Yup the 6497 is the way to go for a first service. It’s big and friendly, but everything is there so it’s a great place to learn.That's awesome and very impressive, seems like a short time to get to a full service! Hoping to do my first full service soon. Need a few more tools methinks. I've done alot of modding/building and smithin' on dial side and rotor side mainly on 28xx as I find them easiest to deal with. But something is urging me service a 6497 first! Bigger is easier, no?

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dogwood's Watchmaking Journey

- Thread starter dogwood

- Start date

What's really cool is, I have what I affectionately refer to as "The shitbox" full of old movements I messed up back in the day. Plenty of challenges to try to get back up and running!Yup the 6497 is the way to go for a first service. It’s big and friendly, but everything is there so it’s a great place to learn.

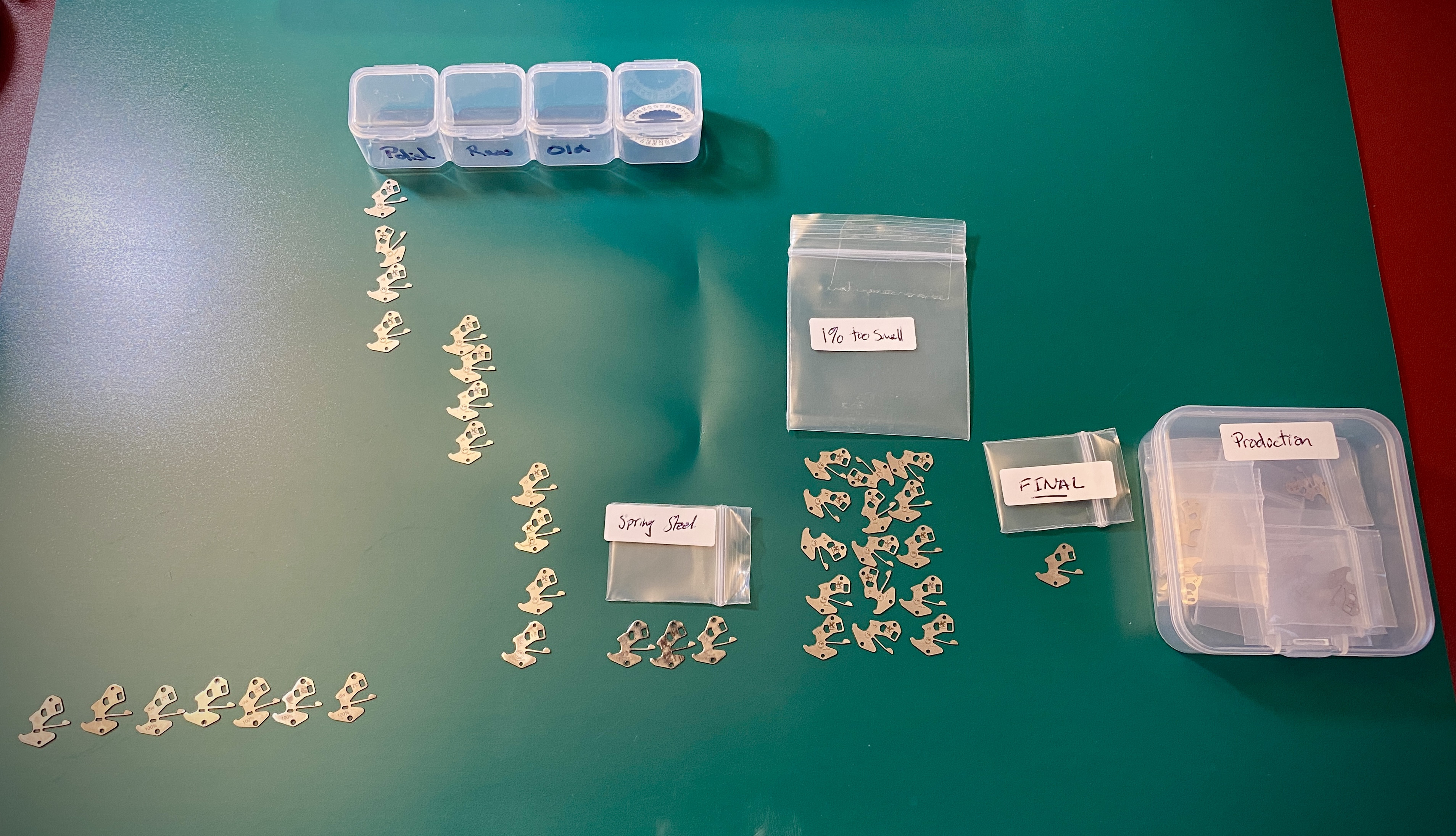

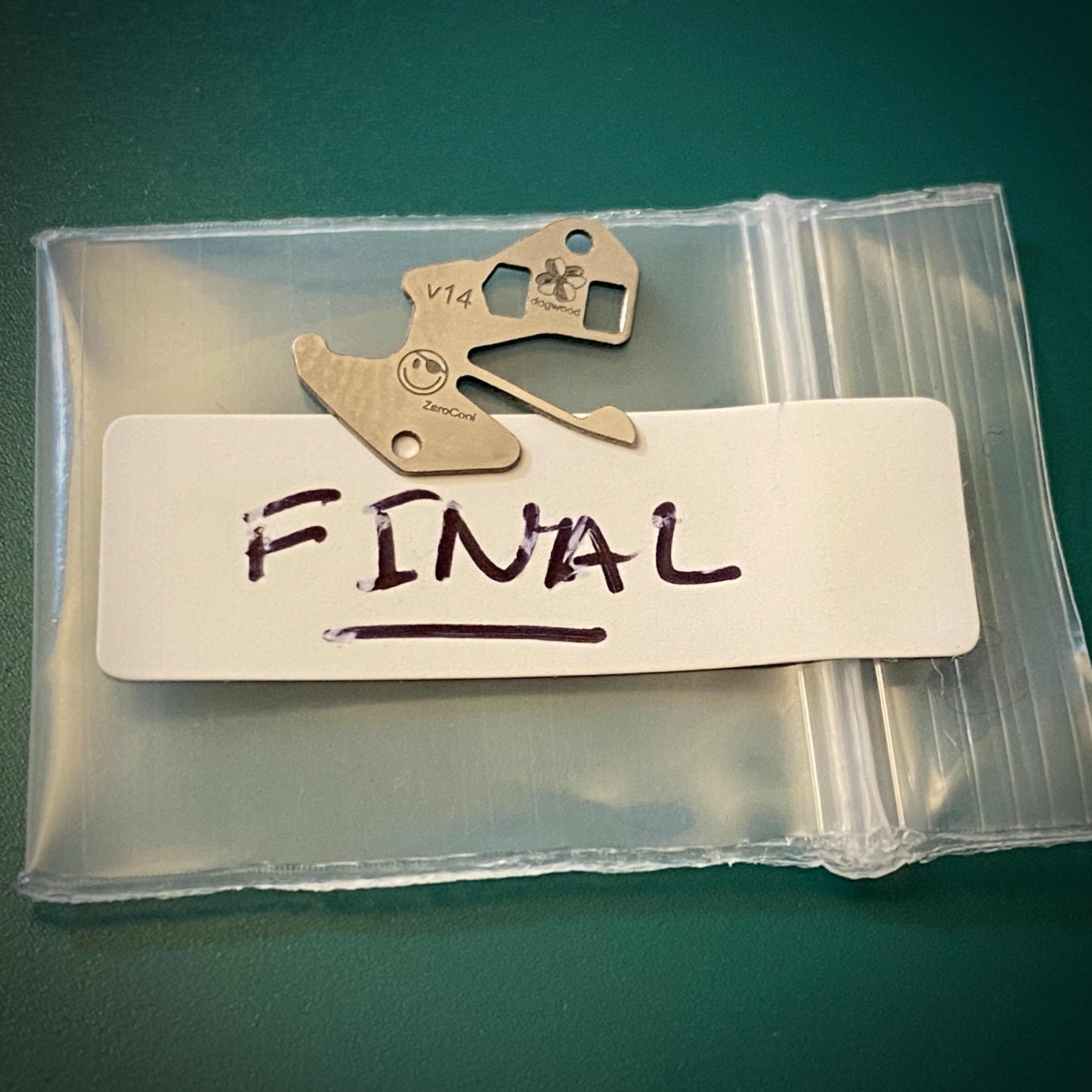

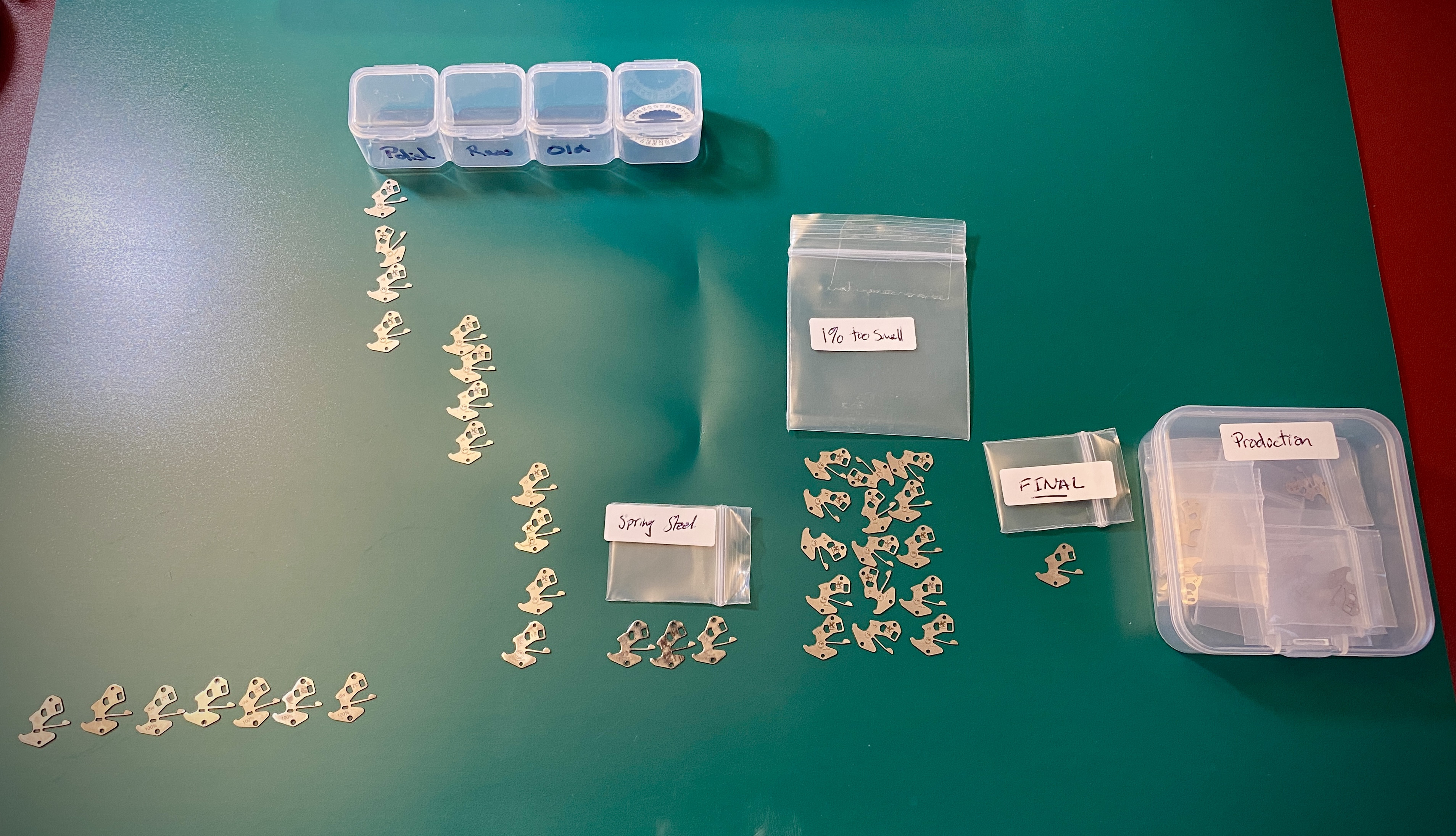

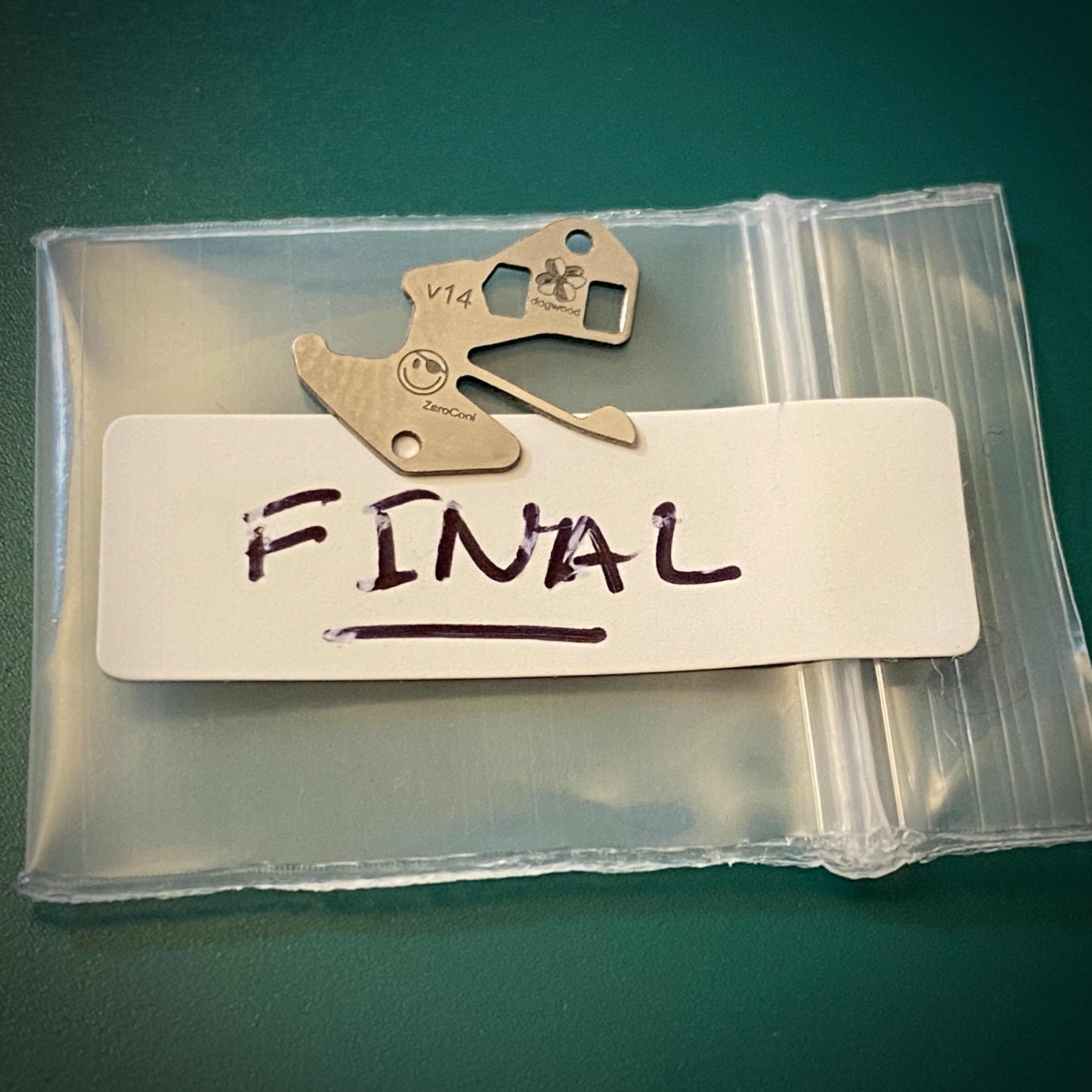

I think we might be getting very very (VERY) close to the vs3235 to “vs3230” setting lever spring conversion mod being finally ready. @xZeroCoolx sent me a final batch of production parts, and they work perfectly.

It has been a long process with many iterations to try to get everything working smoothly.

But at long last? I think we are there…

The action is smooth and there is no interference with the teeth on the sliding pinion.

If you have a VSF 41mm no-date sun, or a VSF oyster perpetual, I think there might finally be a solution to the phantom date correction crown position.

I asked @daytona4me and @trailboss99 If it would be ok for @xZeroCoolx and I to make this mod available to the RWI community, and they said “yes” but we’re still figuring out where / how to make an official announcement and sales thread. So I guess stay tuned as that should happen soon.

It has been a long process with many iterations to try to get everything working smoothly.

But at long last? I think we are there…

The action is smooth and there is no interference with the teeth on the sliding pinion.

If you have a VSF 41mm no-date sun, or a VSF oyster perpetual, I think there might finally be a solution to the phantom date correction crown position.

I asked @daytona4me and @trailboss99 If it would be ok for @xZeroCoolx and I to make this mod available to the RWI community, and they said “yes” but we’re still figuring out where / how to make an official announcement and sales thread. So I guess stay tuned as that should happen soon.

