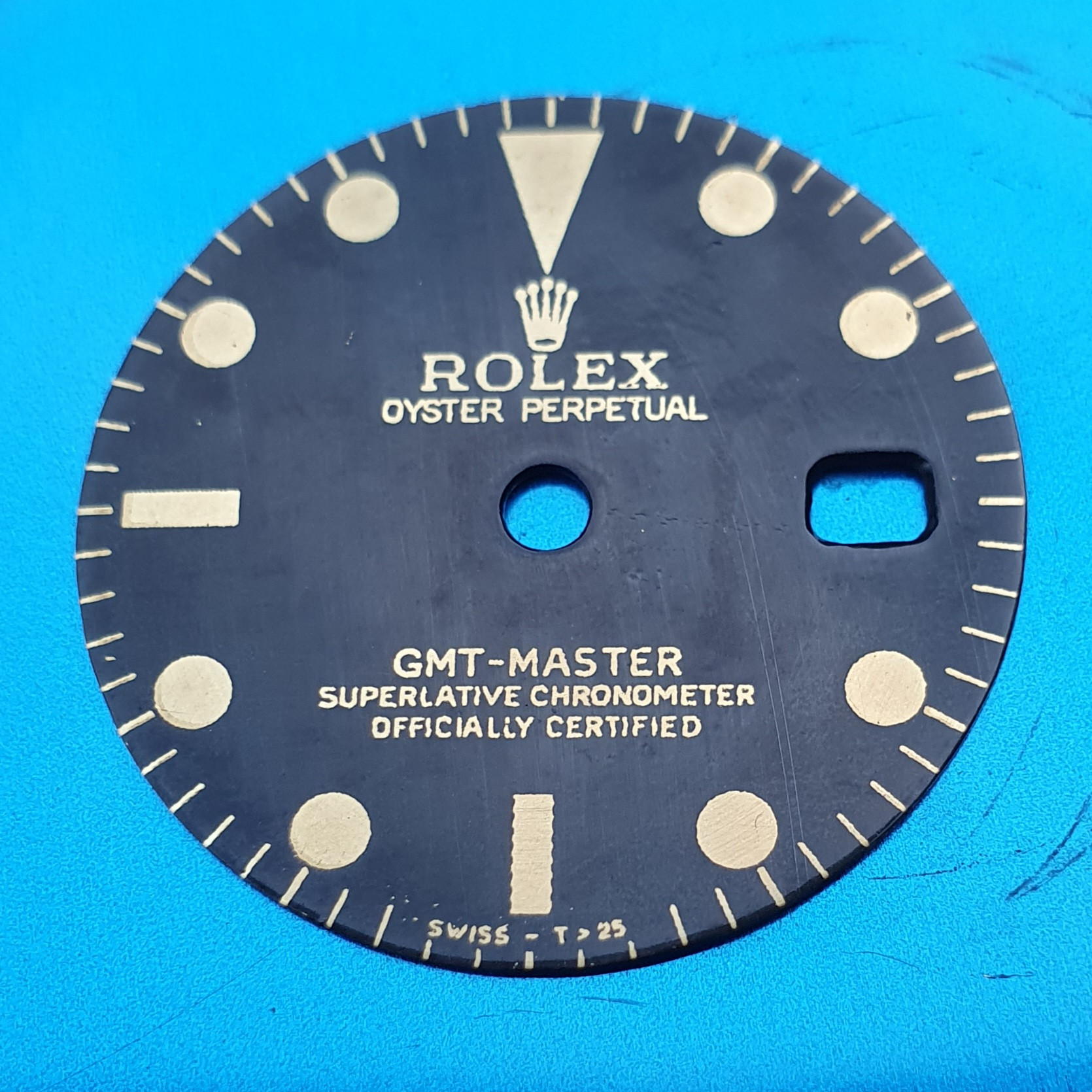

Attempt #2

Things learned…don’t use a finishing nail through the center of the dial when plating. It robs current from the dial and the center doesn’t plate as evenly as the rest of the dial. I need thin brass wire I was told.

I didn’t pay attention to the laser printer artwork I used. I used my junk pile that was printed bad and you can see the little squigglies in the final product. A cleaner print should work great like my attempt #1 above.

