Yes, the gen balance is a drop in replacement for the dd3285 balance.Hi so is it working with the gen balance? Thx

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dogwood's Watchmaking Journey

- Thread starter dogwood

- Start date

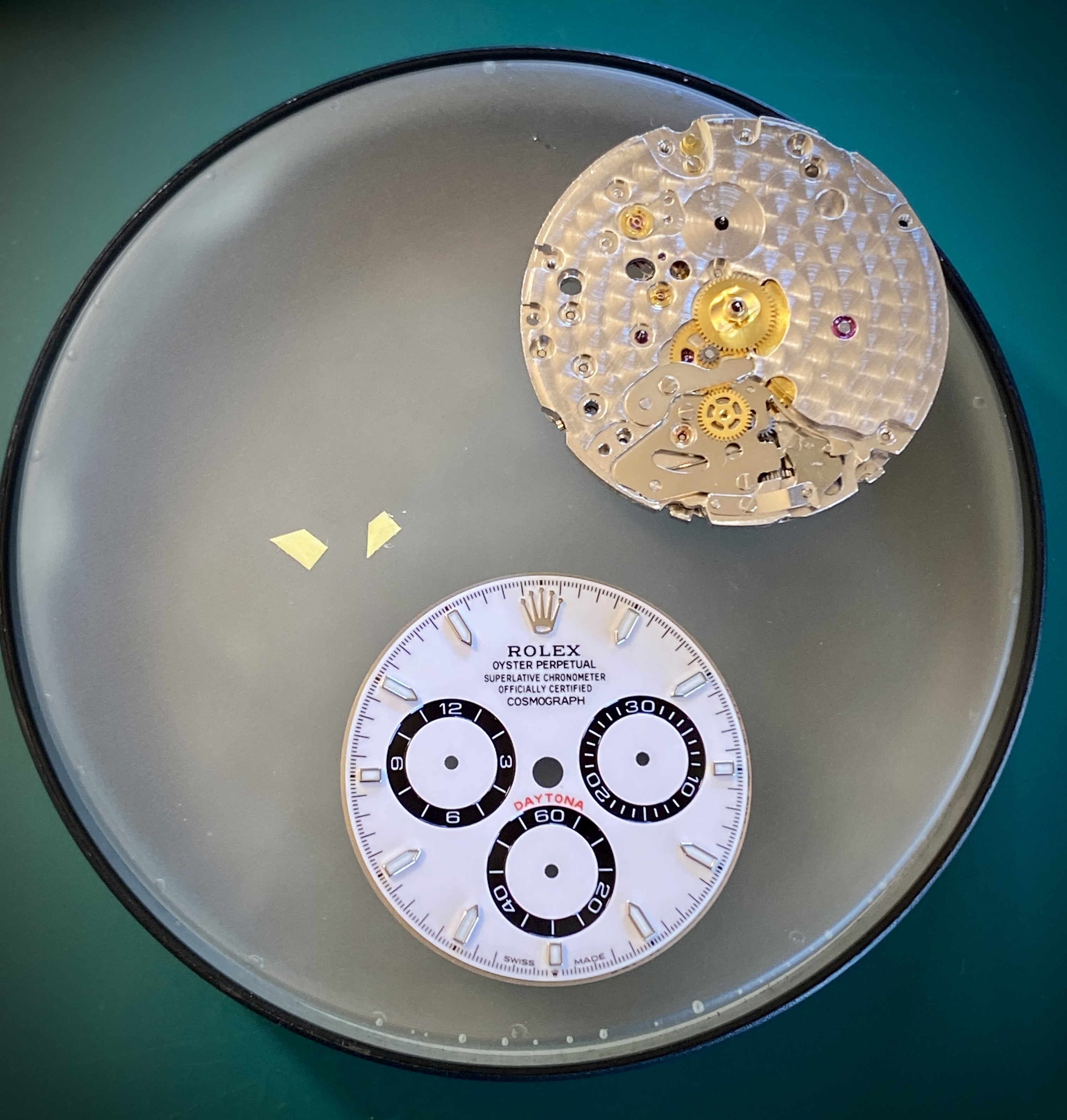

I recently had an SH4131 on my bench from an APSF Daytona. If the chronograph was started the movement would stop. I looked at the movenent and found there was quite a bit of debris visible on the automatic and chronograph bridges. As I dug further into the movement I noticed even more of what looked like metal debris:

After fully disassembling the movements, I swapped fresh 99.9% IPA into my pre-cleaning watch glass, and then hand cleaned all the parts (except the pallet fork and balance) in the IPA with an artist’s paintbrush.

The amount of debris left behind after cleaning was surprising. I left a screw in the watch glass for scale:

Under the microscope it looks like a lot of the debris is metal shavings. I’m guessing these are from the engraving process and either weren’t properly cleaned off before reassembly, or there isn’t proper air filtration in the factories making these movements and metal dust is contaminating the working areas of people assembling movements.

