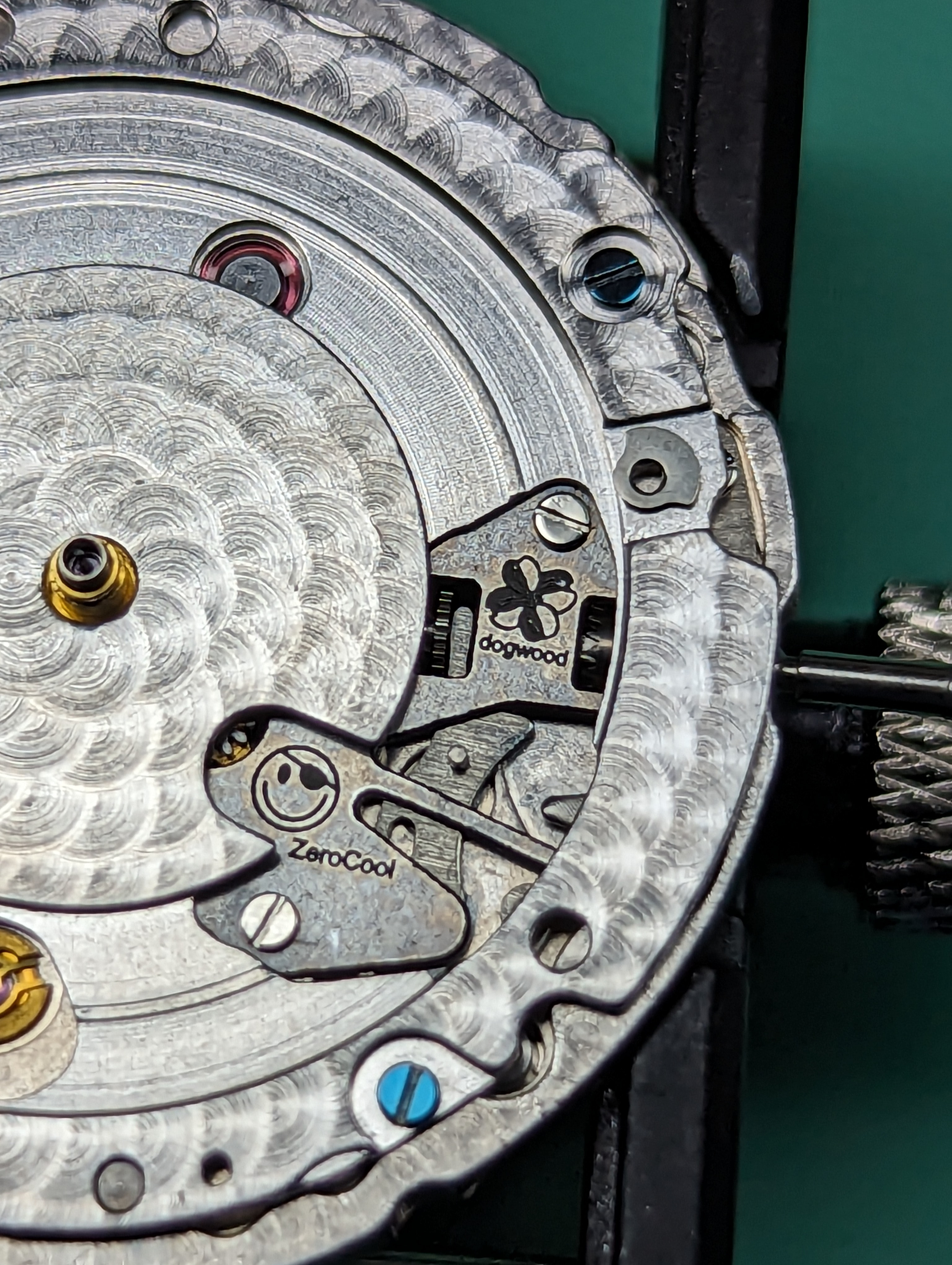

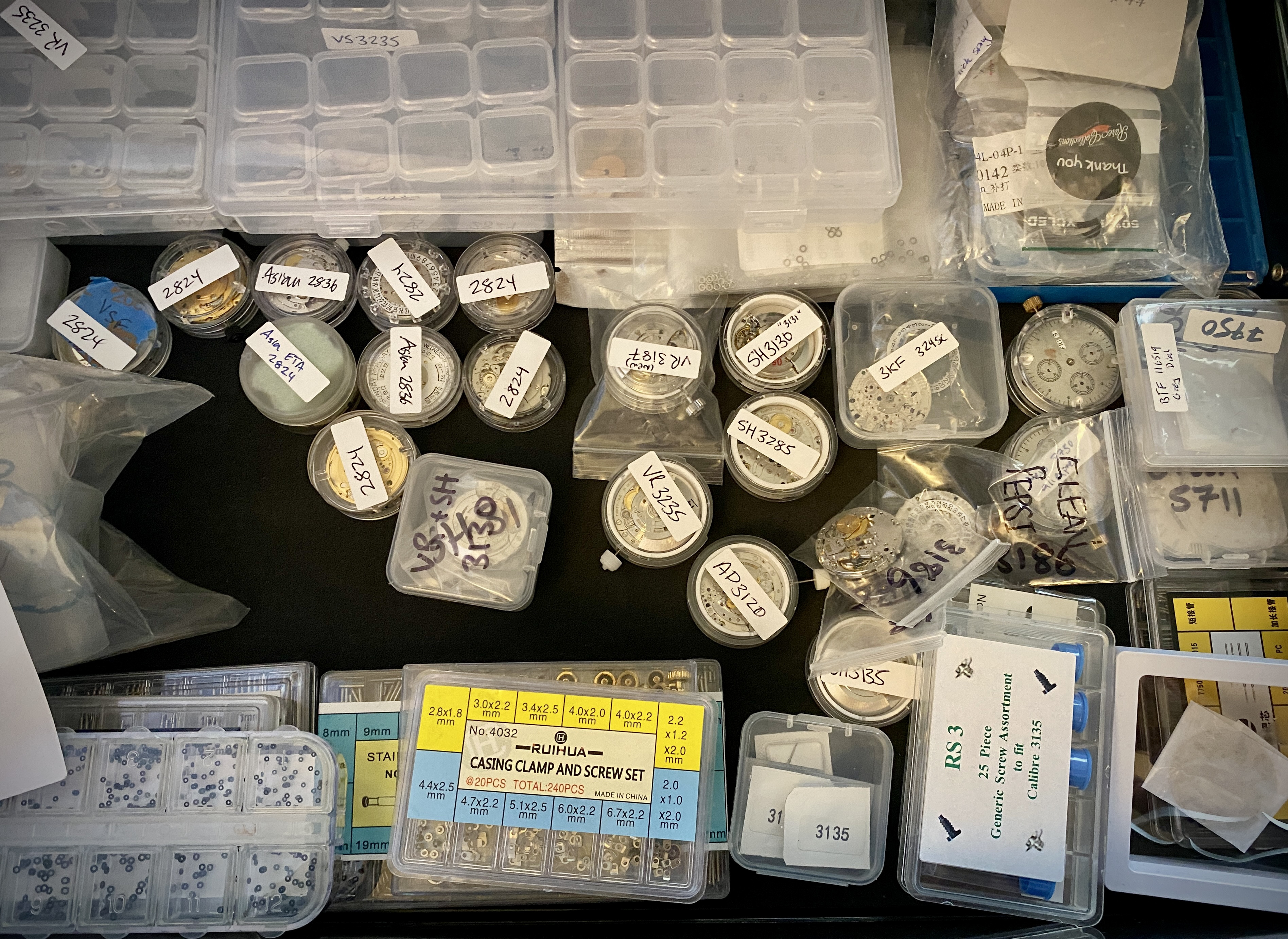

