I had an interesting 16650 build on my bench this week from

@GregB. Greg purchased the watch

here on RWI, but wanted me to swap in a VS3135 movement. One of the issues certain versions of the VS3135 is that (as

@KJ2020 has

discovered) the date can end up not being perfectly centred in the dial's date window.

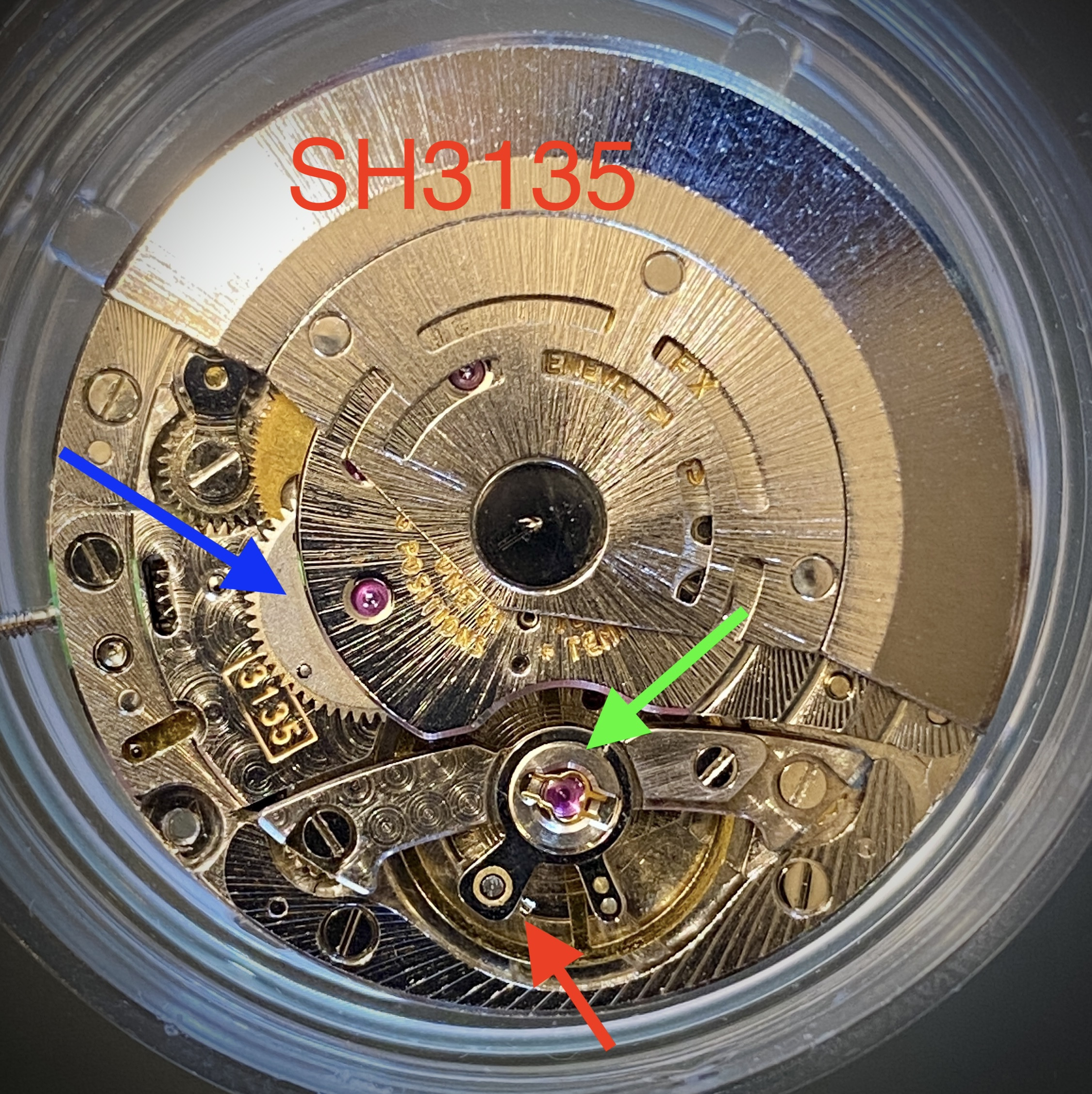

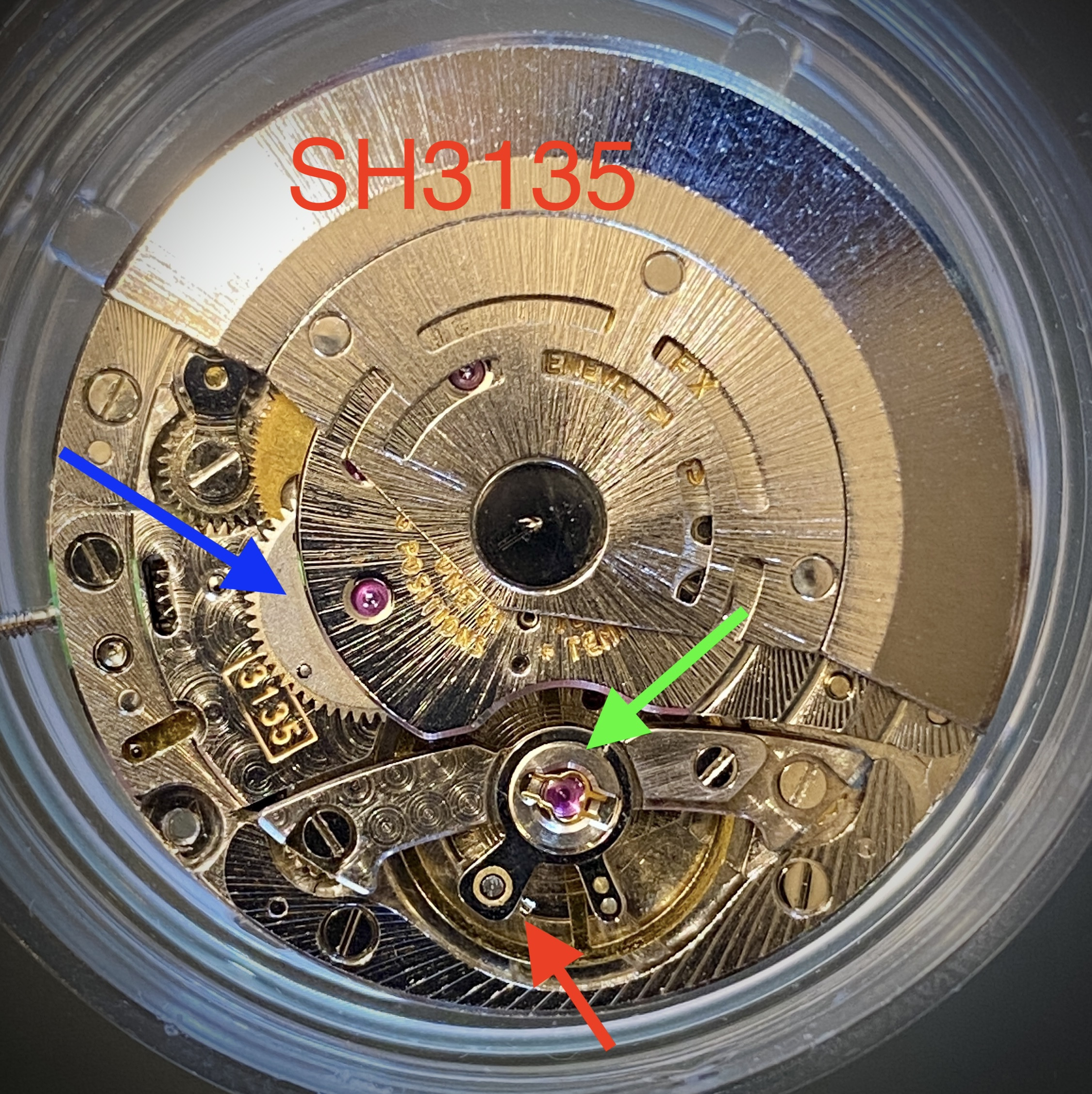

The proposed solution for this problem is to use the date plate from the VR3135 movement to build a hybrid movement with a VS3135 mainplate and a VR3135 dateplate. I tried this, but unlike when KJ2020 did it, the movement I was starting from was an SH3135. Note that the SH3135 has a steel shock setting cup (green arrow), a side mounted screw on the beat adjustor (red arrow), and something that I haven't seen before, a silver coloured reversing wheel (blue arrow).