After fully disassembling the movements, I swapped fresh 99.9% IPA into my pre-cleaning watch glass, and then hand cleaned all the parts (except the pallet fork and balance) in the IPA with an artist’s paintbrush.

The amount of debris left behind after cleaning was surprising. I left a screw in the watch glass for scale:

Under the microscope it looks like a lot of the debris is metal shavings. I’m guessing these are from the engraving process and either weren’t properly cleaned off before reassembly, or there isn’t proper air filtration in the factories making these movements and metal dust is contaminating the working areas of people assembling movements.

I had the pleasure of servicing a DD4131 from a BTF Daytona recently. This was my first time doing a full disassembly and service on the new DD4131 and while I won't post a full part by part break down, there are a couple of things that I think are worthy of praise. The TLDR version is that I think the DD4131 is significantly better than the SH4131. Nota Bene: This isn't influenced by the preceding post where I found an SH4131 to be fouled with metal shavings; but rather the fact that Dandong has done a better job of mechanically replicating the genuine movement. If you're thinking of any kind of franken 12-series Daytona, then we should be starting with a DD4131.

This first thing I want to mention is that both the DD and SH 4131 movements have far more ball bearings supporting their rotors than either we see in either of the 4130s. This is a good thing. The number of ball bearings is a good estimate for the number of points of contact there are between the two pieces separated by the bearings races. In a world of perfect tolerances it would be possible to constrain the movement of a rotor to the winding plane using only three ball bearings. But perfect tolerances aren't what we're dealing with... so more ball bearings equates to a rotor that's more tightly constrained to the plane in which it is supposed to spin. Since a large amount of "rotor noise" is actually the rotor slapping against the bridges and or the caseback, having the rotor be more constrained is a good thing. I also like how both DD and SH have eliminated the ball cages from the design and opted to simply fill the races with as many balls as possible while still leaving just enough room for the two races to be assembled.

The next thing that I'd like to mention is the design of the pallet fork. Similar to the VS3235 (and gen 3235), the new gen 4131 is supposed to have a skewed "chronoenergy" style pallet fork. This pallet fork design results in a high lift angle and uses smaller pallet stones to reduce sliding friction (thus improving power reserve). The Shanghai version of the 4131 doesn't have the skewed design, however the Dandong version does. I don't know if it will be possible to swap in a gen balance into a DD4131, but I can say with certainty that doing so on an SH4131 won't be possible.

The final thing I want to highlight is the escape wheel. The escape wheel starts and stops rotating four times per second, and each time it moves it needs to accelerate and swing through a non-trivial number of degrees of arc. Each acceleration takes energy. While it's true that all the other train wheels also start / stop four times per second, they aren't rotating anywhere near as far in terms of degrees travelled per beat of the watch's movement, so what I'm going to explain next applies less to them than it does for the escape wheel. Without getting into the physics too much, it takes more force to start and stop a heavy object than it does to do the same to a light object. That's why Rolex when to the insane lengths they did to reduce the mass of the escape wheel on the 3235 and 4131 by skeletonizing it and removing any excess metal. I'm honestly shocked that Dandong went to the same lengths to skeletonize the escape wheel on the DD4131. Making parts this small with this level of precision isn not easy. I'm assuming the escape wheel is made using fine blanking on a press, but the inside radii of the punched out sections are so tight it's nearly impossible to see them even under the microscope. This is an impressive feat of engineering. To the annonymous (to us) engineers in Dandong, I salute you.

This first thing I want to mention is that both the DD and SH 4131 movements have far more ball bearings supporting their rotors than either we see in either of the 4130s. This is a good thing. The number of ball bearings is a good estimate for the number of points of contact there are between the two pieces separated by the bearings races. In a world of perfect tolerances it would be possible to constrain the movement of a rotor to the winding plane using only three ball bearings. But perfect tolerances aren't what we're dealing with... so more ball bearings equates to a rotor that's more tightly constrained to the plane in which it is supposed to spin. Since a large amount of "rotor noise" is actually the rotor slapping against the bridges and or the caseback, having the rotor be more constrained is a good thing. I also like how both DD and SH have eliminated the ball cages from the design and opted to simply fill the races with as many balls as possible while still leaving just enough room for the two races to be assembled.

The next thing that I'd like to mention is the design of the pallet fork. Similar to the VS3235 (and gen 3235), the new gen 4131 is supposed to have a skewed "chronoenergy" style pallet fork. This pallet fork design results in a high lift angle and uses smaller pallet stones to reduce sliding friction (thus improving power reserve). The Shanghai version of the 4131 doesn't have the skewed design, however the Dandong version does. I don't know if it will be possible to swap in a gen balance into a DD4131, but I can say with certainty that doing so on an SH4131 won't be possible.