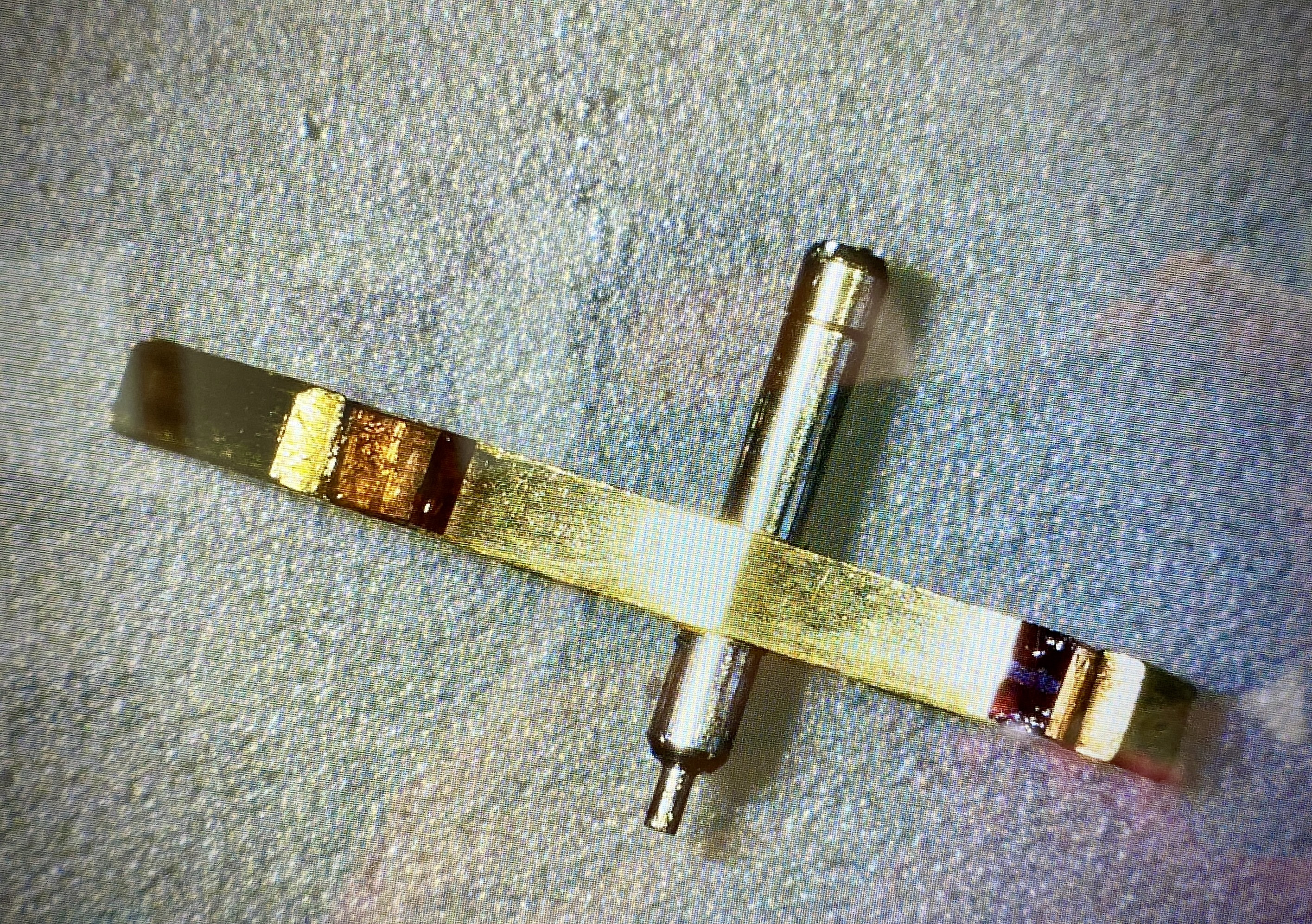

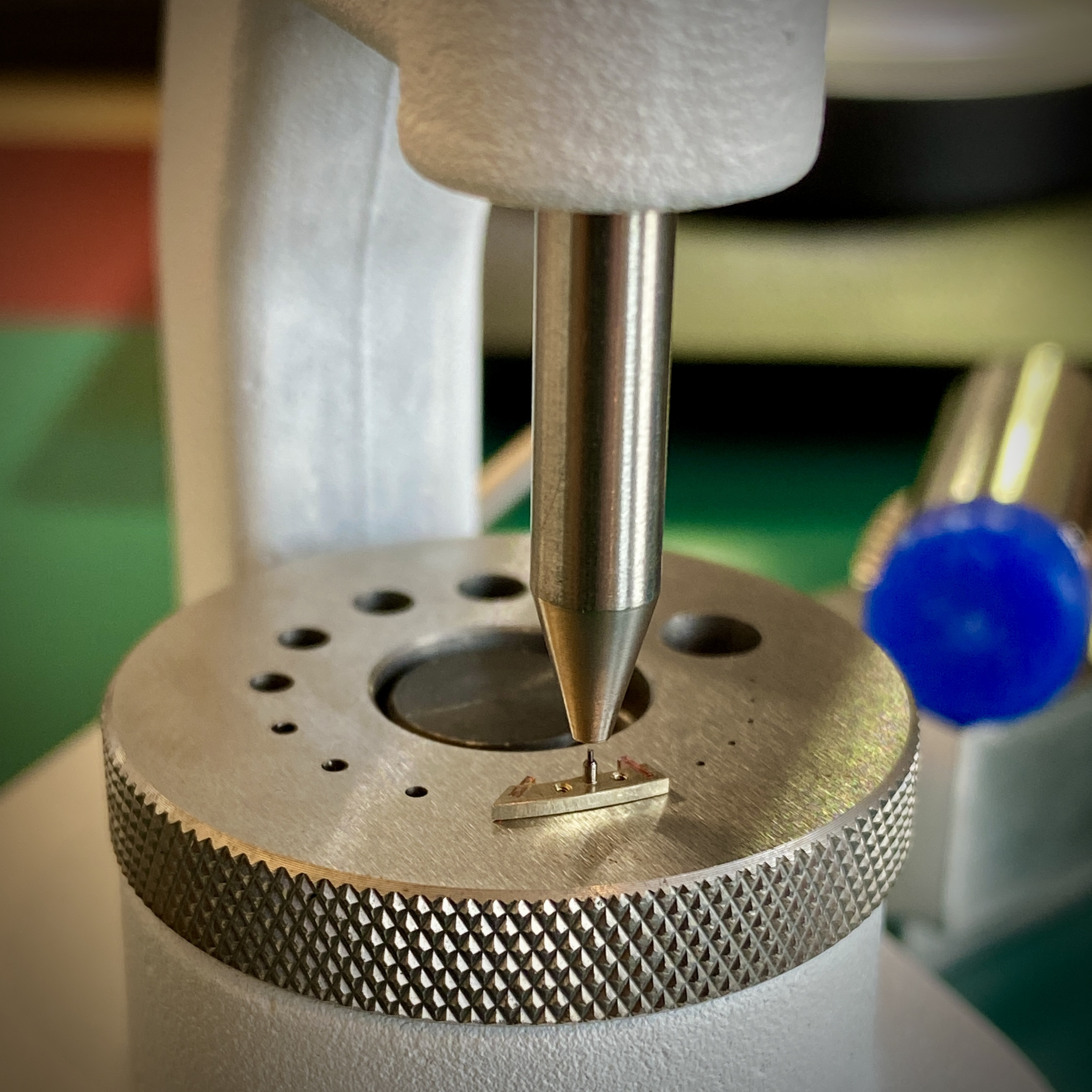

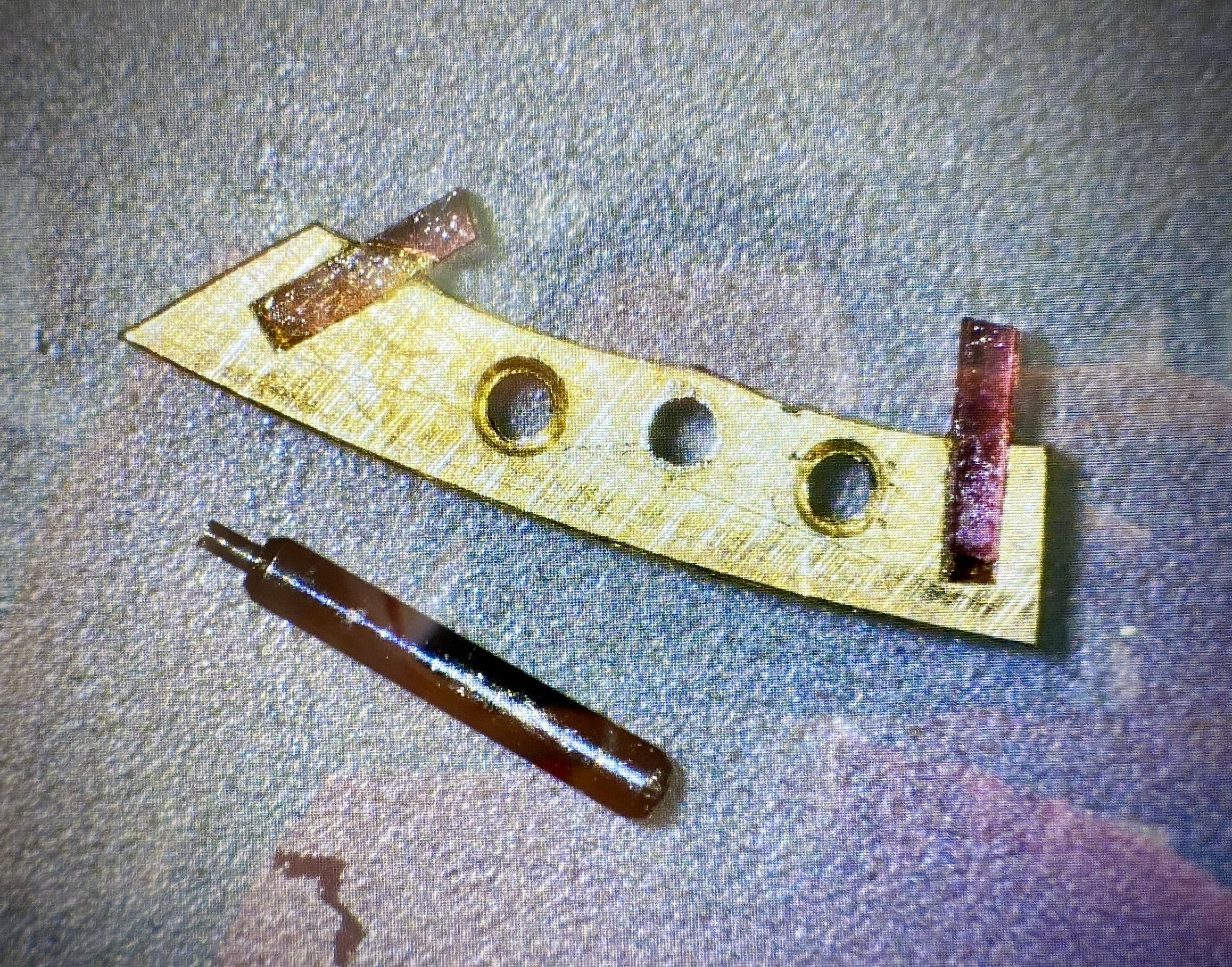

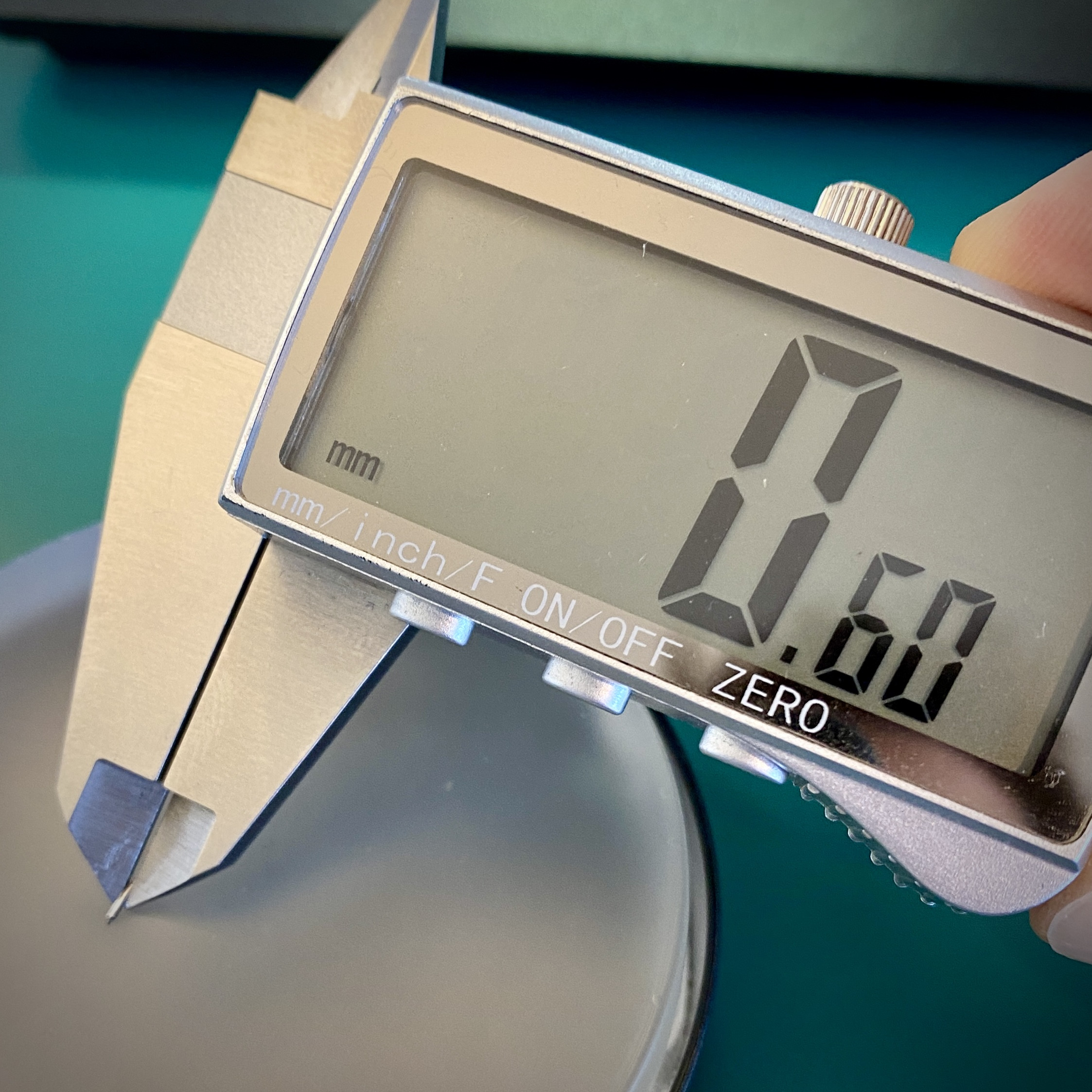

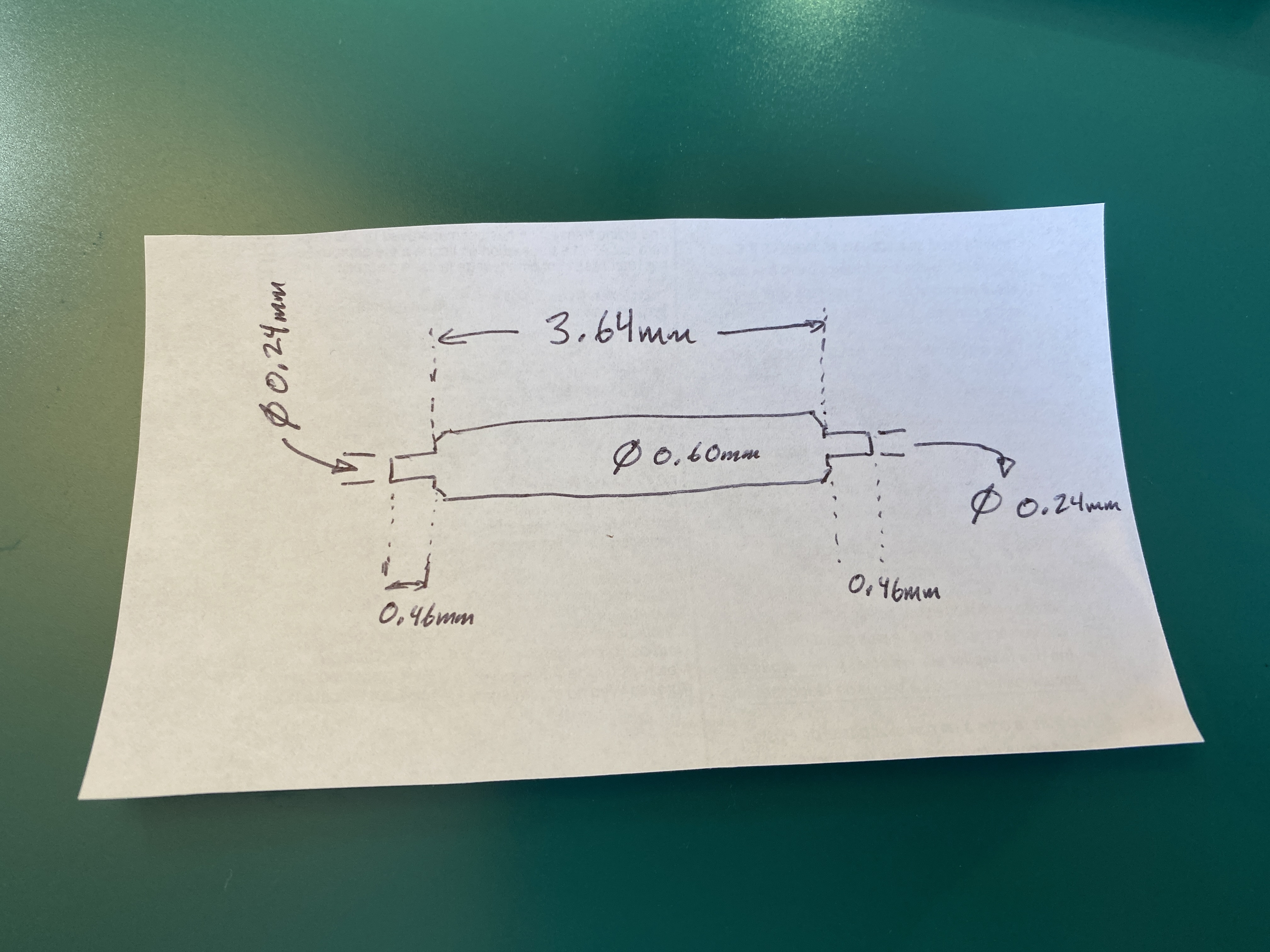

So Bob (the guy who gave me this watch to try to fix) has several lathes in his shop and he figured he’d try to make a new pallet fork arbor. The arbor is a simple geometry, but it is tiny and has very dmall diameter features (ie the pivots). Bob gave it a shot, but couldn’t make it work.So I got to thinking last night that the Waltham pallet fork is actually an assembly of three parts: the pallet stone holder, the balance wheel fork, and the arbor. Only the arbor is broken, so I figured maybe I should see about disassembling the part to get some measurements of the arbor.