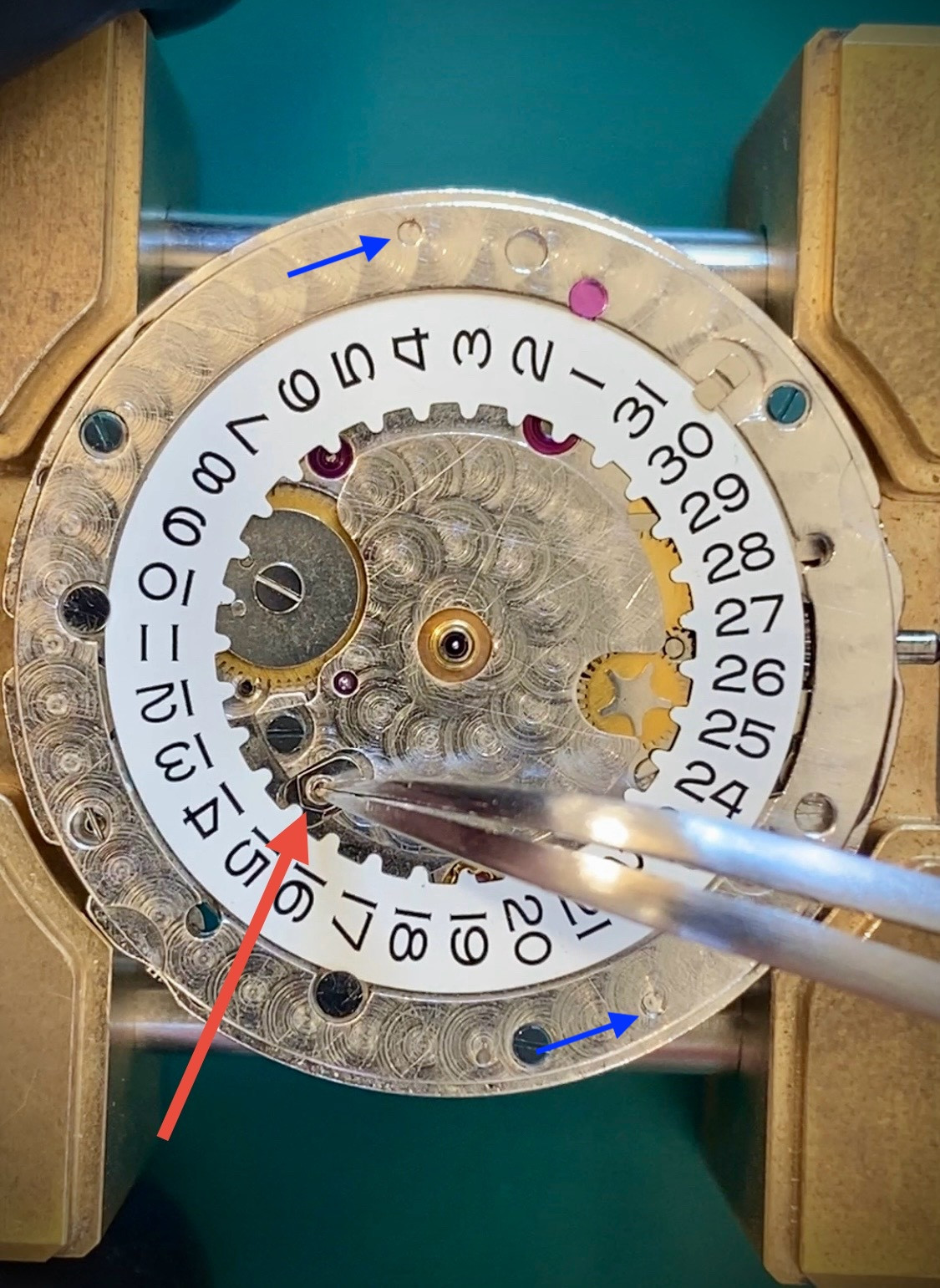

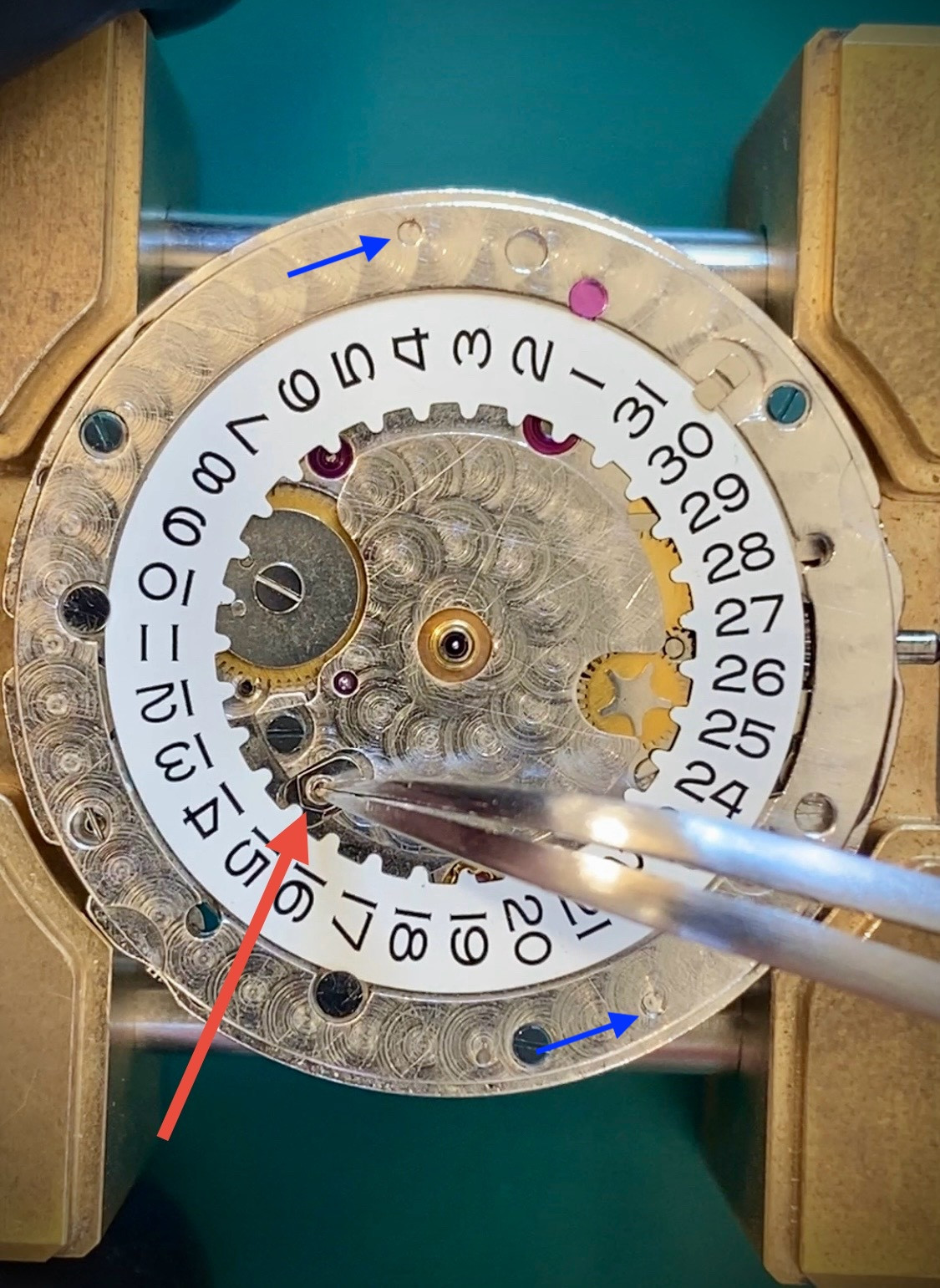

I ran into two issues trying to build a hybrid using the SH3135's date plate. The first issues was that there are two locator pin holes (blue arrows) on the SH3135 date plate which are ever so slightly smaller than the locator pins on the VS3135 mainplate (hurrah for rep movement manufacturing tolerances!!!). The second issue was that the date finger from the SH3135 seemed to be rubbing against something on the VS3135 mainplate. There was quite a bit of friction and the date finger didn't spring back and forth freely. As a result of the friction / binding of the SH3135 date finger, the date wouldn't fully jump forward, nor would the date finger have enough force to centre the date disc by pushing fully into the date disc's teeth.