The final thing I want to highlight is the escape wheel. The escape wheel starts and stops rotating four times per second, and each time it moves it needs to accelerate and swing through a non-trivial number of degrees of arc. Each acceleration takes energy. While it's true that all the other train wheels also start / stop four times per second, they aren't rotating anywhere near as far in terms of degrees travelled per beat of the watch's movement, so what I'm going to explain next applies less to them than it does for the escape wheel. Without getting into the physics too much, it takes more force to start and stop a heavy object than it does to do the same to a light object. That's why Rolex when to the insane lengths they did to reduce the mass of the escape wheel on the 3235 and 4131 by skeletonizing it and removing any excess metal. I'm honestly shocked that Dandong went to the same lengths to skeletonize the escape wheel on the DD4131. Making parts this small with this level of precision isn not easy. I'm assuming the escape wheel is made using fine blanking on a press, but the inside radii of the punched out sections are so tight it's nearly impossible to see them even under the microscope. This is an impressive feat of engineering. To the annonymous (to us) engineers in Dandong, I salute you.

Service

I'm New. Unknown to this website.

- 2/9/24

- 57

- 39

- 18

Awesome review! I'm glad I went with BTF for my 12 series Daytona's.I had the pleasure of servicing a DD4131 from a BTF Daytona recently. This was my first time doing a full disassembly and service on the new DD4131 and while I won't post a full part by part break down, there are a couple of things that I think are worthy of praise. The TLDR version is that I think the DD4131 is significantly better than the SH4131. Nota Bene: This isn't influenced by the preceding post where I found an SH4131 to be fouled with metal shavings; but rather the fact that Dandong has done a better job of mechanically replicating the genuine movement. If you're thinking of any kind of franken 12-series Daytona, then we should be starting with a DD4131.

This first thing I want to mention is that both the DD and SH 4131 movements have far more ball bearings supporting their rotors than either we see in either of the 4130s. This is a good thing. The number of ball bearings is a good estimate for the number of points of contact there are between the two pieces separated by the bearings races. In a world of perfect tolerances it would be possible to constrain the movement of a rotor to the winding plane using only three ball bearings. But perfect tolerances aren't what we're dealing with... so more ball bearings equates to a rotor that's more tightly constrained to the plane in which it is supposed to spin. Since a large amount of "rotor noise" is actually the rotor slapping against the bridges and or the caseback, having the rotor be more constrained is a good thing. I also like how both DD and SH have eliminated the ball cages from the design and opted to simply fill the races with as many balls as possible while still leaving just enough room for the two races to be assembled.

The next thing that I'd like to mention is the design of the pallet fork. Similar to the VS3235 (and gen 3235), the new gen 4131 is supposed to have a skewed "chronoenergy" style pallet fork. This pallet fork design results in a high lift angle and uses smaller pallet stones to reduce sliding friction (thus improving power reserve). The Shanghai version of the 4131 doesn't have the skewed design, however the Dandong version does. I don't know if it will be possible to swap in a gen balance into a DD4131, but I can say with certainty that doing so on an SH4131 won't be possible.

The final thing I want to highlight is the escape wheel. The escape wheel starts and stops rotating four times per second, and each time it moves it needs to accelerate and swing through a non-trivial number of degrees of arc. Each acceleration takes energy. While it's true that all the other train wheels also start / stop four times per second, they aren't rotating anywhere near as far in terms of degrees travelled per beat of the watch's movement, so what I'm going to explain next applies less to them than it does for the escape wheel. Without getting into the physics too much, it takes more force to start and stop a heavy object than it does to do the same to a light object. That's why Rolex when to the insane lengths they did to reduce the mass of the escape wheel on the 3235 and 4131 by skeletonizing it and removing any excess metal. I'm honestly shocked that Dandong went to the same lengths to skeletonize the escape wheel on the DD4131. Making parts this small with this level of precision isn not easy. I'm assuming the escape wheel is made using fine blanking on a press, but the inside radii of the punched out sections are so tight it's nearly impossible to see them even under the microscope. This is an impressive feat of engineering. To the annonymous (to us) engineers in Dandong, I salute you.

