Speaking of crowns, anyone have a link to a good AliExpress replacement for the VSF Daytona crown? Something as good as Clean. Looked but couldn’t find.

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dogwood's Watchmaking Journey

- Thread starter dogwood

- Start date

YesIs that true with genuine crowns as well?

Both models use a 704 crown. But the interface of Gen crown to rep tube can be a bit funky.

Best to replace the tube with a Gen 7030 as well.

Best to replace the tube with a Gen 7030 as well.

Blazinhassan

Do not accept unsolicited offers

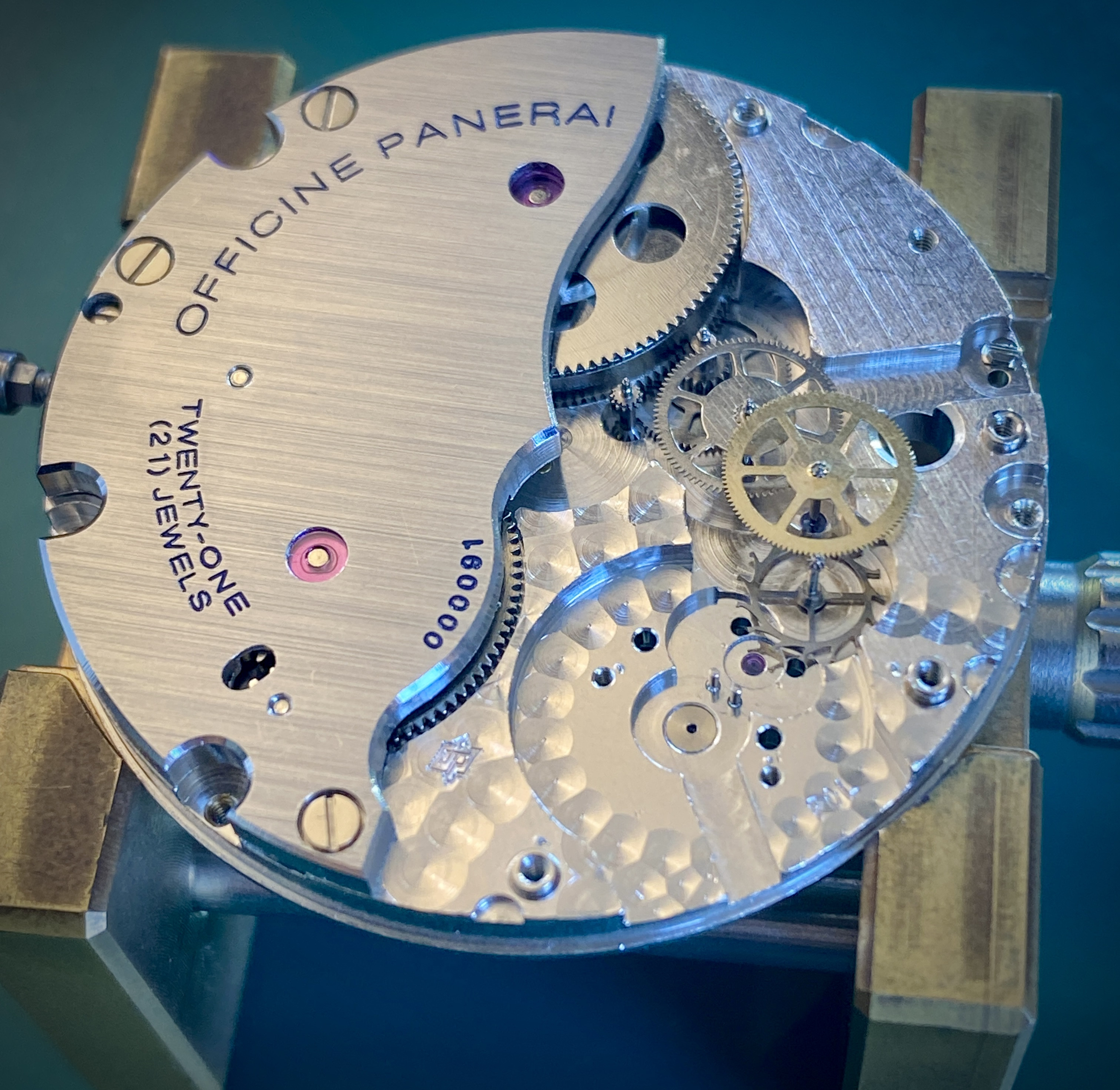

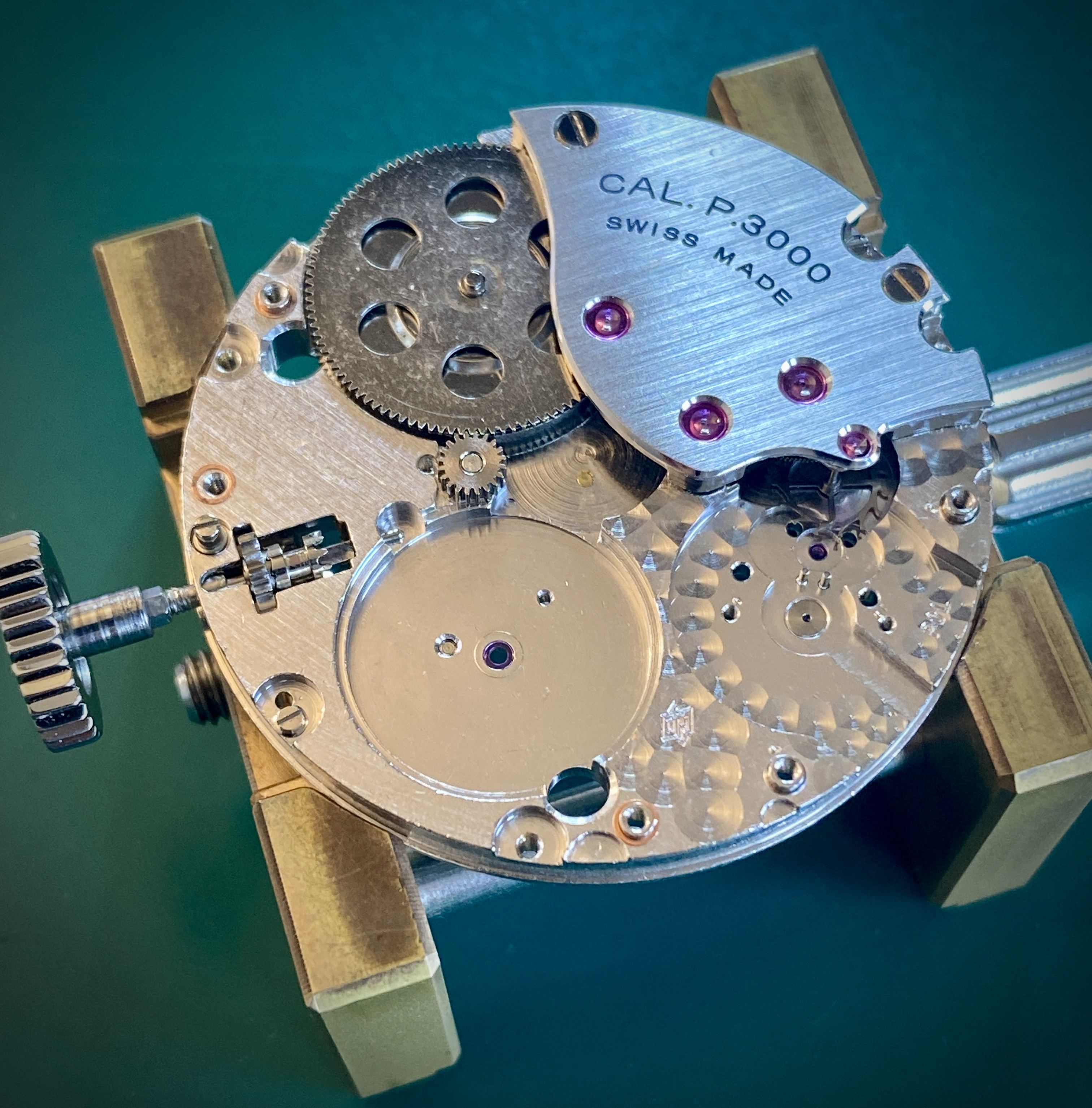

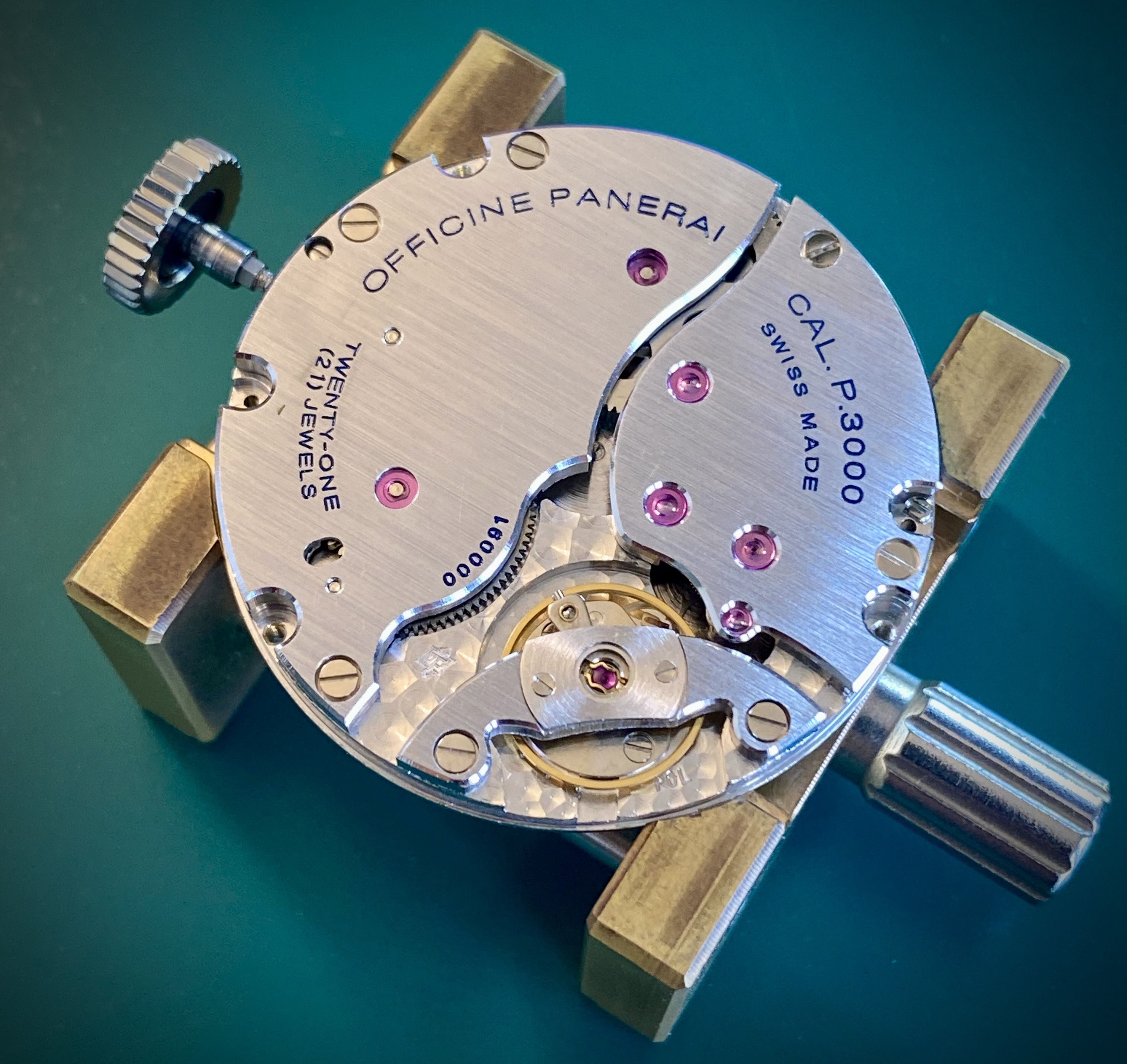

@dogwood good day! I have the same movement on one of my old VSF Pam605 super clone. Something happened and it does not work anymore. I do see some parts lose in the movement.I’ve been working on a clone Panerai P.3000 movement recently. This is a movement that is kinda like the friendly Unitas 6497-2 but is actually quite a different beast. For starters it has two mainspring barrels:

But other than a double mainspring there are no complications at all.