It’s possible this is something that could be made on a jeweler’s lathe by grinding down some 0.60mm round stock.

I suspect the problem is that he’s trying to cut the part on his lathe, but what he needs is a spindle with a grinding tool on his lathe tool post so that he can grind the material away for the pivots rather than trying to cut the metal. I suspect at 0.60mm in diameter there’s no lathe that could spin the part fast enough to get a surface cutting speed high enough to use carbide to cut the metal.

I have a Daytona that I use for athletic activity (running and skiing mostly) and it has a rotor that’s quite loud… but not loud in the “spinning” sense, it’s loud in the “knocks and pings” sense. Here’s a video that shows what I mean (sound on).

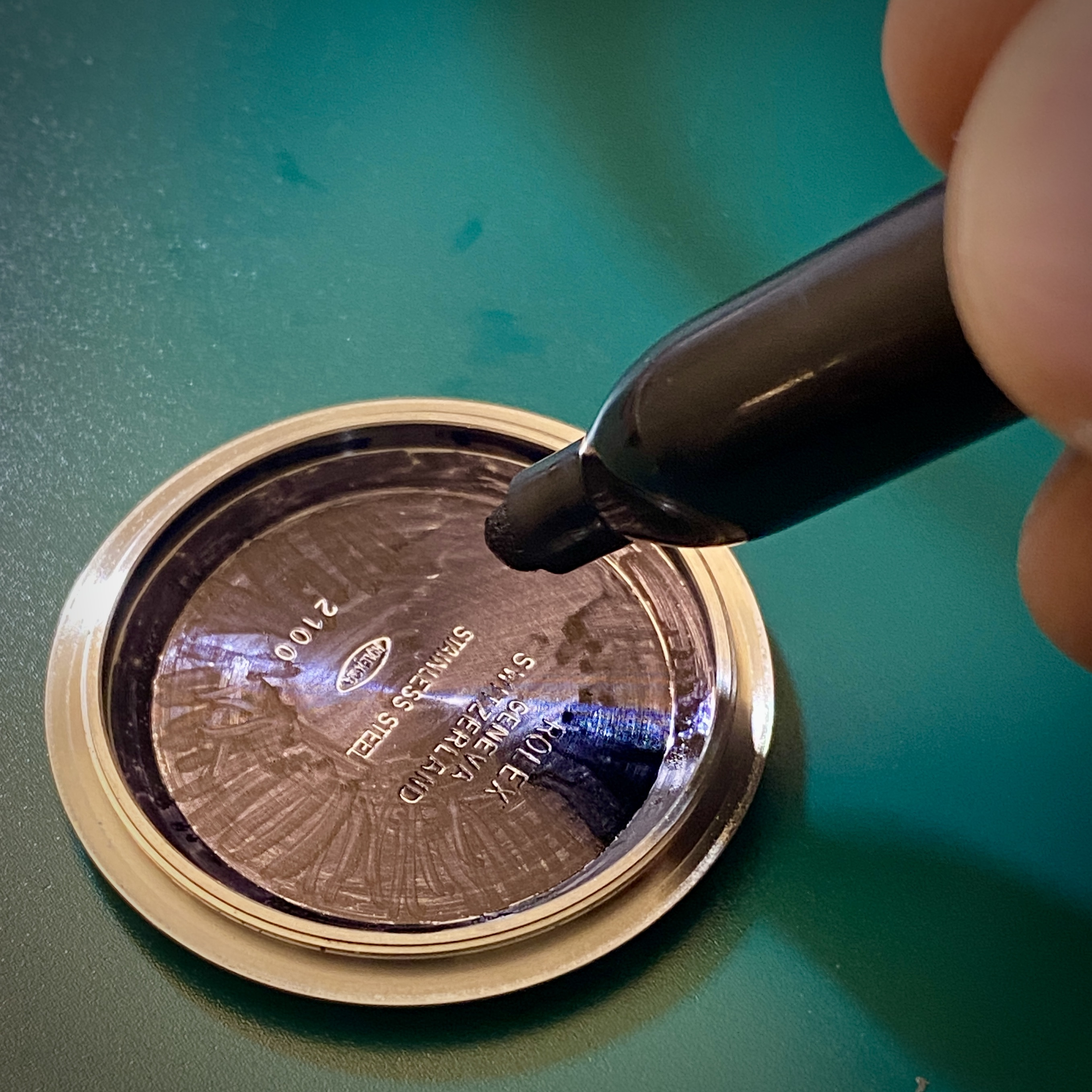

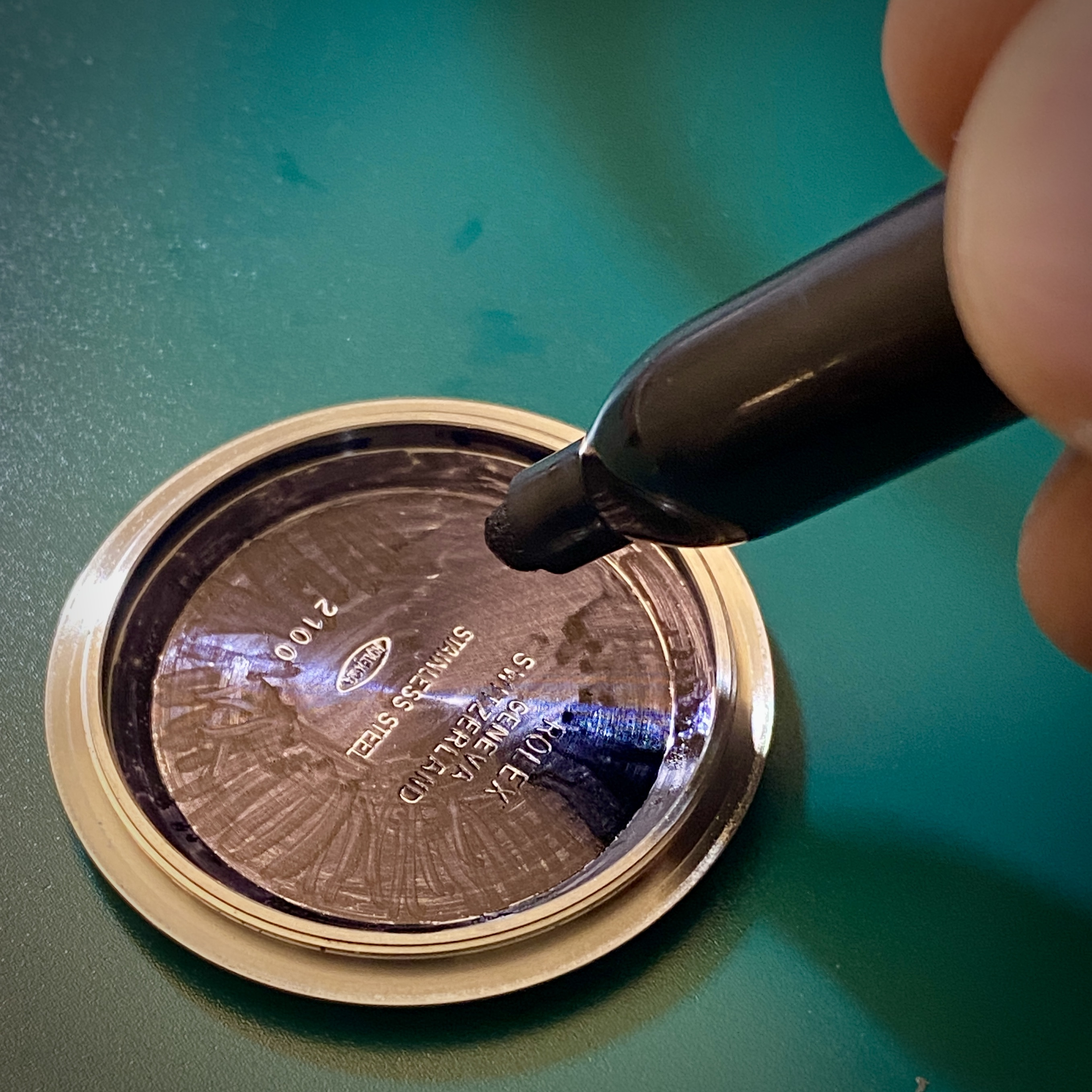

I was pretty sure the rotor must be knocking on the caseback so I decided to test by coloring the casebavk with sharpie and seeing if the ink got removed by the rotor.

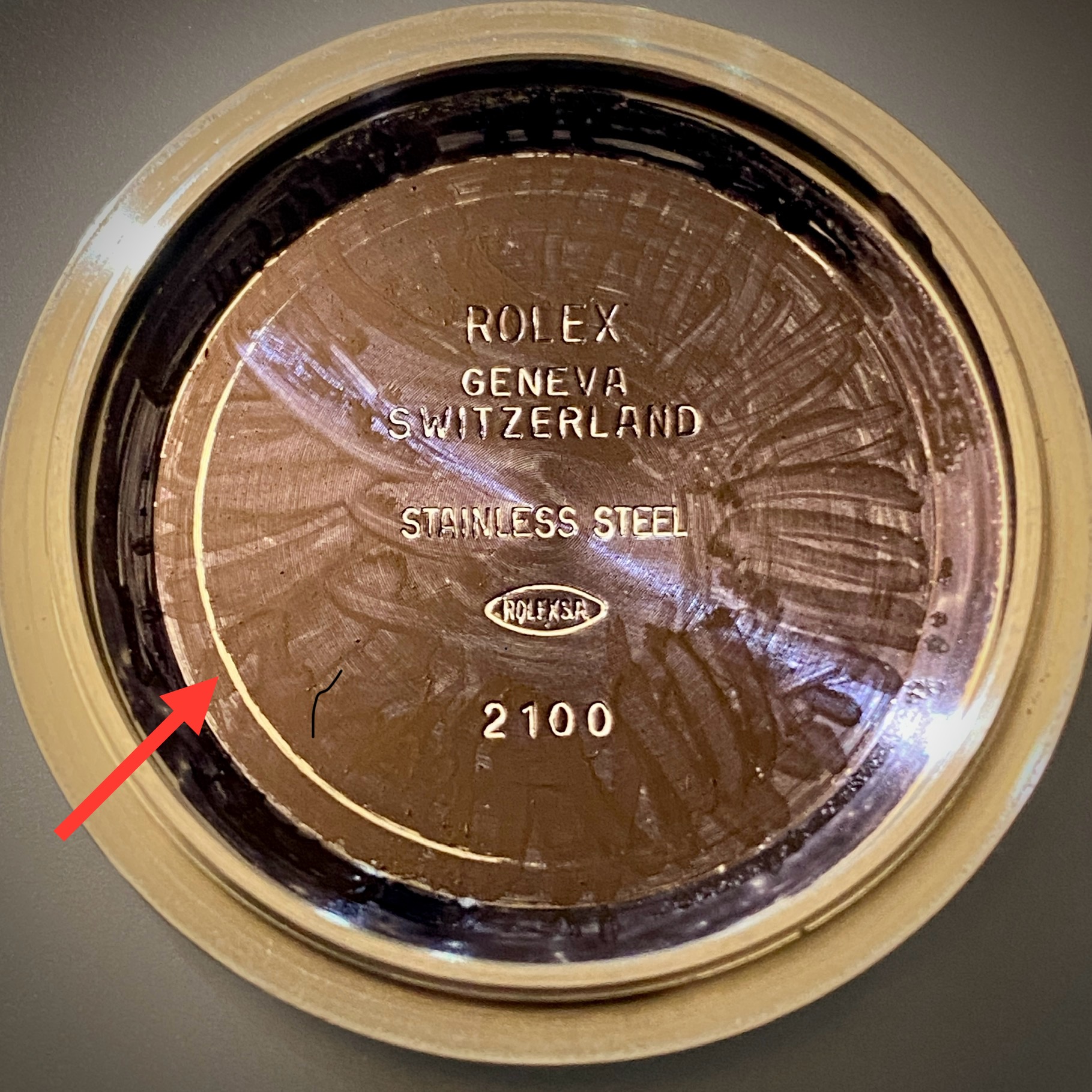

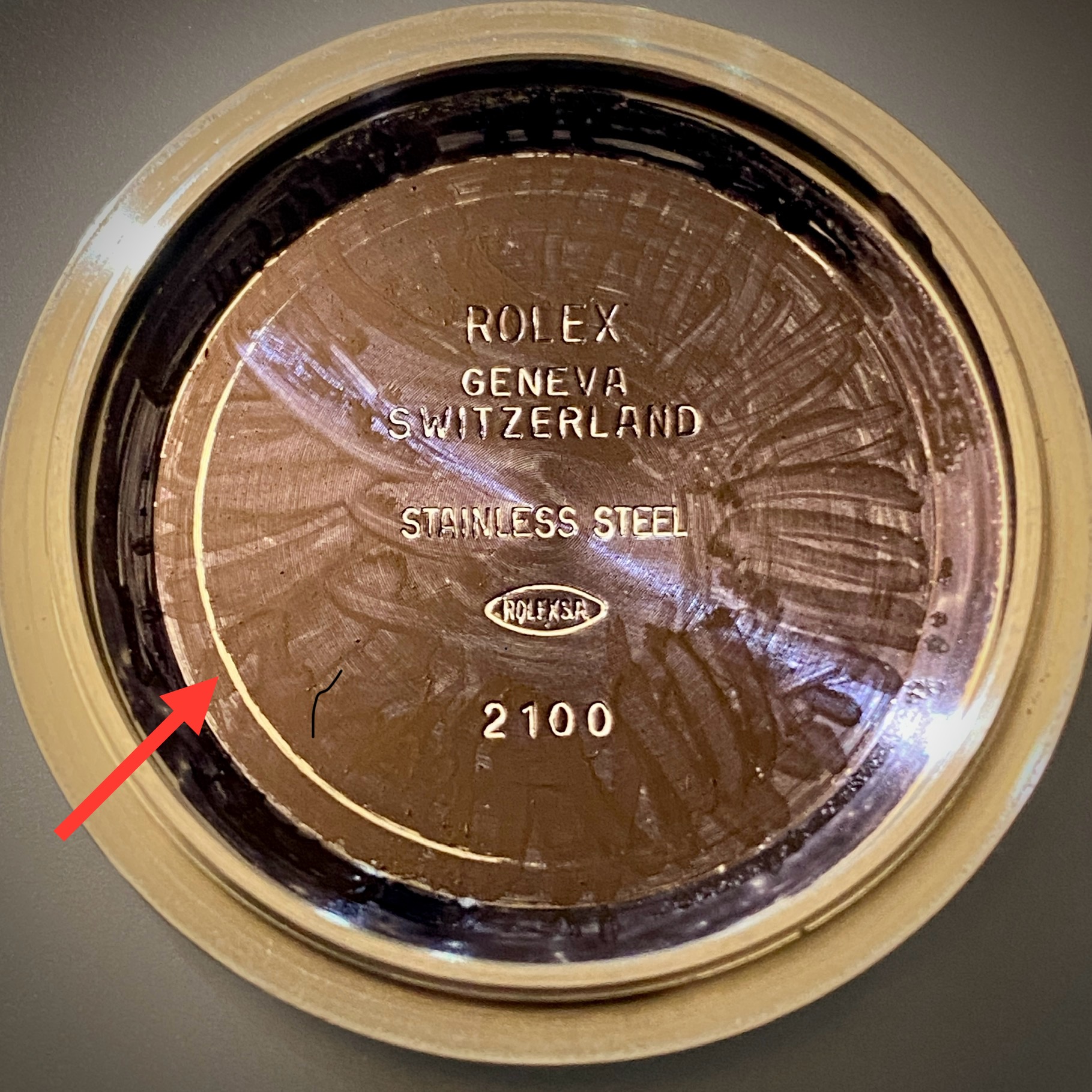

After replacing the caseback and spinning the rotor by moving the watch around, this is what I saw when I removed the caseback.

