April was a tough month with a lot of medical travel — a friend from university was diagnosed with Stage 3B breast cancer. She has a 4 year old son. If she’d caught it a year ago she’d 100% have seen her son graduate and get married. As it stands there’s a less than 20% chance she’ll see his 10th birthday.

We have a cure for cancer, it’s called early detection. I’m as guilty as anybody about this. Mammograms and prostrate exams aren’t pleasant. But they work. If you’re like me and don’t get checked regularly, here’s your shot across the bow — go and get it done.

Ok… I’ll get off my soap box.

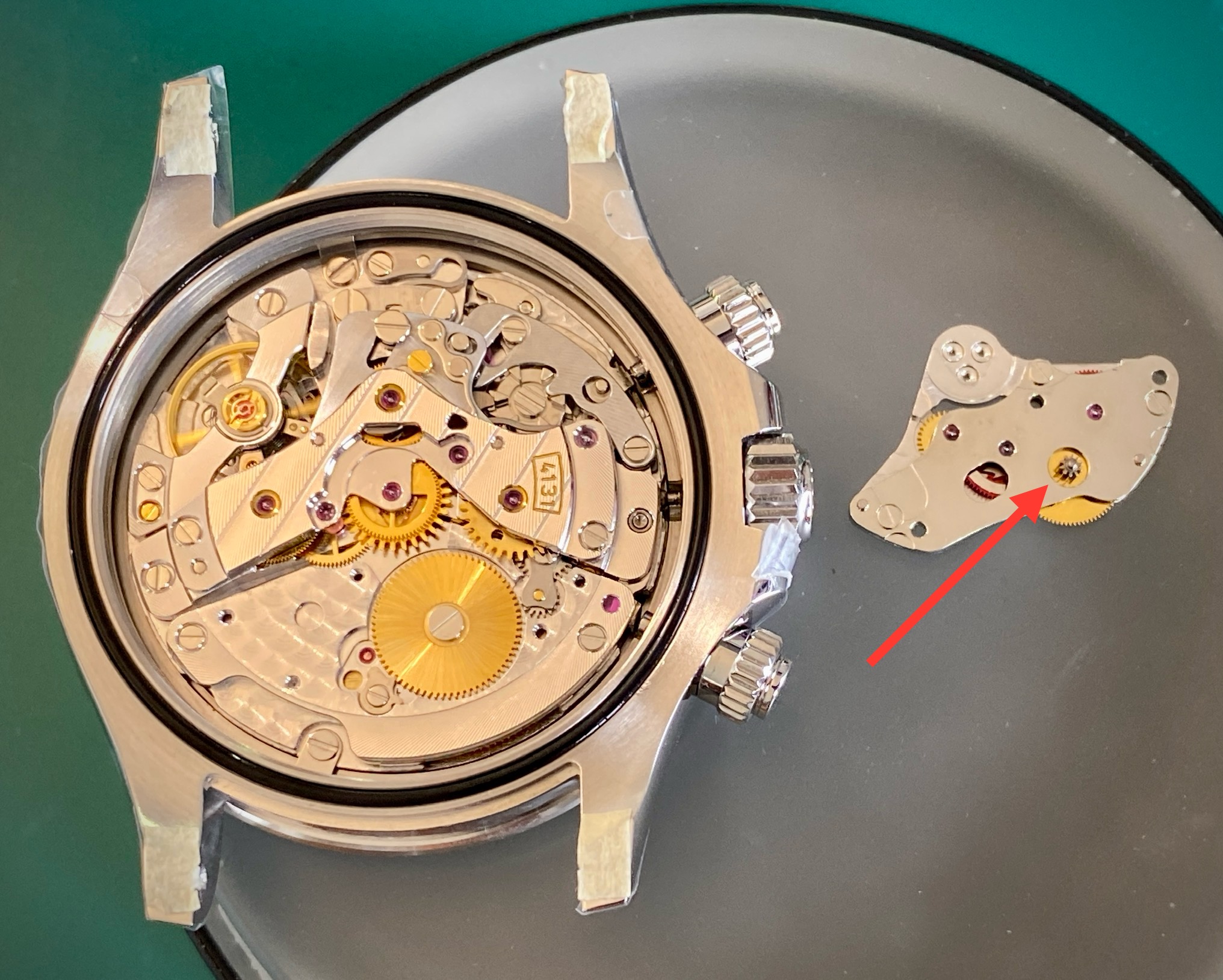