It doesn’t show in the photos but the dial is quite tropical. When the light hits it from the side it appears brown. Dead one and it’s super black. Good ol light refractory.

A positive note and for the life of my I can’t capture on my phone…there is depth! It’s not as much as a Vietnamese dial but hey it’s only my second attempt. Room for improvement.

Anyways here it is. I have

Things learned…don’t use a finishing nail through the center of the dial when plating. It robs current from the dial and the center doesn’t plate as evenly as the rest of the dial. I need thin brass wire I was told.

I didn’t pay attention to the laser printer artwork I used. I used my junk pile that was printed bad and you can see the little squigglies in the final product. A cleaner print should work great like my attempt #1 above.

It doesn’t show in the photos but the dial is quite tropical. When the light hits it from the side it appears brown. Dead one and it’s super black. Good ol light refractory.

A positive note and for the life of my I can’t capture on my phone…there is depth! It’s not as much as a Vietnamese dial but hey it’s only my second attempt. Room for improvement.

Anyways here it is. I have

I read up on these in the past. It’s a UV printer. There was a guy who made pcbs and would take his metal blanks to the local mall and find a custom t shirt or custom apparel store and have them print onto his metal. He would then use acids to etch his boards. I haven’t seen any options at my local mall though. But it’s a good idea though.

