-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dogwood's Watchmaking Journey

- Thread starter dogwood

- Start date

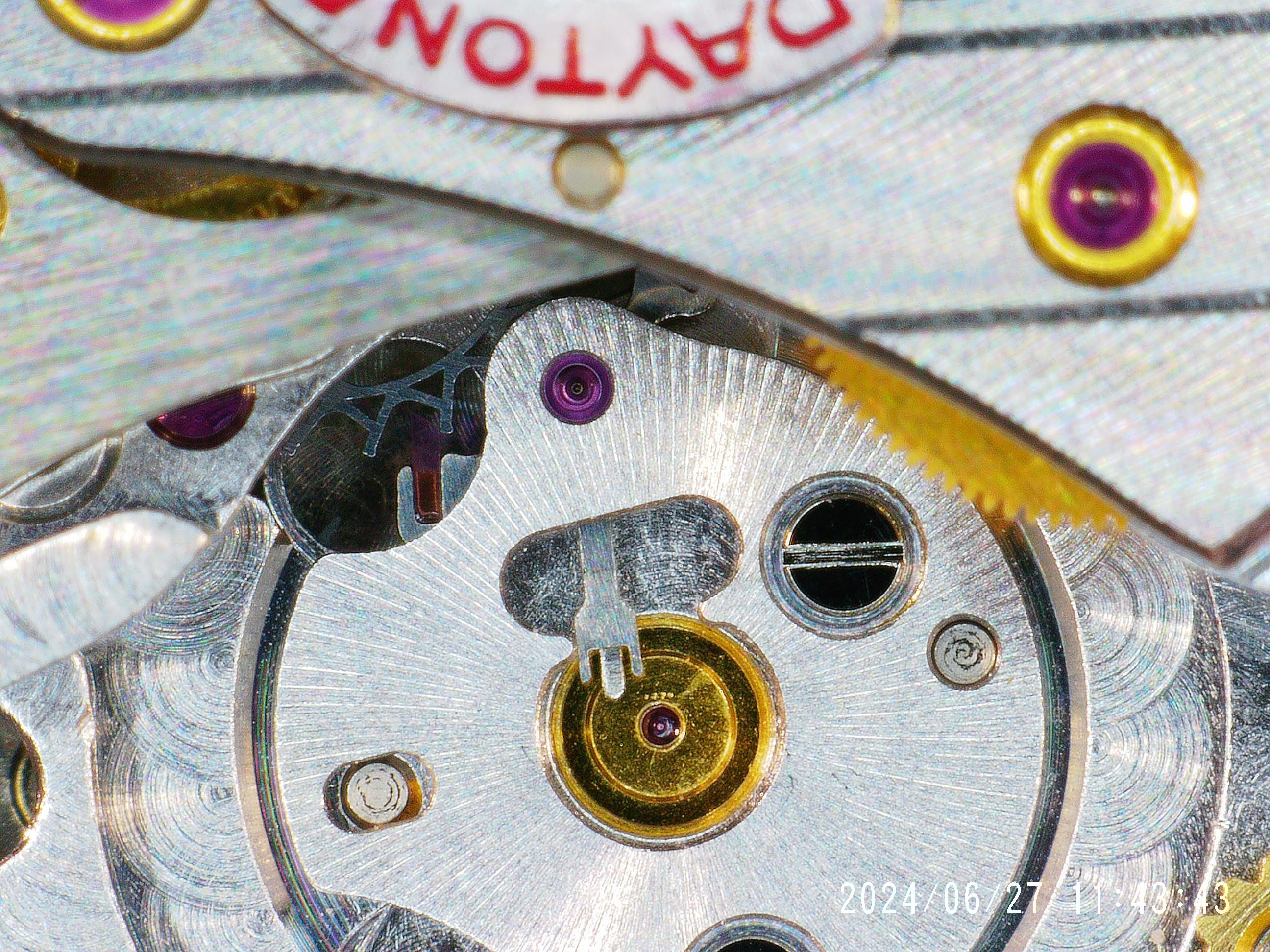

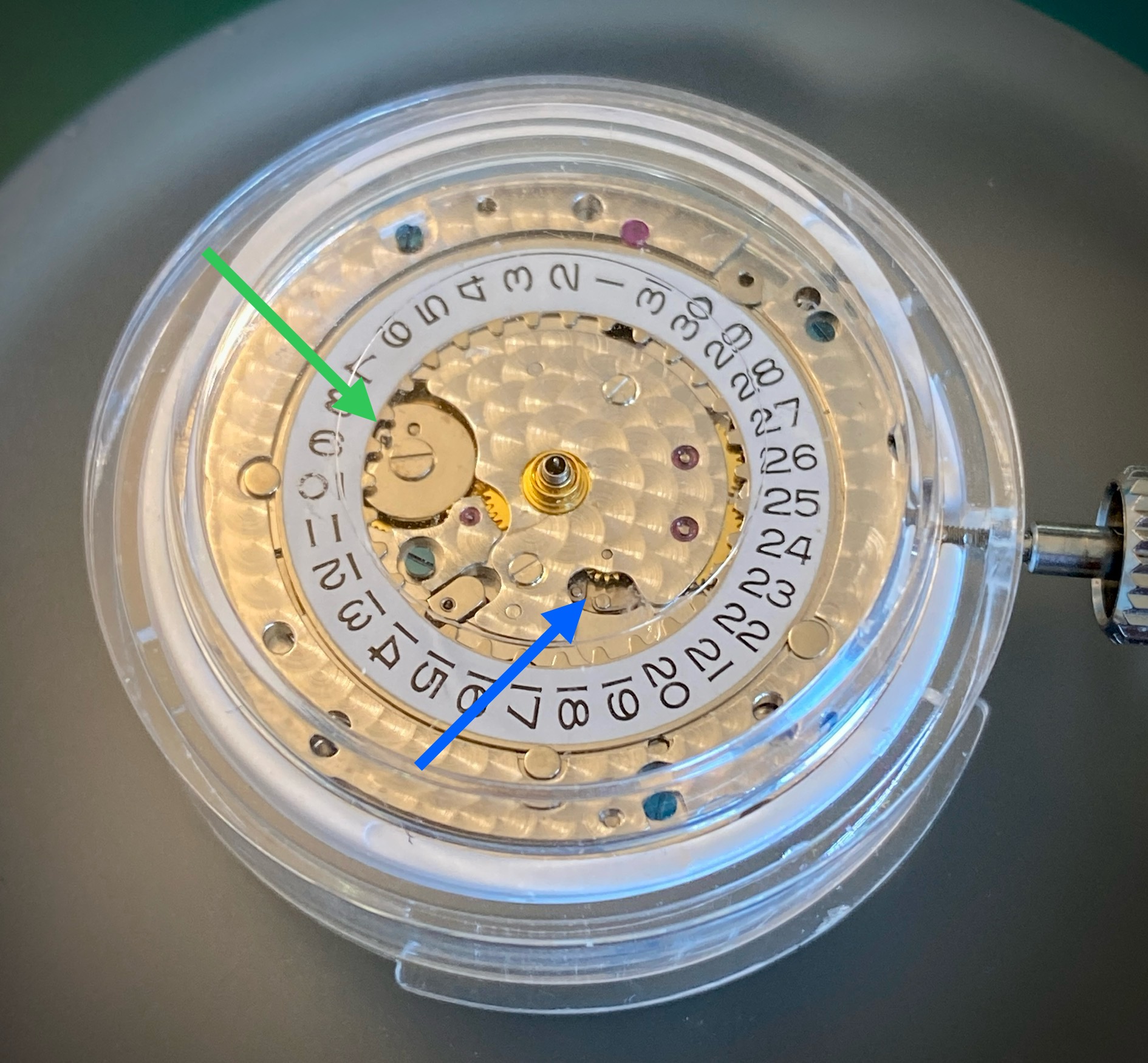

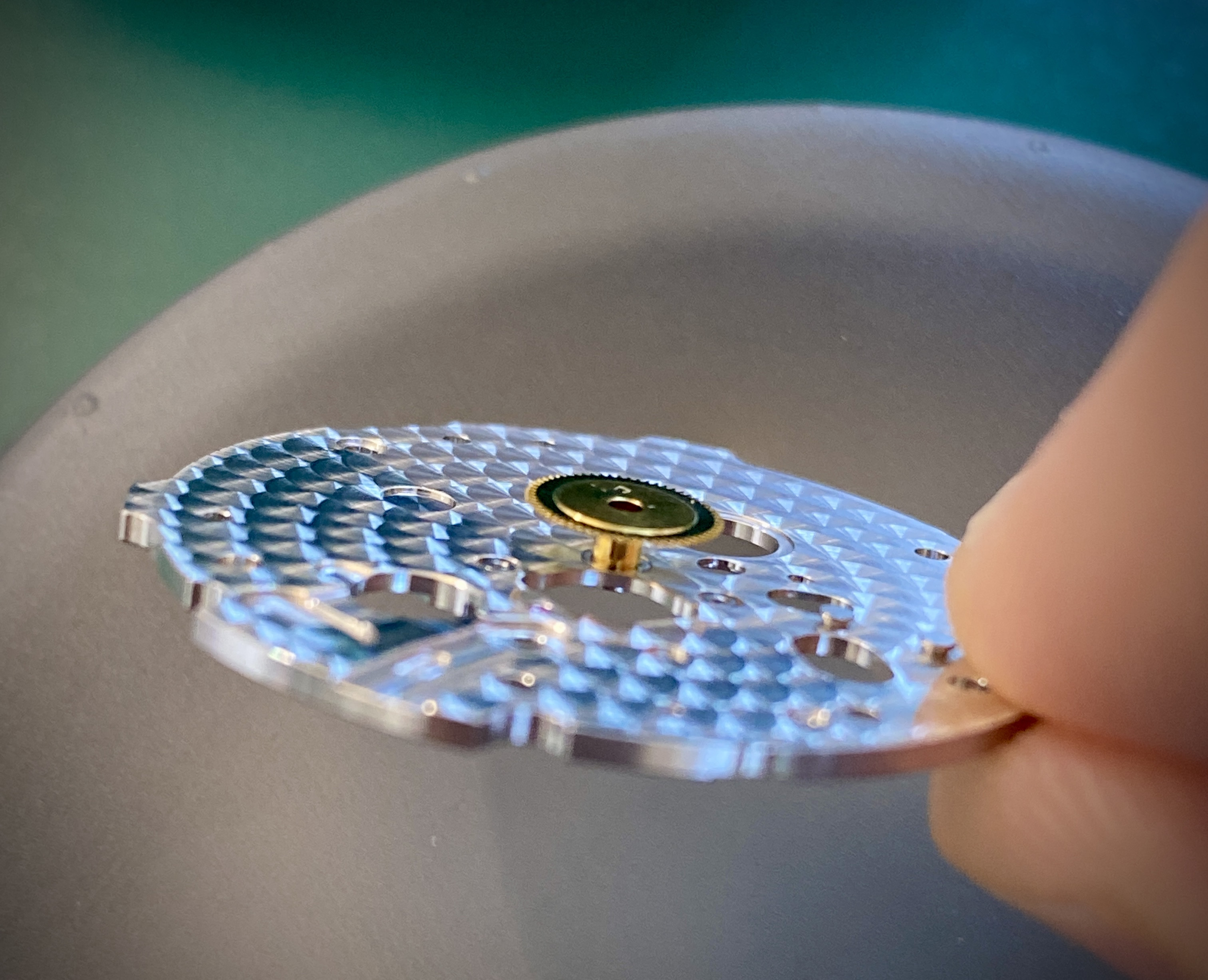

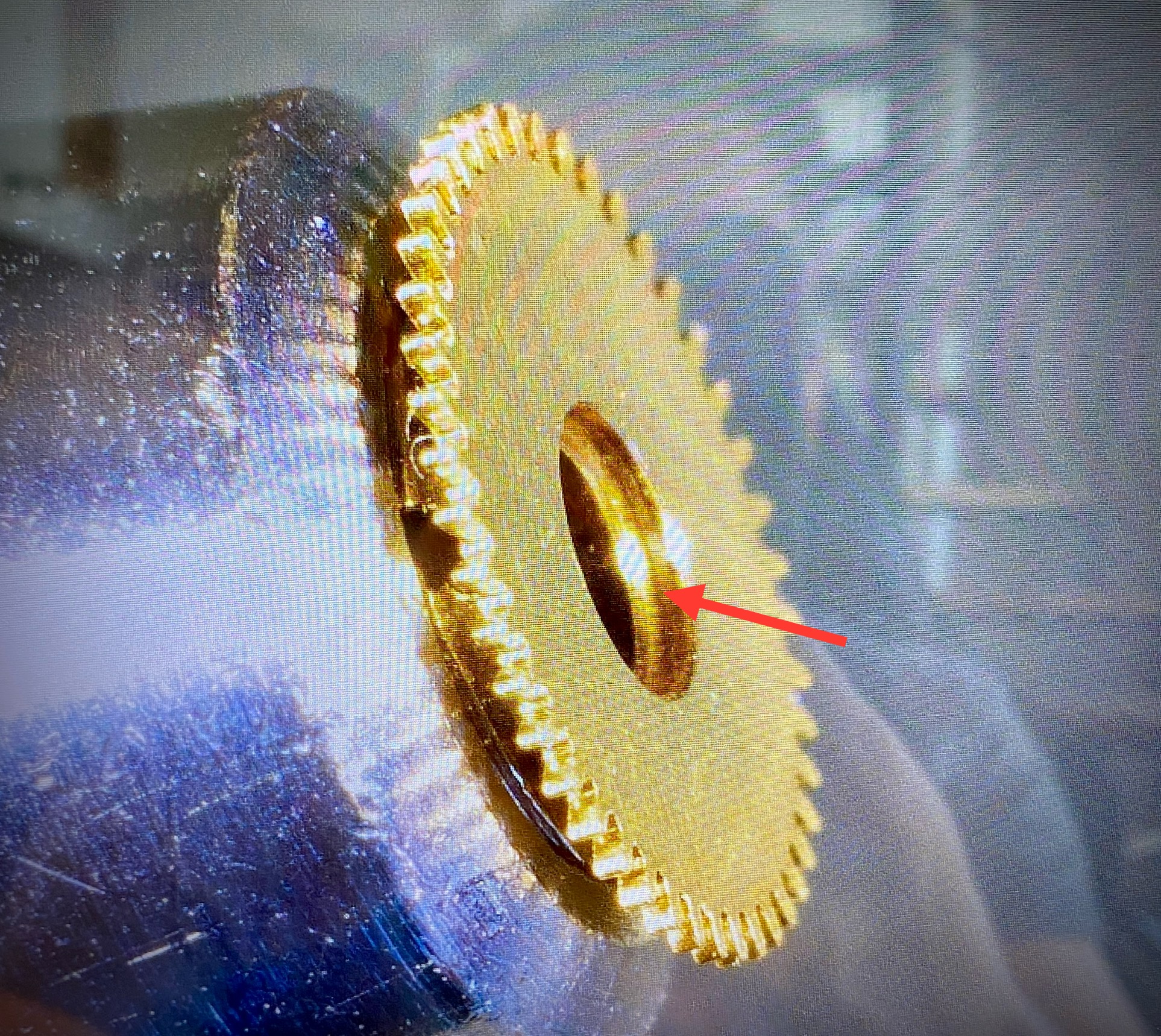

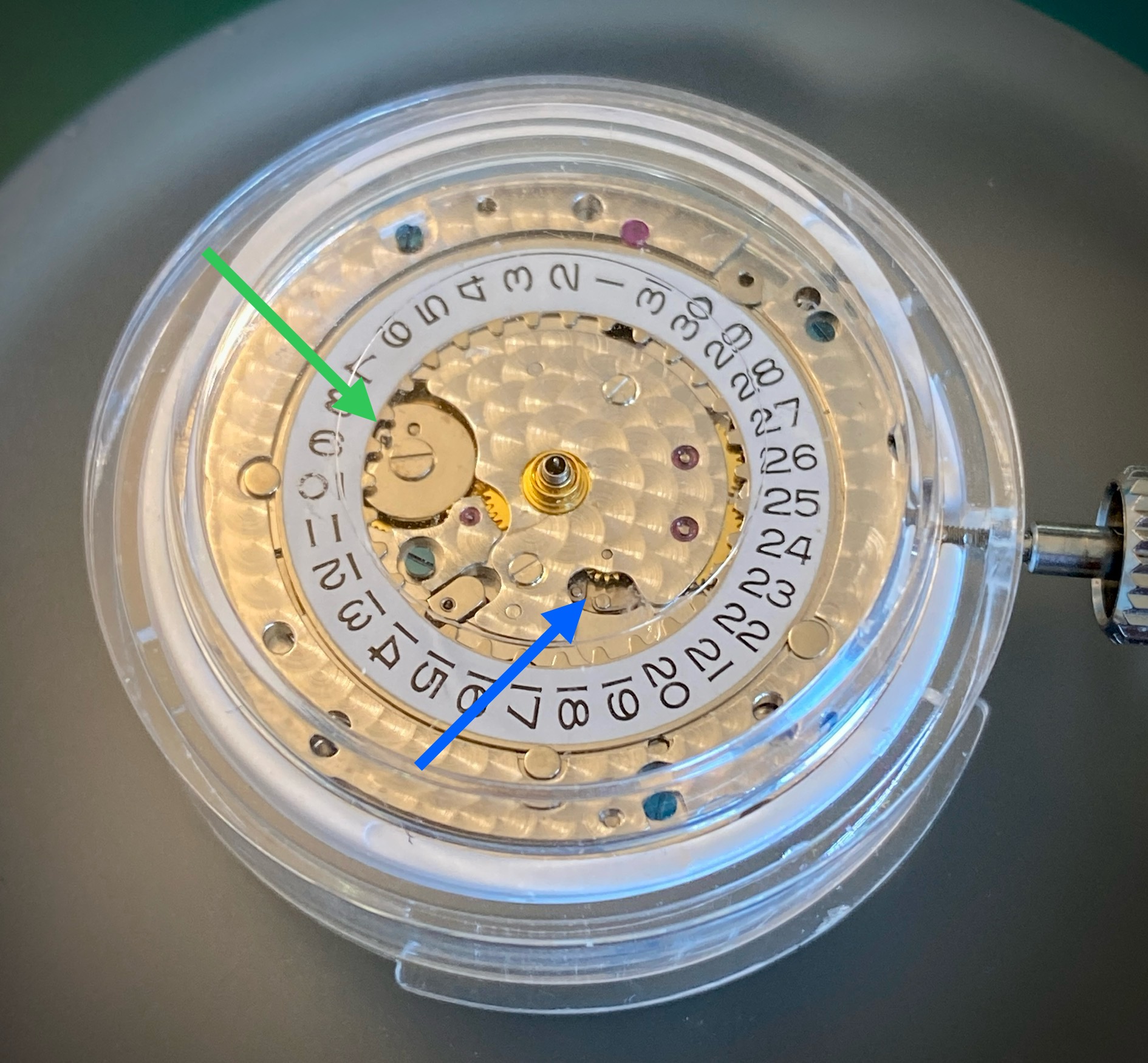

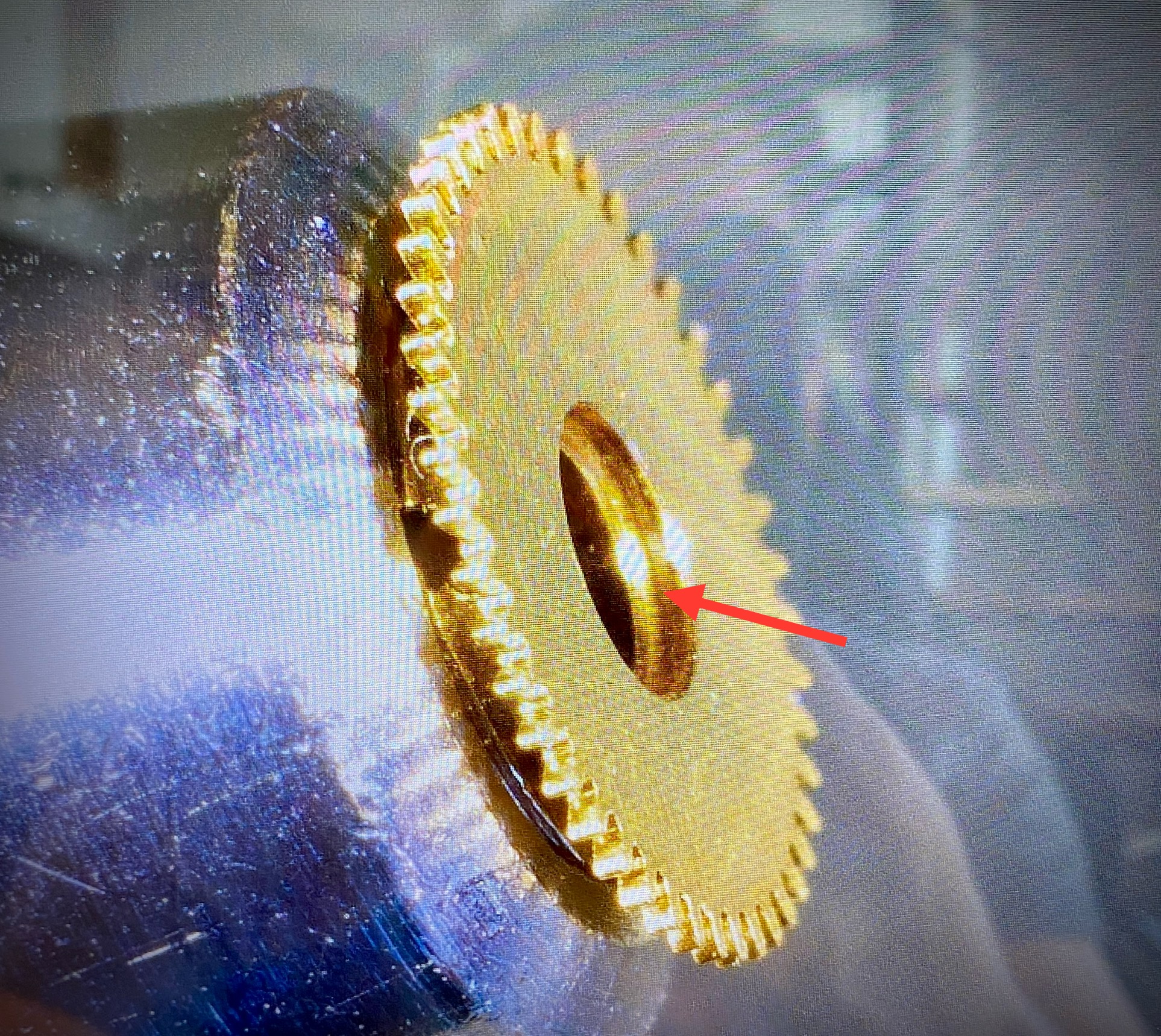

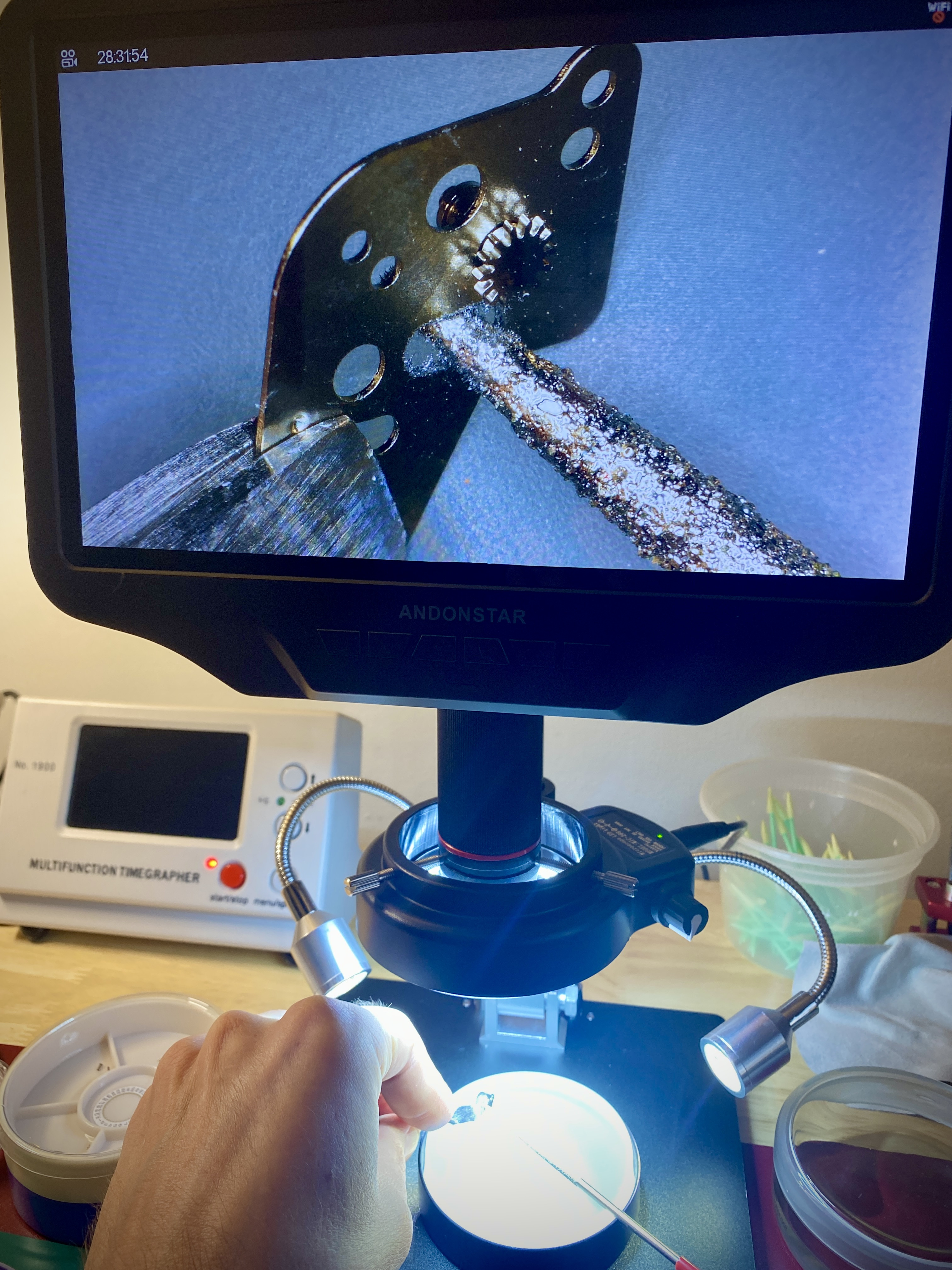

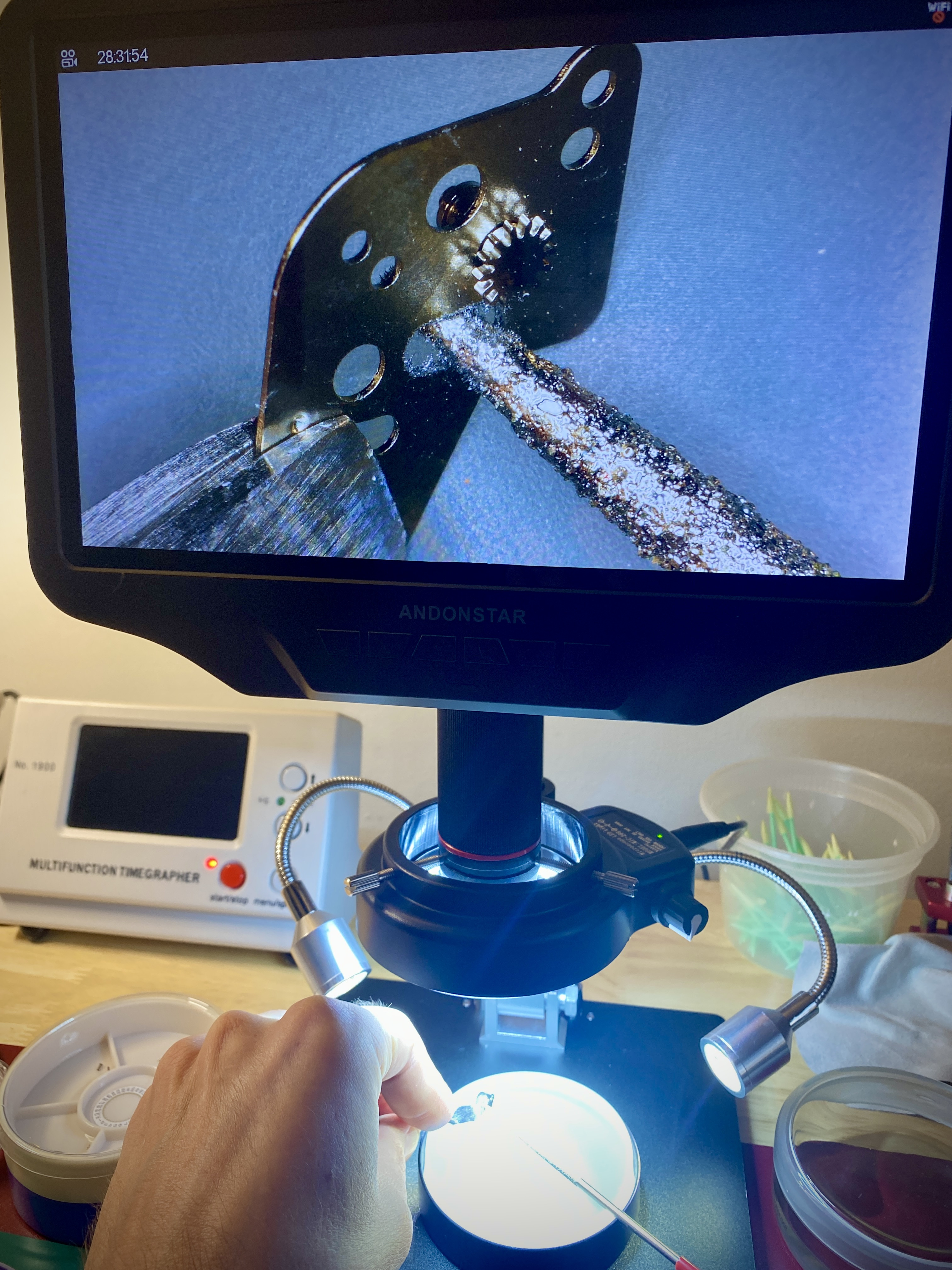

I had a fun reminder today about why Gen balances are so expensive (and good) compared to rep. I'm servicing a DD3285 (I mislabelled the pic VS3235 but it's exactly the same balance assembly) for @CTbeforeLP and he provided me with a gen balance complete to swap in. I couldn't resist having a look at the gen vs. rep balances under my microscope to see how different they are. It's clear that Rolex spares no expense when it comes to fine tuning the poise of their balance wheels. The Dandong balance has exactly one poise correction (I've never seen a rep balance with more than two). The number of corrections on the gen balance is crazy. Clearly Rolex cares deeply about getting an absolutely perfect distribution of mass on the balance wheel.