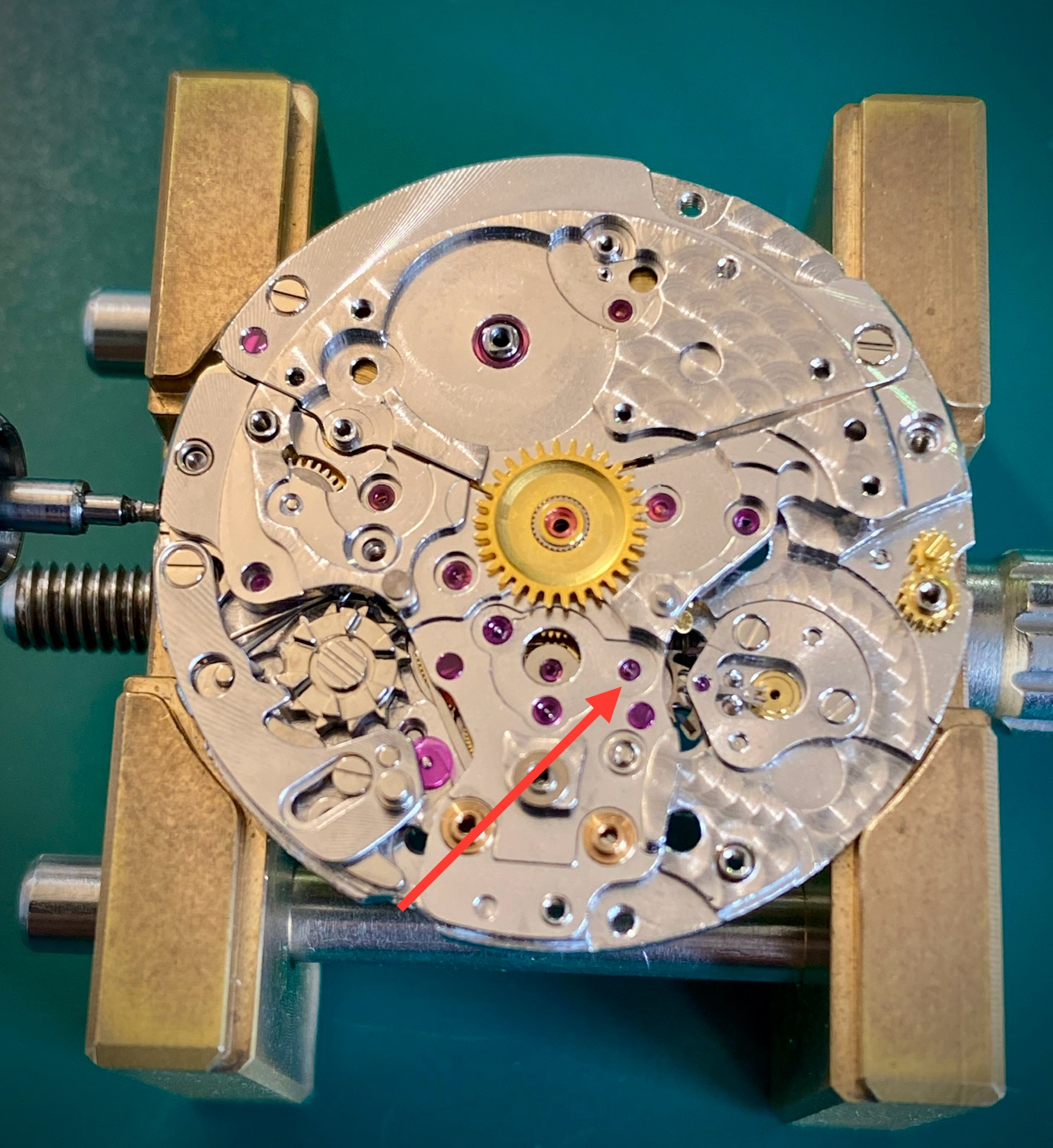

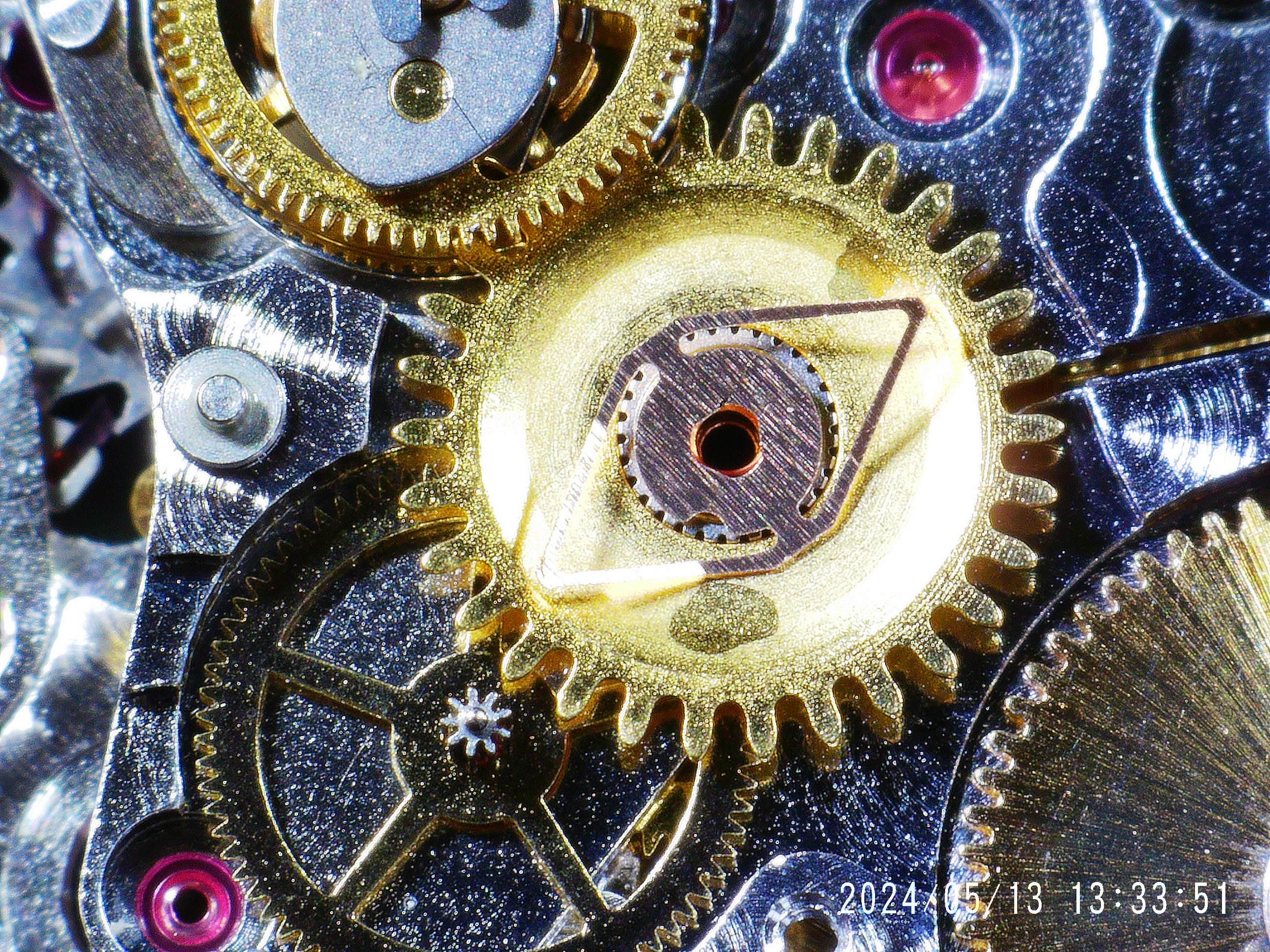

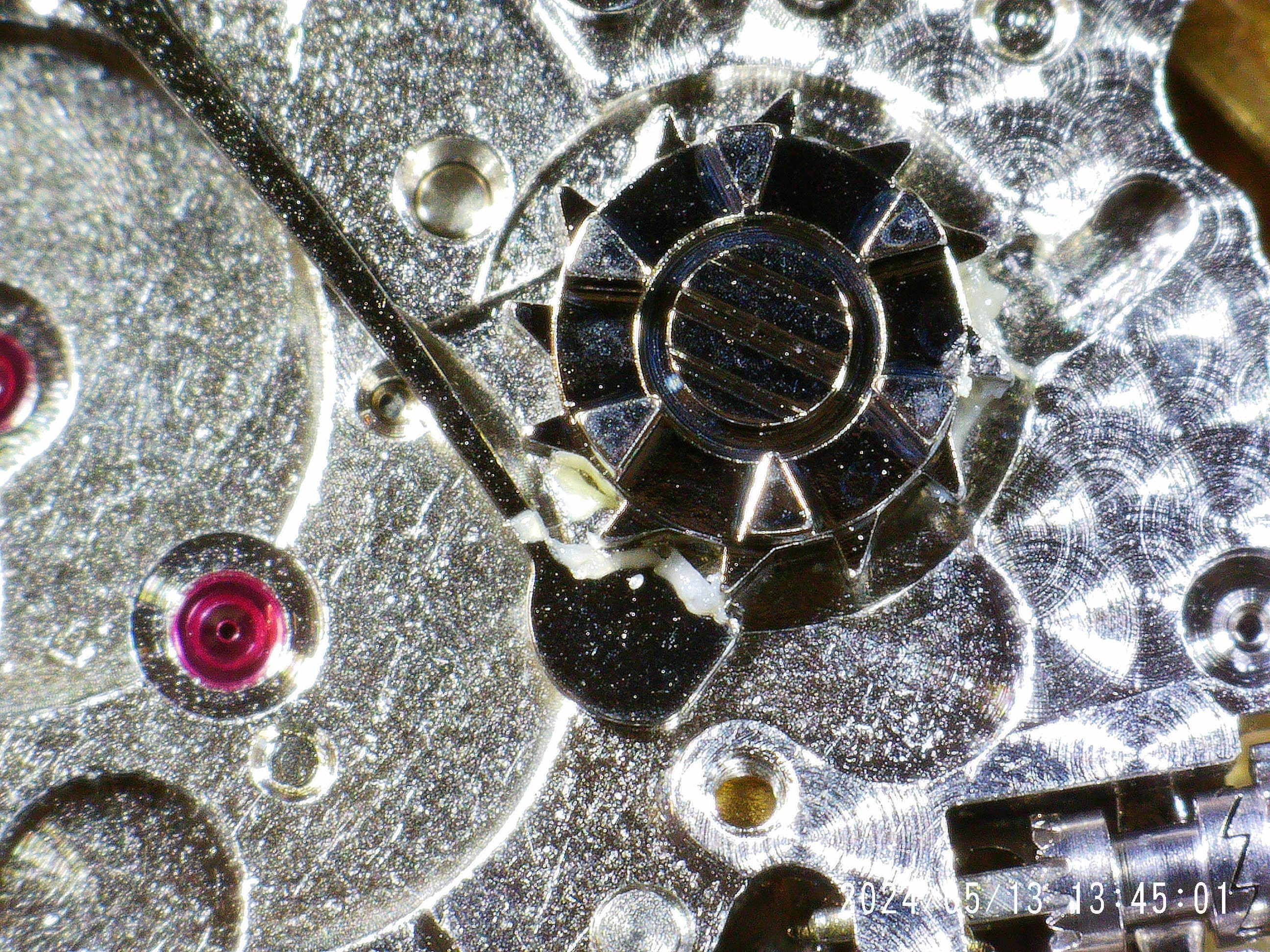

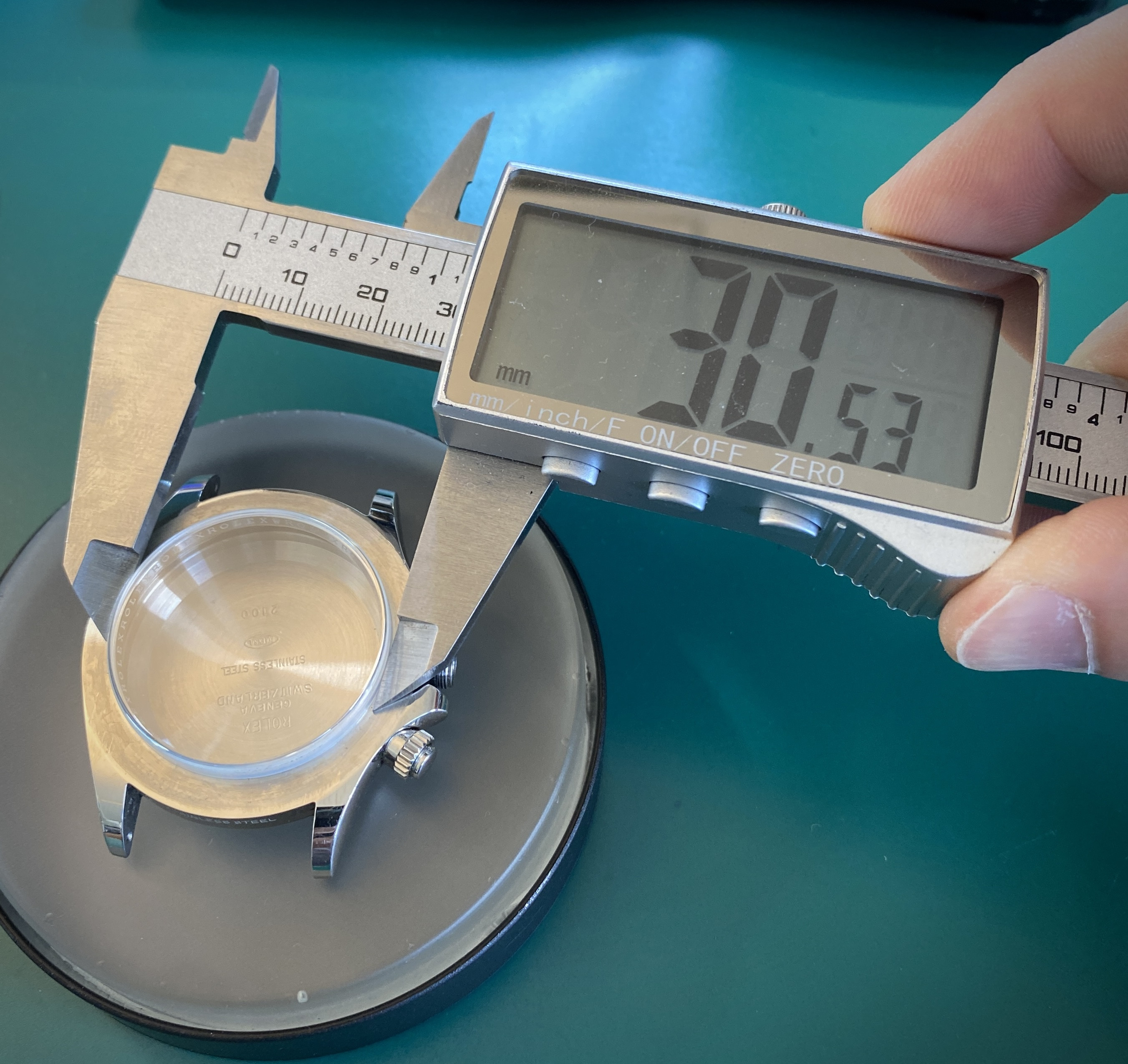

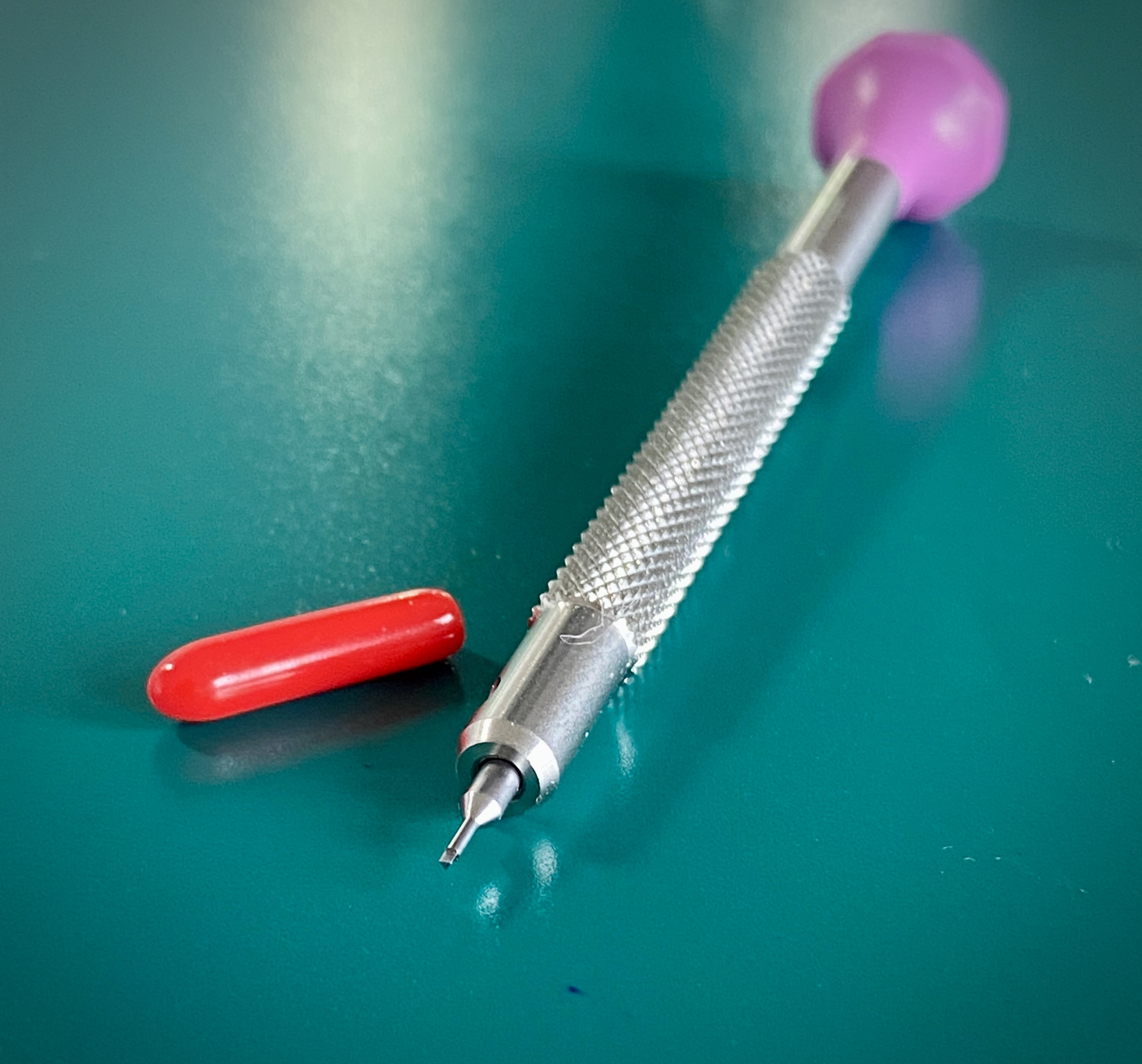

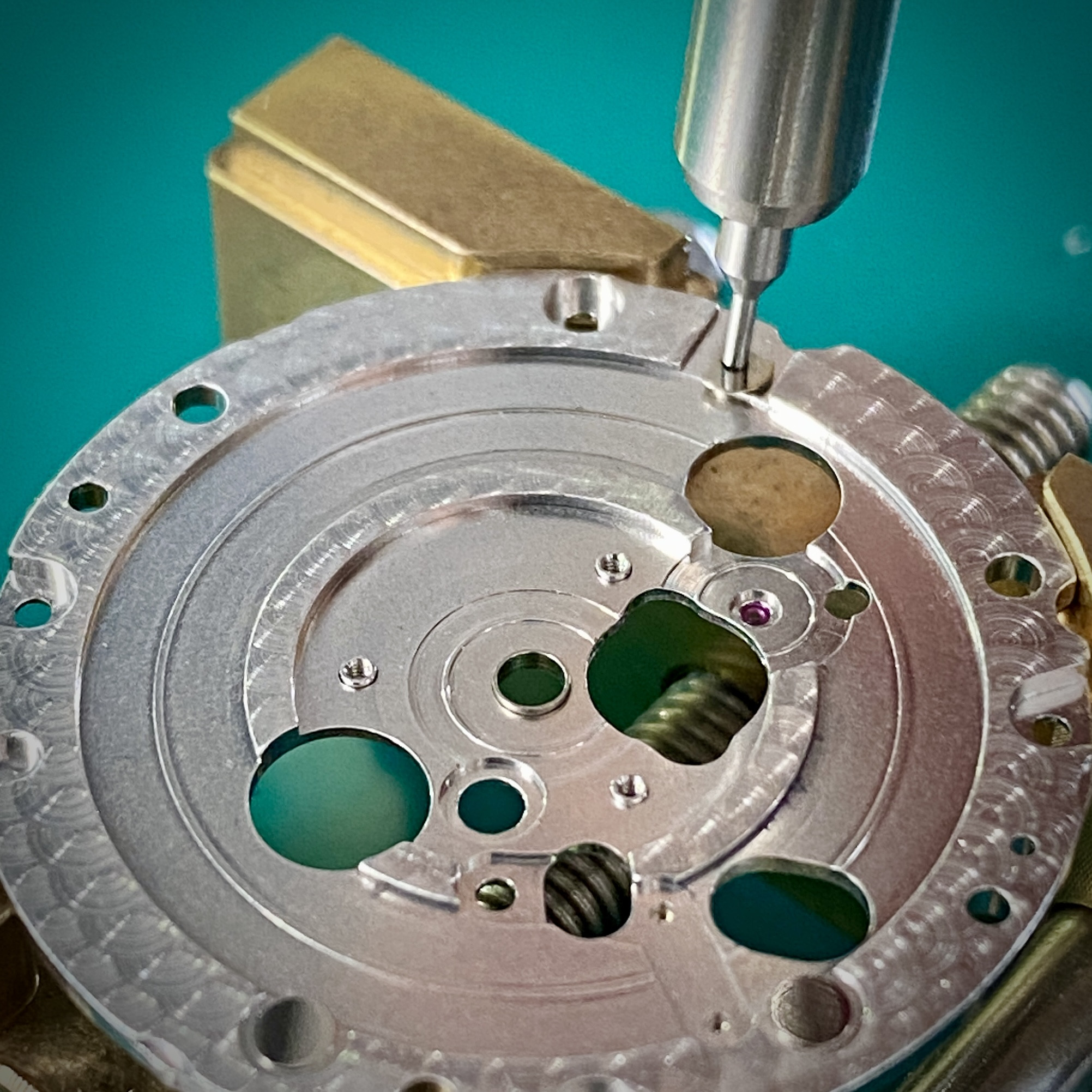