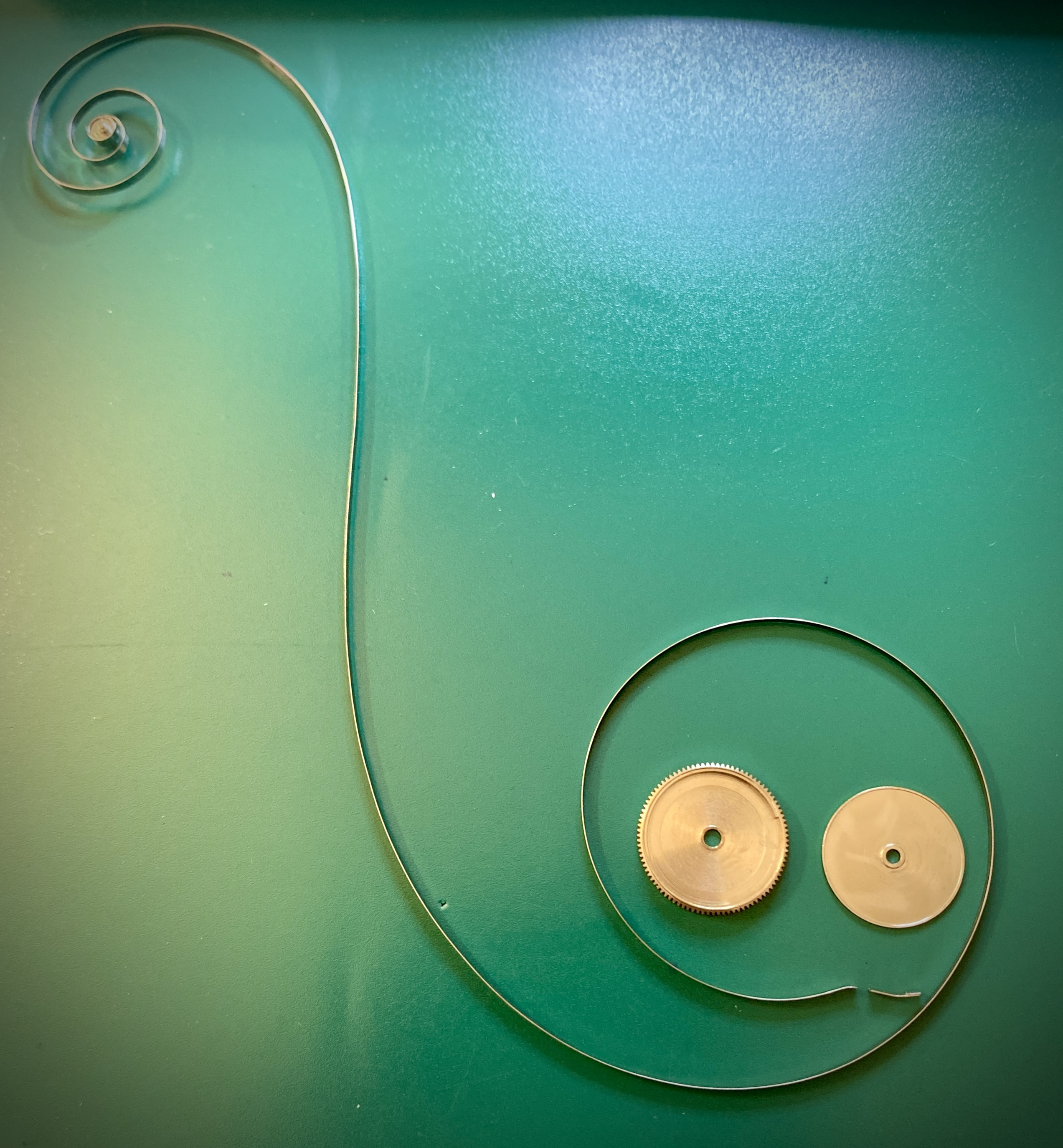

Unfortunately on this movement one of the mainsprings had broken.