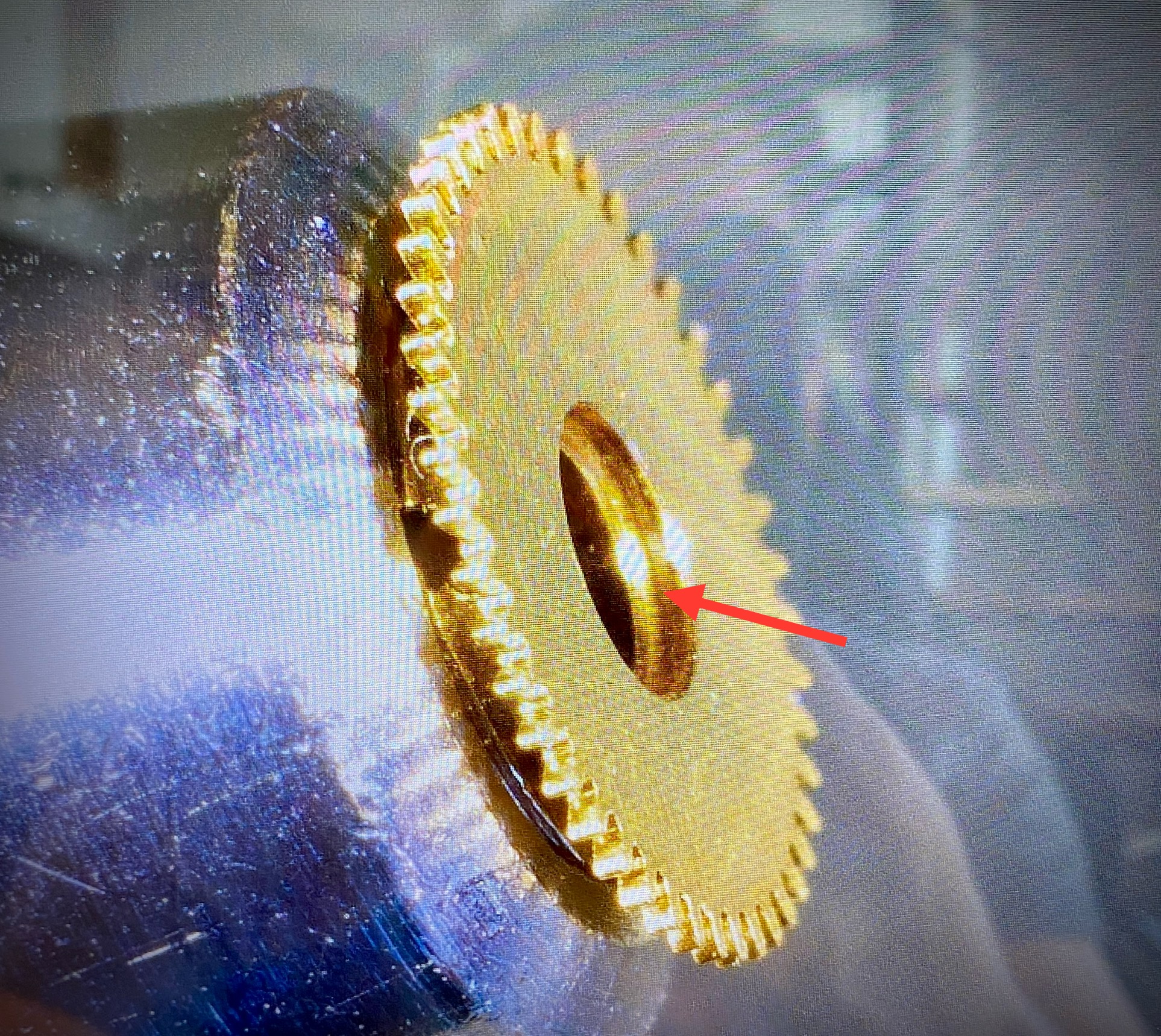

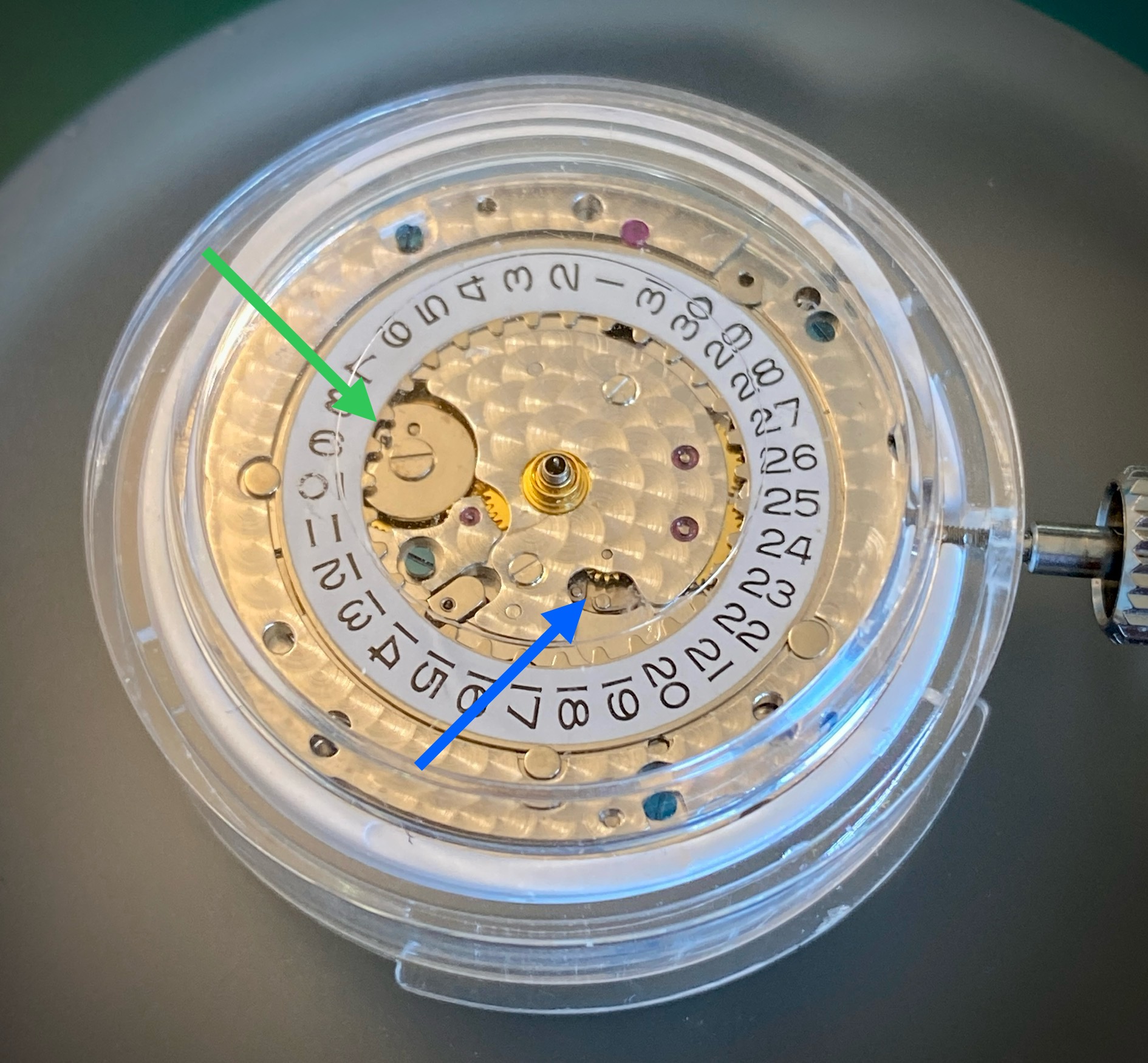

I had an interesting discovery today about the dd3285… the dd3285 24-hour wheel is not compatible with a gen dateplate. The gen dateplate hole is too small and the dd3285 24-hour wheel will fit through but get stuck and won’t spin.

Unfortunately the gen dateplate has a hardened steel bushing in the center hole so it’s not possible to use a broach to open up the hole.

Fortunately, the SH3285 24-hour wheel is a few microns smaller and does fit through the gen dateplate hole.

However, the magic doesn’t end there — neither the DD nor the SH 12-hour wheel is compatible with the gen dateplate. Both the SH and DD parts have an internal shoulder that’s not large enough of a diameter to float on the bushing of the gen dateplate.

Fortunately, I have a kludge of “3285” movement from AliExpress in my parts drawer… this thing has a 31xx style date finger and a 3285 style hour jumper.

I have no idea who makes this abomination, but it turns out it the 12-hour wheel is wide enough to work with the gen 3285 date plate’s bushing.

The fact that this unholy collection of parts can tick together this well is proof that the gods don’t know what we’re doing or are powerless to stop us.

Unfortunately the gen dateplate has a hardened steel bushing in the center hole so it’s not possible to use a broach to open up the hole.

Fortunately, the SH3285 24-hour wheel is a few microns smaller and does fit through the gen dateplate hole.

However, the magic doesn’t end there — neither the DD nor the SH 12-hour wheel is compatible with the gen dateplate. Both the SH and DD parts have an internal shoulder that’s not large enough of a diameter to float on the bushing of the gen dateplate.

Fortunately, I have a kludge of “3285” movement from AliExpress in my parts drawer… this thing has a 31xx style date finger and a 3285 style hour jumper.

I have no idea who makes this abomination, but it turns out it the 12-hour wheel is wide enough to work with the gen 3285 date plate’s bushing.

The fact that this unholy collection of parts can tick together this well is proof that the gods don’t know what we’re doing or are powerless to stop us.

Looking forward to this beauty. Thank you! The rep gods didn't want us to complete this, but they had no idea who they were dealing with 🫡.I had an interesting discovery today about the dd3285… the dd3285 24-hour wheel is not compatible with a gen dateplate. The gen dateplate hole is too small and the dd3285 24-hour wheel will fit through but get stuck and won’t spin.

Unfortunately the gen dateplate has a hardened steel bushing in the center hole so it’s not possible to use a broach to open up the hole.

Fortunately, the SH3285 24-hour wheel is a few microns smaller and does fit through the gen dateplate hole.

However, the magic doesn’t end there — neither the DD nor the SH 12-hour wheel is compatible with the gen dateplate. Both the SH and DD parts have an internal shoulder that’s not large enough of a diameter to float on the bushing of the gen dateplate.

Fortunately, I have a kludge of “3285” movement from AliExpress in my parts drawer… this thing has a 31xx style date finger and a 3285 style hour jumper.

I have no idea who makes this abomination, but it turns out it the 12-hour wheel is wide enough to work with the gen 3285 date plate’s bushing.

The fact that this unholy collection of parts can tick together this well is proof that the gods don’t know what we’re doing or are powerless to stop us.

Does the DD4131 have a uni-directional automatic rotor lile the SL-4801 movement or a bi-directional rotation like gen and SH? Does it have a full ring of ball bearings? And what do you think about its balance complete system compared to SH4131? Do you think DD4131 is superior?

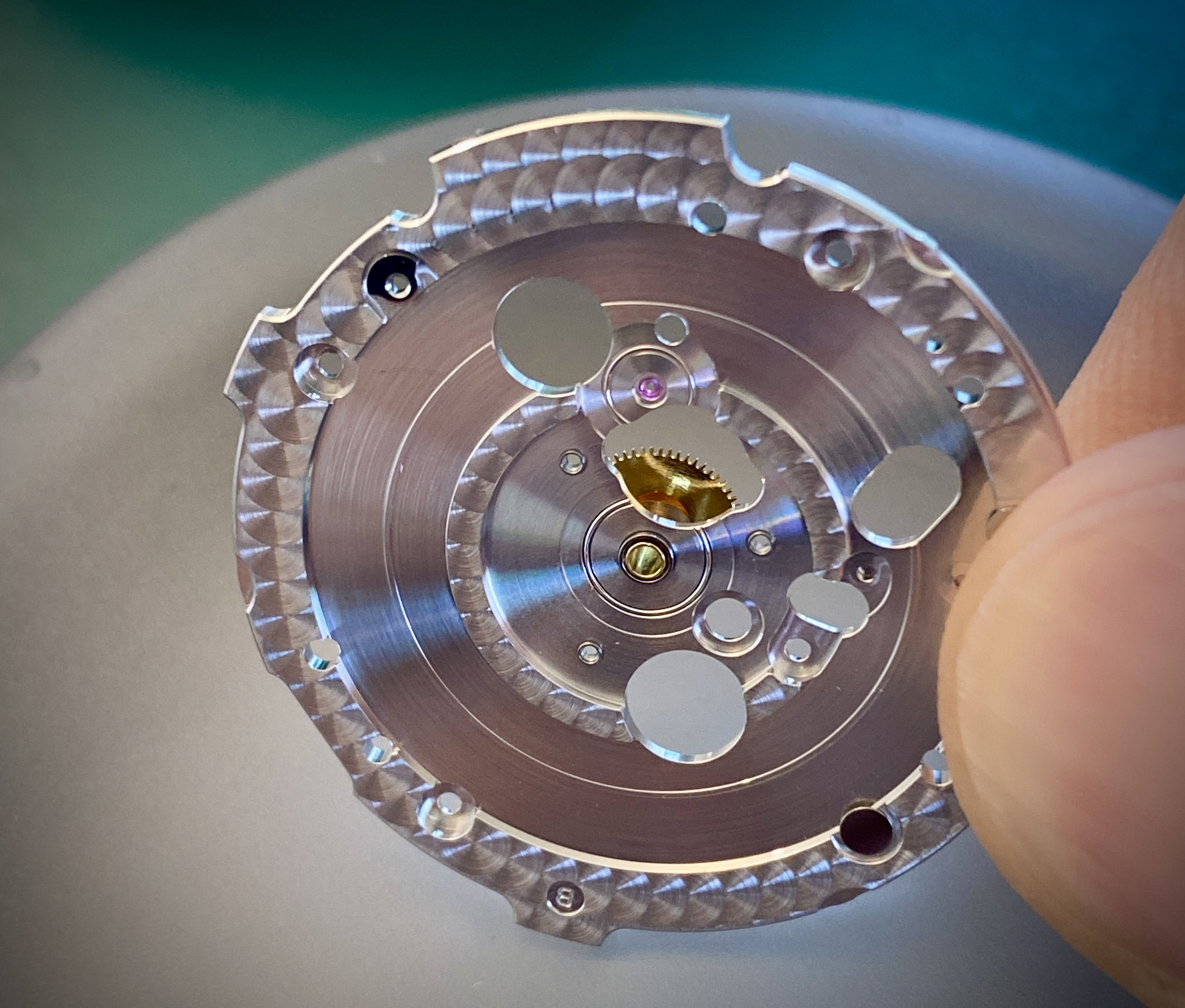

The DD4131 has a bi-directional winding rotor. The rotor has a full ring of ball bearings. I think the balance system on the DD version is superior to the SH.Does the DD4131 have a uni-directional automatic rotor lile the SL-4801 movement or a bi-directional rotation like gen and SH? Does it have a full ring of ball bearings? And what do you think about its balance complete system compared to SH4131? Do you think DD4131 is superior?

I had some fun today building a hybrid vs3186 movement following @WatchSmith.US guide here:

forum.replica-watch.info

forum.replica-watch.info

It’s actually quite an easy hybrid to build. The only complication is having to broach the center bushing on the VS mainplate to allow the minute pinion / cannon pinion from the VR movement to fit the VS mainplate.

The only thing I’ve noticed is that getting the crown into the middle hour-jumping position is quite finicky. It feels like the middle keyless position is shallow and not reassuringly definitive when you pull the crown outwards.

Franken VR3186 recommends

Hey guys, I just bought a CF gmt pepsi with the VR3186 movement and I'm looking to add gen parts to the movement beyond the cosmetics parts outside. I've done alot of research and can't seem to find what gen parts will and won't work with the VR3186. Since it has the new version balance bridge...

It’s actually quite an easy hybrid to build. The only complication is having to broach the center bushing on the VS mainplate to allow the minute pinion / cannon pinion from the VR movement to fit the VS mainplate.

The only thing I’ve noticed is that getting the crown into the middle hour-jumping position is quite finicky. It feels like the middle keyless position is shallow and not reassuringly definitive when you pull the crown outwards.

I ended up having to open up the slot in the keyless works cover ever so slightly to get the crown action to be able to find the middle position smoothly. The problem was that the VR keyless works cover slot is smaller than the VS slot. I used a Diamond file to open the slot at the one end by a few tenths of a millimeter and now the crown action easily finds the middle hour-jumping position.

May I ask out of interest, do you do all of your movement work using the set up in the pic here or do you use a loupe most of the time? I've only ever used a loupe but this looks way easier... am I wrong?I ended up having to open up the slot in the keyless works cover ever so slightly to get the crown action to be able to find the middle position smoothly. The problem was that the VR keyless works cover slot is smaller than the VS slot. I used a Diamond file to open the slot at the one end by a few tenths of a millimeter and now the crown action easily finds the middle hour-jumping position.

I’d say I use the digital microscope for 99% of the work that requires magnification. I wear +2 reading glasses for general bench work like watch assembly. I don’t need reading glasses to read, but the magnification helps when I’m working on watches. The only time I use a loupe is when doing things like jewel setting or staking when it’s awkward to get the jeweling tool or staking set under the microscope at a useful angle.May I ask out of interest, do you do all of your movement work using the set up in the pic here or do you use a loupe most of the time? I've only ever used a loupe but this looks way easier... am I wrong?

