I am looking at one that would have a dpi equivalent of around 720 dpi. I think I just divide resolution by screen size. Would you think that would work? I’m still formulating herePretty awesome technology, but when I considered etching via digital screen, I don't think the dpi was precise enough. Have you compared the PPI of the screen to your desired etch resolution yet?

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

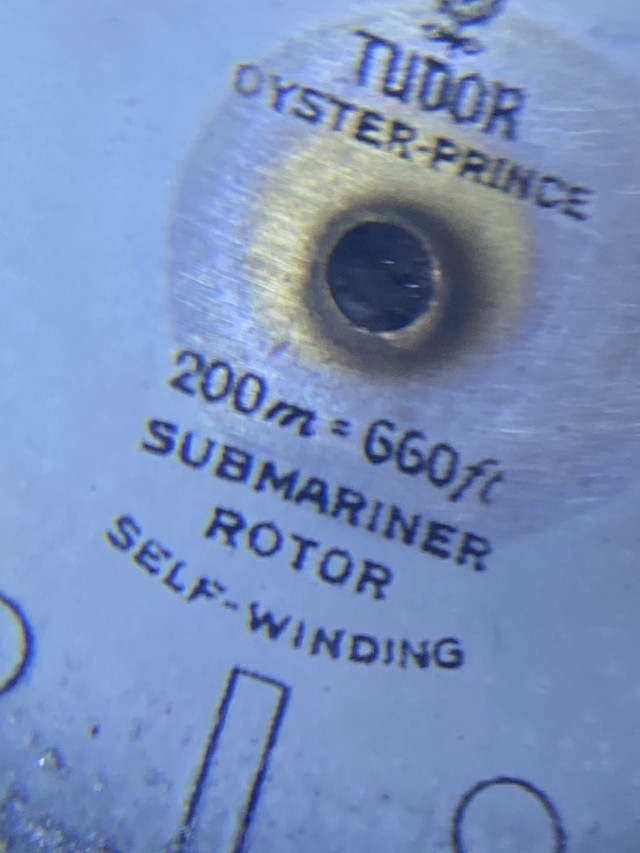

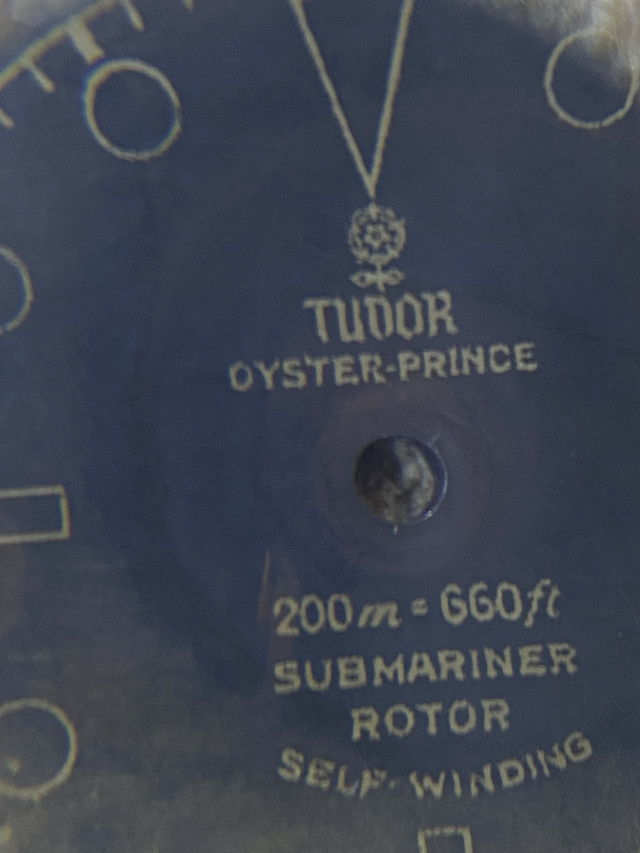

How to make a true gilt dial on the cheap - Tropical or Black

- Thread starter chrome72

- Start date

I think a better question would be if a design prints out well a 600 dpi would the screen resolution equivalent of 600 dpi be enough?

There are some options out there if 1,200ish dpi screen resolution printers.

Any idea if those screen projection part exists out there in other markets and don’t need the printer part? Like are there other routes for products to look at?

There are some options out there if 1,200ish dpi screen resolution printers.

Any idea if those screen projection part exists out there in other markets and don’t need the printer part? Like are there other routes for products to look at?