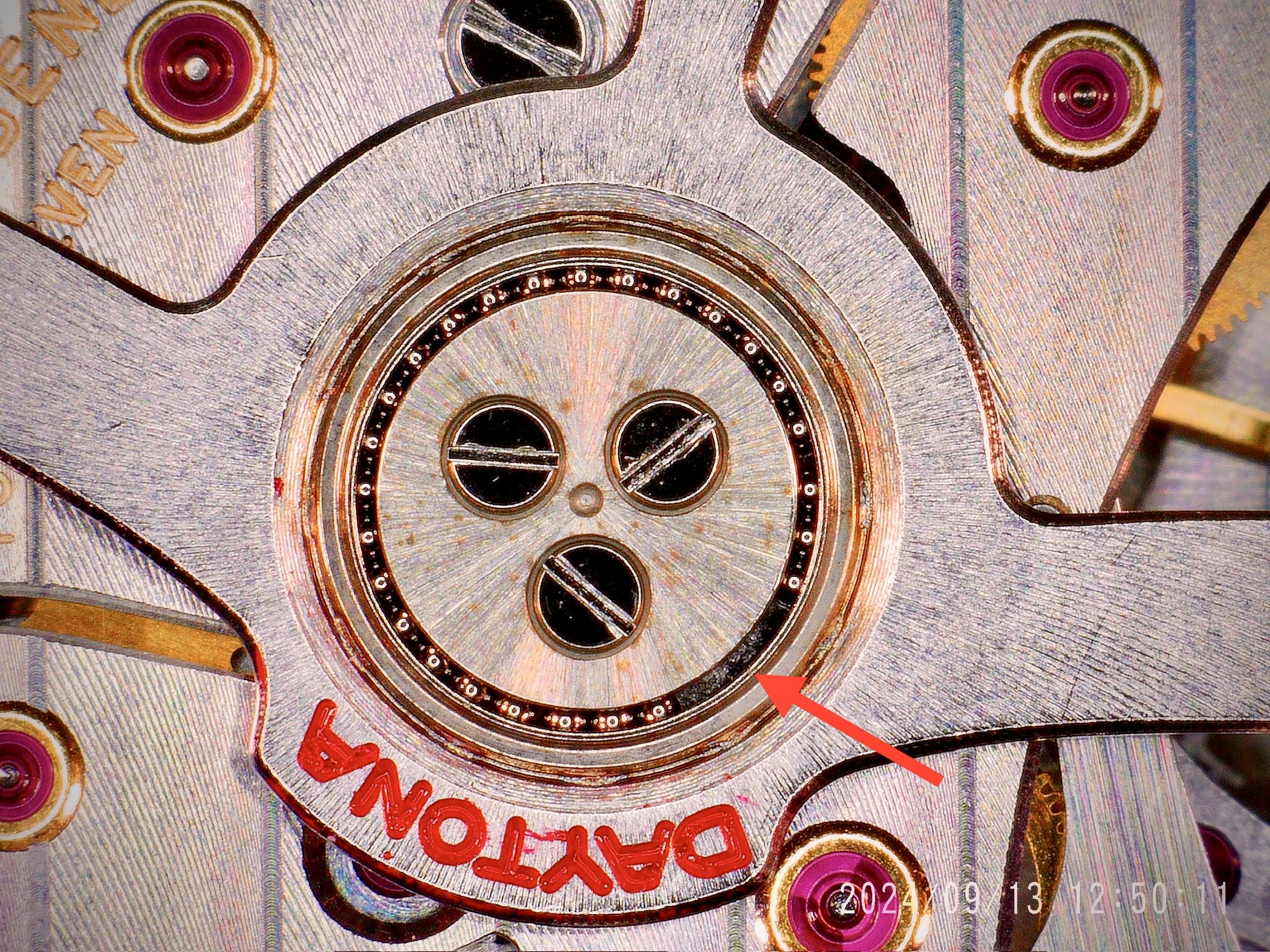

Ok, so it’s embarrassing that it took me this long to figure out that there’s an eccentric screw on the 4130 and 4131 Daytona movements that allows you to adjust the reset position of the chronograph seconds counter hand by +1 to -1 seconds.

I’m not 100% sure I completely understand the adjustment mechanism, but it seems like I get the best results by Tony adjustments and then running the chrono and resetting to check alignment. If anybody knows a good technique for sneaking up on perfect alignment, please let me know.

I’m not 100% sure I completely understand the adjustment mechanism, but it seems like I get the best results by Tony adjustments and then running the chrono and resetting to check alignment. If anybody knows a good technique for sneaking up on perfect alignment, please let me know.