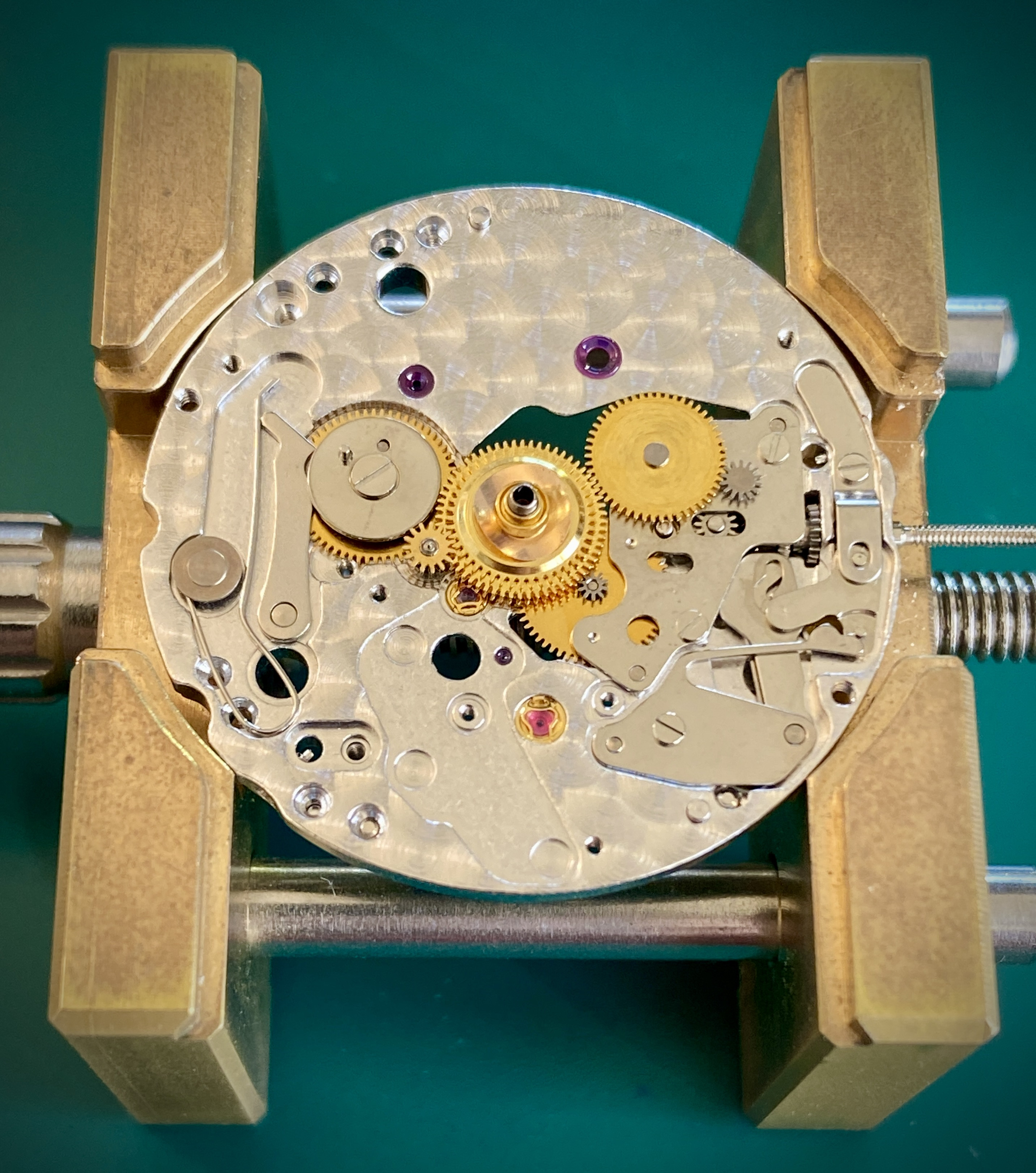

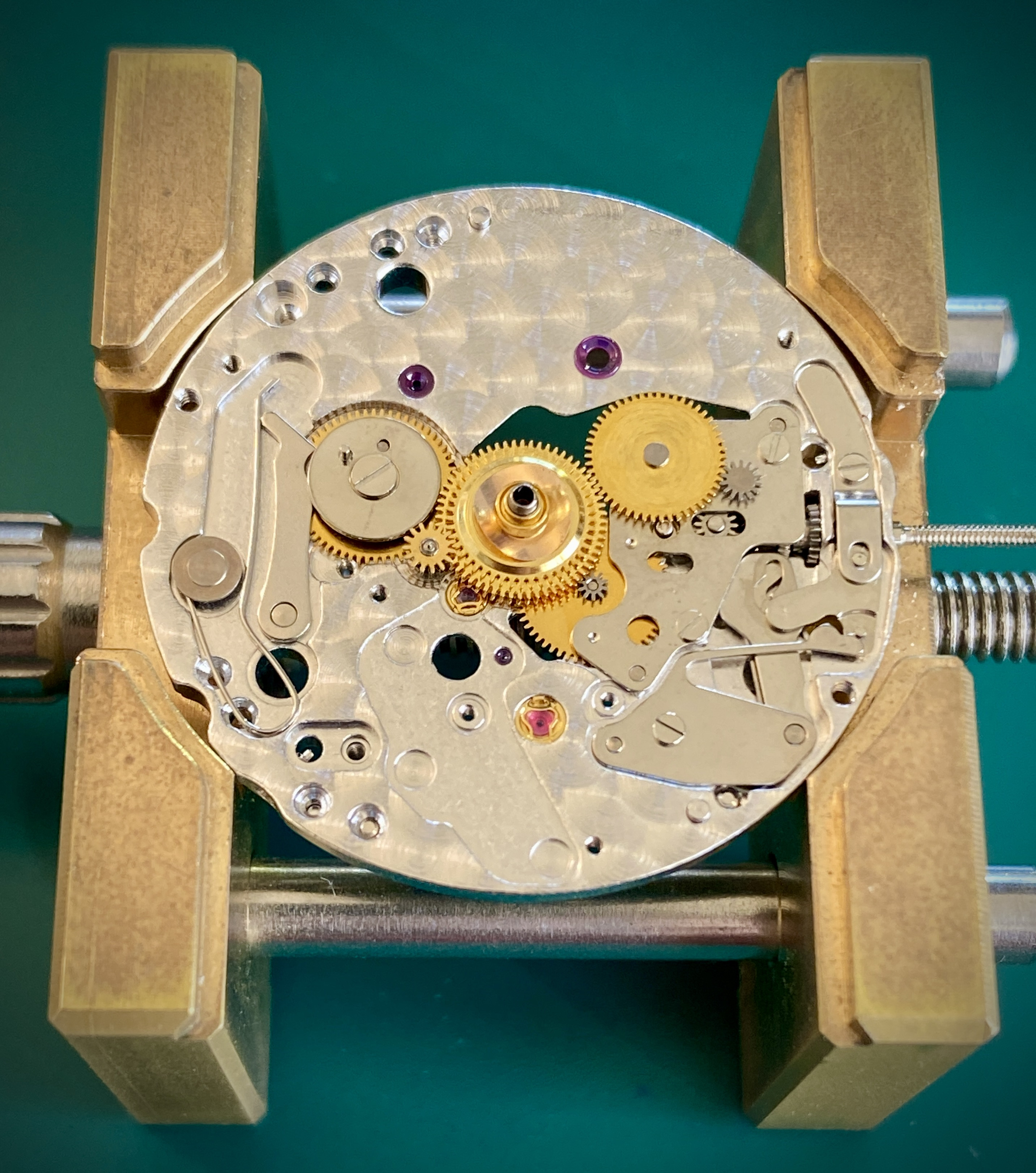

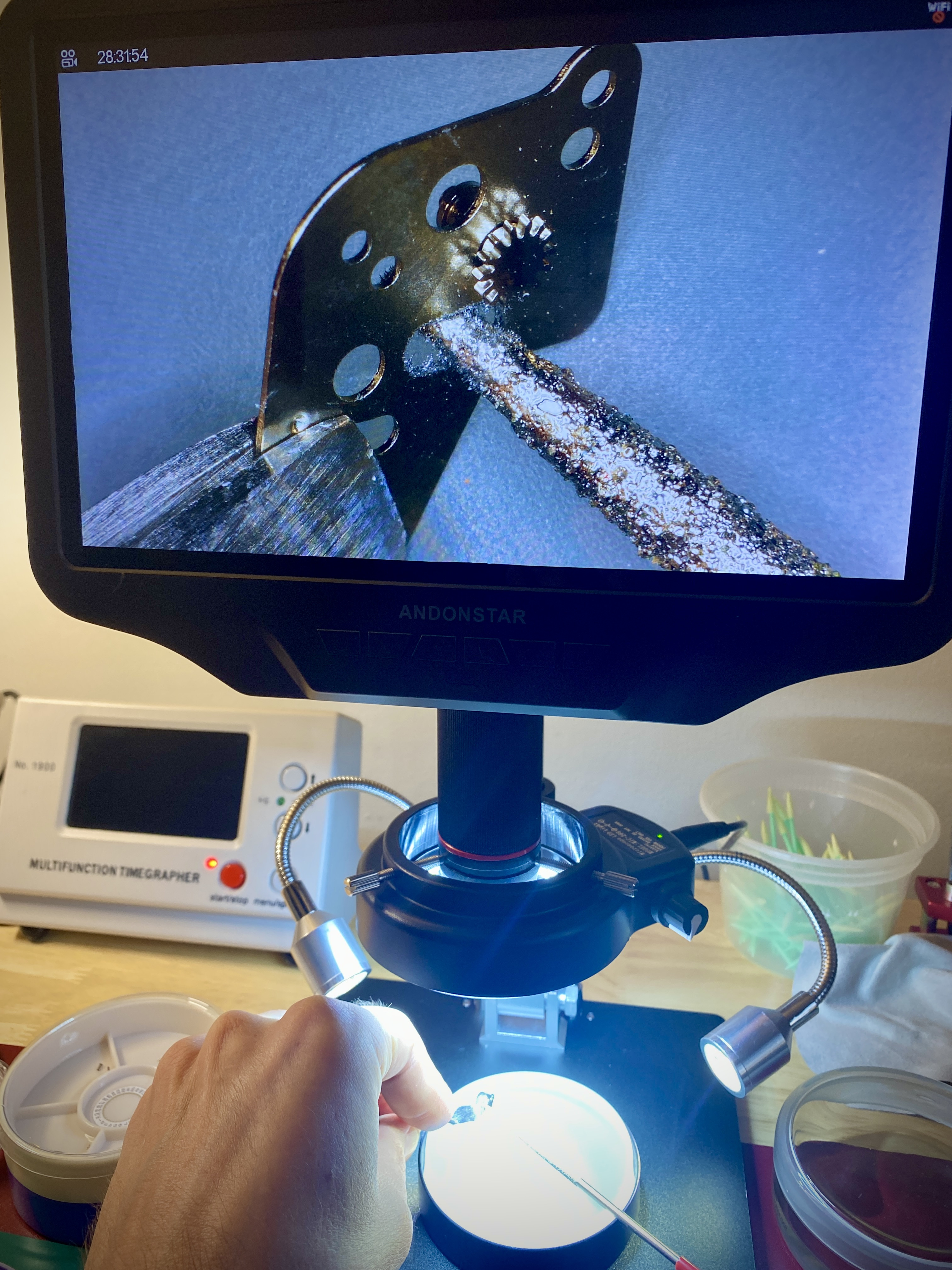

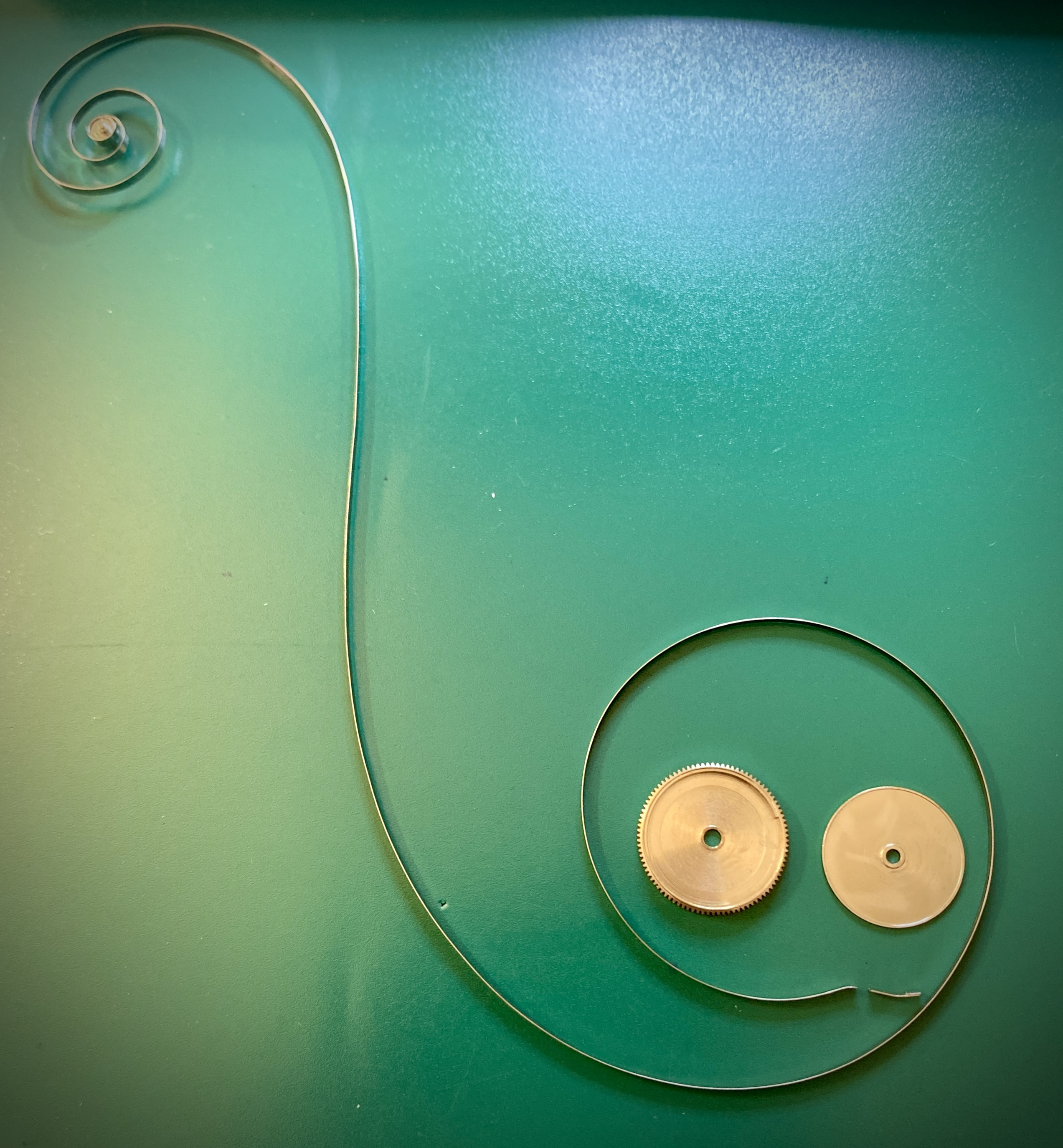

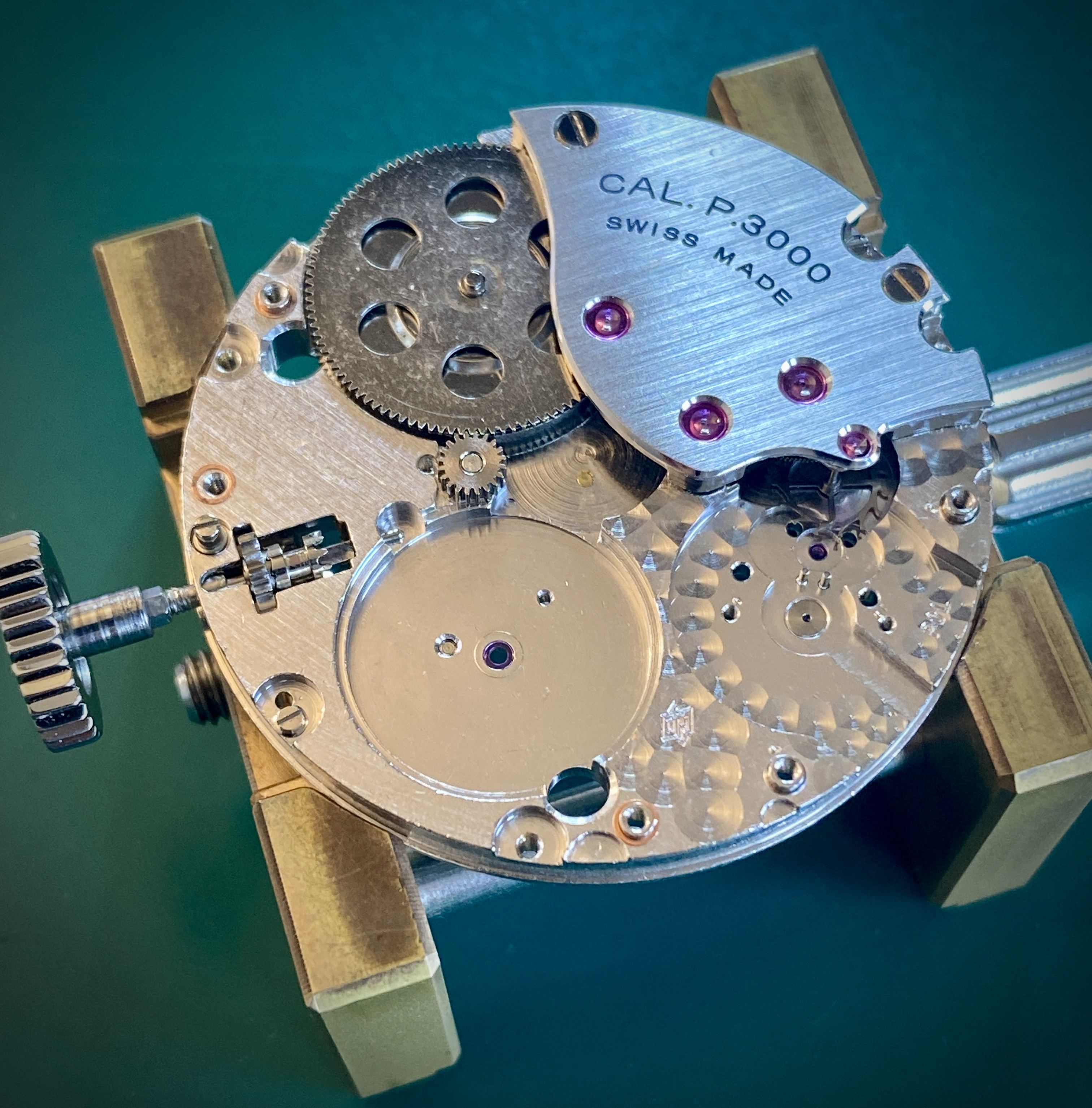

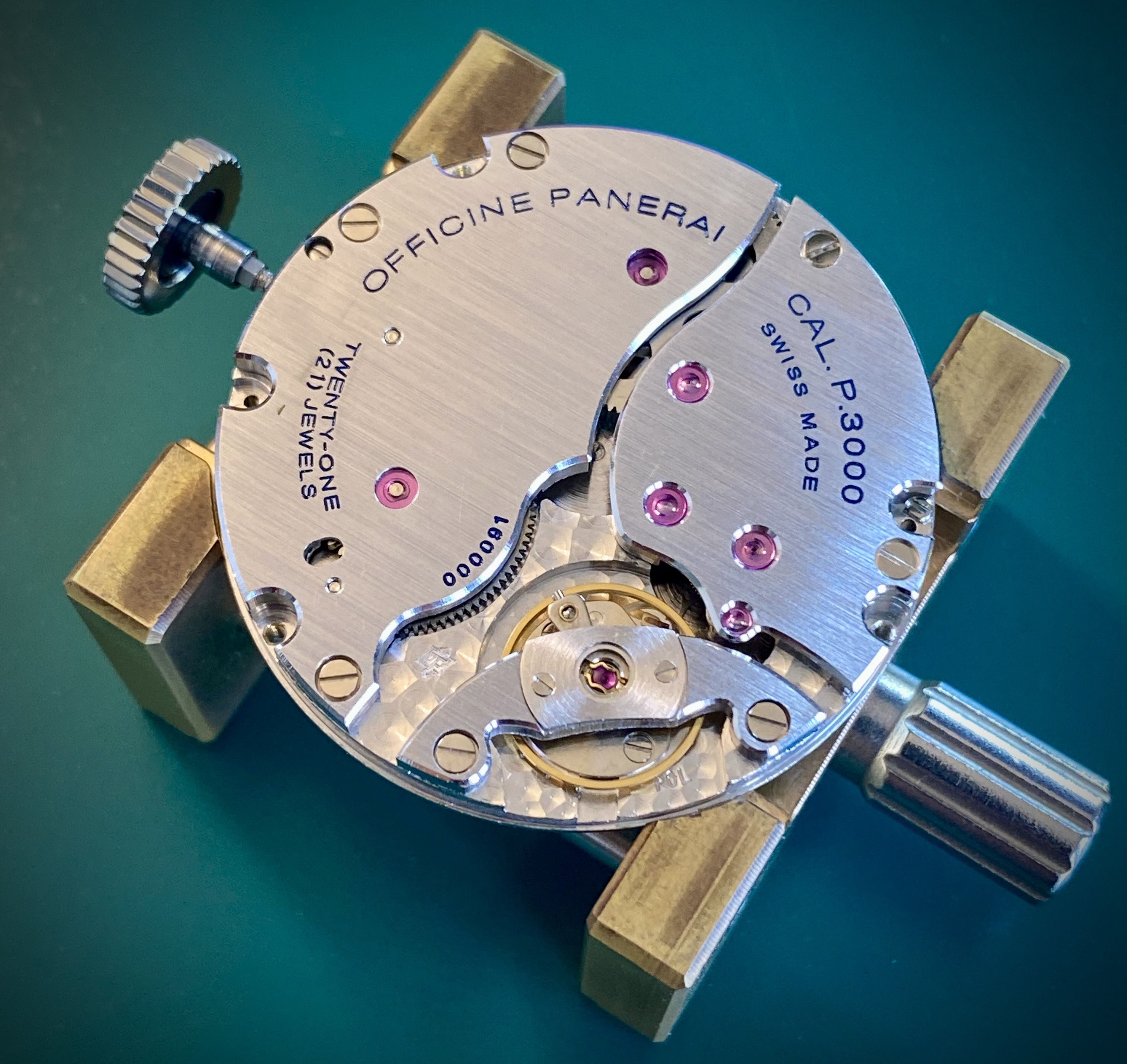

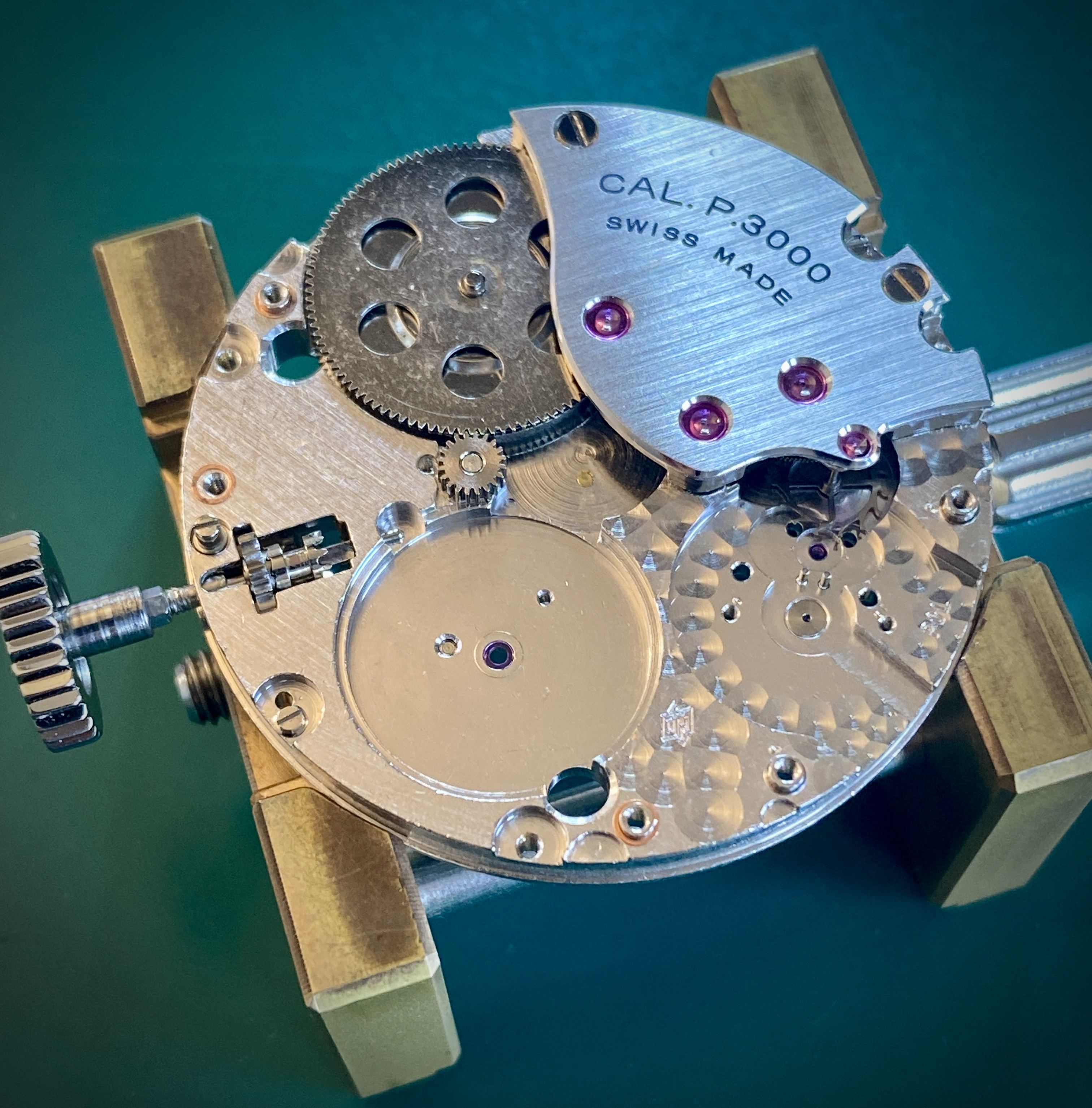

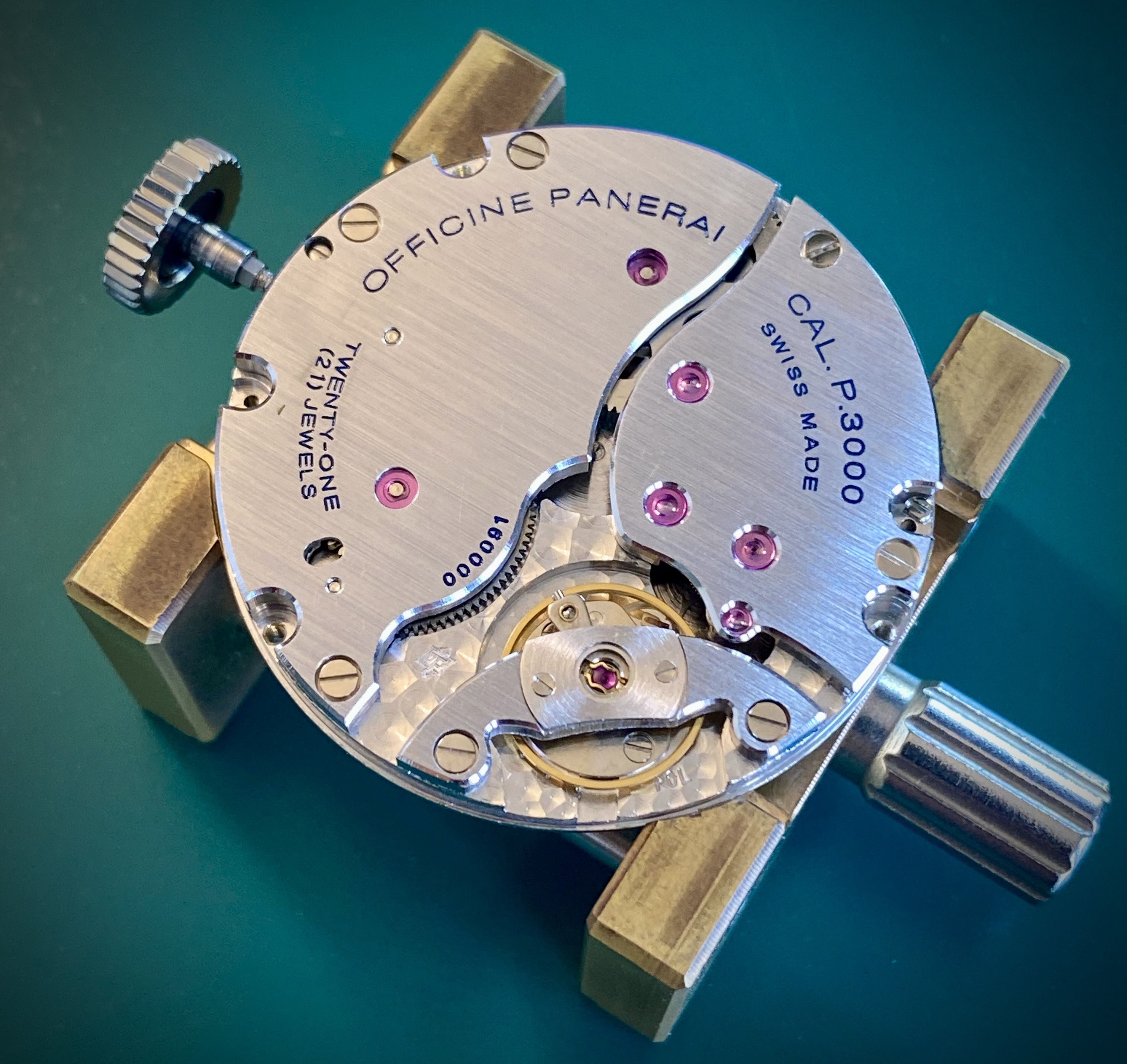

I’ve been working on a clone Panerai P.3000 movement recently. This is a movement that is kinda like the friendly Unitas 6497-2 but is actually quite a different beast. For starters it has two mainspring barrels:

But other than a double mainspring there are no complications at all.

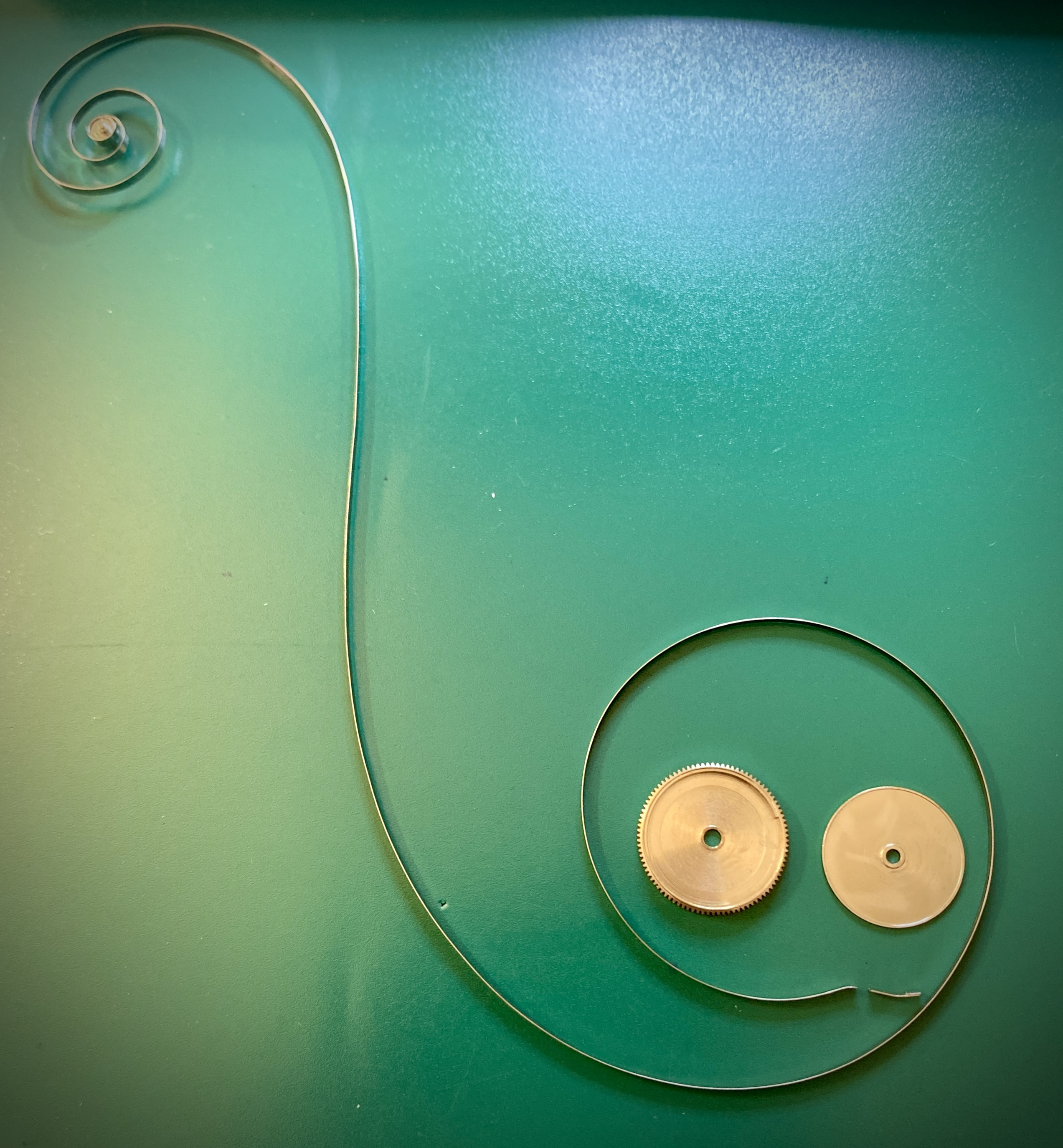

Unfortunately on this movement one of the mainsprings had broken.

I took some measurements of the thickness, height, and length and ordered what I hoped would be a suitable replacement from

OFrei.

In the mean time I took everything else apart and cleaned all the parts first by hand and then in my machine.

When the new mainspring arrived it seemed to fit in the barrel and on the arbor so I’d call that a win.