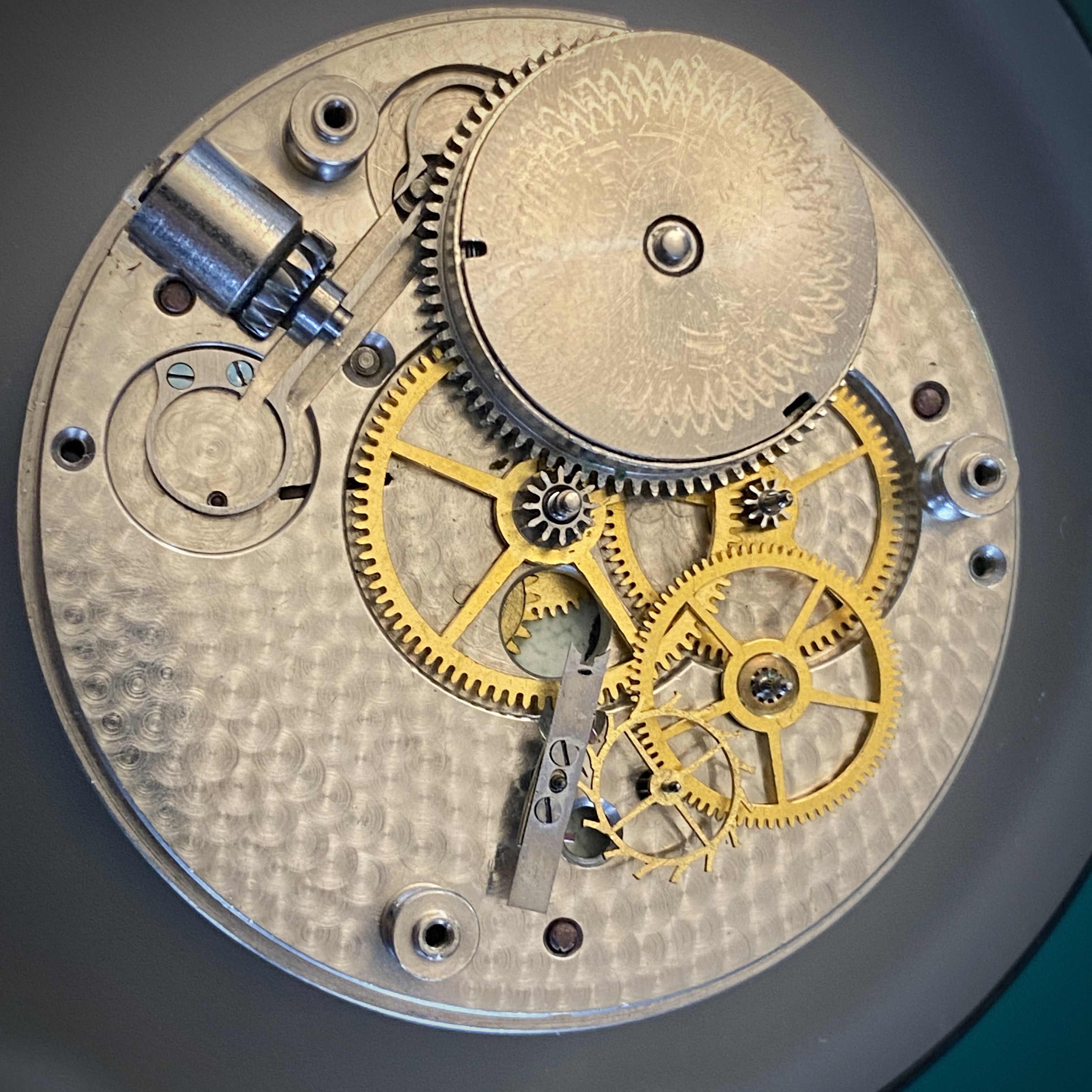

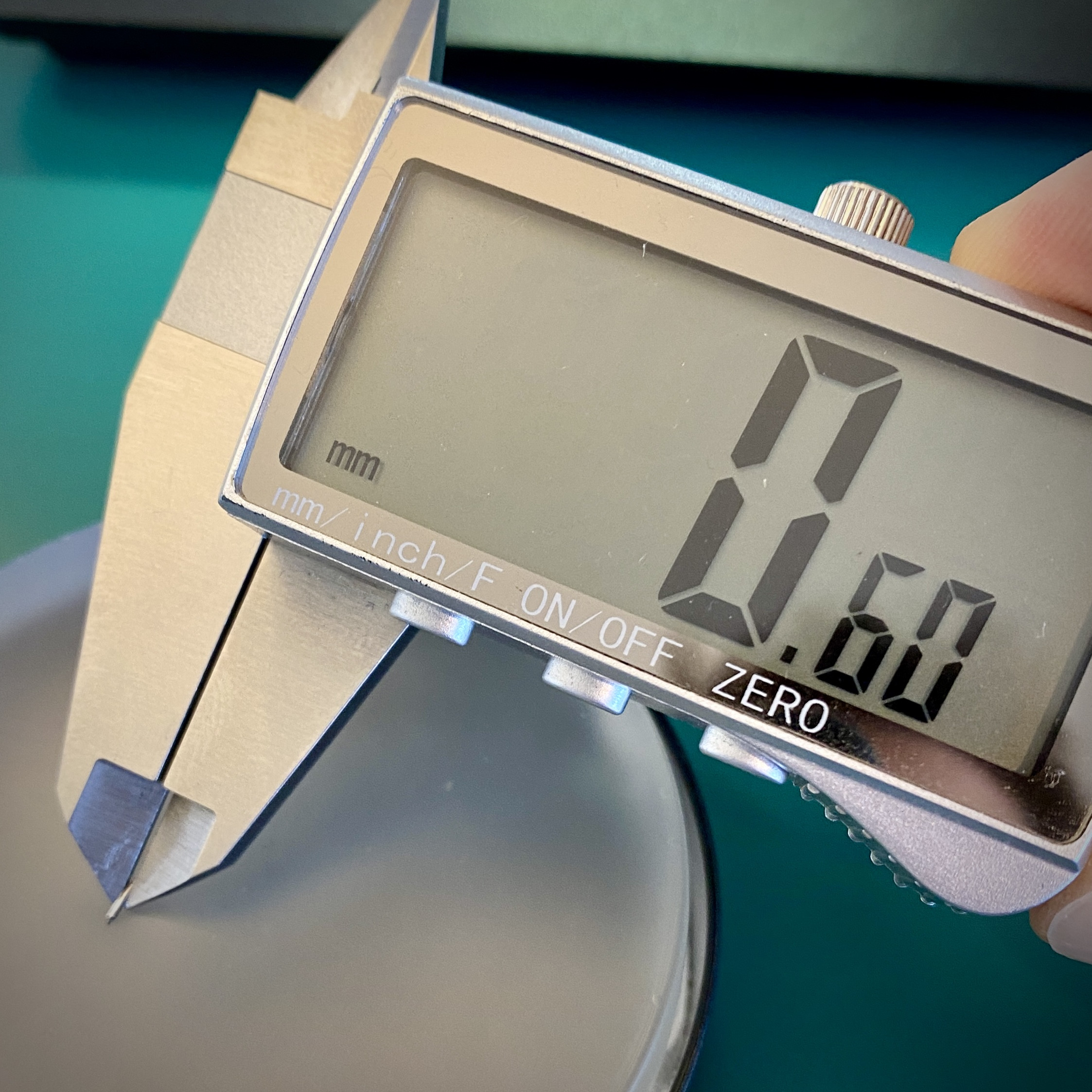