I took some measurements of the thickness, height, and length and ordered what I hoped would be a suitable replacement from

OFrei.

In the mean time I took everything else apart and cleaned all the parts first by hand and then in my machine.

When the new mainspring arrived it seemed to fit in the barrel and on the arbor so I’d call that a win.

The only other tricky part of servicing this movement is getting the train bridge back on. Most of the train wheels have very long arbors and stand on tiny pivots.

Initially I’d reassembled the dial side and the double mainsprings with their bridge on the balance side, but I found that with the mainspring bridge in place it was incredibly hard to access the underside of the train bridge with tweezers to align the train wheels when I was trying to get the train bridge on. Similarly, having the dial side assembled meant that there was an extra set of teeth for the long tall motion transfer pinion to mesh with. (I’m not sure if “motion transfer pinion” is the right name but on this movement there an intermediate wheel between the second wheel and the minute pinion on the dial side — this intermediate wheel is a tall arbor with a pinion on it that constantly wants to fall over).

I was eventually able to make everything line up, then got the barrel bridge back on and installed the pallet fork and balance. The movement is ticking nicely now.

This was a fun movement but I have a new appreciation for the ease of installing 2824, 3135, and 3235 train bridges now.

I am in Calgary, may I contact you for a repair?

Sorry if this isn’t allowed, but I just wanted to check. I have been trying to find someone that can repair, and finally I was able to

Thank you in advance!

DM me. I’m not an official trusted vendor here on RWI, but I have taken on the occasional project from fellow rep loving Canadians if it’s something that’s interesting / in my wheelhouse.@dogwood good day! I have the same movement on one of my old VSF Pam605 super clone. Something happened and it does not work anymore. I do see some parts lose in the movement.

I am in Calgary, may I contact you for a repair?

Sorry if this isn’t allowed, but I just wanted to check. I have been trying to find someone that can repair, and finally I was able to

Thank you in advance!

I had a Dandong 3285 from a Clean Factory GMT across my bench today that was running with somewhat low amplitude. Under the microscope the movement looked about "average" in terms of debris that was visible just with the caseback off -- a bit of lint here and there, but nothing obviously filthy. Some movements look filthy when you open the caseback, but this one wasn't one of those. Anyway, before I serviced the movement, swapped out the fluids in both my cleaning machine and also my pre-cleaning watch glass. I've started pre-cleaning watch parts with a paintbrush in 99.9% IPA in a watch glass before I run the parts through the cleaning machine since I find that the artist's paintbrush does a good job of lifting off grease which I've found can really cling to certain parts on reps (e.g. many of the components in the keyless works).