So had a thought…if you attended high school and had chemistry chances are you turned a penny silver and gold. It’s really electroless plating of zinc. I will try this when I get my hands on the ingredients. IF this works and doesn’t make the toner swell it should lock in the space around the toner so when you apply a black chromate to the zinc or any other acid that turns the zinc black or brown the toner is kind of locked in. Plus this stuff is readily available and easy to do. I’ll also try cheap zinc plating with electricity with a piece of zinc and vinegar and a wall charger.

Science.

Science.

To black the zinc plating you need black passivate.So had a thought…if you attended high school and had chemistry chances are you turned a penny silver and gold. It’s really electroless plating of zinc. I will try this when I get my hands on the ingredients. IF this works and doesn’t make the toner swell it should lock in the space around the toner so when you apply a black chromate to the zinc or any other acid that turns the zinc black or brown the toner is kind of locked in. Plus this stuff is readily available and easy to do. I’ll also try cheap zinc plating with electricity with a piece of zinc and vinegar and a wall charger.

Science.

Zinc Passivate -Black | Gateros Plating Ltd

Our Black Zinc Passivate is essential for post-plating protection, increasing corrosion resistance and giving a dark black colour. With the black passivate we include 5 litres worth of Rogard Supreme Seal 500 Rogard is used to seal the passivate after application, it also helps to prevent wear...

www.gaterosplating.co.uk

www.gaterosplating.co.uk

doesn’t black chromate mean passivation? Is there another option?To black the zinc plating you need black passivate.

Zinc Passivate -Black | Gateros Plating Ltd

Our Black Zinc Passivate is essential for post-plating protection, increasing corrosion resistance and giving a dark black colour. With the black passivate we include 5 litres worth of Rogard Supreme Seal 500 Rogard is used to seal the passivate after application, it also helps to prevent wear...www.gaterosplating.co.uk

I got my zinc in and got some other ingredients for chemical plating of zinc aka the “silver penny” trick.

Yes mate, passivate is chromate as far as I'm aware. I just wanted to link you through to a product you can read up on it to give you a better idea. I got all the electroplating kit, pad printer and I've made my cliches so all I need to find now is the right ink. This company apparently supplies swiss watchmakers so I'm going to fire them an email off.

www.berlacgroup.com

www.berlacgroup.com

Surface finishing of watches & jewelry | BERLAC GROUP

High-end lacquers for watches and jewelry through excellent processing. ✓ individual small quantities ✓ consultation ► Convince yourself

Rock n roll. I found a supplier state side..Caswell that i have seen have great results and hard to mess up. Before I invest more, want to see if toner transfer will hold up to zinc plating. If it doesn't will try photoresist with a refurb resin printer and see if that holds up to acids and zinc plating. If it doesn't.....I'll have to crawl back to pad printing which I don't want to do ha.Yes mate, passivate is chromate as far as I'm aware. I just wanted to link you through to a product you can read up on it to give you a better idea. I got all the electroplating kit, pad printer and I've made my cliches so all I need to find now is the right ink. This company apparently supplies swiss watchmakers so I'm going to fire them an email off.

Surface finishing of watches & jewelry | BERLAC GROUP

High-end lacquers for watches and jewelry through excellent processing. ✓ individual small quantities ✓ consultation ► Convince yourselfwww.berlacgroup.com

What pad printer did you end up going with.

Just one of these cheap ones.What pad printer did you end up going with.

NEW Manual Watch Dial Pad Printing Machine Watch Dial Printer | eBay

Model UP-50 Watch Dial Pad Printer. W atch dial pad printing machine Feature 2 Special for printing watch dial, suitable to printing small quantity. 1X Watch Dial Pad Printing Machine. Max printing area 30x30mm.

www.ebay.co.uk

For a bit I will be posting about DIY zinc plating to see if its viable for dumb DIY. If I can get the zinc to plate nicely AND not destroy the resist mask I will move onto applying acids to get browns and a black chromate to get deep black. If toner fails, I will also try photoresist method.

Experiment 1: Will the chemical zinc plating method work with toner?

I tried the "turn a copper penny silver" method using lye+water+zinc+ heat...really a chemical plating bath. It melted off the toner but I got a nice shiny zinc plated brass dial to tinker with now. I am thinking the chemical method of zinc plating won't work.

Next I will try the standard method of zinc plating...home brew electroplating. Got some zinc dissolving into vinegar, salt and sugar. Hopefully that will be reading in a day or so and can tinker. It looks like the zinc plates pretty quickly with this method.