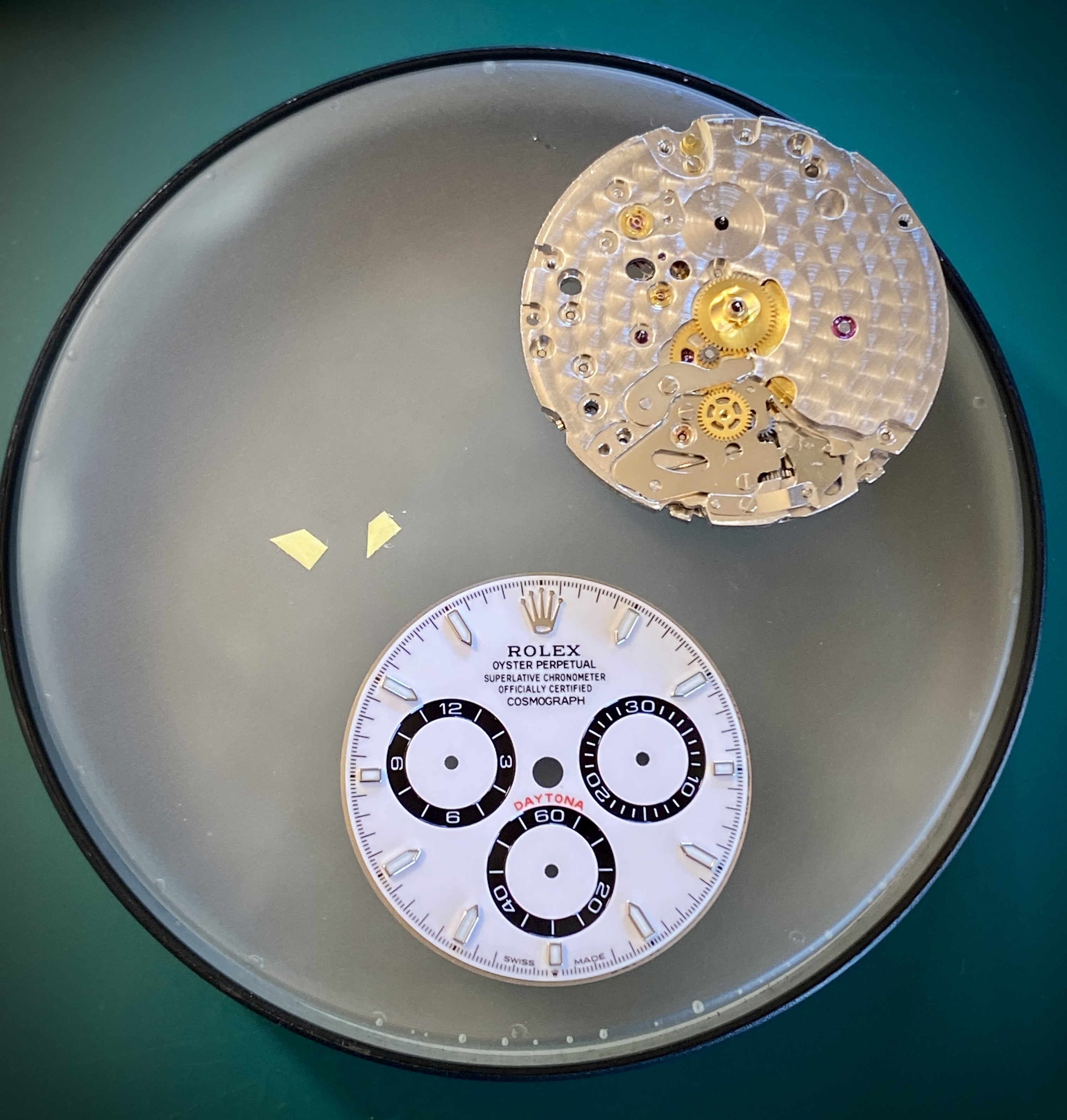

I had the chance to use @KJ2020’s dial washing technique today. This dial arrived on my bench filthy! Whatever was on there was thick and greasy.

I used one of my parts trays as a container and put in a bit of dish washing soap (Palmolive) and some warm tap water. Then I used an artists brush to scrub the dial.

After soaping and scrubbing I rinsed under tap water.

I had to repeat the process three times to remove all the grease. I was trying to be careful not to accidentally scratch the dial with the paint brush, so maybe I was being too gentle.

Regardless, after each attempt, I used an air blower to puff dry the dial so as to avoid any water marks. When I was puff drying I placed the dial on a thick microfiber cloth to absorb the water that got blown to the sides.

I’m happy to report the method works flawlessly. The dial looks great now.

I used one of my parts trays as a container and put in a bit of dish washing soap (Palmolive) and some warm tap water. Then I used an artists brush to scrub the dial.

After soaping and scrubbing I rinsed under tap water.

I had to repeat the process three times to remove all the grease. I was trying to be careful not to accidentally scratch the dial with the paint brush, so maybe I was being too gentle.

Regardless, after each attempt, I used an air blower to puff dry the dial so as to avoid any water marks. When I was puff drying I placed the dial on a thick microfiber cloth to absorb the water that got blown to the sides.

I’m happy to report the method works flawlessly. The dial looks great now.

Thank you for this, this helped me realign my CF w/ 4131 and now my OCD not kicking me in head! Thank you petehudso!Ok, so it’s embarrassing that it took me this long to figure out that there’s an eccentric screw on the 4130 and 4131 Daytona movements that allows you to adjust the reset position of the chronograph seconds counter hand by +1 to -1 seconds.