The rotor had clearly been hitting the caseback.

I measured the caseback at around 0.85mm thick. So I figured there would be enough “meat” left if I tried removing a bit of material from the caseback to make more room for the rotor.

I still don’t have a lathe, so I resorted to using the poor man alternative: a three jaw chuck mounted to a drill.

I used sandpaper to try to remove a few hundredths of a mm of thickness, but wasn’t making much progress. I’m heading home over Xmas and I might try to do this operation on my Dad’s friend Bob’s proper lathe. I’ll report back if I’m able to solve the issue. But for now, at least I know what the issue is and I think I have a workable solution.

I was pretty sure the rotor must be knocking on the caseback so I decided to test by coloring the casebavk with sharpie and seeing if the ink got removed by the rotor.

After replacing the caseback and spinning the rotor by moving the watch around, this is what I saw when I removed the caseback.

The rotor had clearly been hitting the caseback.

I measured the caseback at around 0.85mm thick. So I figured there would be enough “meat” left if I tried removing a bit of material from the caseback to make more room for the rotor.

I still don’t have a lathe, so I resorted to using the poor man alternative: a three jaw chuck mounted to a drill.

I used sandpaper to try to remove a few hundredths of a mm of thickness, but wasn’t making much progress. I’m heading home over Xmas and I might try to do this operation on my Dad’s friend Bob’s proper lathe. I’ll report back if I’m able to solve the issue. But for now, at least I know what the issue is and I think I have a workable solution.

Theodorius

Getting To Know The Place

Great updates  Thank you.

Thank you.

A quick and reliable fix will be also to get a new Case O-Ring which maybe + 0.1mm in thickness from the used one.

Sometimes the caseback is way too tight and the O-Ring is squeeze out flat. From my Water Resistance professional digital testers, I have noticed keeping the case hand tight, the O-Ring between case & caseback does a very good job as well, and you have the space required for free Rotor move.

Regards

A quick and reliable fix will be also to get a new Case O-Ring which maybe + 0.1mm in thickness from the used one.

Sometimes the caseback is way too tight and the O-Ring is squeeze out flat. From my Water Resistance professional digital testers, I have noticed keeping the case hand tight, the O-Ring between case & caseback does a very good job as well, and you have the space required for free Rotor move.

Regards

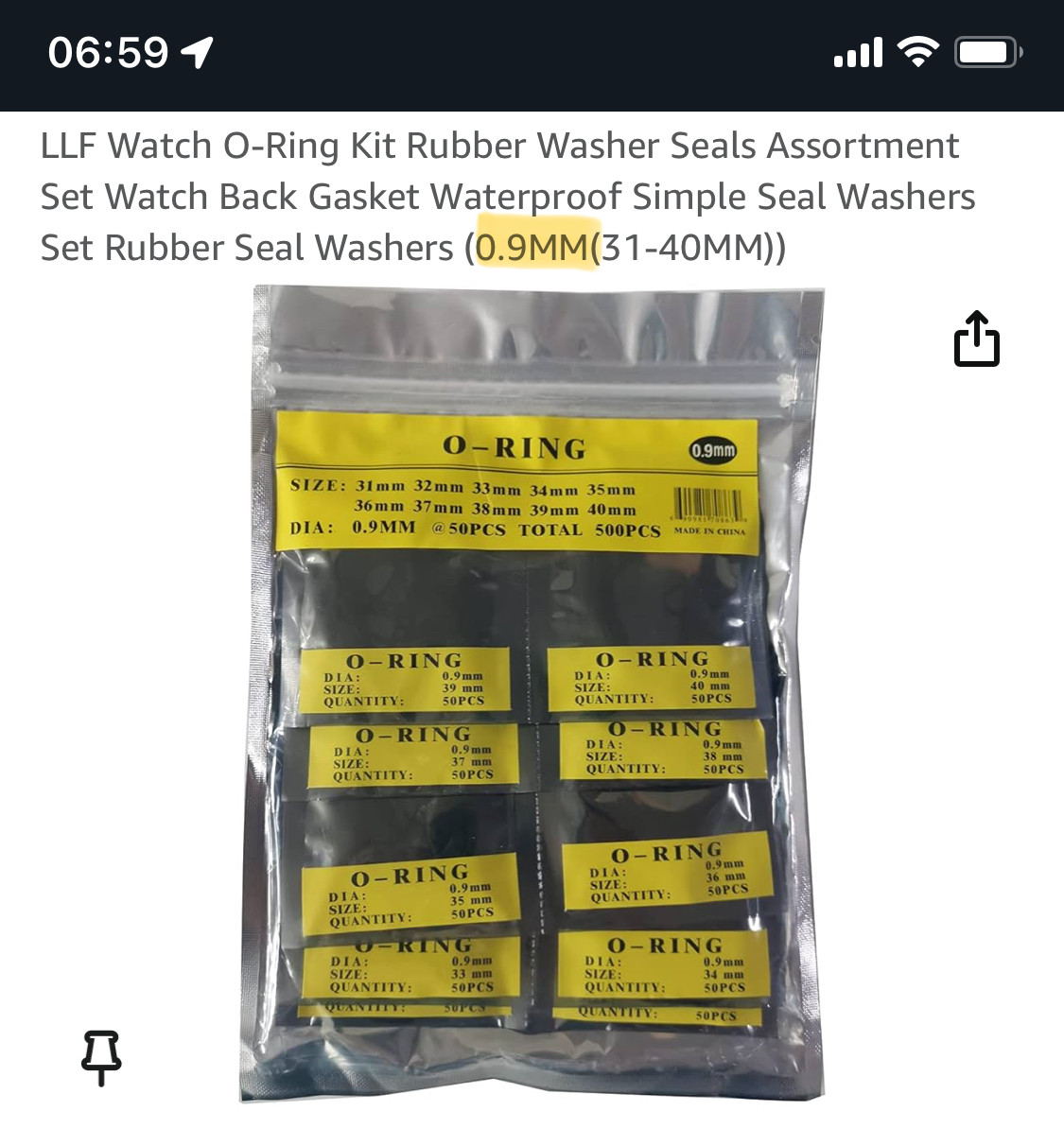

Yup I was thinking the same thing. The stock o-ring was 0.70mm. I tried an o-ring from my parts drawer that claimed it was 0.8mm (but when I measured it it was only 0.74mm). I’ve ordered yet another set of o-rings that are 0.9mm in cross section, so we’ll see if that solves it.Great updatesThank you.

A quick and reliable fix will be also to get a new Case O-Ring which maybe + 0.1mm in thickness from the used one.

Sometimes the caseback is way too tight and the O-Ring is squeeze out flat. From my Water Resistance professional digital testers, I have noticed keeping the case hand tight, the O-Ring between case & caseback does a very good job as well, and you have the space required for free Rotor move.

Regards

Theodorius

Getting To Know The Place

That's a good way to proceed.

If the 0.9mm is too thick to be inserted in the caseback gap, you can try on more option:

Use an elastic glue to fill approx. 1/3 of the gap, wait until is halfway dry and insert even back the 0.7mm or what is best fit.

Do not push the O-Ring all way down, leave it evenly dry, and then you got the height required.

Good luck

Theo

If the 0.9mm is too thick to be inserted in the caseback gap, you can try on more option:

Use an elastic glue to fill approx. 1/3 of the gap, wait until is halfway dry and insert even back the 0.7mm or what is best fit.

Do not push the O-Ring all way down, leave it evenly dry, and then you got the height required.

Good luck

Theo

At long last... the phantom date correction mod for the 3235 is ready for prime time. Here's a link to the release announcement:

forum.replica-watch.info

forum.replica-watch.info

NEW RELEASE: VSF 3235 -> 3230 Phantom Date Fix Mod

Hello RepFam! If you own a VSF Oyster Perpetual or a VSF 41mm no-date Submariner, congratulations, you have the best possible movement in your rep. However, when VSF made these reps, they didn't get Dandong to modify the VS3235 into a VS3230... that means that there's a phantom date correction...

My MGF JLC Reverso arrived today and the strap leaves much to be desired (or as @TESLA760 put it: “rep straps are made out of cat taint”).

I felt that before I threw it out, I’d try to condition my “cat taint” leather strap… after doing a bit of reading I found that most leather conditioners are simply rendered fats from certain animals. The two I had on hand were Mink Oil (which unsurprisingly comes from rendering the subcutaneous fat from minks), and dubbin (which comes from rendering the fat out of cattle shin bones).

I decided to go for the mink oil first since my dubbin has a silicone additive for waterproofing boot leather — something I felt I didn’t need up against my skin. I’ve heard that mink oil is slightly acidic and can damage stitching, but the acidity also helps really soften leather. I figured there was very little downside to giving mink oil a try.

I used a cloth to run in a bit of mink oil onto both the inside and outside of the strap, then I placed it by the fire to let the heat help the leather absorb the oil.

I’ll report back on how it turns out.

I felt that before I threw it out, I’d try to condition my “cat taint” leather strap… after doing a bit of reading I found that most leather conditioners are simply rendered fats from certain animals. The two I had on hand were Mink Oil (which unsurprisingly comes from rendering the subcutaneous fat from minks), and dubbin (which comes from rendering the fat out of cattle shin bones).

I decided to go for the mink oil first since my dubbin has a silicone additive for waterproofing boot leather — something I felt I didn’t need up against my skin. I’ve heard that mink oil is slightly acidic and can damage stitching, but the acidity also helps really soften leather. I figured there was very little downside to giving mink oil a try.

I used a cloth to run in a bit of mink oil onto both the inside and outside of the strap, then I placed it by the fire to let the heat help the leather absorb the oil.

I’ll report back on how it turns out.

It took all my willpower to fight the engineer urge to disassemble the movement as soon as it was unpacked. I will eventually take a look and do a full movement breakdown. For now, the watch feels nice on the wrist.@dogwood , the big question I have is, how is the watch? Have you had a peek at the movement yet?

It’s cool how the two watch dials can be set to completely different time zones. The crown has three positions: 0) winding, 1) setting the time on the blue dial, 2) setting the time on the silver dial. This implies a movement with two “cannon pinions” or rather two independent friction fit couplings between the front / back motion works and the escapement.