Experiment 1: Will the chemical zinc plating method work with toner?

I tried the "turn a copper penny silver" method using lye+water+zinc+ heat...really a chemical plating bath. It melted off the toner but I got a nice shiny zinc plated brass dial to tinker with now. I am thinking the chemical method of zinc plating won't work.

Next I will try the standard method of zinc plating...home brew electroplating. Got some zinc dissolving into vinegar, salt and sugar. Hopefully that will be reading in a day or so and can tinker. It looks like the zinc plates pretty quickly with this method.

I'm still here for more learning, knowledge sharing, successes, and failures!

Here's my reasoning with zero knowledge:

Bleach is a rather strong base that destroys many plastics. Lye is the base of bases, so possibly it will faster destroy similar plastics?

1) It's got be easiest to plate the dials how you want and THEN etch the negative, vs. covering the details of the dials and working outward.

2) I'm confident in photoresist etching, and now wish I spent more time practicing it instead of toner. I've done resist film twice and done toner transfer too many times to count. But whether silk screening, pcb making, or making cliches for pad printing, all "the long term doers" and knowledgable people seem to eventually abandon toner. That leaves photo-something to pursue. Once that film has time to set in, it's on there good. Like too good when it really burns on there after getting exposed and left there.

Finally, I can print at least (supposedly) double the resolution for almost nothing on my inkjet. I'm more than happy to send some prints to you (Chrome) if you want. PM me and/or send the files. A few transparencies shipped to Houston should be easy. I'm almost next door with the alligators and the swamps.

Here's my reasoning with zero knowledge:

Bleach is a rather strong base that destroys many plastics. Lye is the base of bases, so possibly it will faster destroy similar plastics?

1) It's got be easiest to plate the dials how you want and THEN etch the negative, vs. covering the details of the dials and working outward.

2) I'm confident in photoresist etching, and now wish I spent more time practicing it instead of toner. I've done resist film twice and done toner transfer too many times to count. But whether silk screening, pcb making, or making cliches for pad printing, all "the long term doers" and knowledgable people seem to eventually abandon toner. That leaves photo-something to pursue. Once that film has time to set in, it's on there good. Like too good when it really burns on there after getting exposed and left there.

Finally, I can print at least (supposedly) double the resolution for almost nothing on my inkjet. I'm more than happy to send some prints to you (Chrome) if you want. PM me and/or send the files. A few transparencies shipped to Houston should be easy. I'm almost next door with the alligators and the swamps.

@WatchN3RD

I was naively hoping the chemical plating would work.

I don’t know if photoresist would stick to a patinad surface or a black chromate surface. I will have to find out. It might not make it possible to treat the dial first then remove the negative image. Who knows. Guess one of us has to try the photoresist part! However it would stick to say an already zinc plated dial a la the chemical planting method. I will have to try.

Why I knew toner wasn’t the end all be all I knew it could do a lot. The limitation so far is the acids that look like it make it swell slightly. I will test today with toner transfer AND electroplating. I am hoping that there is no interaction and the zinc plating locks the toner in place giving it no room to swell

For pursuing photoresist on my side I’m focusing on either resin MSLA printer which uses UV light and a led screen. The mask is on the led screen itself so you don’t need to print anything out. The one I am looking at has the equivalent of 1,200isg dpi.

If I am feeling up to it I would make something like this

www.allaboutcircuits.com

www.allaboutcircuits.com

Basically a light source and your mask get condensed by a focal lense and that image gets sent through another smaller reducing lens (aka an old microscope). This is how microchips are made. You can get incredibly complex, detailed images burned onto a photo resistant film and the are measured not in mm but um (micrometers). I had a chat with a researcher at Rice university about this. They thought it might by be over kill but it would work. They think the resin printer or the standard way of a uv light would work.

I want to go the resin printer route because it locks in the variables of Light power, distance from the light so all I have to worry about is time.

I was naively hoping the chemical plating would work.

I don’t know if photoresist would stick to a patinad surface or a black chromate surface. I will have to find out. It might not make it possible to treat the dial first then remove the negative image. Who knows. Guess one of us has to try the photoresist part! However it would stick to say an already zinc plated dial a la the chemical planting method. I will have to try.