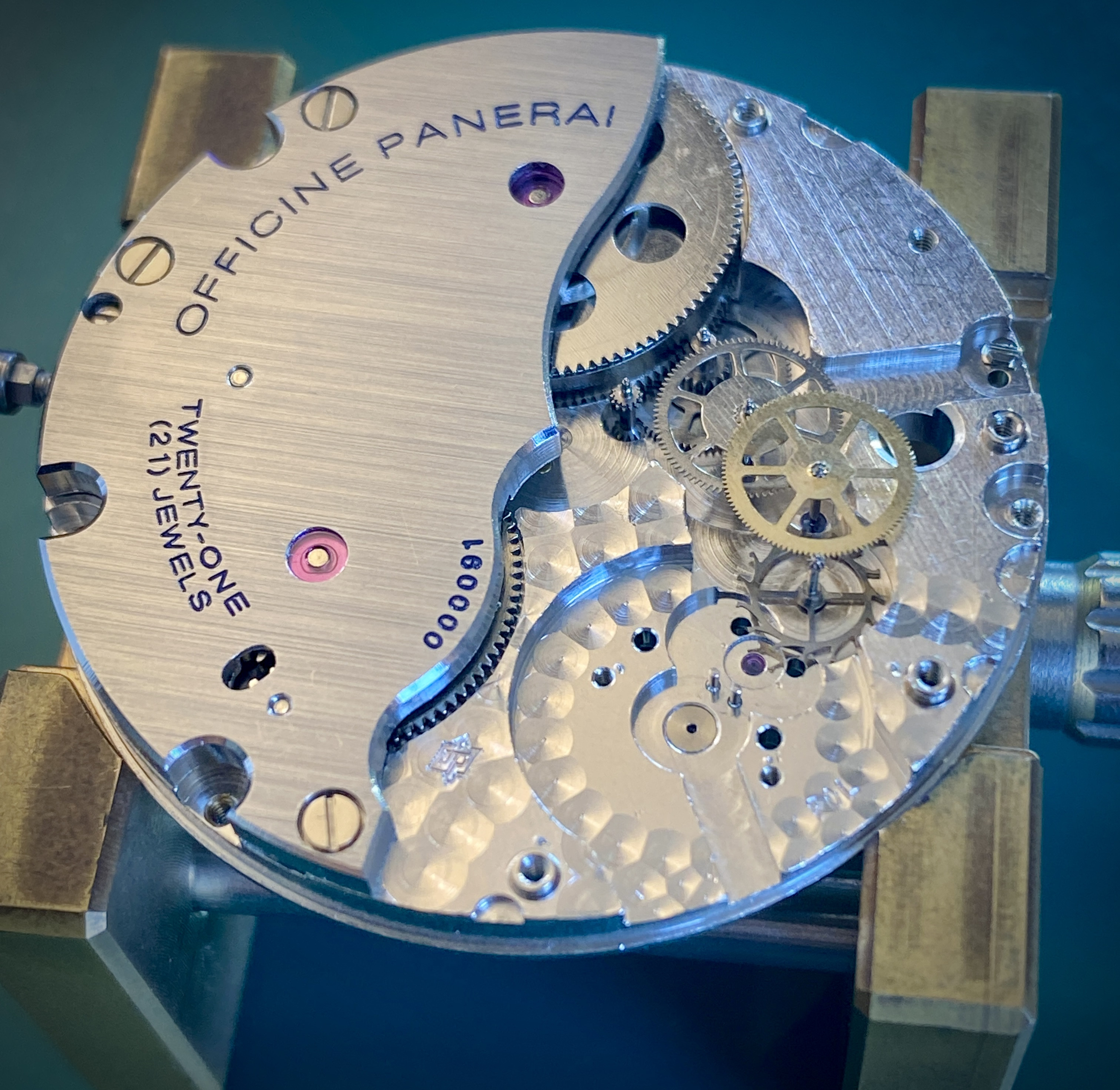

The only other tricky part of servicing this movement is getting the train bridge back on. Most of the train wheels have very long arbors and stand on tiny pivots.

Initially I’d reassembled the dial side and the double mainsprings with their bridge on the balance side, but I found that with the mainspring bridge in place it was incredibly hard to access the underside of the train bridge with tweezers to align the train wheels when I was trying to get the train bridge on. Similarly, having the dial side assembled meant that there was an extra set of teeth for the long tall motion transfer pinion to mesh with. (I’m not sure if “motion transfer pinion” is the right name but on this movement there an intermediate wheel between the second wheel and the minute pinion on the dial side — this intermediate wheel is a tall arbor with a pinion on it that constantly wants to fall over).

I was eventually able to make everything line up, then got the barrel bridge back on and installed the pallet fork and balance. The movement is ticking nicely now.

This was a fun movement but I have a new appreciation for the ease of installing 2824, 3135, and 3235 train bridges now.

But other than a double mainspring there are no complications at all.

Unfortunately on this movement one of the mainsprings had broken.

I took some measurements of the thickness, height, and length and ordered what I hoped would be a suitable replacement from

OFrei.

In the mean time I took everything else apart and cleaned all the parts first by hand and then in my machine.

When the new mainspring arrived it seemed to fit in the barrel and on the arbor so I’d call that a win.

The only other tricky part of servicing this movement is getting the train bridge back on. Most of the train wheels have very long arbors and stand on tiny pivots.

Initially I’d reassembled the dial side and the double mainsprings with their bridge on the balance side, but I found that with the mainspring bridge in place it was incredibly hard to access the underside of the train bridge with tweezers to align the train wheels when I was trying to get the train bridge on. Similarly, having the dial side assembled meant that there was an extra set of teeth for the long tall motion transfer pinion to mesh with. (I’m not sure if “motion transfer pinion” is the right name but on this movement there an intermediate wheel between the second wheel and the minute pinion on the dial side — this intermediate wheel is a tall arbor with a pinion on it that constantly wants to fall over).

I was eventually able to make everything line up, then got the barrel bridge back on and installed the pallet fork and balance. The movement is ticking nicely now.

This was a fun movement but I have a new appreciation for the ease of installing 2824, 3135, and 3235 train bridges now.

This thread is fantastic. I'm learning quite a bit. Thanks, @dogwood !

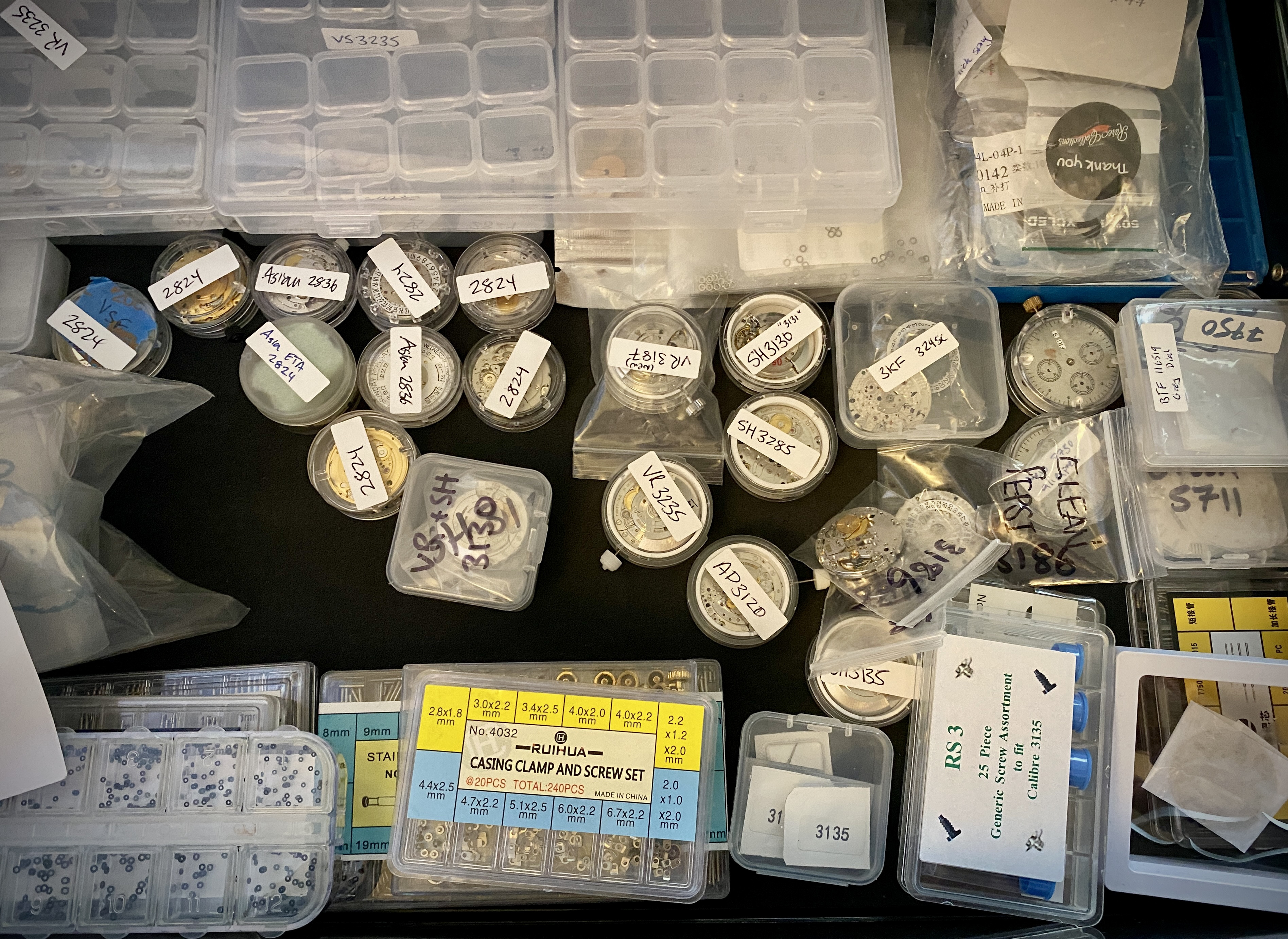

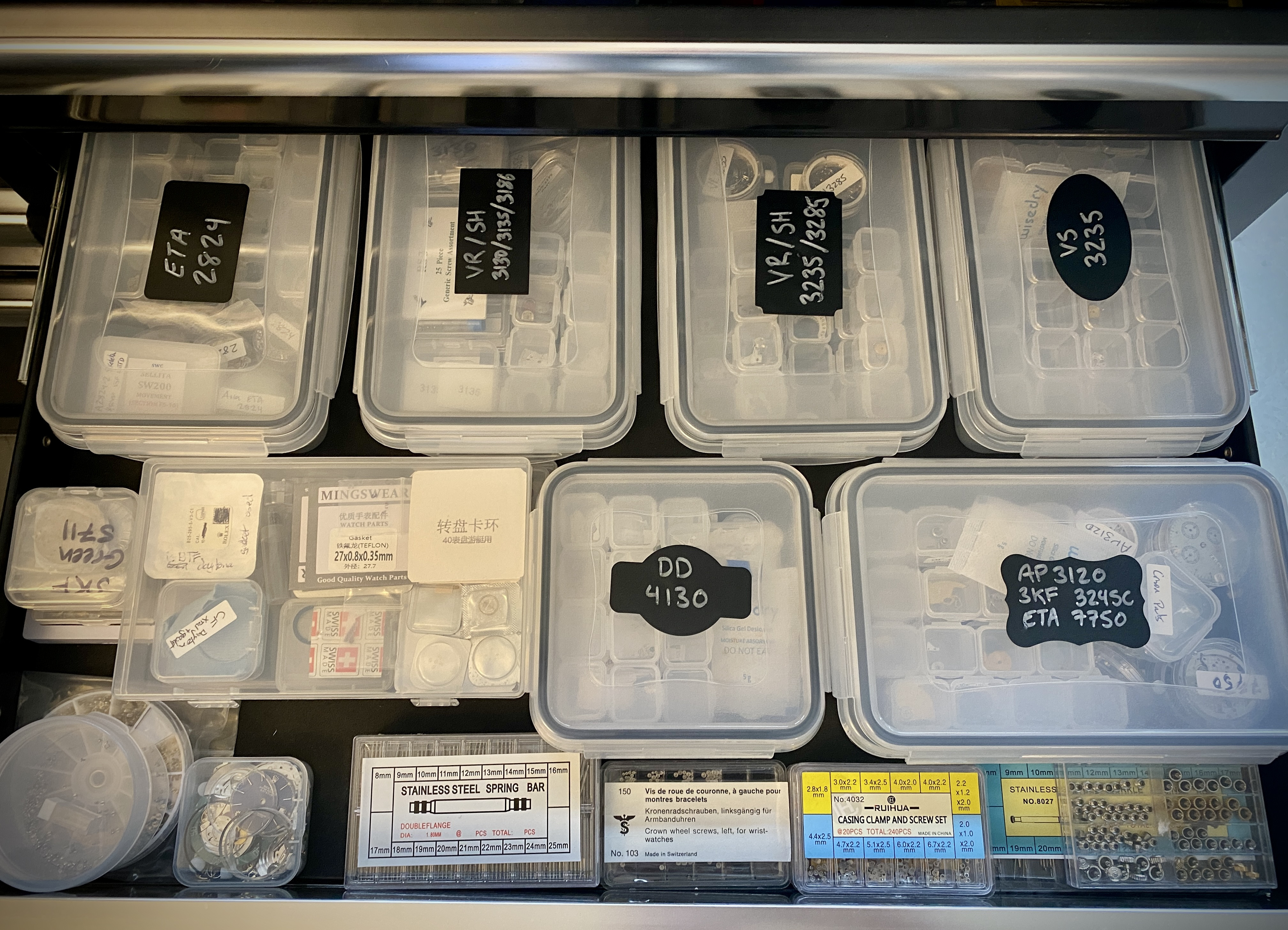

Amazing collection of parts here. Have you found any generic cheap screw set that works well with the rolex clone movements or do we have to splurge for the expensive perrin set?After yesterday’s tool improvement / maintenance, I decided it was time to clean up my parts drawer.

Which things were generally well labeled, they weren’t that organized. Also, I live in Vancouver which has long damp winters. I figured it would be a good idea to store my spare parts / movements in air tight containers with a desiccant to ward off moisture and corrosion.

The rubber gasket on the lids of these containers makes a nice seal. Hopefully this will prevent any issues. And as a benefit, things are more organized now.

I haven’t. It’s almost worth buying broken rep movements to start building a collection of spares including screws.Amazing collection of parts here. Have you found any generic cheap screw set that works well with the rolex clone movements or do we have to splurge for the expensive perrin set?

Yeah, that's what I gathered as well. Thanks!I haven’t. It’s almost worth buying broken rep movements to start building a collection of spares including screws.