I’m not 100% sure I completely understand the adjustment mechanism, but it seems like I get the best results by Tony adjustments and then running the chrono and resetting to check alignment. If anybody knows a good technique for sneaking up on perfect alignment, please let me know.

Karma4U

Getting To Know The Place

- 21/3/21

- 52

- 36

- 18

Very good post im looking to puchase VSF or CF 126500 black face with the dd4131, this post has been very imformative 10/10

it’s been a quite few months but now that Canada Post is back to work, I’ve had some interesting stuff across my bench.

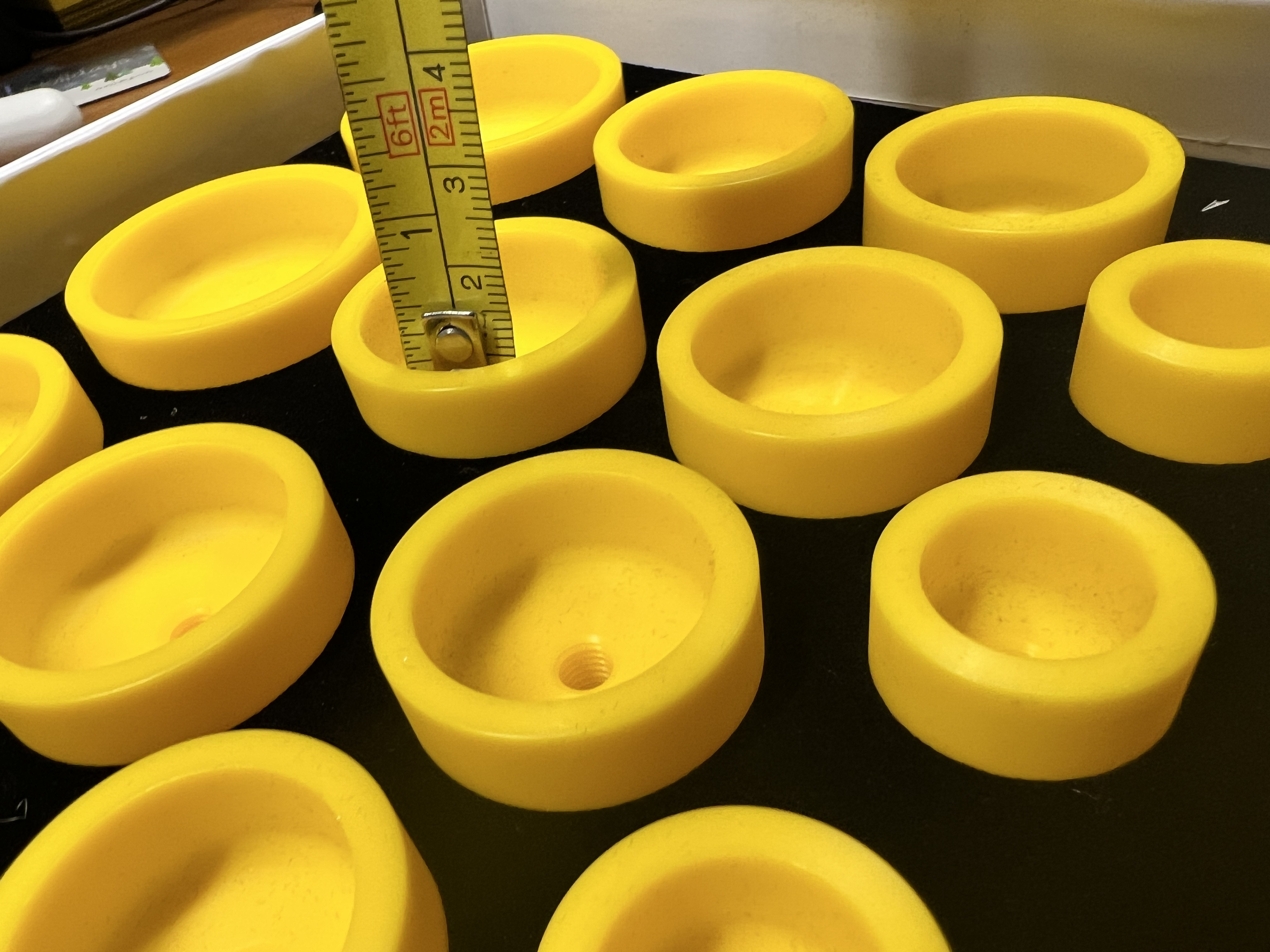

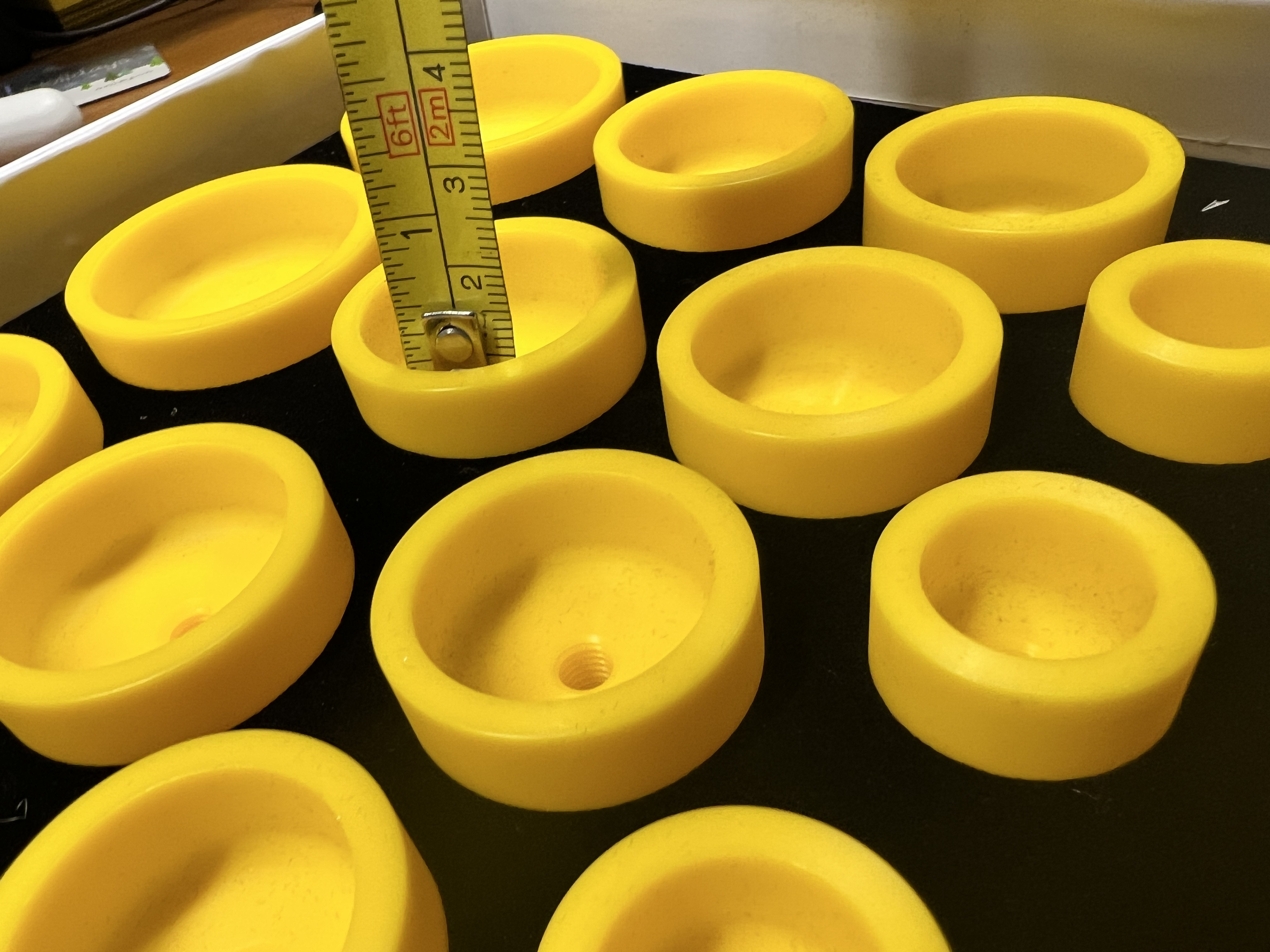

First up are some new tools. There’s a saying I’ve heard from a female friend: “a woman can never be too skinny, too rich, or own too many shoes”… I’m not sure what the equivalent is for a hobby watchmaker, but I’d say a watchmaker can never own too many dies for his press. I recently bought a new set on AliExpress that covers 8mm to 48mm in 0.5mm increments (the green ones, the red ones came with the press). The dies are delrin (or another hard dense plastic) and weren’t too expensive at C$100 including shipping. They aren’t that deep and have flat profiles, but I think they’ll help with the odd unexpected or improvised press job where I don’t have a bespoke die for the job.

I’m also overdue to mention that @xZeroCoolx sent me a production version of his triangular socket tool for rotating the date disc retainer on 3235 movements (works on both Shanghai and Dandong 32xx movements). I helped test an early version of this tool which was softer steel; the production version is hardened tool steel and shows no signs of wear after many uses.