Why I knew toner wasn’t the end all be all I knew it could do a lot. The limitation so far is the acids that look like it make it swell slightly. I will test today with toner transfer AND electroplating. I am hoping that there is no interaction and the zinc plating locks the toner in place giving it no room to swell

For pursuing photoresist on my side I’m focusing on either resin MSLA printer which uses UV light and a led screen. The mask is on the led screen itself so you don’t need to print anything out. The one I am looking at has the equivalent of 1,200isg dpi.

If I am feeling up to it I would make something like this

Retro Builds: DIY Photolithography Microfeature Fabrication - Projects

Learn how to use photolithography to shrink a design by as much as a factor of 40.

Basically a light source and your mask get condensed by a focal lense and that image gets sent through another smaller reducing lens (aka an old microscope). This is how microchips are made. You can get incredibly complex, detailed images burned onto a photo resistant film and the are measured not in mm but um (micrometers). I had a chat with a researcher at Rice university about this. They thought it might by be over kill but it would work. They think the resin printer or the standard way of a uv light would work.

I want to go the resin printer route because it locks in the variables of Light power, distance from the light so all I have to worry about is time.

bigtiddygothgf

Active Member

- 7/10/18

- 323

- 149

- 43

After all this time, effort and money spent trying all these alternate processes, that so far still produce unsatisfactory results, why not just cut the fat and pad print at this point? No shade or hostility just curious why the strong avoidance of pad printing.

Great question! Its one I ask myself sometimes. I set out to kind of make a process that anyone can do that isn't cost prohibitive. Pad printing is probably the best option however its expensive to buy machinery, expensive to make a cliche. Ink can be expensive and it smells. I am forced to do it in my shed and in the heat of Texas it makes pad printing a no go for 6 months of the year. I would rather tinker inside. I think I can do something that is just as good as pad printing.After all this time, effort and money spent trying all these alternate processes, that so far still produce unsatisfactory results, why not just cut the fat and pad print at this point? No shade or hostility just curious why the strong avoidance of pad printing.

I am trying to post my 2nd zinc plating experiment but RWI isn't letting me post it without an error message. I was testing to see if zinc messes with toner and it didn't. I capture all serifs when I zinc plate.

Zinc plating experiment 2: does the toner hold up in a zinc plating bath if using electricity? YES!

Great results with first try. Lessons learned too.

I did a homebrew zinc/vinegar/sugar/salt recipe and got a dull zinc finish.

The zinc plating did not affect the toner. Whatever was transferred to the brass stayed as is. No swelling of toner. All serifs look nice.

I dipped the dial into M38 patina I mostly use and it instantly turned black. However when I wiped off the first layer of patina it took some zinc with it. I know that I had the dial too close to the anode so it plated very fast. Fast platings tend to fall off. Next time I will have it further away so it plates slower.

Looking under the microscope the brass revealed is just as it was transferred onto the metal. You can see the tiny zig zag of the printer ha.

I couldn’t tell if there was depth to the plating. I doubt it was in there long enough for it to do so. But next attempt will be further away from the anode and leave it in there for like 20 min. That way the brass text would be recessed, just like the real ones.

Great results with first try. Lessons learned too.

I did a homebrew zinc/vinegar/sugar/salt recipe and got a dull zinc finish.

The zinc plating did not affect the toner. Whatever was transferred to the brass stayed as is. No swelling of toner. All serifs look nice.

I dipped the dial into M38 patina I mostly use and it instantly turned black. However when I wiped off the first layer of patina it took some zinc with it. I know that I had the dial too close to the anode so it plated very fast. Fast platings tend to fall off. Next time I will have it further away so it plates slower.

Looking under the microscope the brass revealed is just as it was transferred onto the metal. You can see the tiny zig zag of the printer ha.

I couldn’t tell if there was depth to the plating. I doubt it was in there long enough for it to do so. But next attempt will be further away from the anode and leave it in there for like 20 min. That way the brass text would be recessed, just like the real ones.

I need that exact lens! Have not been able to find any information on this except for a few cheap craft projectors that can only reduce the image a small amount. But when you say, 1200dpi, I'm guessing that's the final resolution equivalent after the screen has been reduced? If not, that should be amazing resolution.@WatchN3RD

I was naively hoping the chemical plating would work.

I don’t know if photoresist would stick to a patinad surface or a black chromate surface. I will have to find out. It might not make it possible to treat the dial first then remove the negative image. Who knows. Guess one of us has to try the photoresist part! However it would stick to say an already zinc plated dial a la the chemical planting method. I will have to try.