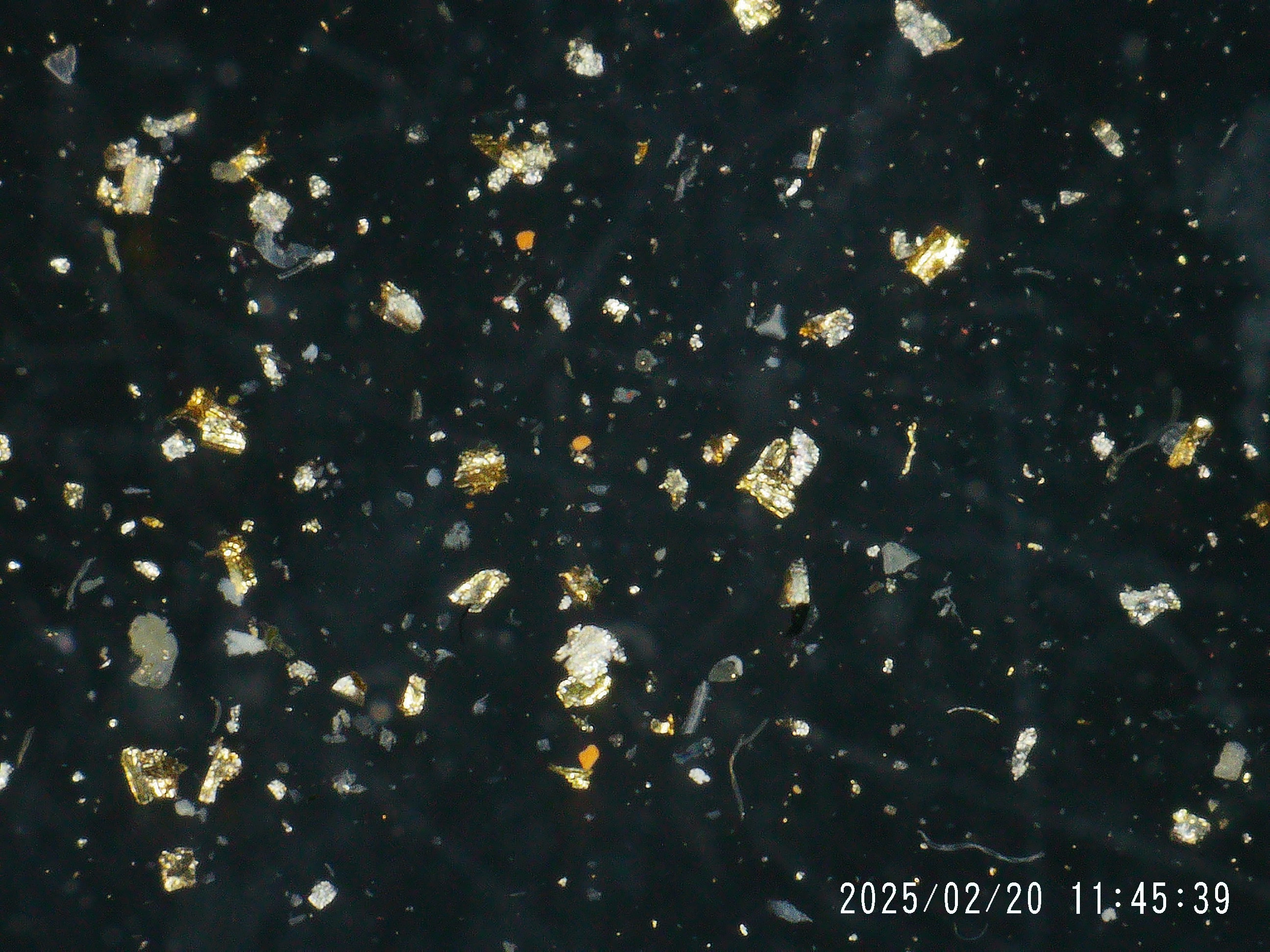

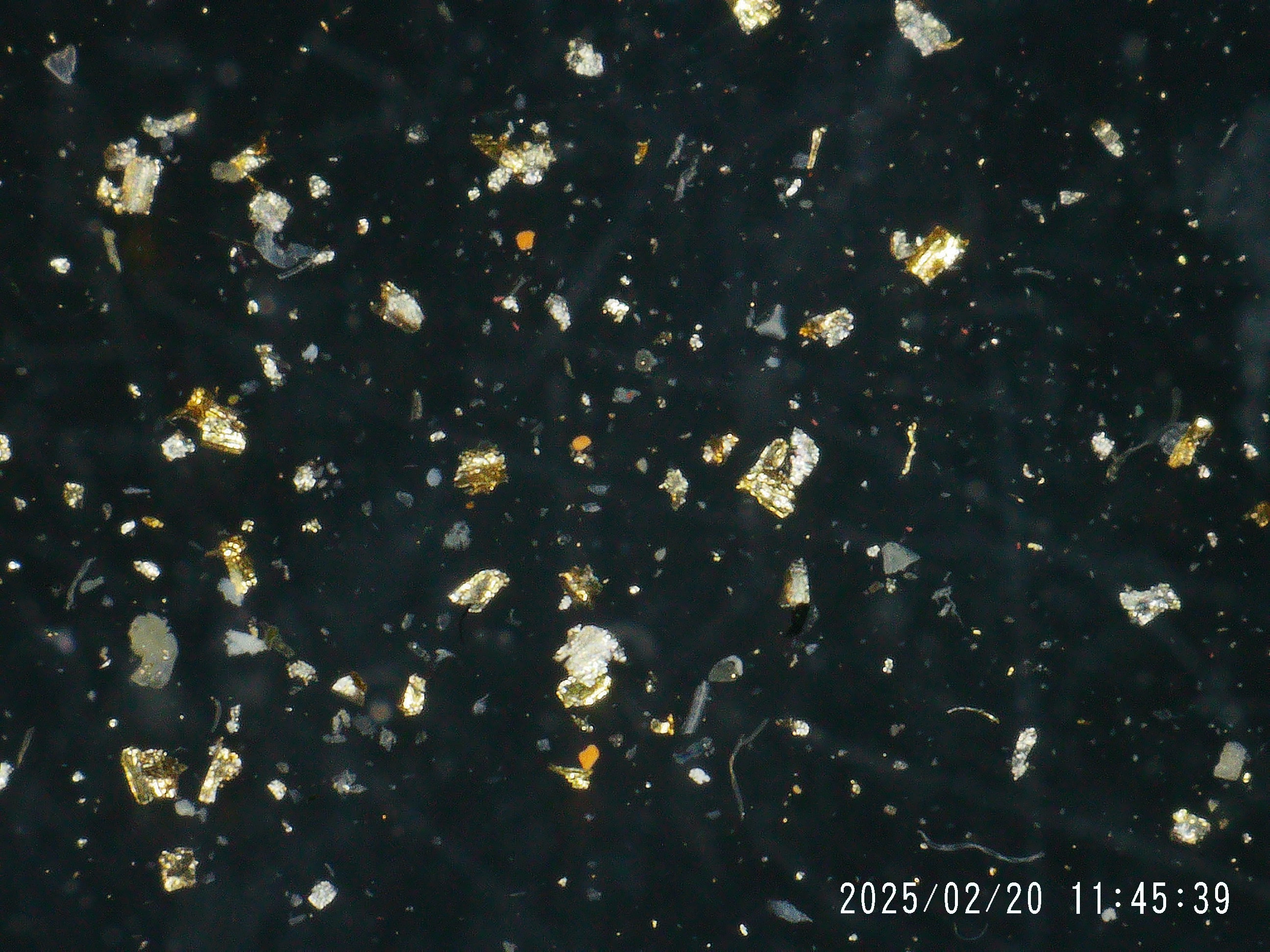

After pre-cleaning all of the components (except the pallet fork and balance since they don't like taking IPA baths), I checked the bottom of the watch glass for the quantity and type of debris that my pre-cleaning had removed. This is what I found (1.5mm springbar for scale).

Under the microscope it's obvious that this debris is brass dust, most likely from the engraving process.

It's my understanding that these movements are manufactured "sterile" in the sense that they aren't engraved at the Dandong factory. As I understand things, the movements are sent to the factories we know (e.g. Clean Factory, VSF, etc...) where the movements are engraved and assembled. It's not surprising that the conditions under which final assembly takes place are far from "clean room" standards. To me, this speaks to the need to get any rep serviced within 12-18 months of it arriving in your hands if it's going to be a daily wear watch, even if that watch is form a high end rep factory like Clean.

After pre-cleaning all of the components (except the pallet fork and balance since they don't like taking IPA baths), I checked the bottom of the watch glass for the quantity and type of debris that my pre-cleaning had removed. This is what I found (1.5mm springbar for scale).

Under the microscope it's obvious that this debris is brass dust, most likely from the engraving process.

It's my understanding that these movements are manufactured "sterile" in the sense that they aren't engraved at the Dandong factory. As I understand things, the movements are sent to the factories we know (e.g. Clean Factory, VSF, etc...) where the movements are engraved and assembled. It's not surprising that the conditions under which final assembly takes place are far from "clean room" standards. To me, this speaks to the need to get any rep serviced within 12-18 months of it arriving in your hands if it's going to be a daily wear watch, even if that watch is form a high end rep factory like Clean.