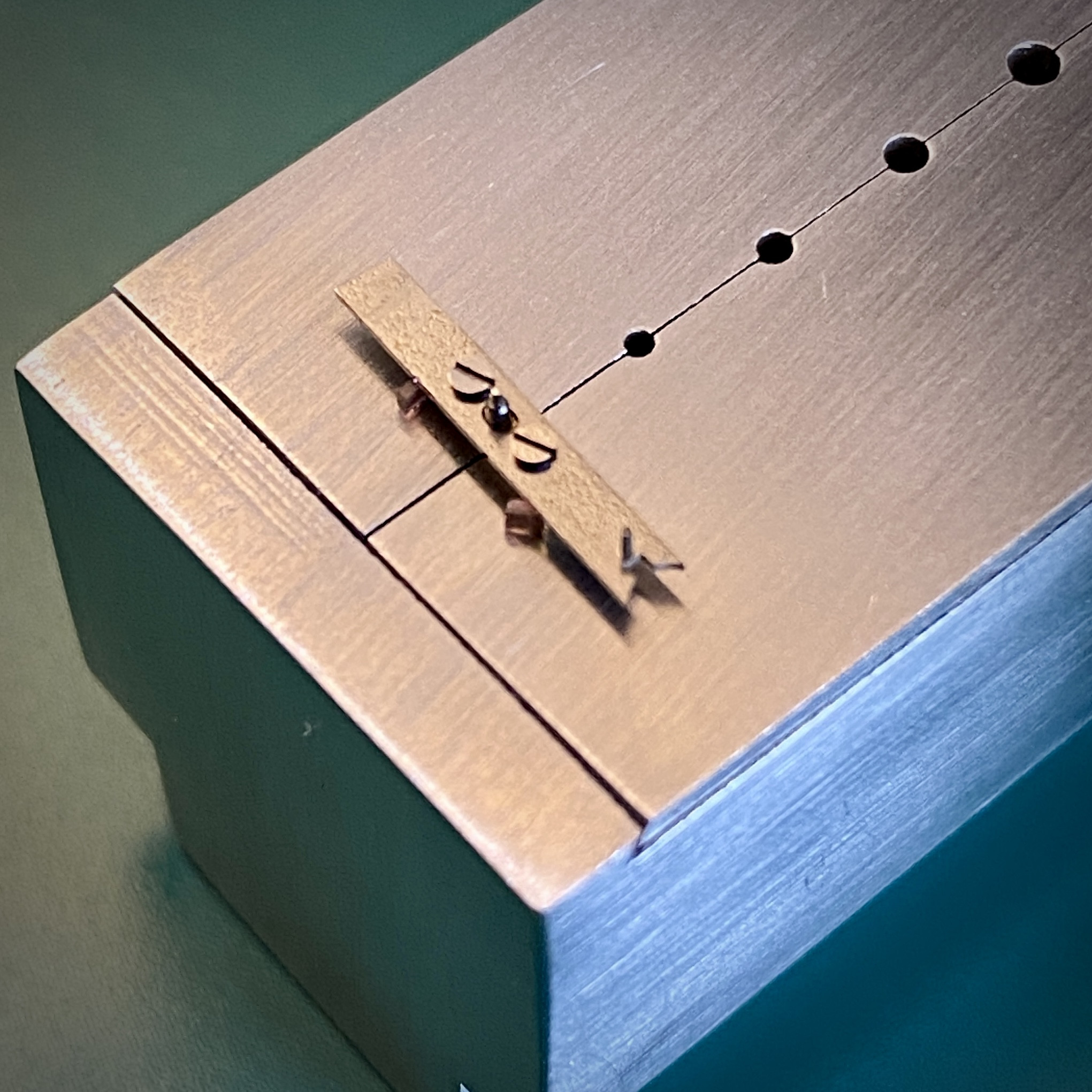

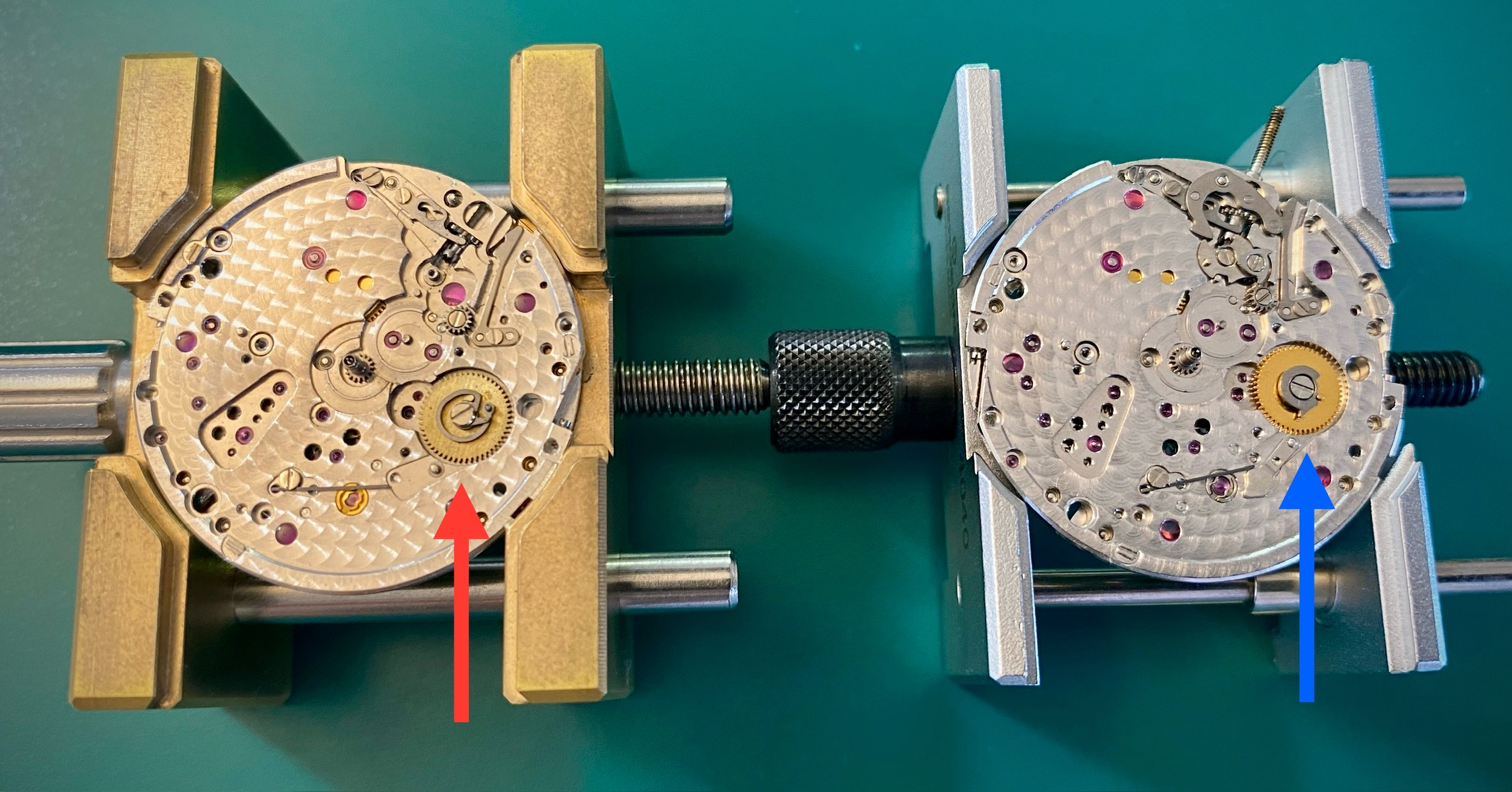

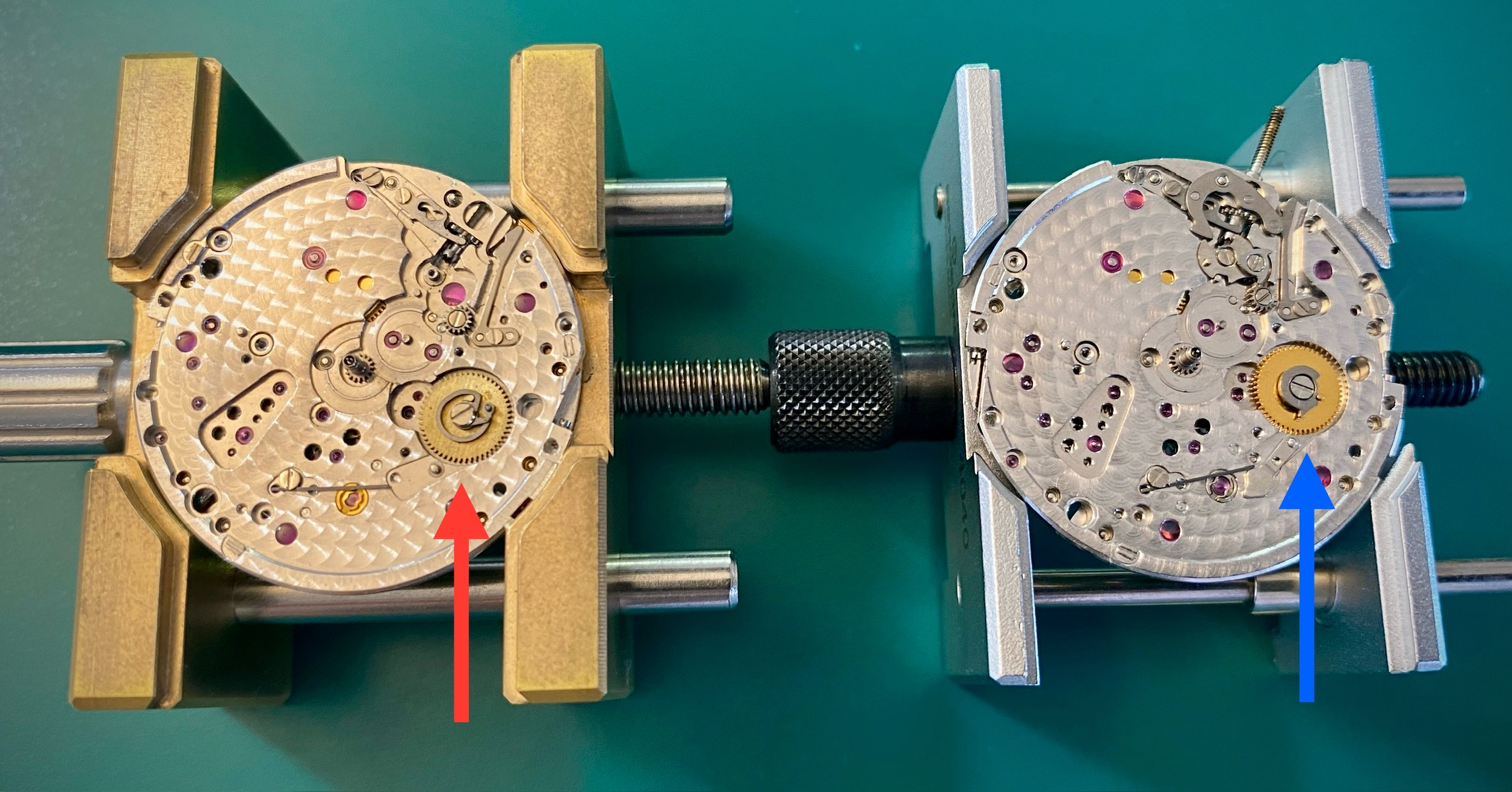

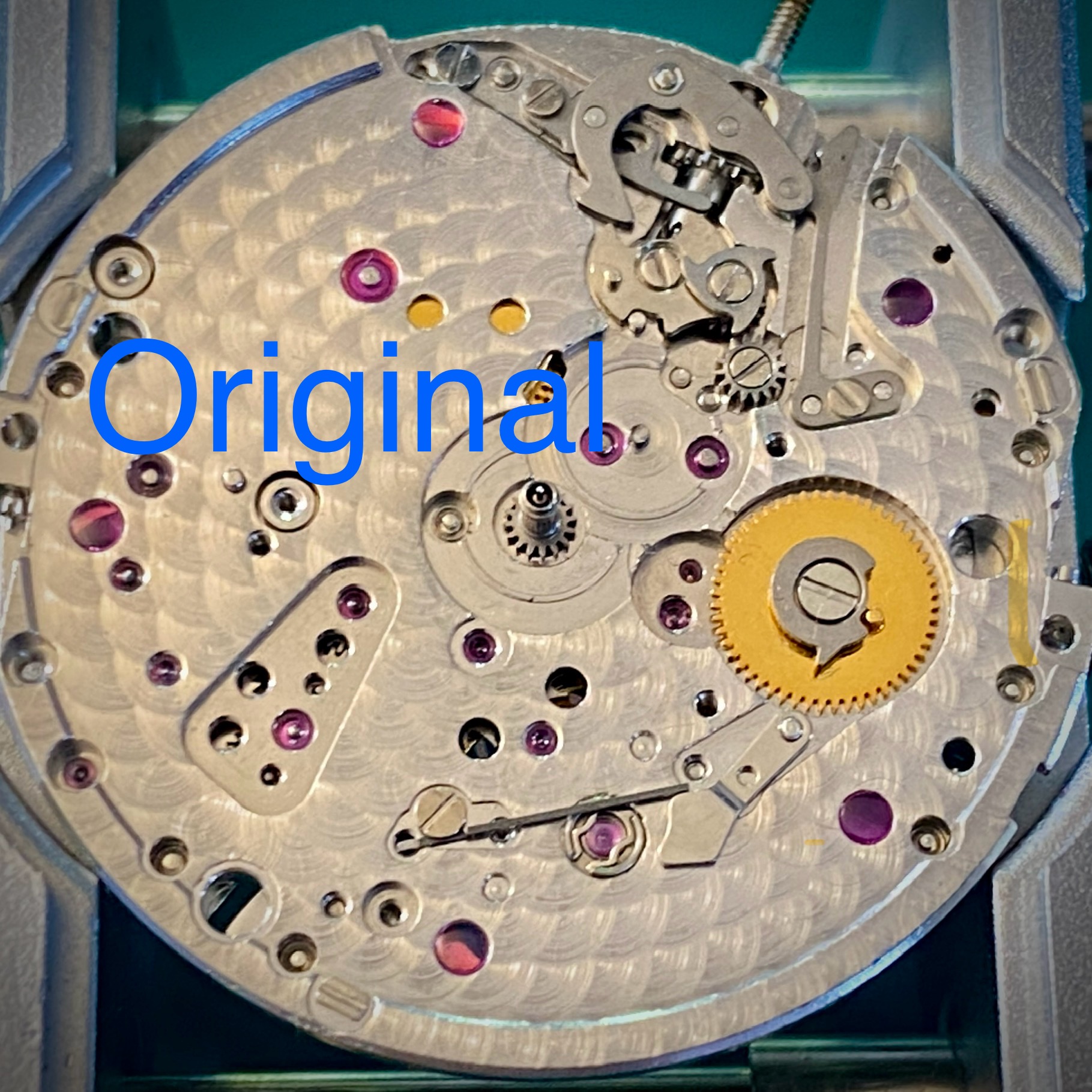

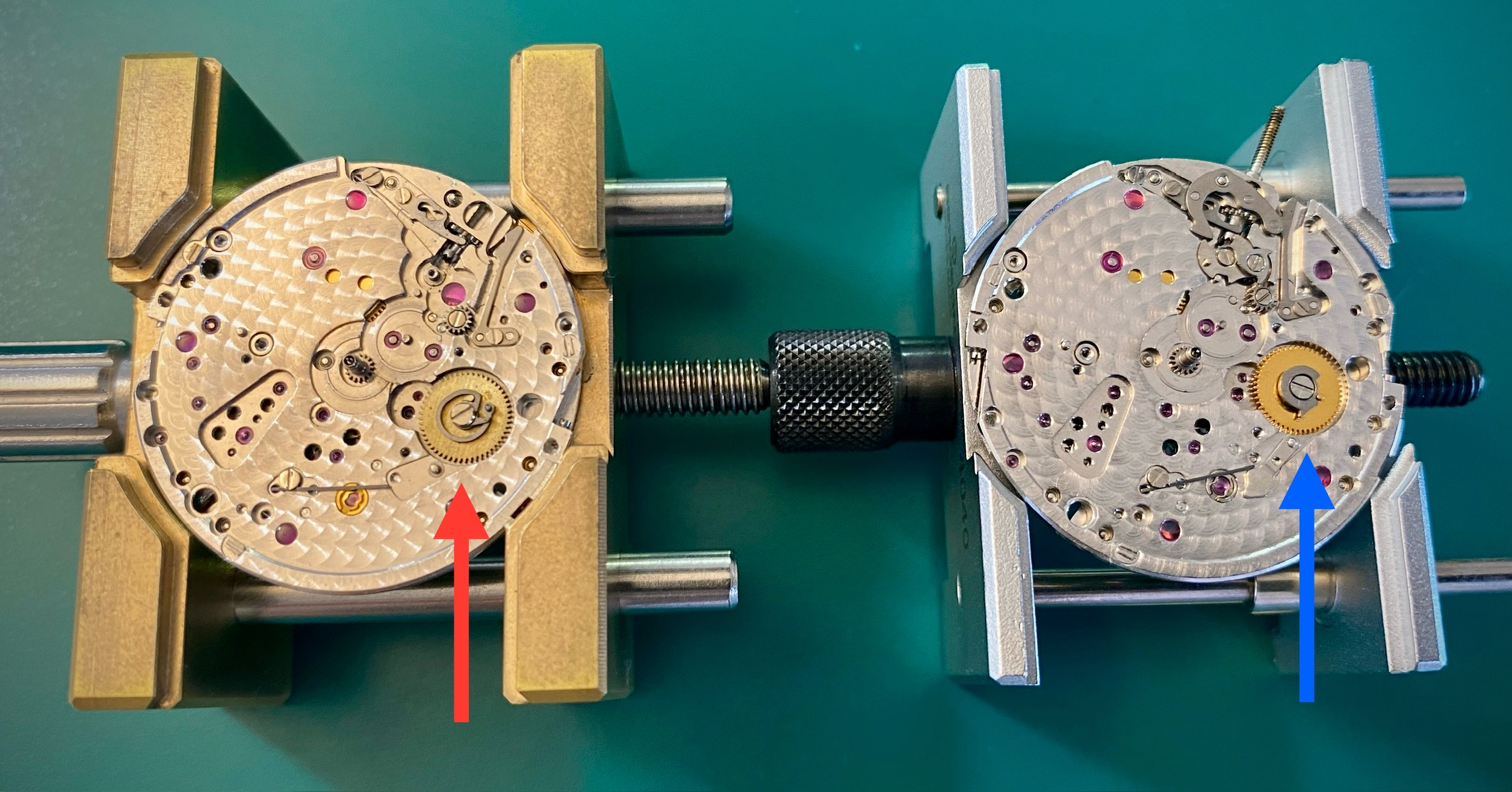

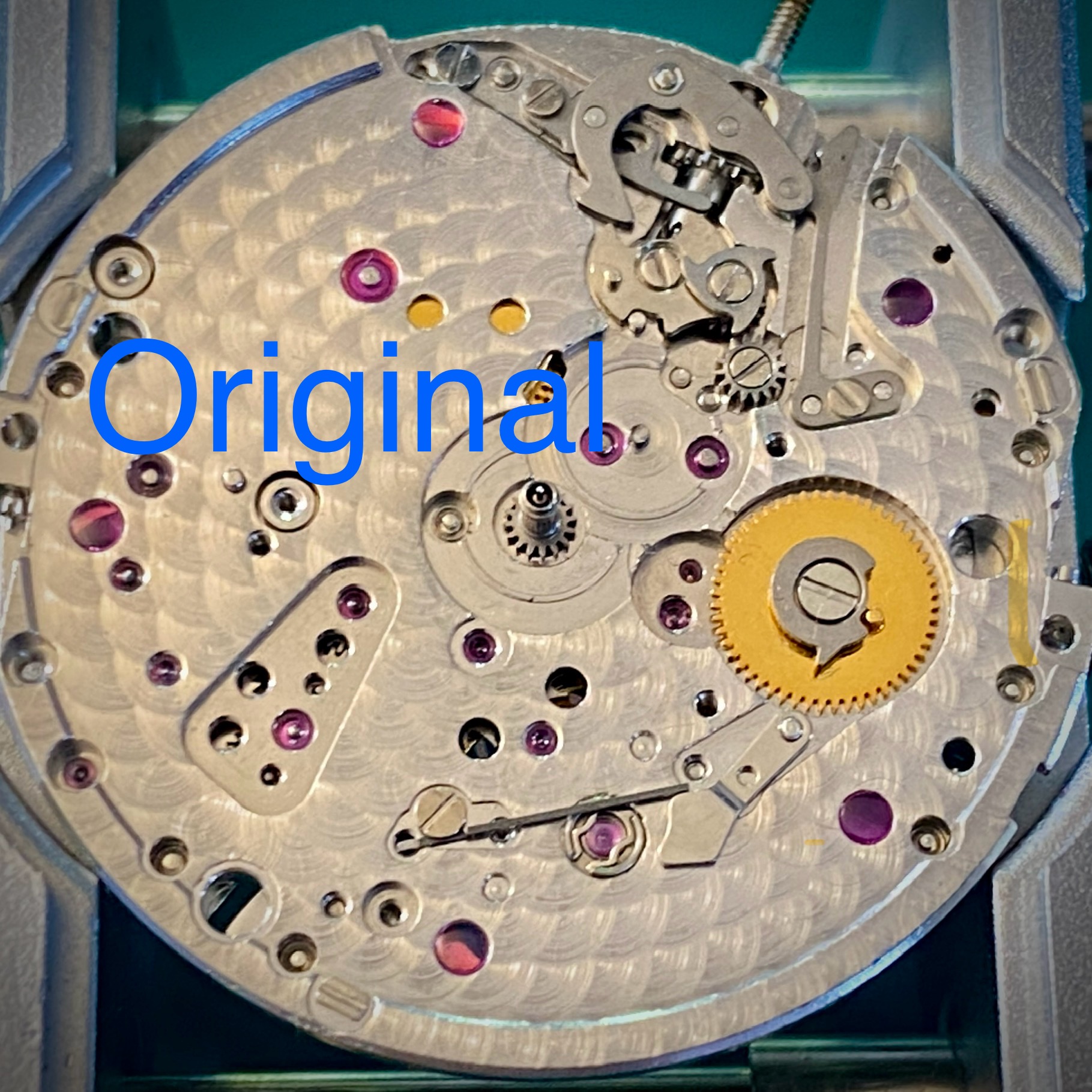

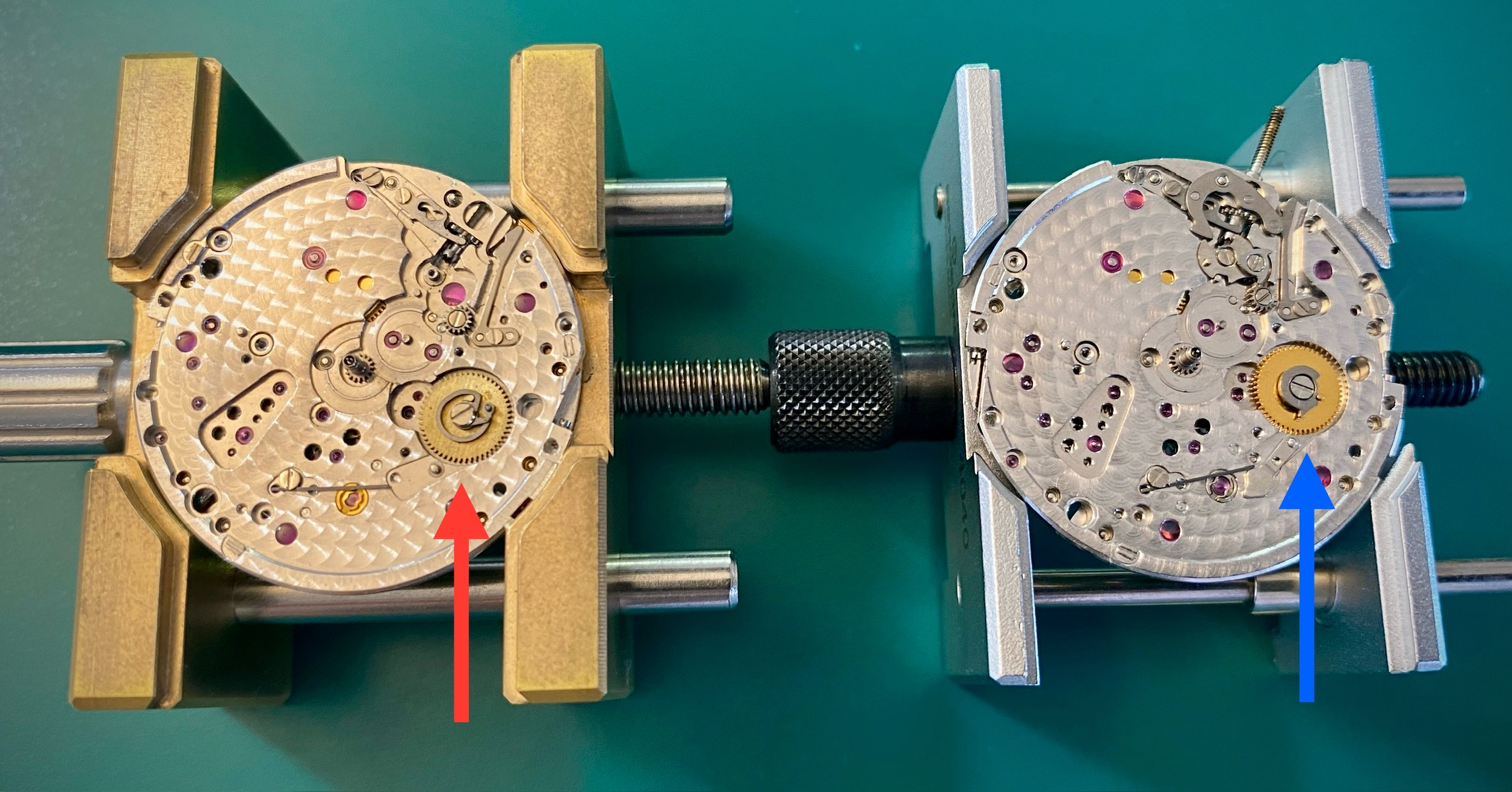

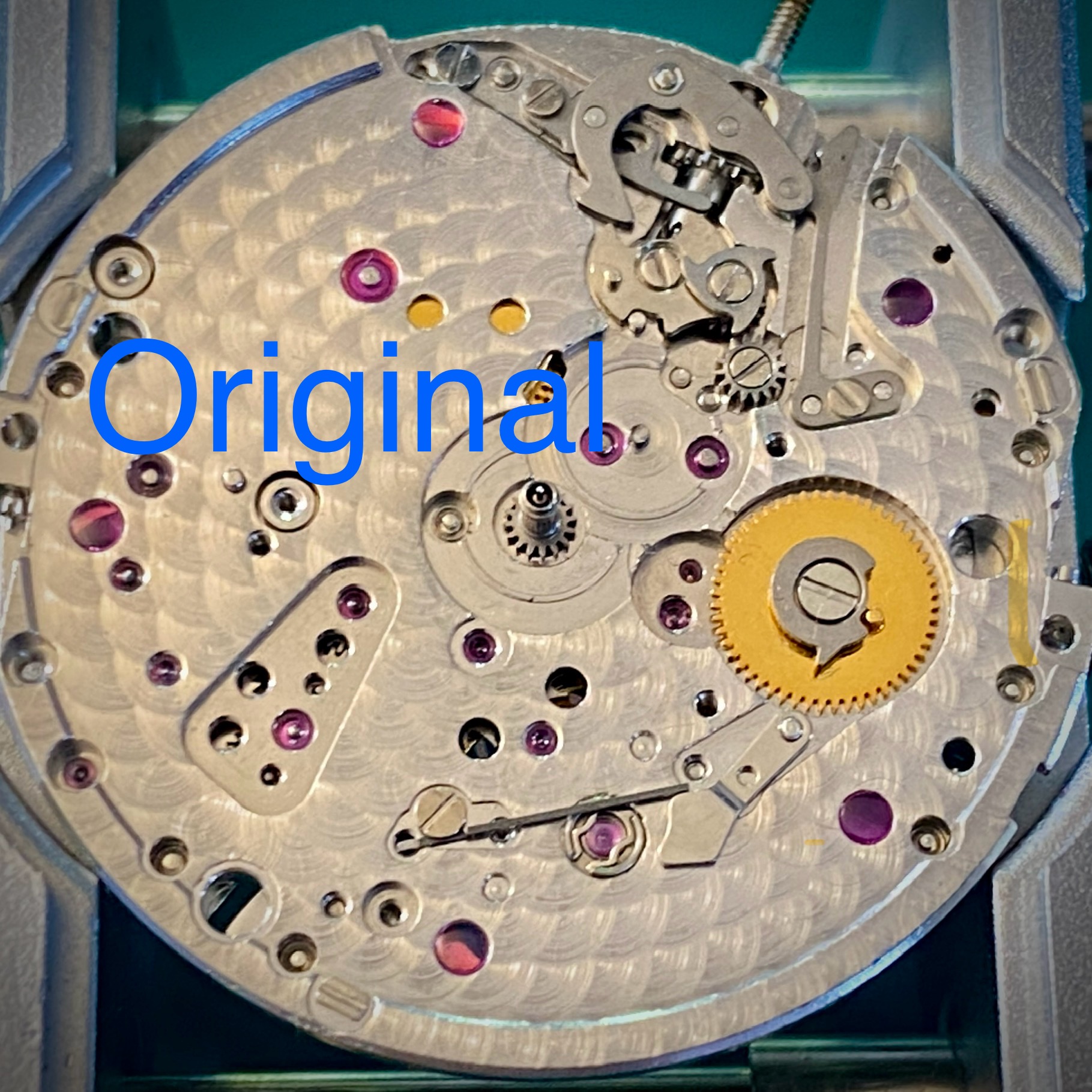

I had a really interesting project on my bench this week: an AP rep with a clone 3120 movement that had an instant date change mod. I