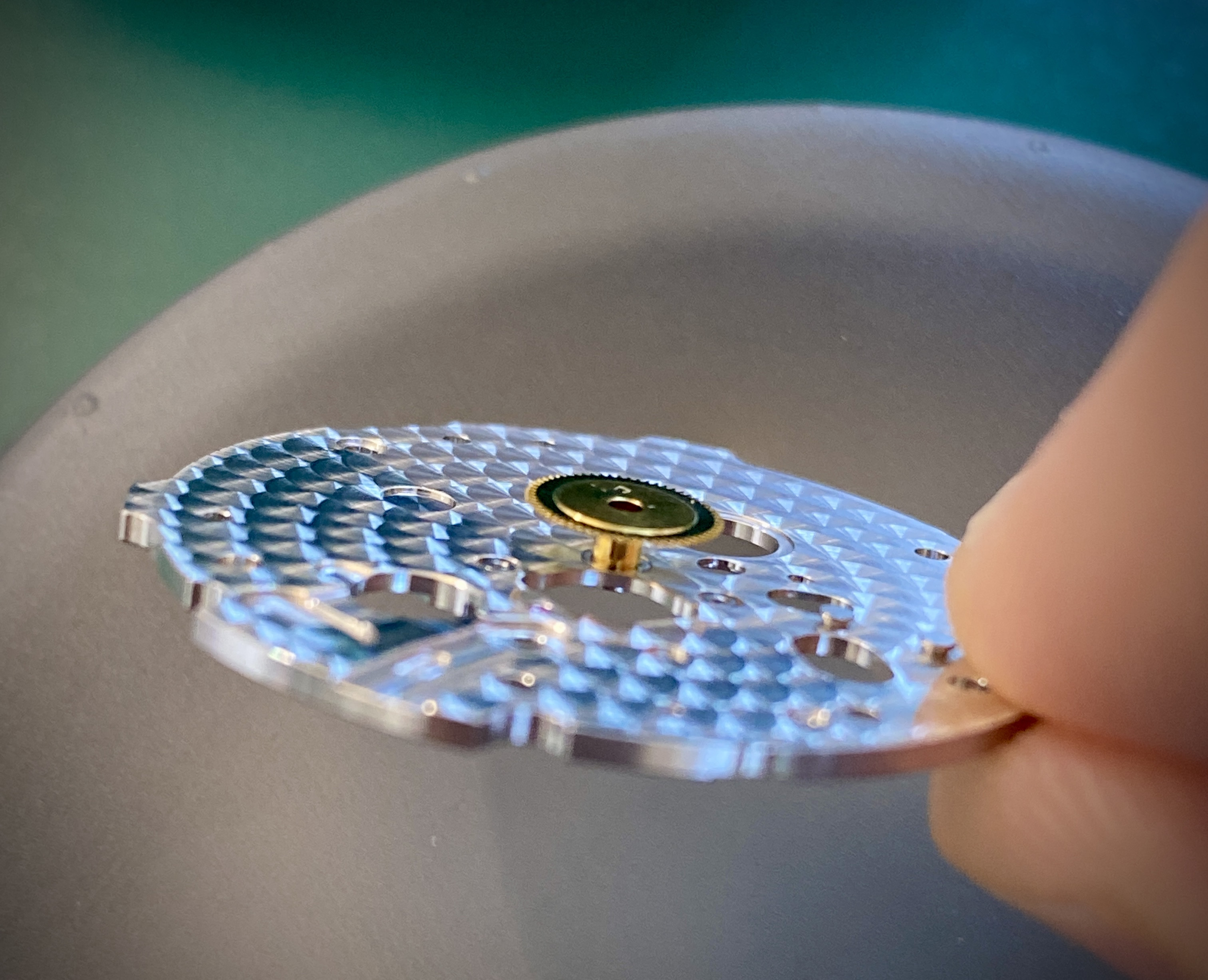

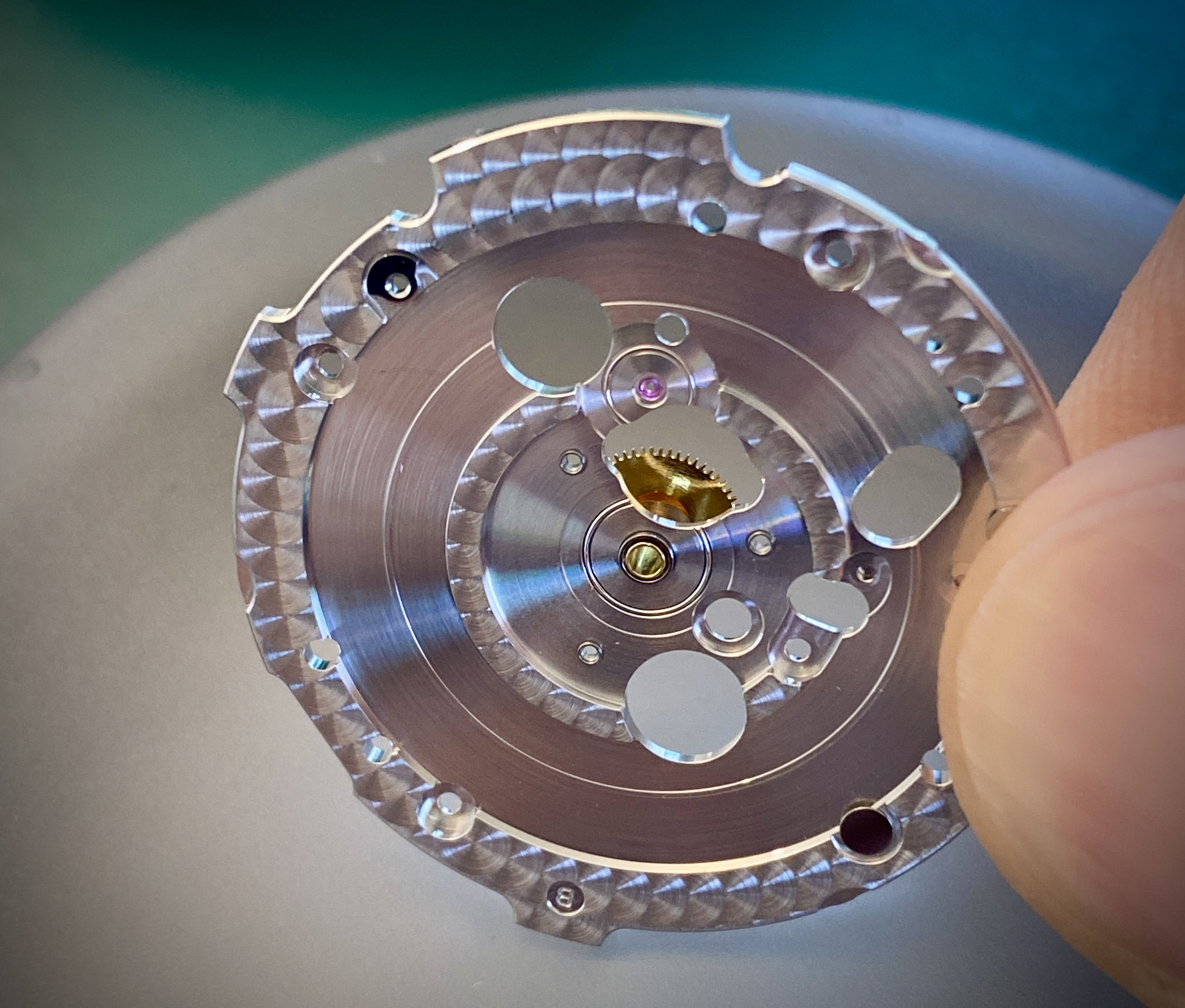

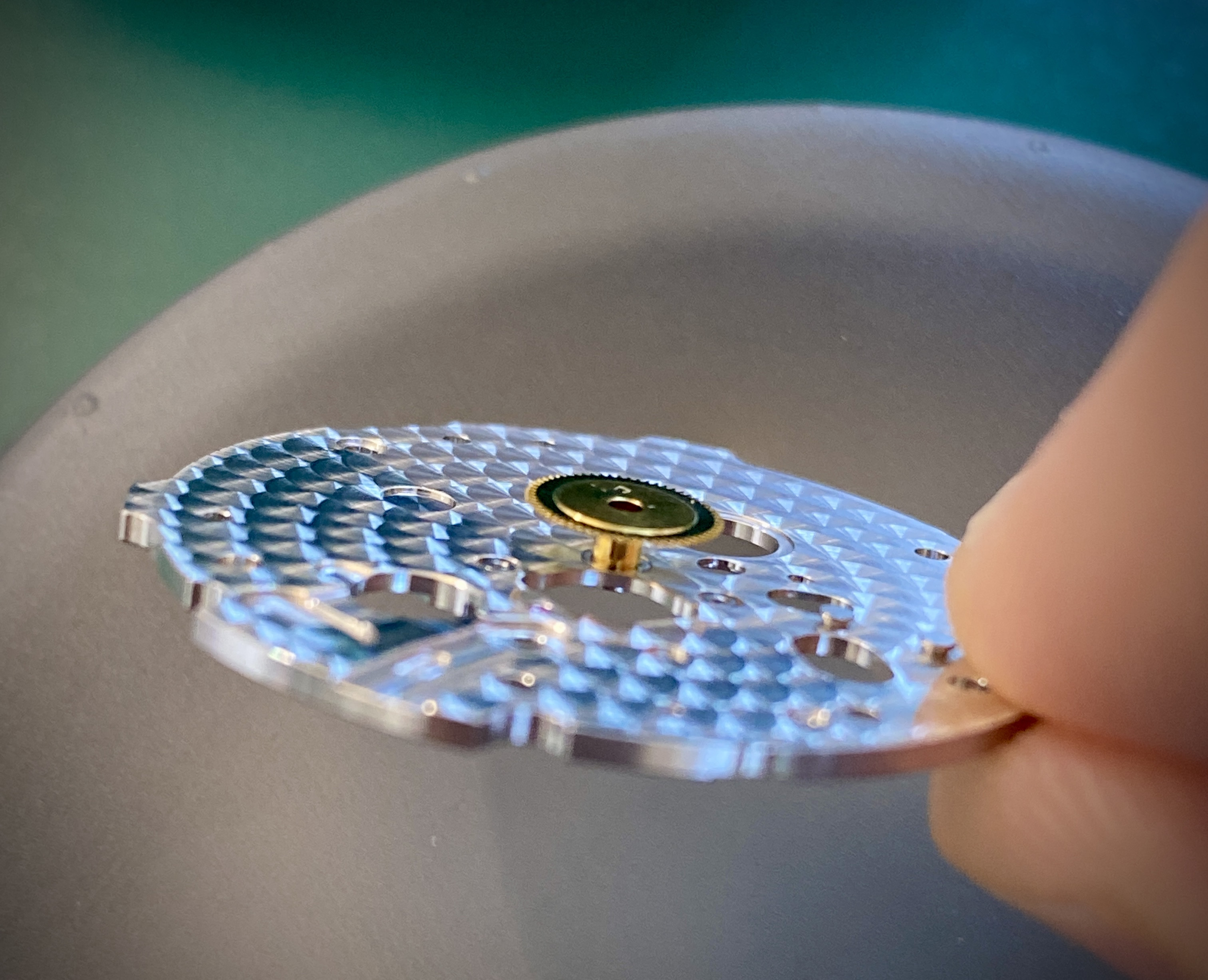

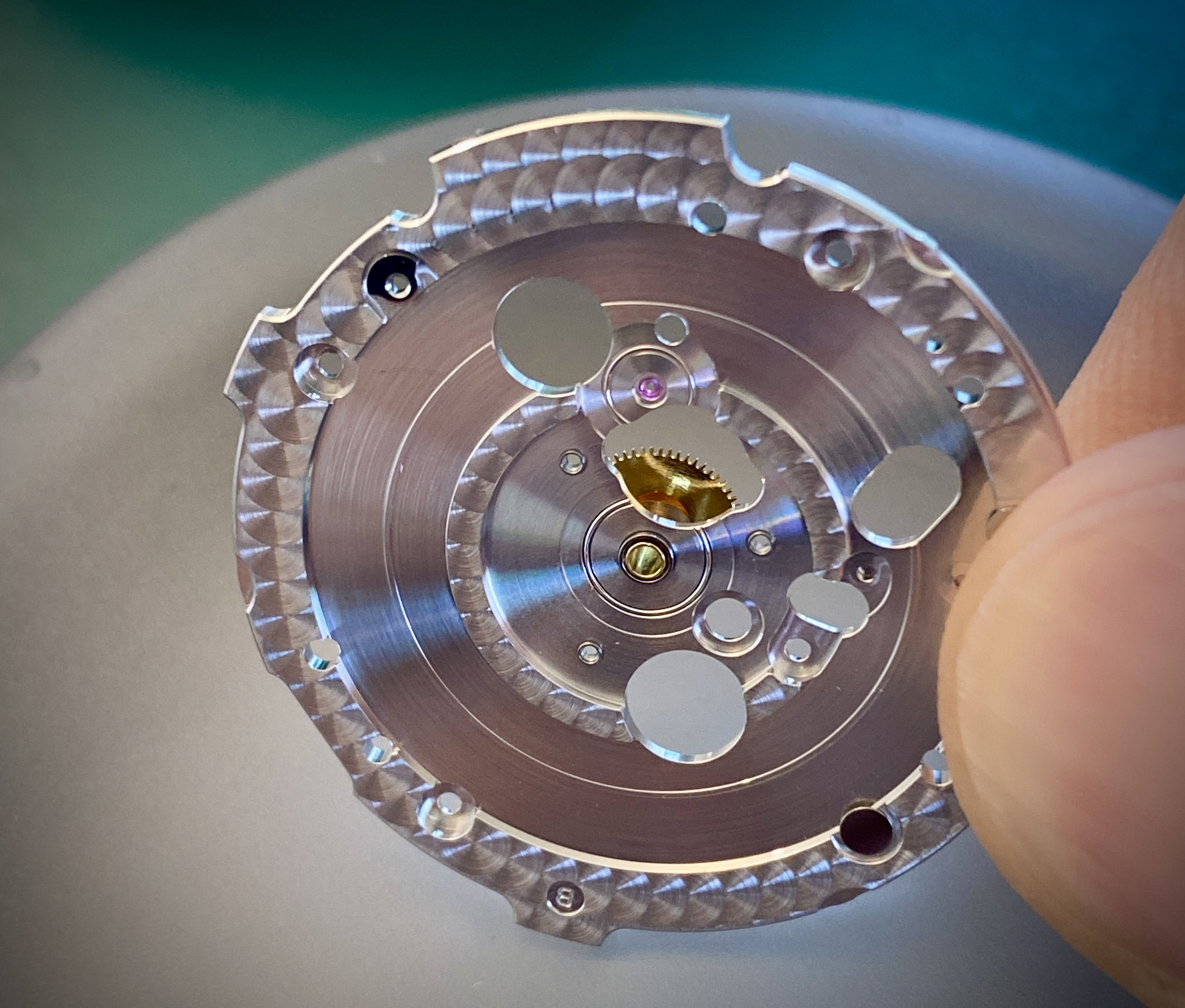

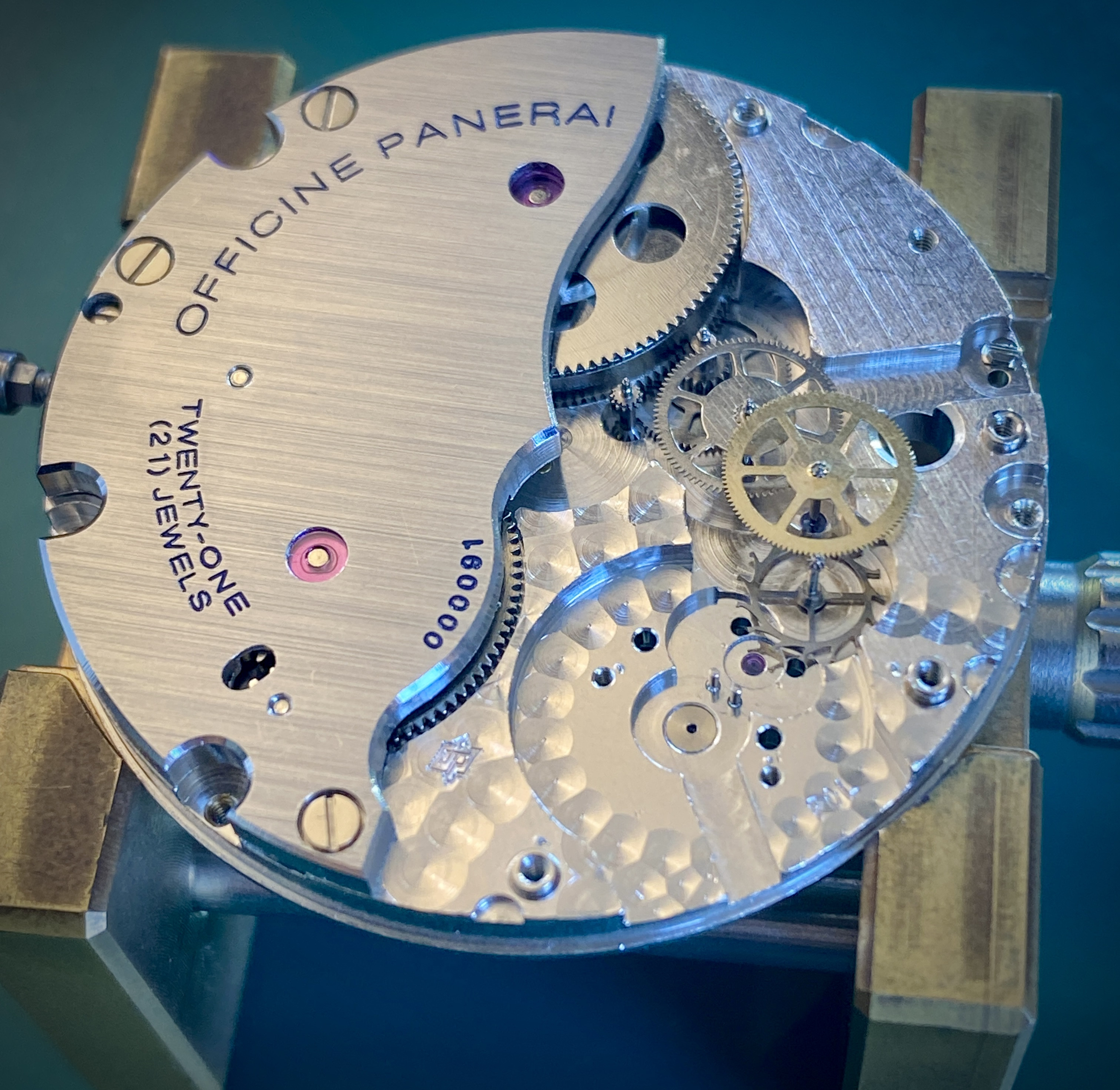

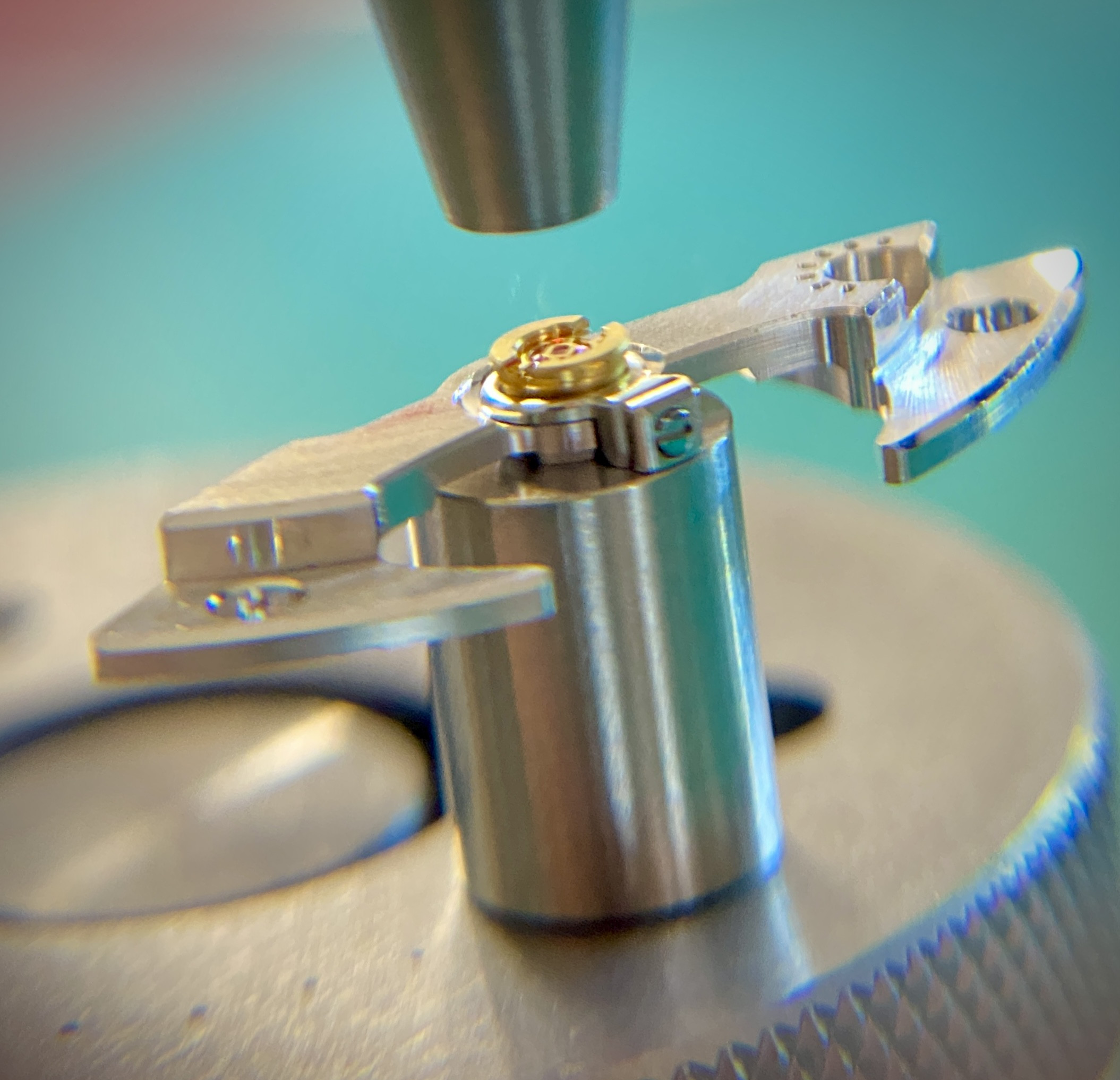

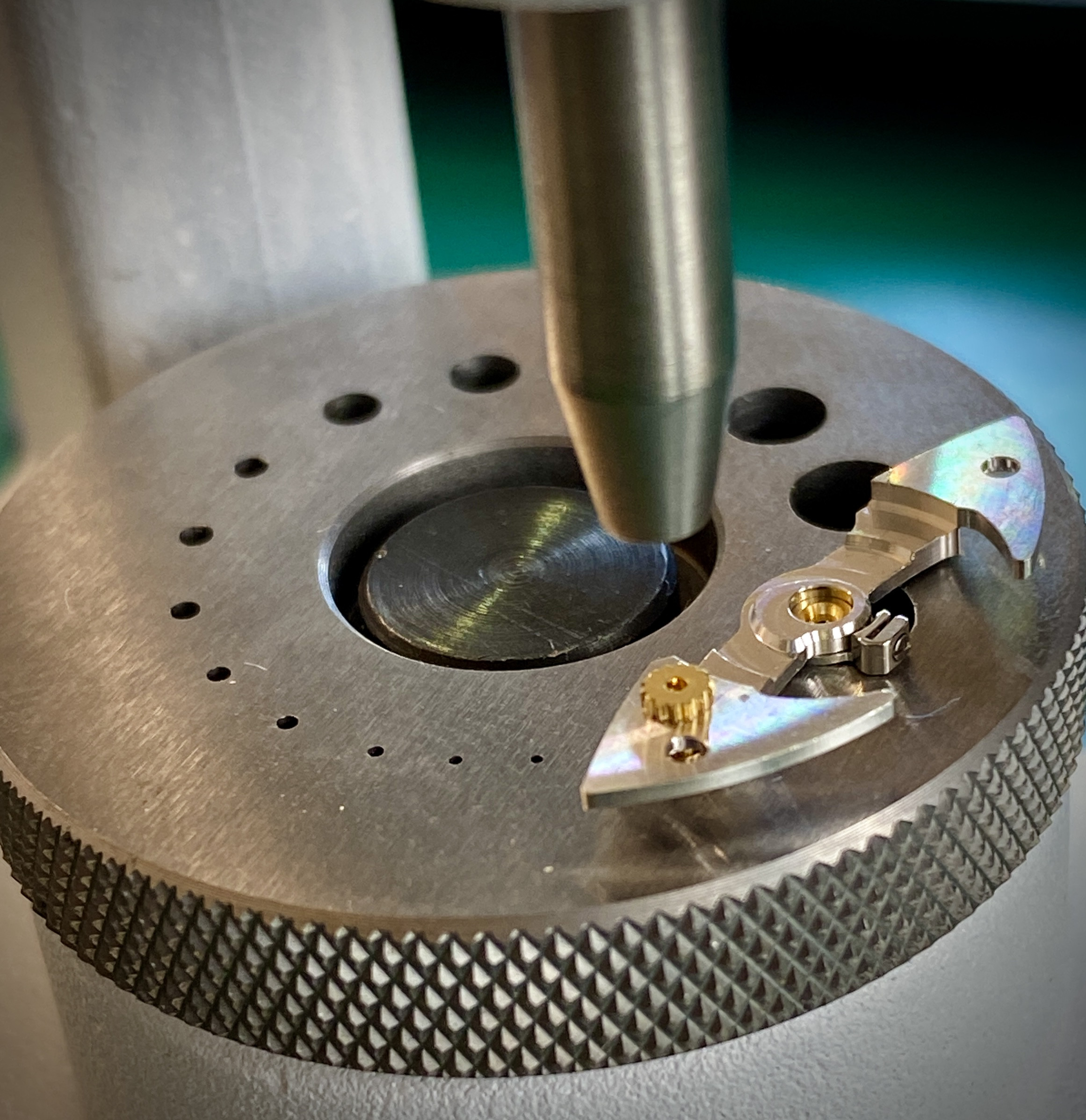

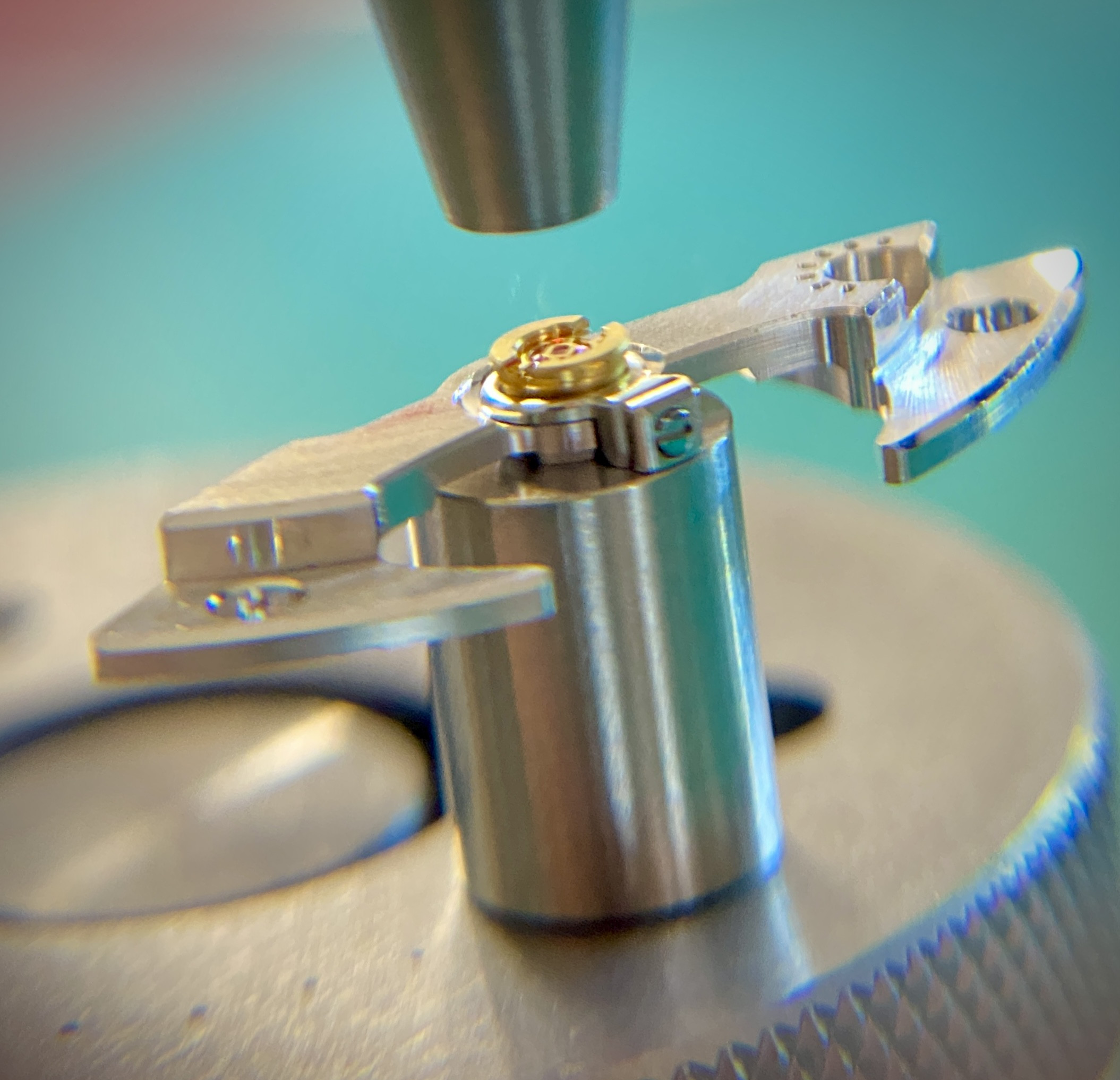

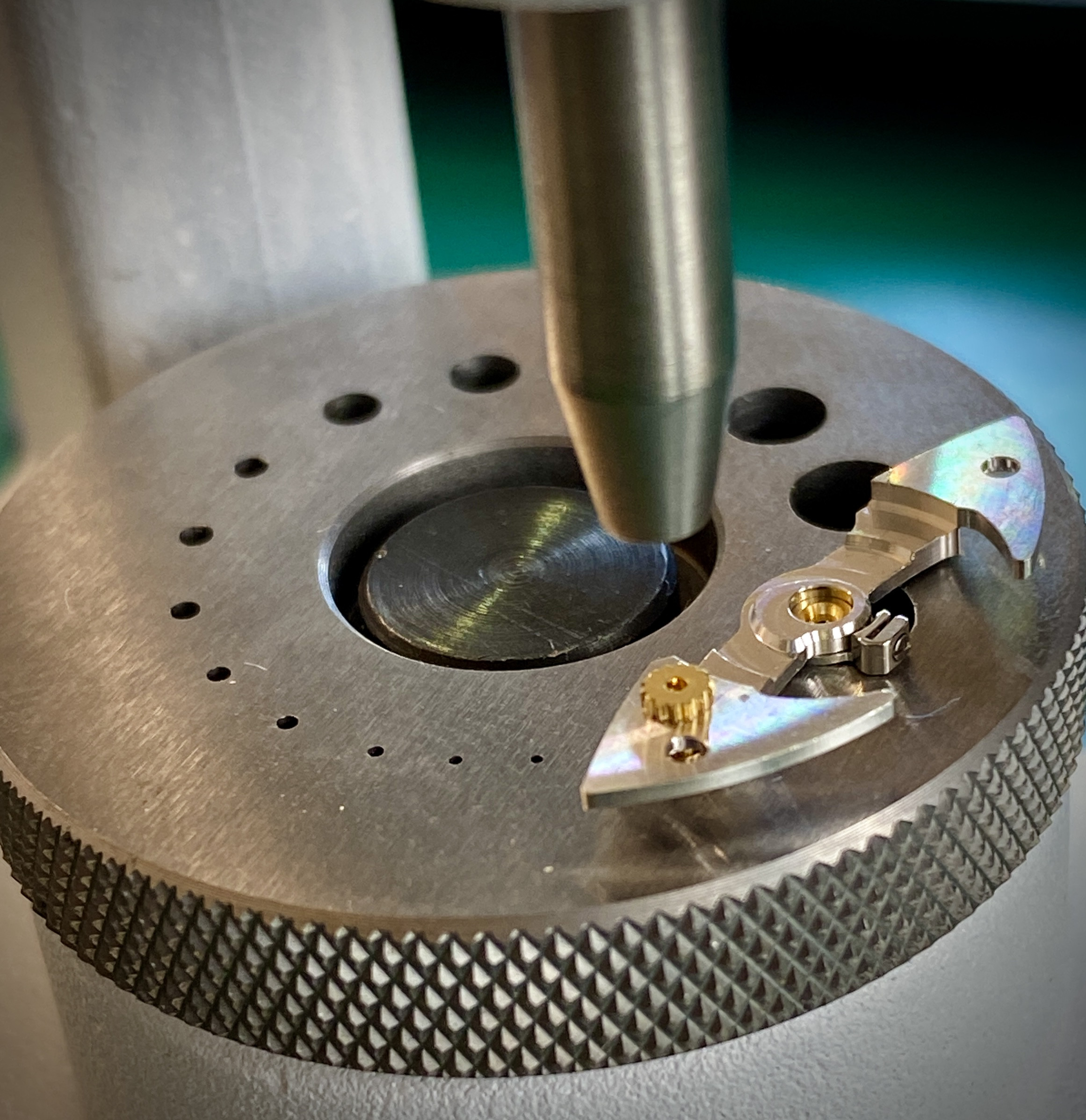

I had a fun challenge on my bench today — a dd3285 gen balance swap. While normally a gen balance swap is a pretty easy thing to do, this gen balance came with the balance bridge in parts.

I’ve never done an assembly like this before, but it seems like the parts are simply go together as a press fit. With a warning from @Oascom and a few other watchmakers that I’m on a group chat with that “the parts go together with less force than you think”; I set up my staking set and got things lined up.

A few taps with my jeweler’s hammer and the shock setting and hairspring stud were solidly in place.

In hindsight I should have done the endshake adjustor first since that would have allowed me to have a flat surface to stake against from the bottom of the bridge, but I managed by offsetting the bottom anvil to allow the shock setting to hang in one of the anvil wells.

The endshake adjustor needs to also be staked from the top, so I changed to a narrower stake to push the brass screw head down into the pinion.

In the end it was quite an easy procedure. Hopefully I didn’t mess anything up.

I’ve never done an assembly like this before, but it seems like the parts are simply go together as a press fit. With a warning from @Oascom and a few other watchmakers that I’m on a group chat with that “the parts go together with less force than you think”; I set up my staking set and got things lined up.

A few taps with my jeweler’s hammer and the shock setting and hairspring stud were solidly in place.

In hindsight I should have done the endshake adjustor first since that would have allowed me to have a flat surface to stake against from the bottom of the bridge, but I managed by offsetting the bottom anvil to allow the shock setting to hang in one of the anvil wells.

The endshake adjustor needs to also be staked from the top, so I changed to a narrower stake to push the brass screw head down into the pinion.

In the end it was quite an easy procedure. Hopefully I didn’t mess anything up.