In the end, my solution was to revert back to a fully VS3135 movement, and to ever so slightly bend the dial feet to introduce a dial rotation so that the date was correctly centred in the dial's date window.

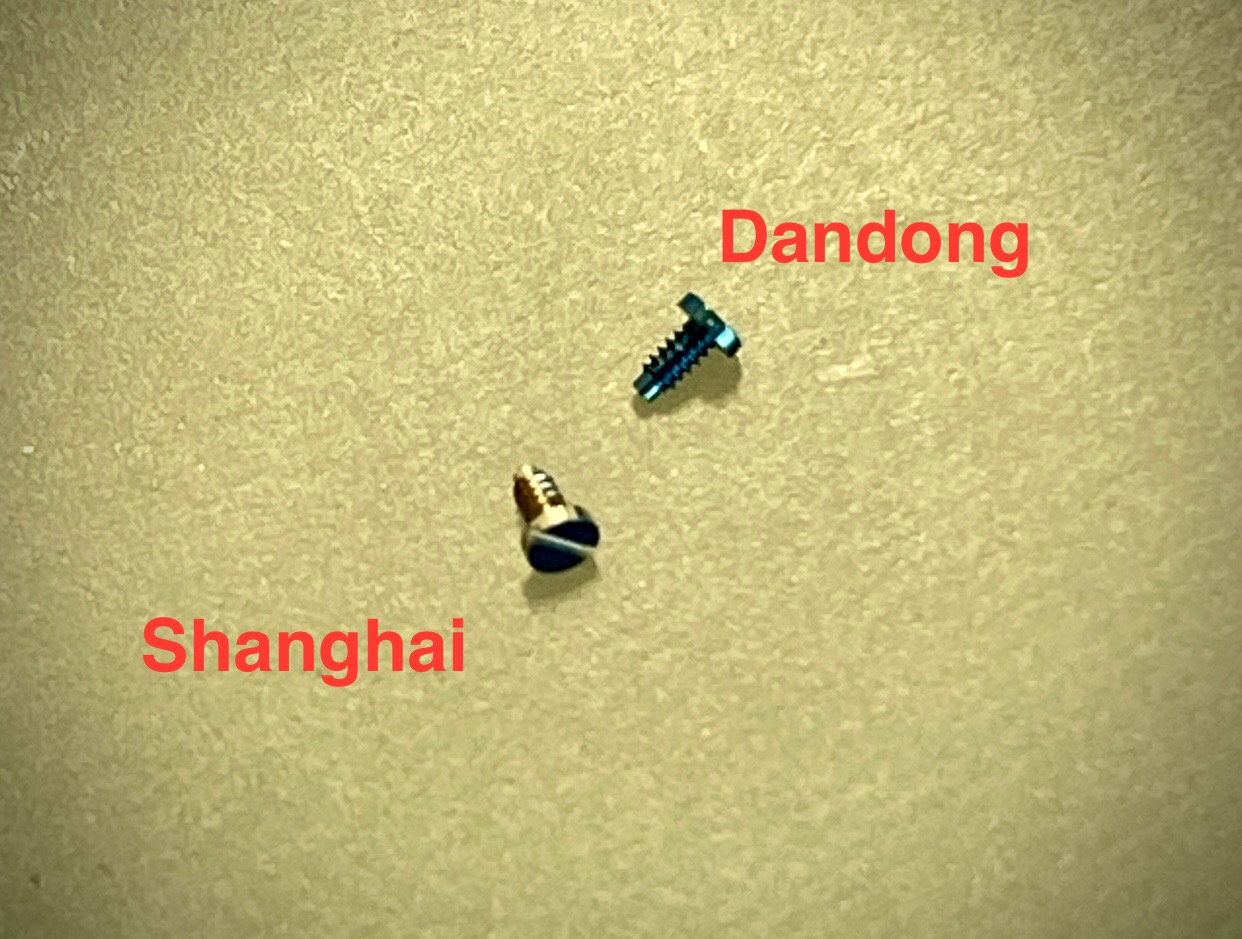