haven't seen this mod before and I don't know if it's been documented here (I didn't look to hard, so maybe I'm wrong). Regardless, the mechanism for the instant date change is quite clever. Here's a pic showing the two date change mechanisms the instant date change is on the left (red arrow), and the standard clone movement mechanism is on the right (blue arrow).

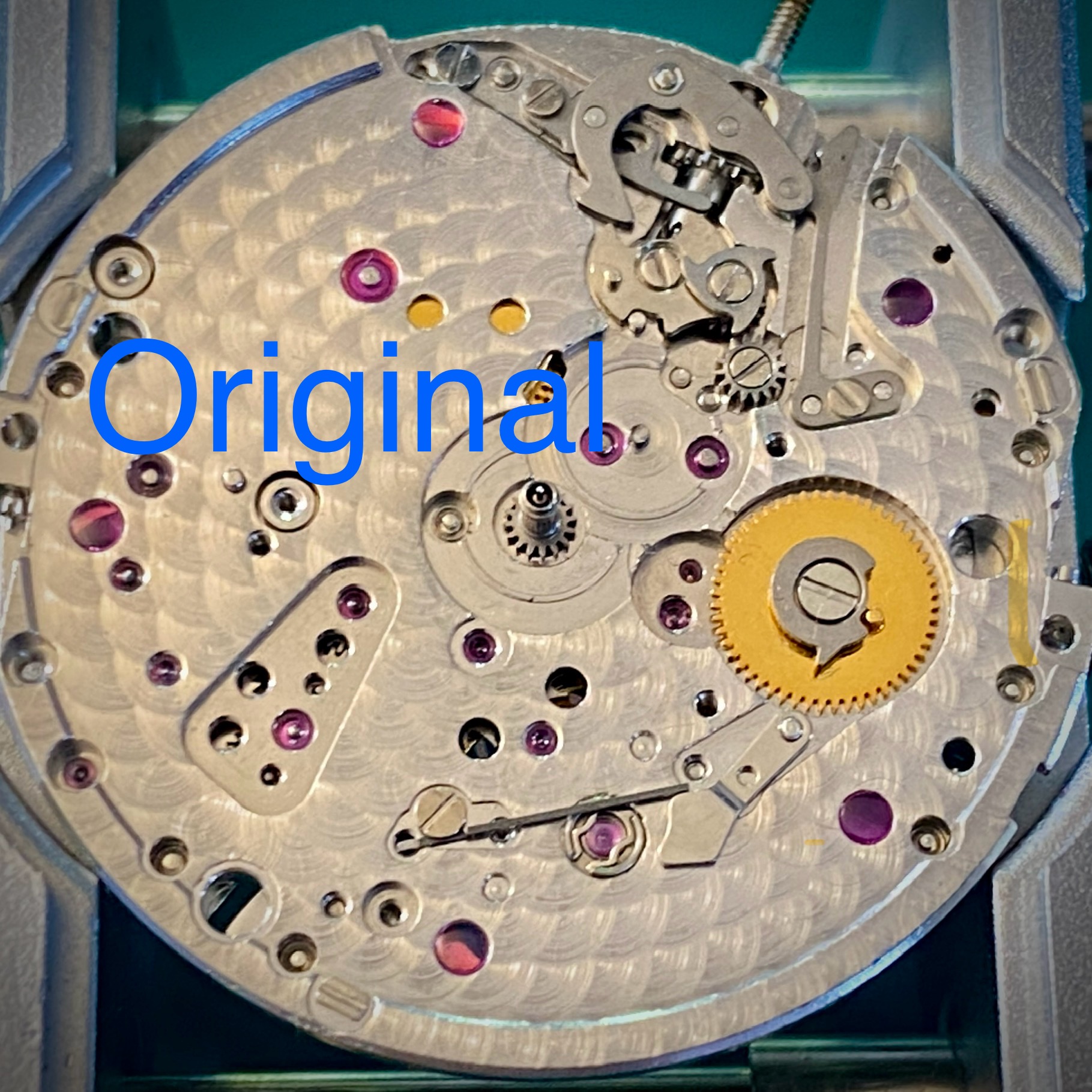

And here are a couple of close up pics of both mechanisms:

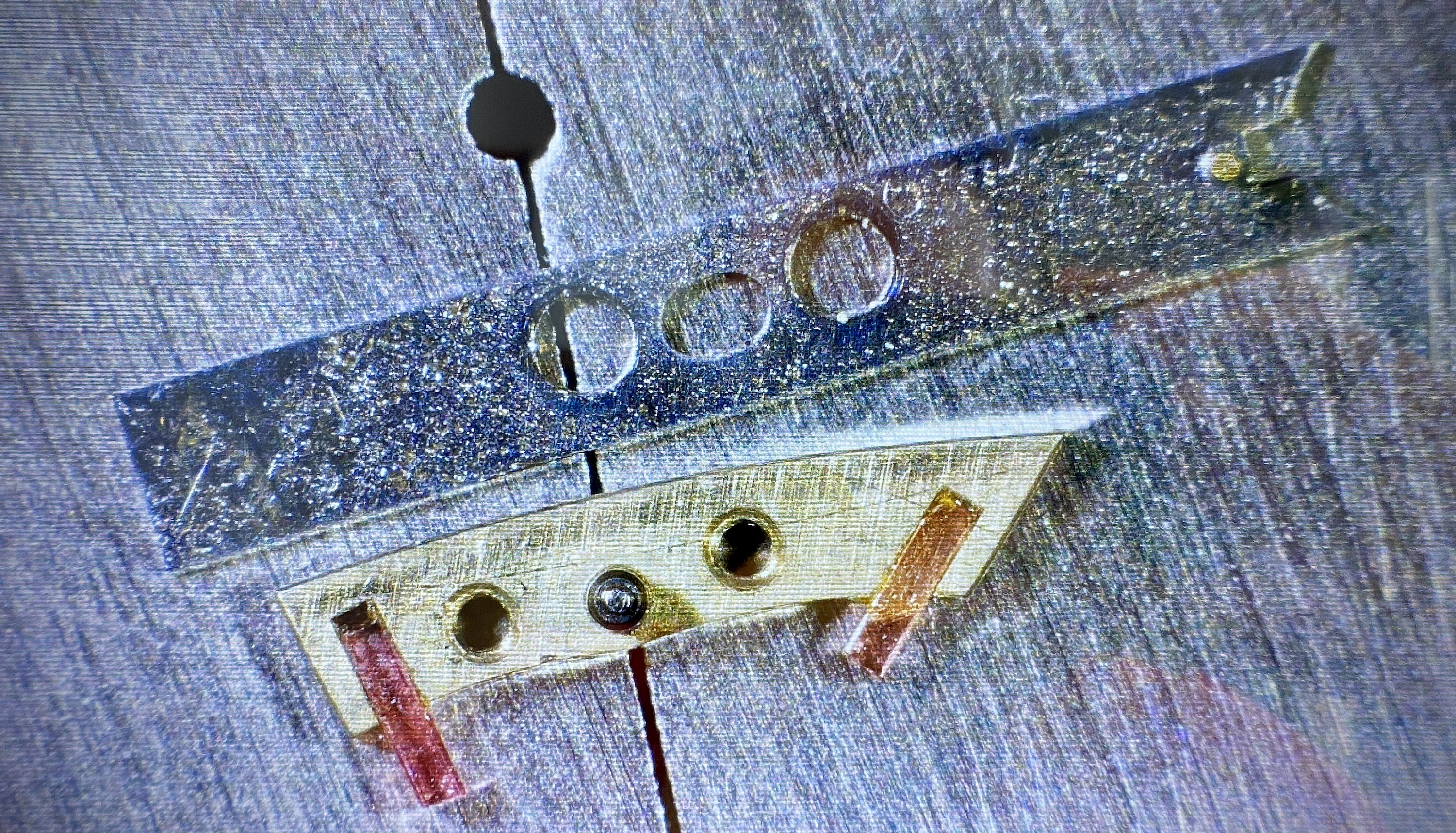

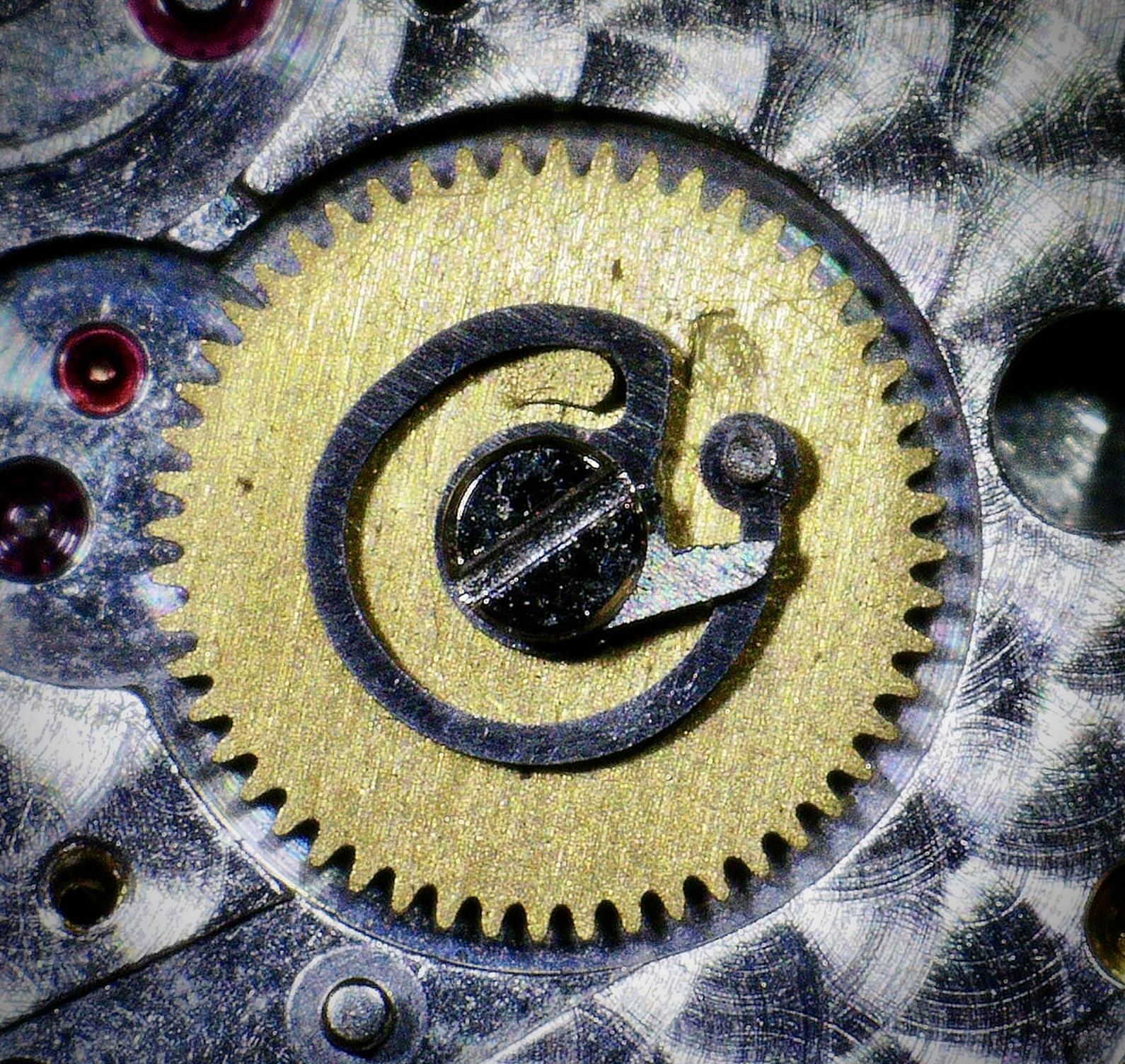

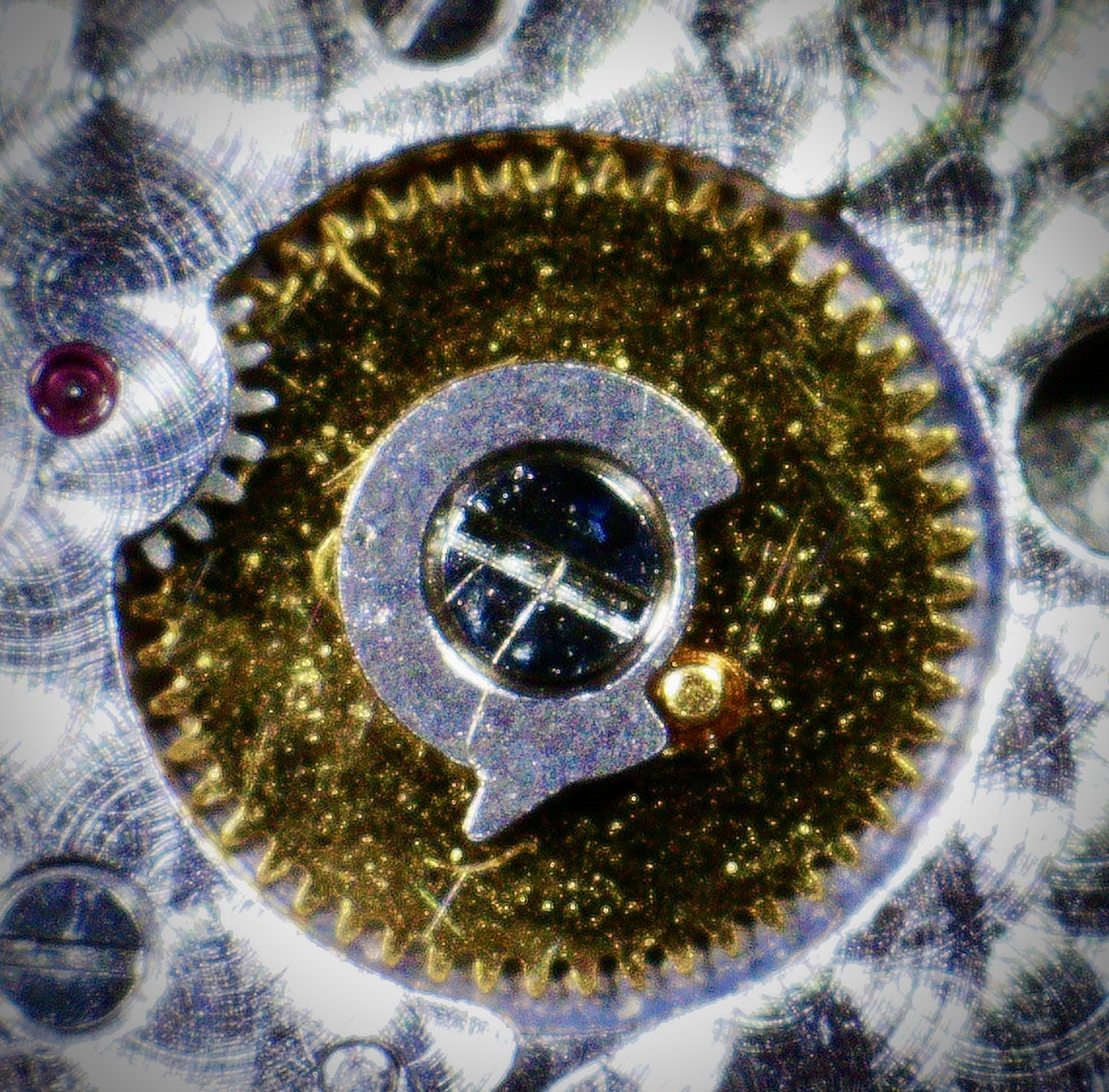

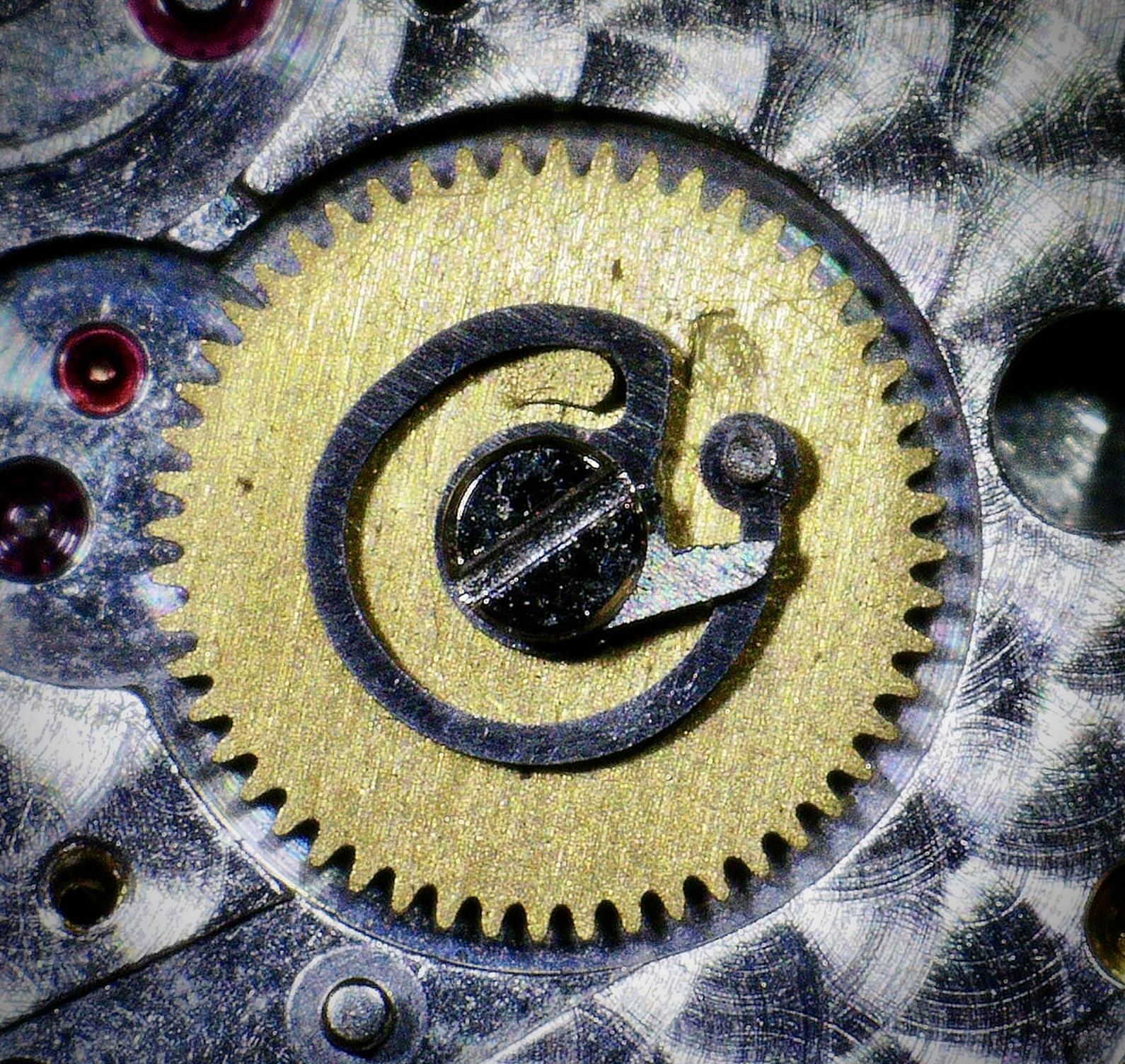

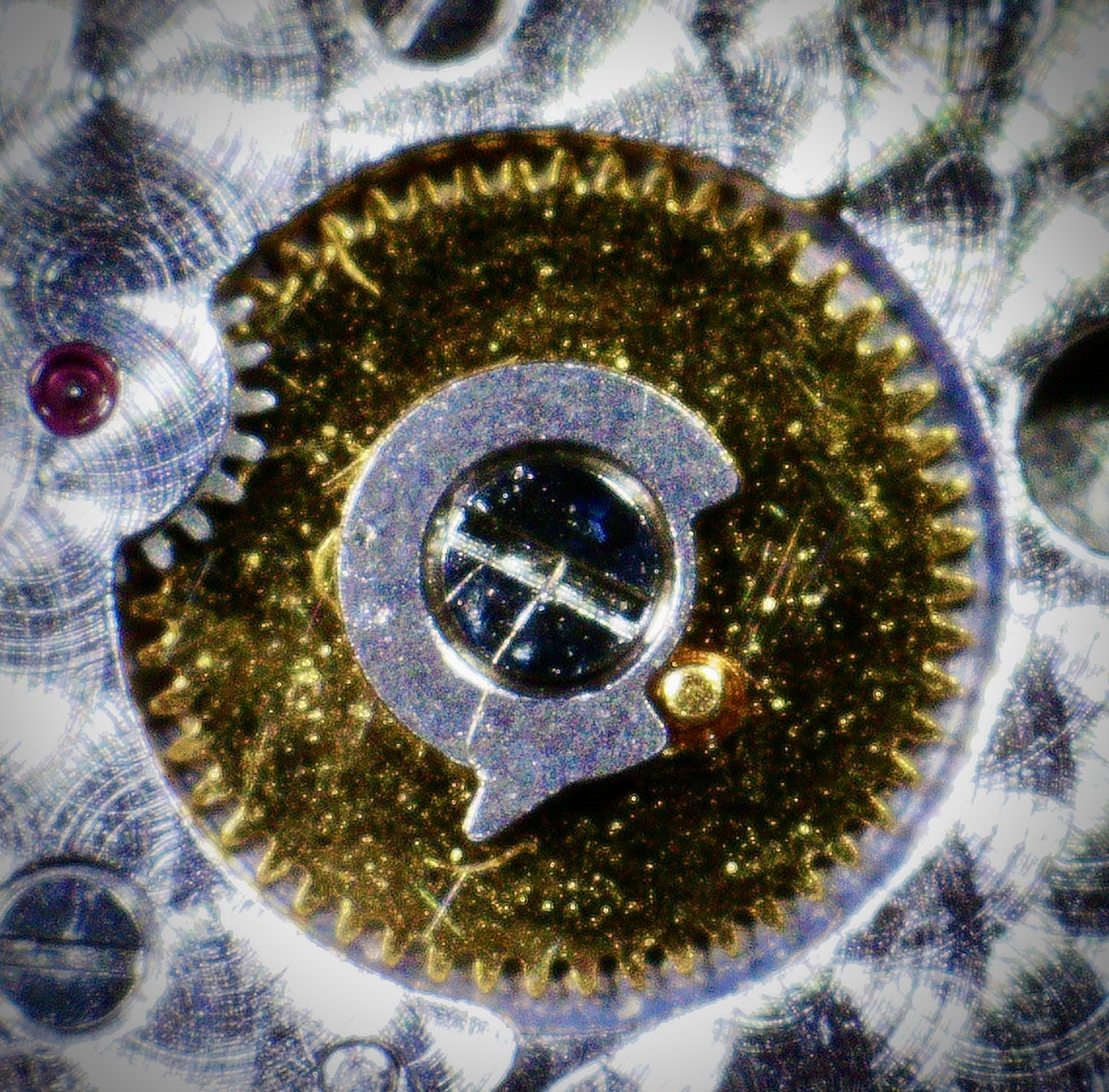

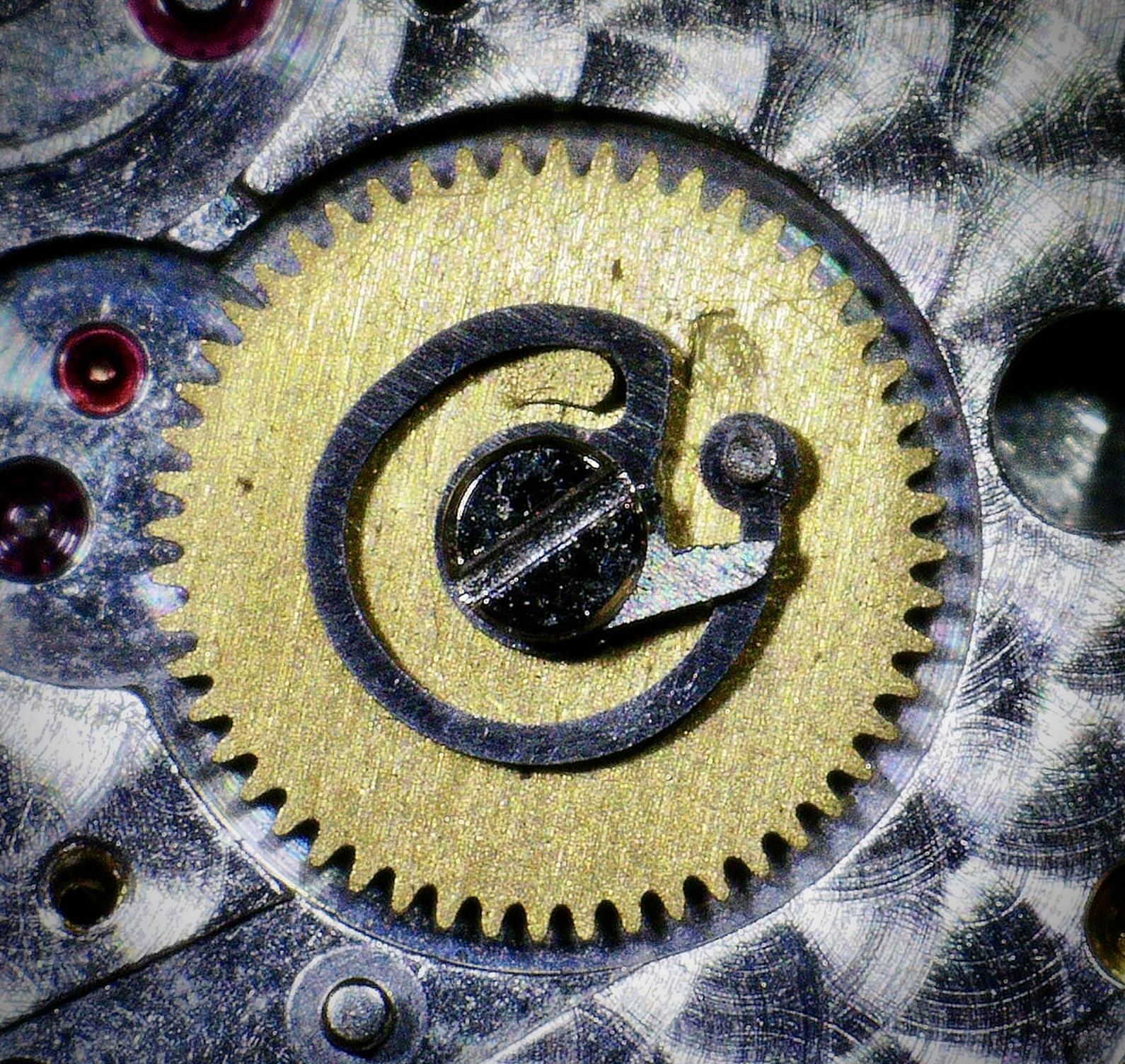

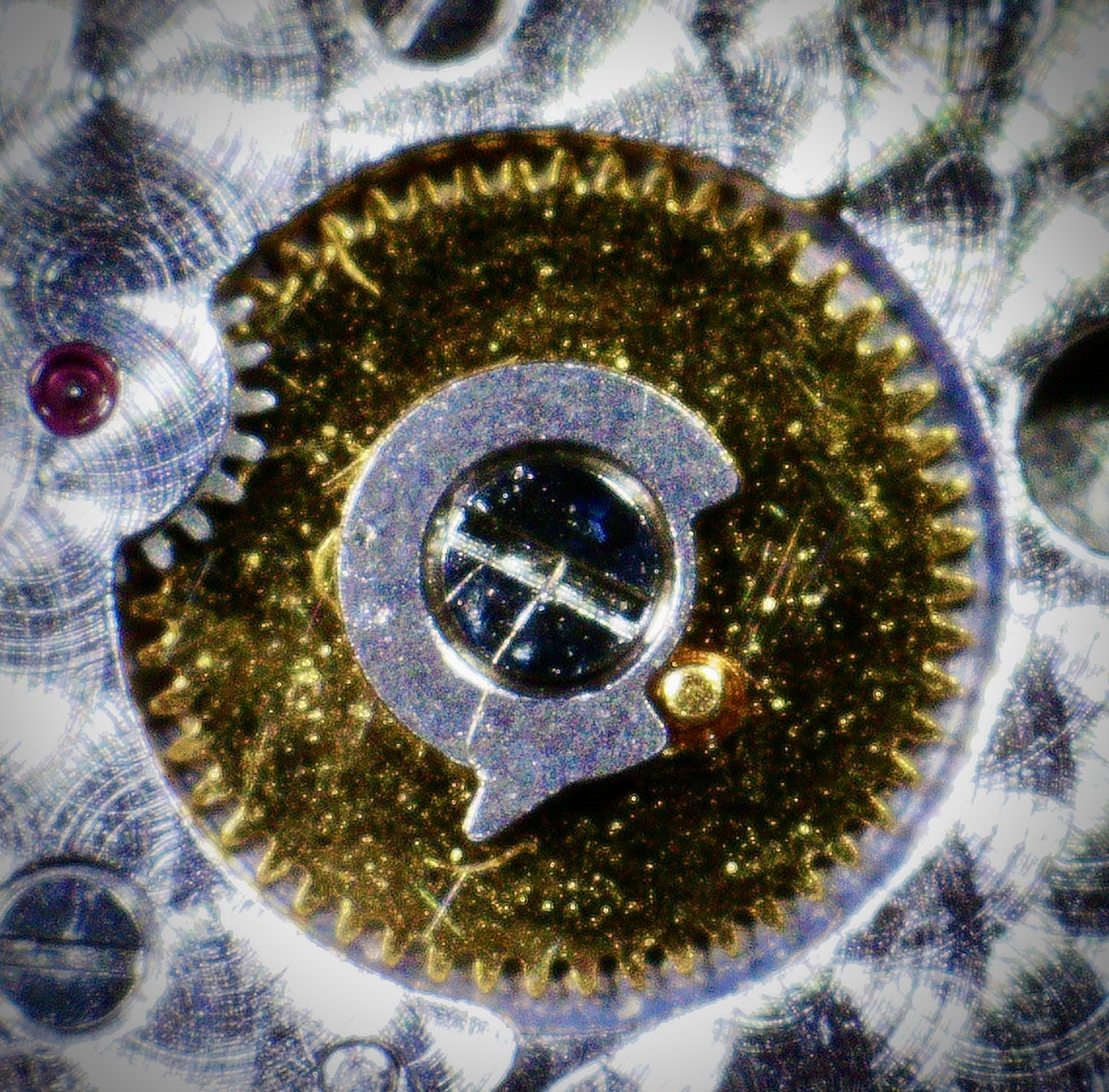

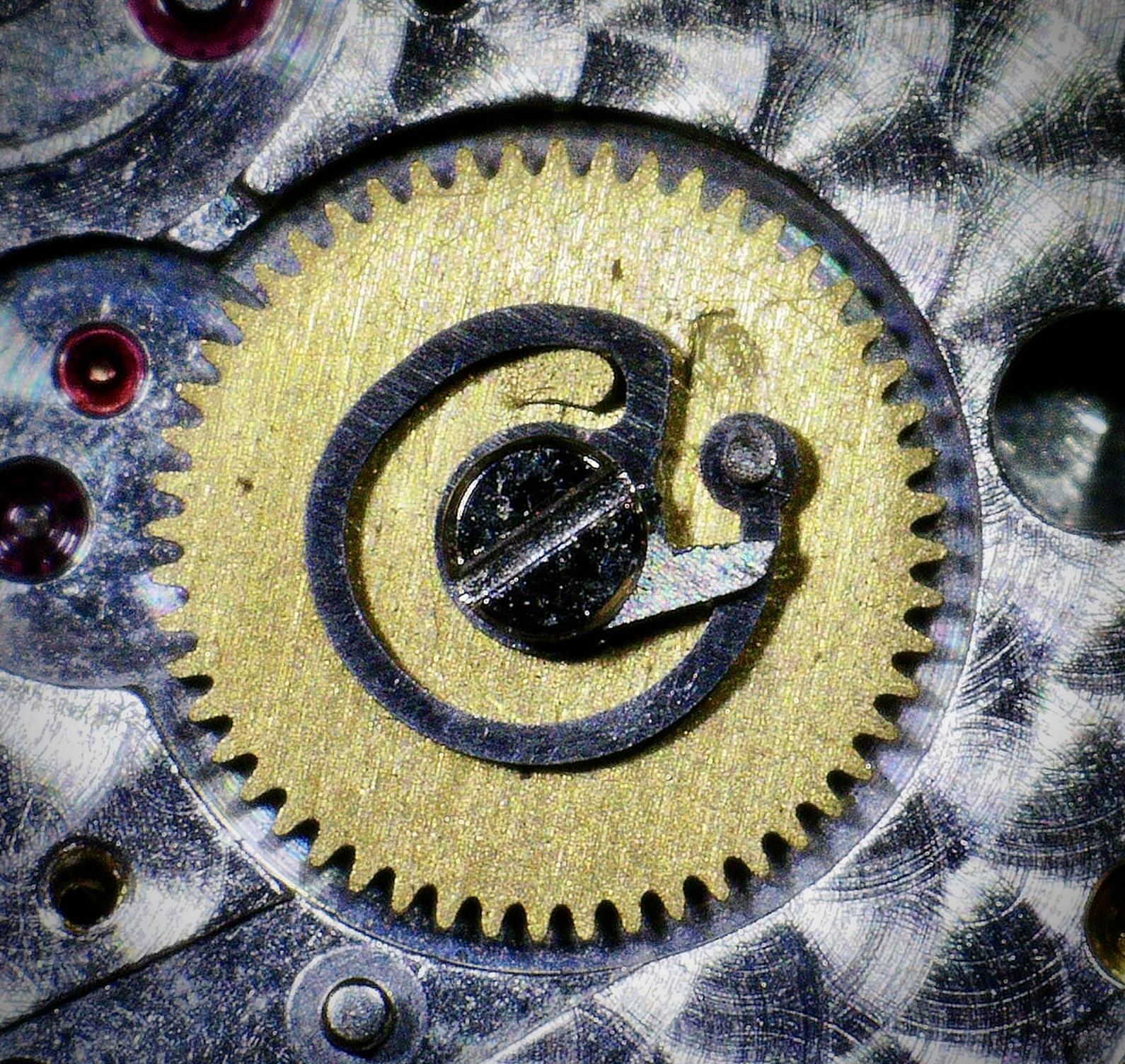

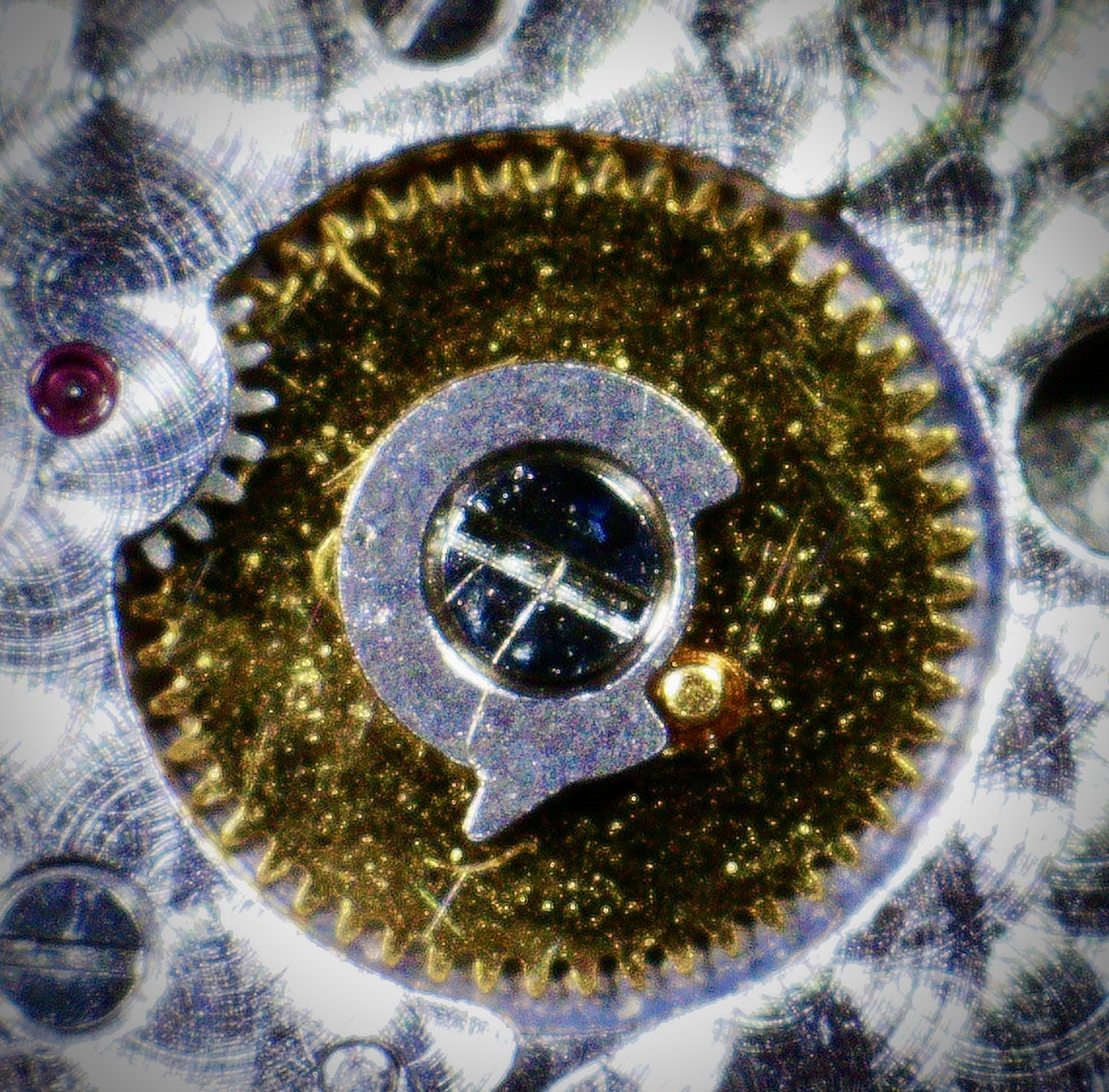

And because I know somebody will want a macro view, here's what they look like under the microscope:

The mod consists of three parts (four if you count the screw, which is the same as the stock screw). There's the date gear which has a punched ramp pusher rather than a pin like the stock part, the spring, and the part that looks like the number 6.

The mechanical linkage of how this mod works is ingenious. The 6 part blocks the pin on the spring to build up energy for the jump, and the base of the spring then pushes the end of the spring with the pin on it around the 6 part. To get the date to flip at midnight you need to align the 6 part so that it's slightly "ahead" of the tooth on the date wheel. Here's a video of how it all works.

And here's a video of what it all looks like when the dial and hands are back on:

This is a very cool little mod which I've never seen on an clone AP 3120 before. I think this mod is available from some of the well known modding workshops in China, but I'm not sure if TDs can source it.

I don't know what the gen mechanism looks like. Perhaps @legend can comment.

And here are a couple of close up pics of both mechanisms:

And because I know somebody will want a macro view, here's what they look like under the microscope:

The mod consists of three parts (four if you count the screw, which is the same as the stock screw). There's the date gear which has a punched ramp pusher rather than a pin like the stock part, the spring, and the part that looks like the number 6.

The mechanical linkage of how this mod works is ingenious. The 6 part blocks the pin on the spring to build up energy for the jump, and the base of the spring then pushes the end of the spring with the pin on it around the 6 part. To get the date to flip at midnight you need to align the 6 part so that it's slightly "ahead" of the tooth on the date wheel. Here's a video of how it all works.

And here's a video of what it all looks like when the dial and hands are back on:

This is a very cool little mod which I've never seen on an clone AP 3120 before. I think this mod is available from some of the well known modding workshops in China, but I'm not sure if TDs can source it.

I don't know what the gen mechanism looks like. Perhaps @legend can comment.

- 28/5/19

- 4,901

- 7,851

- 113

I am absolutely stunned with how simple that mod is. You said it best, "ingenious". Too bad if it ever broke it would be hard to find the part I'm sure. But it looks very sturdy honestly and not likely to break easily since it's so simple.I had a really interesting project on my bench this week: an AP rep with a clone 3120 movement that had an instant date change mod. I haven't seen this mod before and I don't know if it's been documented here (I didn't look to hard, so maybe I'm wrong). Regardless, the mechanism for the instant date change is quite clever. Here's a pic showing the two date change mechanisms the instant date change is on the left (red arrow), and the standard clone movement mechanism is on the right (blue arrow).