First up are some new tools. There’s a saying I’ve heard from a female friend: “a woman can never be too skinny, too rich, or own too many shoes”… I’m not sure what the equivalent is for a hobby watchmaker, but I’d say a watchmaker can never own too many dies for his press. I recently bought a new set on AliExpress that covers 8mm to 48mm in 0.5mm increments (the green ones, the red ones came with the press). The dies are delrin (or another hard dense plastic) and weren’t too expensive at C$100 including shipping. They aren’t that deep and have flat profiles, but I think they’ll help with the odd unexpected or improvised press job where I don’t have a bespoke die for the job.

I’m also overdue to mention that @xZeroCoolx sent me a production version of his triangular socket tool for rotating the date disc retainer on 3235 movements (works on both Shanghai and Dandong 32xx movements). I helped test an early version of this tool which was softer steel; the production version is hardened tool steel and shows no signs of wear after many uses.

I also had a BTF 12-series Daytona on my bench from @CTbeforeLP and it reminded me again how much of a joy this movement is to work on. I don’t want to throw shade on the Shanghai 4131 because so far it’s been reliable; but the Dandong 4131 is next level. Dandong went so far beyond what they had to in designing and manufacturing this movement. Everything is beautifully replicated and the attention to detail is stunning.

I know most people will never see the internal workings of a Daytona movement, but if you’re in the market for a 12-series Daytona, I would strongly suggest you get one with a Dandong movement (ie a BTF or VSF watch).

I did see something strange in this watch though… I’ve never seen this before, but there were two paper shims under the dial.

I’m not sure if these were in place to raise the dial slightly or if this was simply a manufacturing and assembly error. I worry that shims like this would cause problems over time if the paper breaks down and fibers migrate elsewhere in the movement and foul up the pivots.

I know most people will never see the internal workings of a Daytona movement, but if you’re in the market for a 12-series Daytona, I would strongly suggest you get one with a Dandong movement (ie a BTF or VSF watch).

I did see something strange in this watch though… I’ve never seen this before, but there were two paper shims under the dial.

I’m not sure if these were in place to raise the dial slightly or if this was simply a manufacturing and assembly error. I worry that shims like this would cause problems over time if the paper breaks down and fibers migrate elsewhere in the movement and foul up the pivots.

Hello. Amazing info and work here. Pure gold.

Can you tell if the balance bridge and wheel are the same in 4131 and 4130? I m wondering if i can upgrade a dd4131 with these parts off a 4130

Can you tell if the balance bridge and wheel are the same in 4131 and 4130? I m wondering if i can upgrade a dd4131 with these parts off a 4130

The gen 4130 and 4131 balances and bridge are different. same with the Dandong 4130 and 4131. Perhaps some parts are interchangeable between the 4130 and 4131, but not the balance.Hello. Amazing info and work here. Pure gold.

Can you tell if the balance bridge and wheel are the same in 4131 and 4130? I m wondering if i can upgrade a dd4131 with these parts off a 4130

Awesome post as always dogwood, love reading this thread. Speaking of the dies, I got the same green die set from AliX and they work well...but you're right about them being too shallow, especially when pressing a retaining ring for a big watch (ex SD43)! So I got this set also from AliX, think it was ~$50USD shipped...works great when it's needed, the dies are about 11mm deep at the edge (which is rounded), slightly more deeper in the center. Keep up the good work mate, thank you!

it’s been a quite few months but now that Canada Post is back to work, I’ve had some interesting stuff across my bench.

First up are some new tools. There’s a saying I’ve heard from a female friend: “a woman can never be too skinny, too rich, or own too many shoes”… I’m not sure what the equivalent is for a hobby watchmaker, but I’d say a watchmaker can never own too many dies for his press. I recently bought a new set on AliExpress that covers 8mm to 48mm in 0.5mm increments (the green ones, the red ones came with the press). The dies are delrin (or another hard dense plastic) and weren’t too expensive at C$100 including shipping. They aren’t that deep and have flat profiles, but I think they’ll help with the odd unexpected or improvised press job where I don’t have a bespoke die for the job.

Wow! this is another level of watchmaking, this thread is very informative, way above my skills. I came across it while researching the ST1903. I've started it from the beginning, fascinating!

Watchbeasty

Watch collector

- 26/5/22

- 7

- 1

- 3

May I ask if the crown is compatible between 116500 and 126500?

I thinking of changing the crown of vsf 126500 with 116500.

I thinking of changing the crown of vsf 126500 with 116500.

I don't know but @CTbeforeLP and @xZeroCoolx are the jedi masters of crown thread compatibility.May I ask if the crown is compatible between 116500 and 126500?

I thinking of changing the crown of vsf 126500 with 116500.

Yes, it will work!May I ask if the crown is compatible between 116500 and 126500?

I thinking of changing the crown of vsf 126500 with 116500.

Is that true with genuine crowns as well?Yes, it will work!