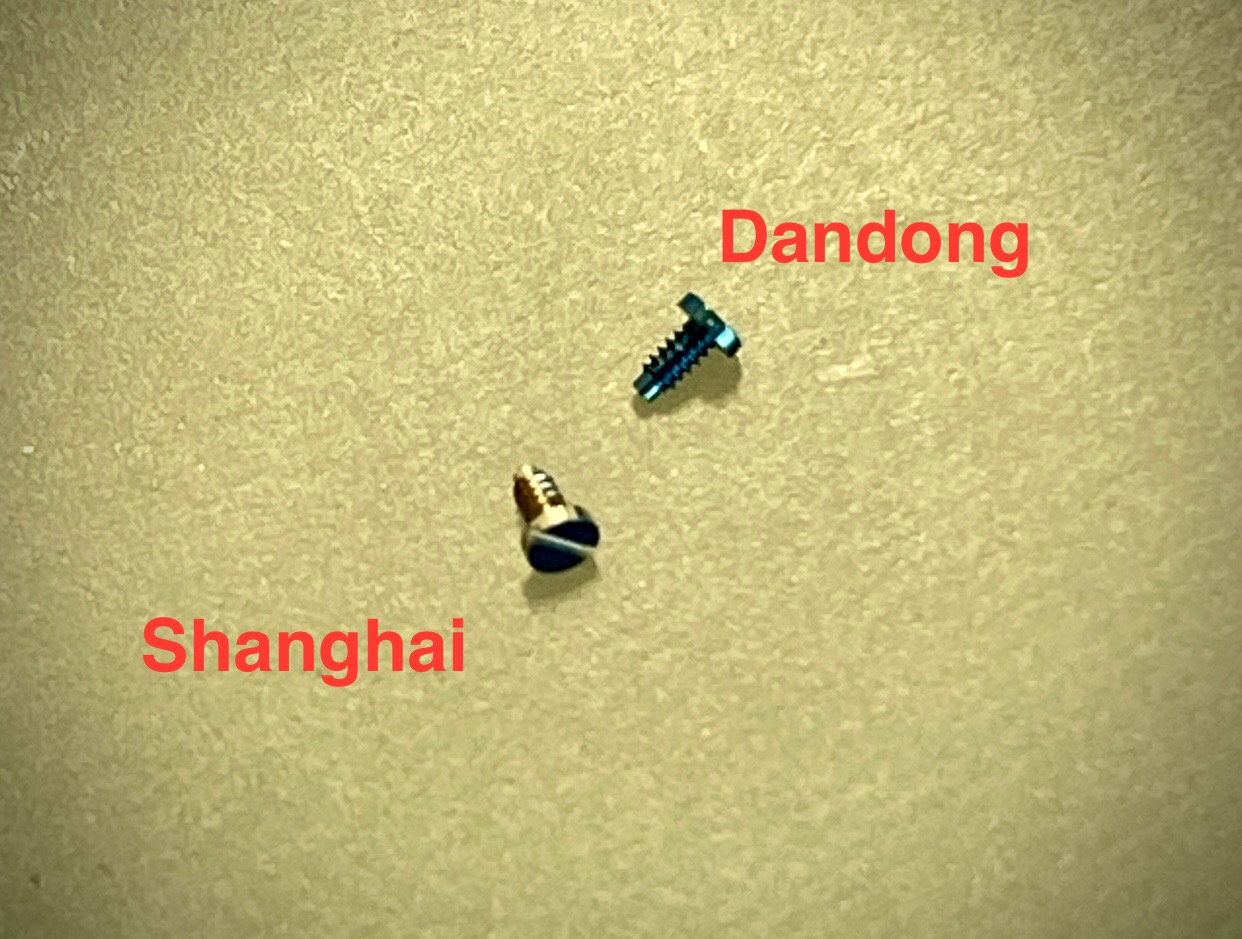

One other thing that I noticed which I don't remember seeing before is that the SH3135 date plate screws aren't fully blued. The VS3135 date plate screws are fully blued. I guess this is just another way that the manufacturer of the SH3135 cut corners.