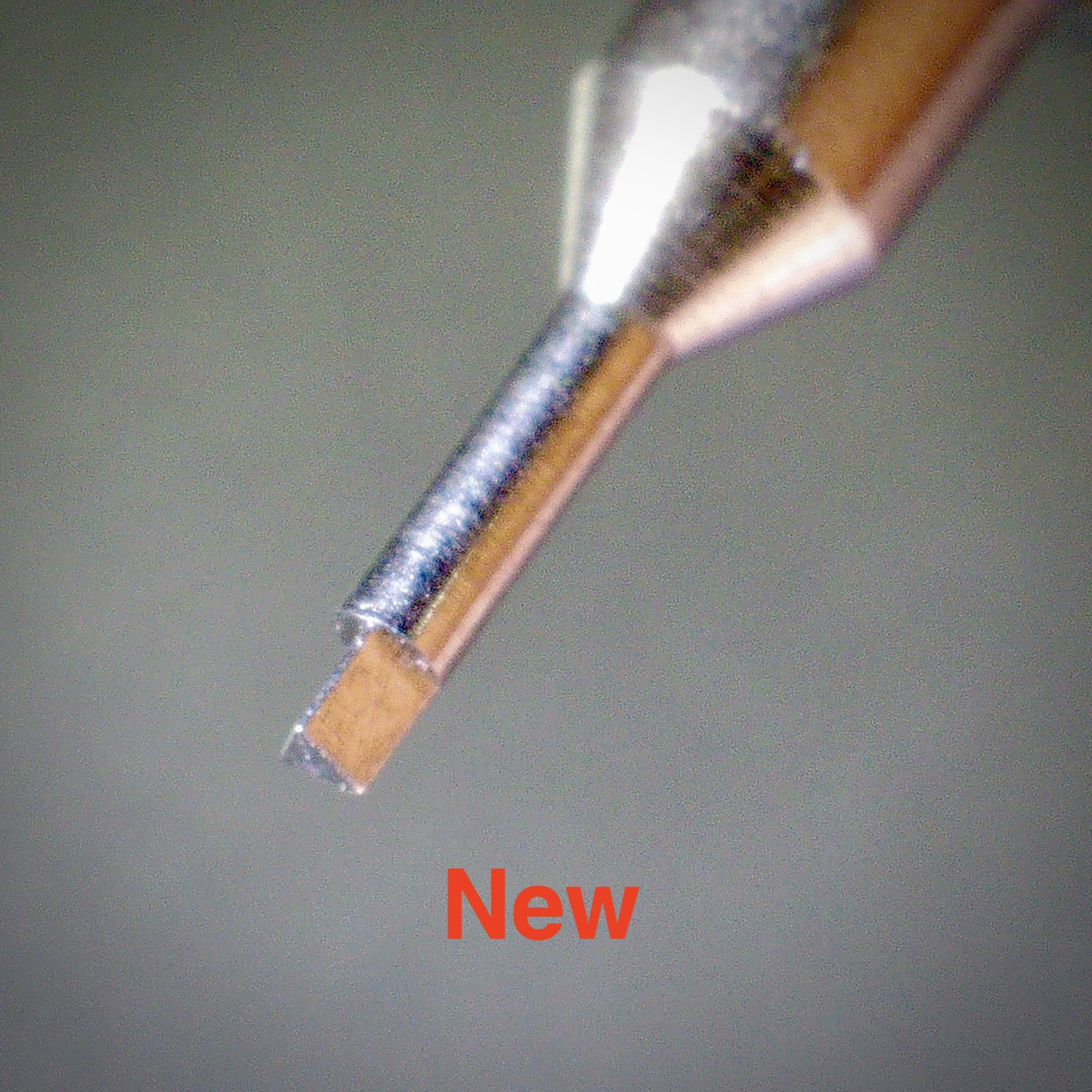

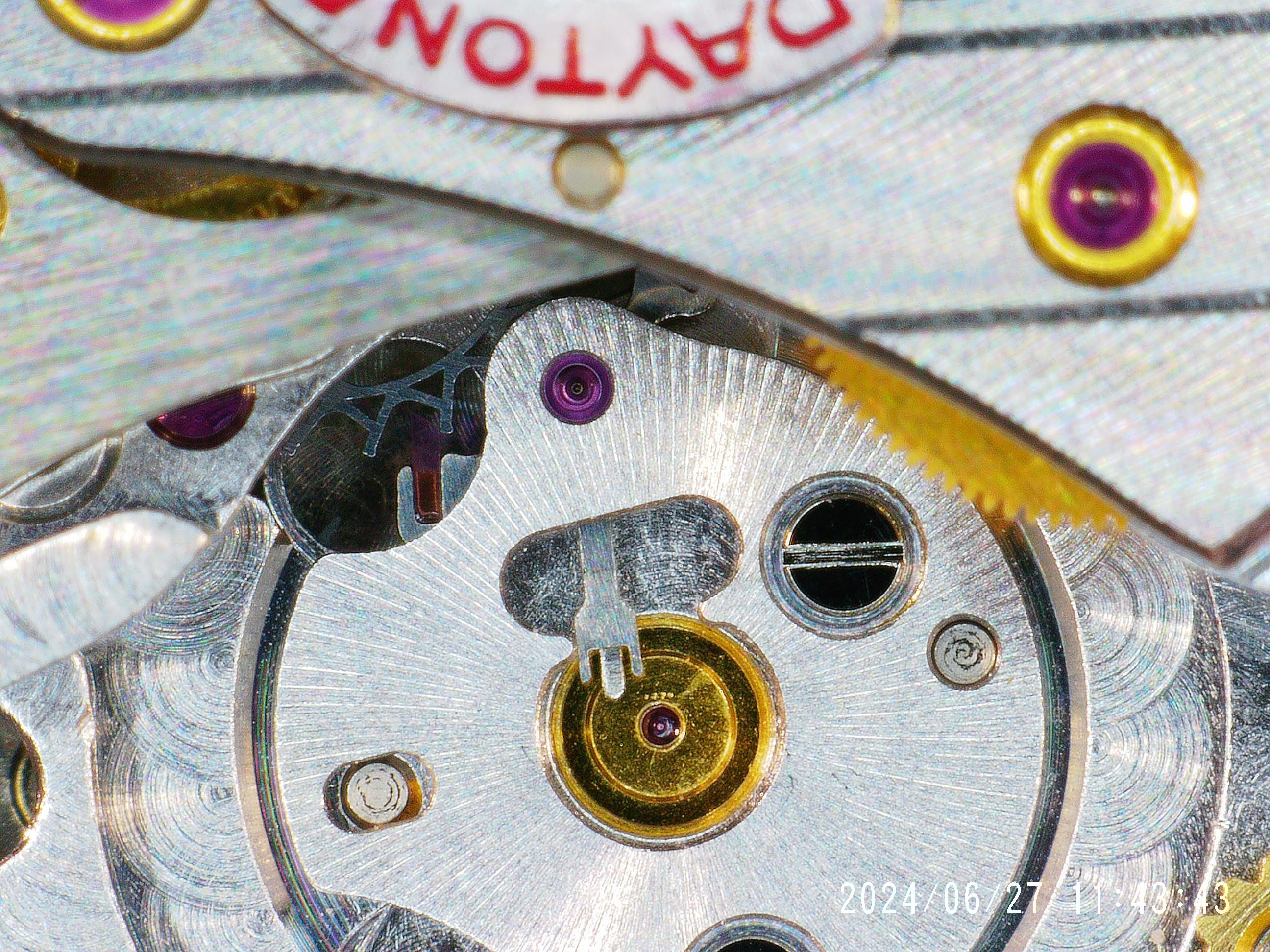

Something else I don’t do often enough is organize my parts drawer, so that’s what I’ve been doing today. I’ve accumulated quite a few vr31XX movements over the past few years. Today I broken them down to squirrel the parts into my spares drawer.

We have a cure for cancer, it’s called early detection. I’m as guilty as anybody about this. Mammograms and prostrate exams aren’t pleasant. But they work. If you’re like me and don’t get checked regularly, here’s your shot across the bow — go and get it done.

Ok… I’ll get off my soap box.

Something else I don’t do often enough is organize my parts drawer, so that’s what I’ve been doing today. I’ve accumulated quite a few vr31XX movements over the past few years. Today I broken them down to squirrel the parts into my spares drawer.