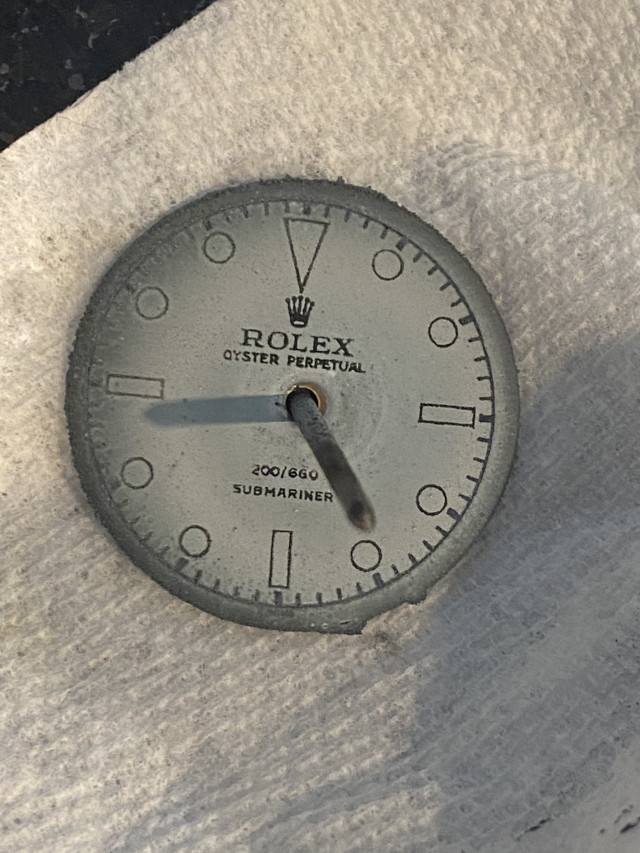

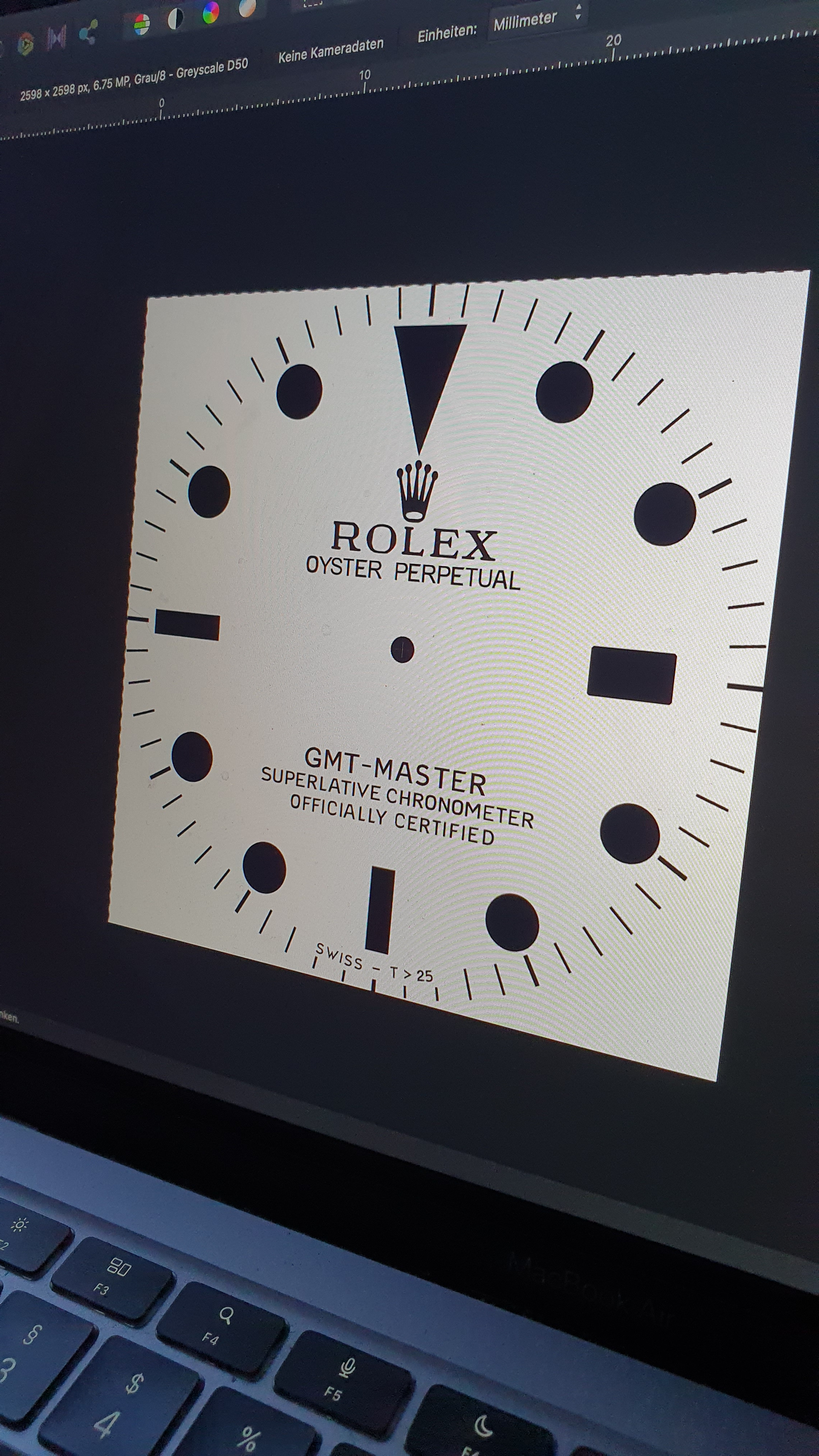

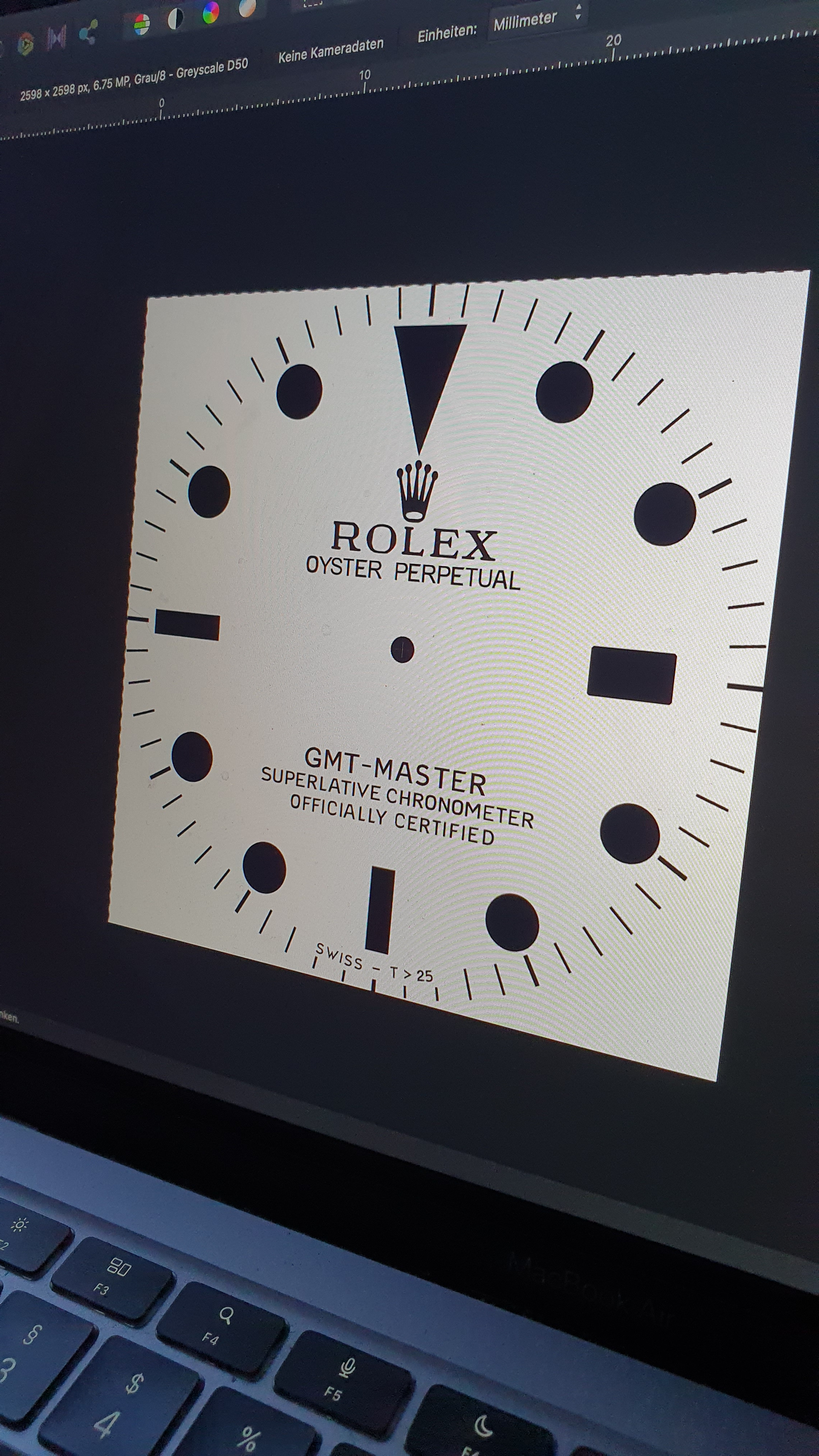

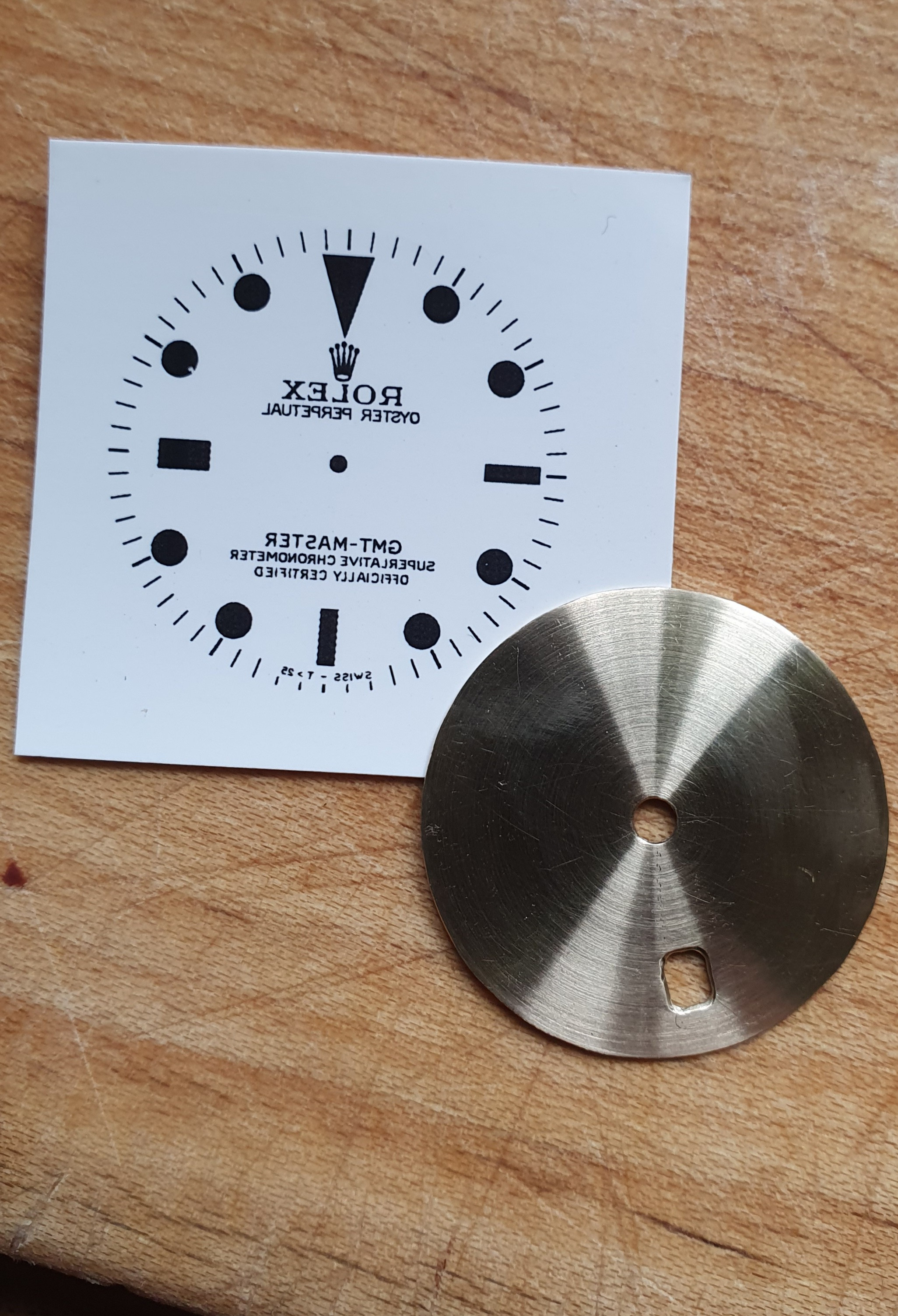

I tried it again!

The last attempt from @WatchN3RD at the decal thread give me the motivation to try again a dial based on the toner transfer - blacked method. I will write all my learning to this thread. Maybe it helps someone.

Printer driver

In the past month, I learned a lot about my printer. Especially that I have to use a different driver to optimize the result. So if you have a Mac and like to print decals or to the toner transfer, don't use the default Air Printer from Apple. Search for the factory driver and use it. You will get a lot more options to get a better result.

Correct DPI settings

DPI is a number that shows the grade of your printer. The common DPI of a laser printer is 300 x 300 dpi. This is not enough for our dials. You better use a printer with 1200 x 1200 dpi. Mine has, 2400 x 600 dpi. That is for sure not the best. To get the best out of your printer, you need an image with the same resolution. In the past, I thought I can use a vector image for the best result, but I learned that my software is not printing as it should. So I created I TIFF file with the same resolution (dpi) as my printer (in my case 2400 x 2400) and use the common image program to print. A lot of people write they have problems to print with illustrator and use Photoshop. I am using Affinity Designer to create the image and Affinity Photo to create a Tiff out of my vector file.

Use Font instead of Vector files

In the past, I used photos from the original watches and rebuild the dial in Affinity Designer. One Problem was that the small fonts doesn't look sharp. This time I started us a font and redesign the dial. Finding the correct font is nearly impossible. You can find similar fonts and reshape single letters. Well this is very time consuming, and maybe the learning with the less optimization. So better you skip this ;-)

Toner Transfer

I use this Sunnyscopa Decal Transfer stuff and clearly use the description to get a good result. The most important part is to get rid of bubbles. I always use gloves.