Why I knew toner wasn’t the end all be all I knew it could do a lot. The limitation so far is the acids that look like it make it swell slightly. I will test today with toner transfer AND electroplating. I am hoping that there is no interaction and the zinc plating locks the toner in place giving it no room to swell

For pursuing photoresist on my side I’m focusing on either resin MSLA printer which uses UV light and a led screen. The mask is on the led screen itself so you don’t need to print anything out. The one I am looking at has the equivalent of 1,200isg dpi.

If I am feeling up to it I would make something like this

Retro Builds: DIY Photolithography Microfeature Fabrication - Projects

Learn how to use photolithography to shrink a design by as much as a factor of 40.www.allaboutcircuits.com

Basically a light source and your mask get condensed by a focal lense and that image gets sent through another smaller reducing lens (aka an old microscope). This is how microchips are made. You can get incredibly complex, detailed images burned onto a photo resistant film and the are measured not in mm but um (micrometers). I had a chat with a researcher at Rice university about this. They thought it might by be over kill but it would work. They think the resin printer or the standard way of a uv light would work.

I want to go the resin printer route because it locks in the variables of Light power, distance from the light so all I have to worry about is time.

@WatchN3RD the 1,200 dpi is coming from a lcd screen. It’s the mars 4 msla resin printer. It has a resolution of 8520x4320 pixels and a 7” screen which puts the ppi at 1,217 and ppi and dpi should be the same. You can get these on eBay at the elegoo outlet store for $99.

For the lens, that is something different. That is for photolithography. The resolution for lenses a different beast. You can use camera lenses if you can figure out how to attach it to a dlp projector. Here is a kid who is making microchips in his basement using this set up. He is behind 50 years in technology but still making microchips! He is doing this with a dlp projector and a microscope

For the lens, that is something different. That is for photolithography. The resolution for lenses a different beast. You can use camera lenses if you can figure out how to attach it to a dlp projector. Here is a kid who is making microchips in his basement using this set up. He is behind 50 years in technology but still making microchips! He is doing this with a dlp projector and a microscope

I should add this kid above is getting details as small as 10 um= .01mm. That is insane. I’m some of them have text that is a fraction of a mm. Per the Rice university researcher “.45mm text is huge” ha.

For me, I wouldn't say my results have been unsatisfactory, but I do find the entire toner transfer process unsatisfactory!After all this time, effort and money spent trying all these alternate processes, that so far still produce unsatisfactory results, why not just cut the fat and pad print at this point? No shade or hostility just curious why the strong avoidance of pad printing.

I have not tried pad printing simply because I don't know enough about minute details it entails. I'm worried I'd end up with a (possibly) expensive piece of equipment and not have a reliable source of information when $HIT goes wrong.

I'm definitely not against pad printing though. Stopped myself numerous times from pulling the buy trigger only because I wasn't confident in my knowledge thus far.

But photoresist carries over into production of clichés for pad printing, silkscreening, and other processes. Therefore, that knowledge is still relevant if I go the pad-printing route. Light is amazingly detailed with the proper process. Just think of the details old (real) film negatives have.

Sorry about the novel, I'm totally with you. I just don't want to jump the gun and make a waste of it. I'm all about pad printing at some point though.

That's what I'm talking about! I often use the term photoresist improperly, but photolithography is the correct term I should be using. That's a complete game changer.@WatchN3RD the 1,200 dpi is coming from a lcd screen. It’s the mars 4 msla resin printer. It has a resolution of 8520x4320 pixels and a 7” screen which puts the ppi at 1,217 and ppi and dpi should be the same. You can get these on eBay at the elegoo outlet store for $99.

For the lens, that is something different. That is for photolithography. The resolution for lenses a different beast. You can use camera lenses if you can figure out how to attach it to a dlp projector. Here is a kid who is making microchips in his basement using this set up. He is behind 50 years in technology but still making microchips! He is doing this with a dlp projector and a microscope

I just talked with a hexavalent black chromate manufacturer about the black on gilt dials and showed him the tropical dials. The silver in the black chromate is what turns the zinc black. He told me it looked like the browns on tropical dials were due to less than desirable silver ions in the black chromate solution and that their product is a 2 step mixture with the 2nd part being the silver ions. He said I could probably just put in less than recommended silver ions and blast it with UV light to get the browns and get a natural tropical dial. Their product also doesn't really care if the zinc plating was done with an alkaline or acidic zinc plating bath which is cool.

Hexavalant black chromate is hazardous though

Hexavalant black chromate is hazardous though