And here are a couple of close up pics of both mechanisms:

And because I know somebody will want a macro view, here's what they look like under the microscope:

The mod consists of three parts (four if you count the screw, which is the same as the stock screw). There's the date gear which has a punched ramp pusher rather than a pin like the stock part, the spring, and the part that looks like the number 6.

The mechanical linkage of how this mod works is ingenious. The 6 part blocks the pin on the spring to build up energy for the jump, and the base of the spring then pushes the end of the spring with the pin on it around the 6 part. To get the date to flip at midnight you need to align the 6 part so that it's slightly "ahead" of the tooth on the date wheel. Here's a video of how it all works.

And here's a video of what it all looks like when the dial and hands are back on:

This is a very cool little mod which I've never seen on an clone AP 3120 before. I think this mod is available from some of the well known modding workshops in China, but I'm not sure if TDs can source it.

I don't know what the gen mechanism looks like. Perhaps @legend can comment.

this on a 15400 would beI had a really interesting project on my bench this week: an AP rep with a clone 3120 movement that had an instant date change mod. I haven't seen this mod before and I don't know if it's been documented here (I didn't look to hard, so maybe I'm wrong). Regardless, the mechanism for the instant date change is quite clever. Here's a pic showing the two date change mechanisms the instant date change is on the left (red arrow), and the standard clone movement mechanism is on the right (blue arrow).

And here are a couple of close up pics of both mechanisms:

And because I know somebody will want a macro view, here's what they look like under the microscope:

The mod consists of three parts (four if you count the screw, which is the same as the stock screw). There's the date gear which has a punched ramp pusher rather than a pin like the stock part, the spring, and the part that looks like the number 6.

The mechanical linkage of how this mod works is ingenious. The 6 part blocks the pin on the spring to build up energy for the jump, and the base of the spring then pushes the end of the spring with the pin on it around the 6 part. To get the date to flip at midnight you need to align the 6 part so that it's slightly "ahead" of the tooth on the date wheel. Here's a video of how it all works.

And here's a video of what it all looks like when the dial and hands are back on:

This is a very cool little mod which I've never seen on an clone AP 3120 before. I think this mod is available from some of the well known modding workshops in China, but I'm not sure if TDs can source it.

I don't know what the gen mechanism looks like. Perhaps @legend can comment.

GeneralRep

Getting To Know The Place

It works on my (18cm) wrist. It’s probably a little thicker than the gen, but not overly so.How do you like the reverso thus far? How about hte proportions?