Blacken

I used a bath of Ballistol Nerofor 3 times for 1-3 minutes each step. After step 1 and 2 I rub gently the dial under fresh water with my hand (wearing gloves). Just to get rid of the top layer of slag. At the last step, I just let the water run over the dial without wiping the surface by hand. Then I put die dial into the heater (180°C) for 10 minutes.

Using Nitrocellulose as clear coat

After removing the toner transfer with Acton and try the dial, I use Nitrocellulose. I just tried it once but with a good result. It is sufficient to apply a thin layer.

The last attempt from @WatchN3RD at the decal thread give me the motivation to try again a dial based on the toner transfer - blacked method. I will write all my learning to this thread. Maybe it helps someone.

Printer driver

In the past month, I learned a lot about my printer. Especially that I have to use a different driver to optimize the result. So if you have a Mac and like to print decals or to the toner transfer, don't use the default Air Printer from Apple. Search for the factory driver and use it. You will get a lot more options to get a better result.

Correct DPI settings

DPI is a number that shows the grade of your printer. The common DPI of a laser printer is 300 x 300 dpi. This is not enough for our dials. You better use a printer with 1200 x 1200 dpi. Mine has, 2400 x 600 dpi. That is for sure not the best. To get the best out of your printer, you need an image with the same resolution. In the past, I thought I can use a vector image for the best result, but I learned that my software is not printing as it should. So I created I TIFF file with the same resolution (dpi) as my printer (in my case 2400 x 2400) and use the common image program to print. A lot of people write they have problems to print with illustrator and use Photoshop. I am using Affinity Designer to create the image and Affinity Photo to create a Tiff out of my vector file.

Use Font instead of Vector files

In the past, I used photos from the original watches and rebuild the dial in Affinity Designer. One Problem was that the small fonts doesn't look sharp. This time I started us a font and redesign the dial. Finding the correct font is nearly impossible. You can find similar fonts and reshape single letters. Well this is very time consuming, and maybe the learning with the less optimization. So better you skip this ;-)

Toner Transfer

I use this Sunnyscopa Decal Transfer stuff and clearly use the description to get a good result. The most important part is to get rid of bubbles. I always use gloves.

Blacken

I used a bath of Ballistol Nerofor 3 times for 1-3 minutes each step. After step 1 and 2 I rub gently the dial under fresh water with my hand (wearing gloves). Just to get rid of the top layer of slag. At the last step, I just let the water run over the dial without wiping the surface by hand. Then I put die dial into the heater (180°C) for 10 minutes.

Using Nitrocellulose as clear coat

After removing the toner transfer with Acton and try the dial, I use Nitrocellulose. I just tried it once but with a good result. It is sufficient to apply a thin layer.

I love it!

Are you using the same transfer paper as before that doesn't require/recommend using a glue to assist with the transfer? I'm curious, if you are using glue, what are you cleaning it off with before blackening?

Are you using the same transfer paper as before that doesn't require/recommend using a glue to assist with the transfer? I'm curious, if you are using glue, what are you cleaning it off with before blackening?

Thanks. I use the same as before some from AliXpress. It is without glue. Before the blackening I use a common soap / washing up liquid mixture to clean it for 10 minutes. I am not sure if this is necessary.I love it!

Are you using the same transfer paper as before that doesn't require/recommend using a glue to assist with the transfer? I'm curious, if you are using glue, what are you cleaning it off with before blackening?

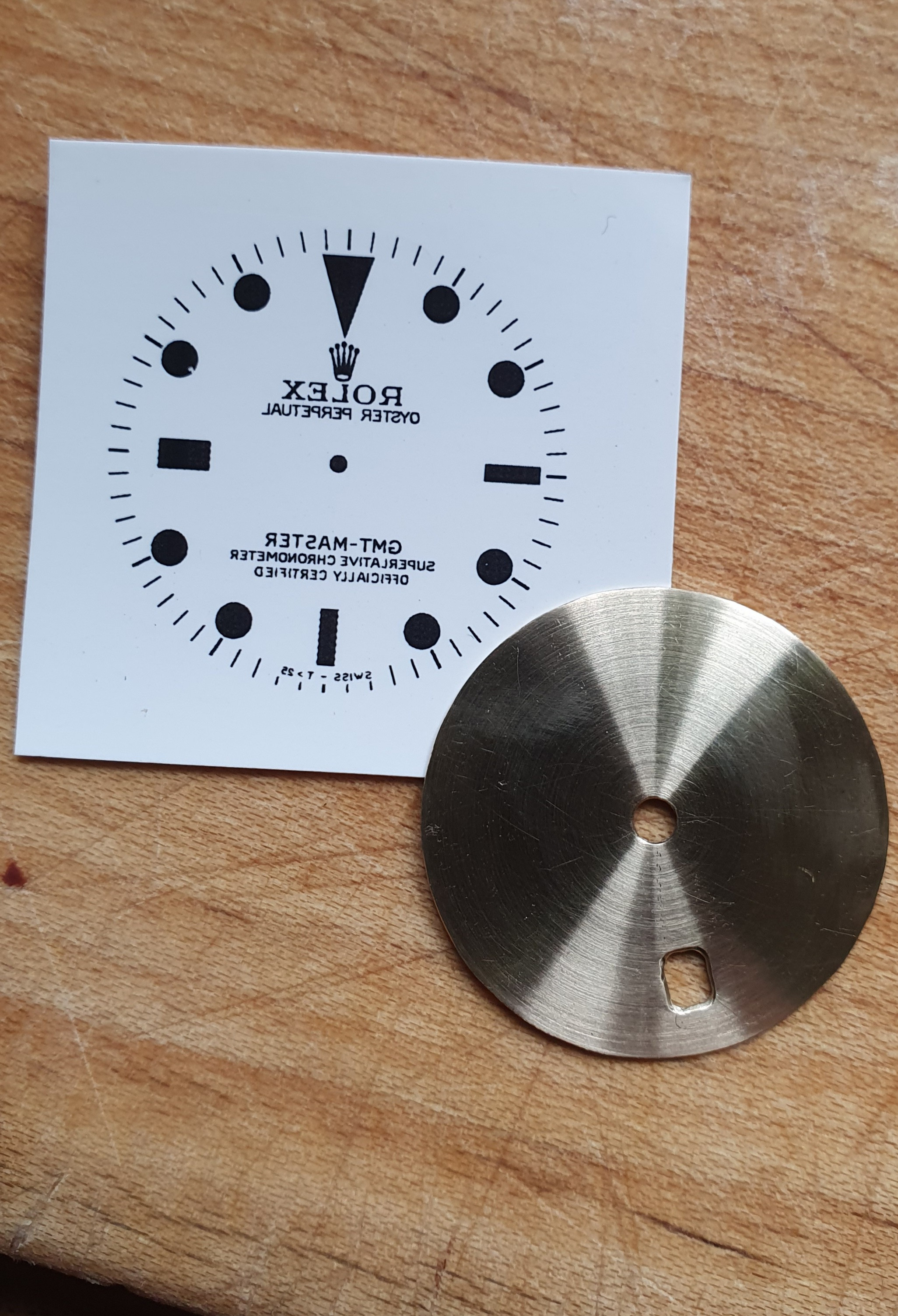

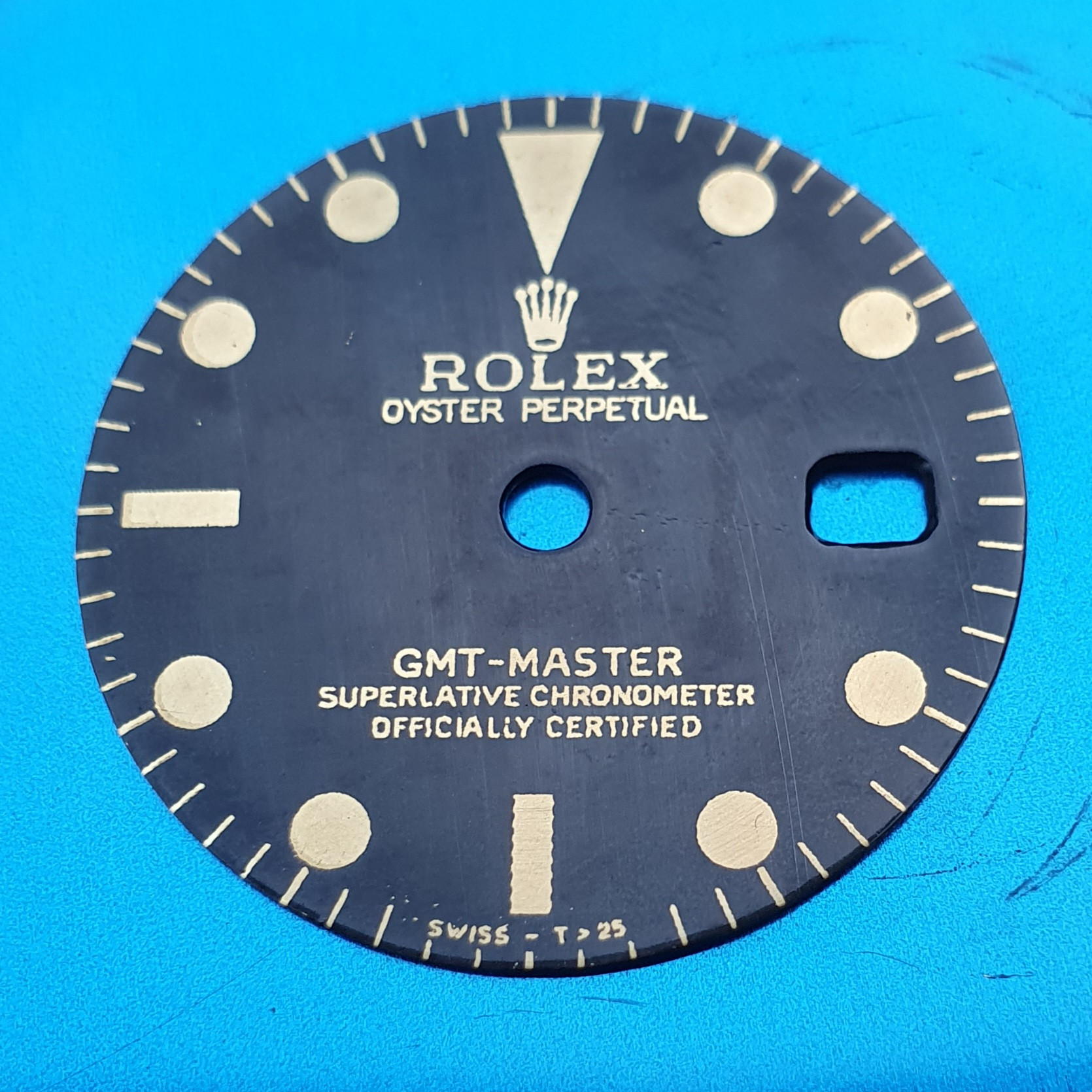

Ok attempt #3 of figuring out zinc plating and blackening. I have been short of time so my aim was more figuring out the plating vs perfect transfer of details.

I solved a problem. Previous attempt the area around the center of the dial wouldn’t plate very well. I used super thin stainless steel wire instead of a finishing nail as suggested by a plater. It worked perfectly.

I used the blackening acid m38 and gave it a few immersions/wipes and I think i over did it. I noticed that on the 3rd immersion it started to become kind of dotty. I don’t know if it shows up well in the pics. I think I know why the chromates were used. It’s a one dip and done and dry to harden.

Anyways here is attempt #3. Good black color and some negative depth.

I solved a problem. Previous attempt the area around the center of the dial wouldn’t plate very well. I used super thin stainless steel wire instead of a finishing nail as suggested by a plater. It worked perfectly.

I used the blackening acid m38 and gave it a few immersions/wipes and I think i over did it. I noticed that on the 3rd immersion it started to become kind of dotty. I don’t know if it shows up well in the pics. I think I know why the chromates were used. It’s a one dip and done and dry to harden.

Anyways here is attempt #3. Good black color and some negative depth.