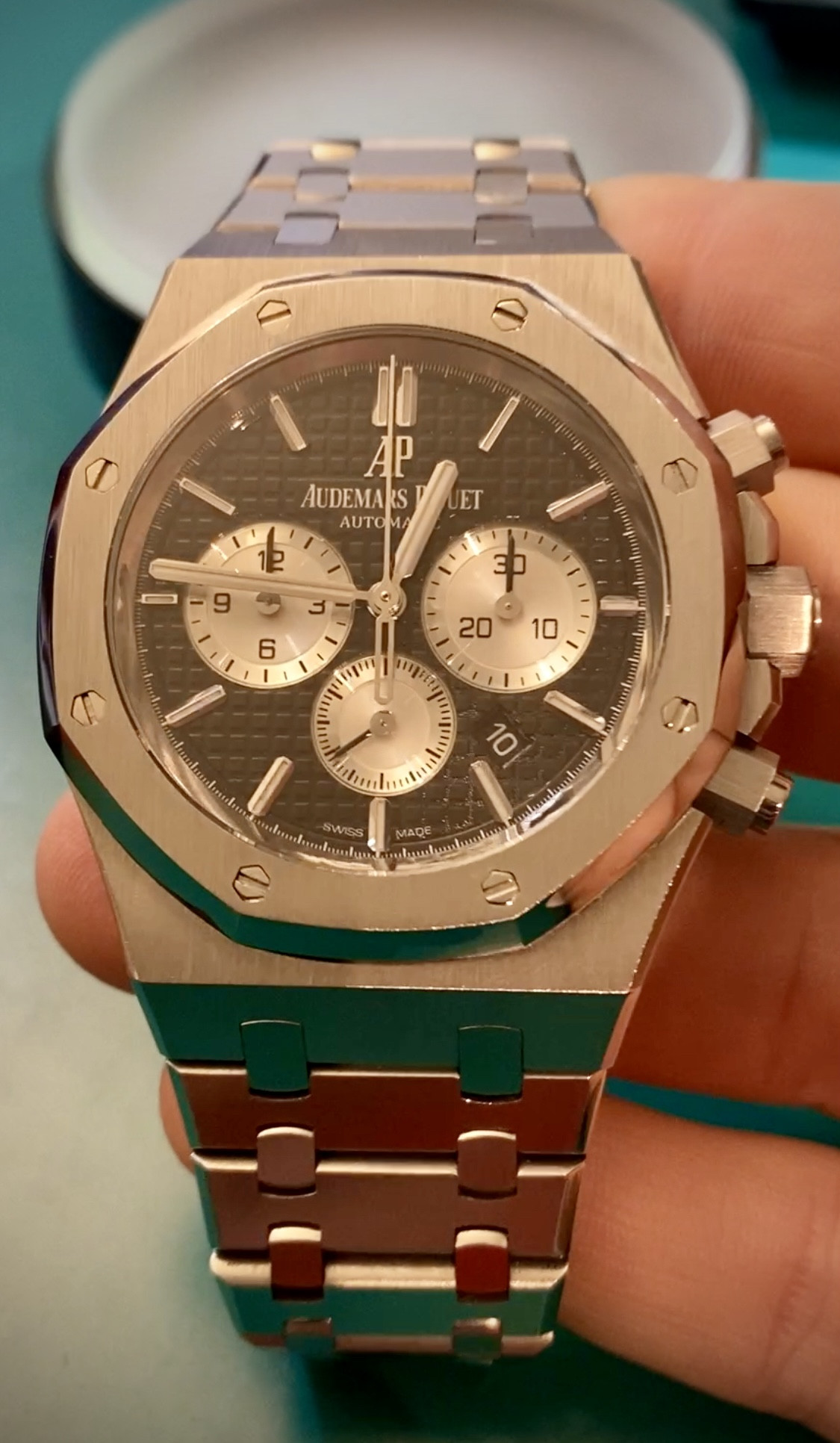

I was working on a tungsten Daytona this evening and thought I’d share some pics. The donor watch in this case is a CF Daytona which tips the scales at 143g.

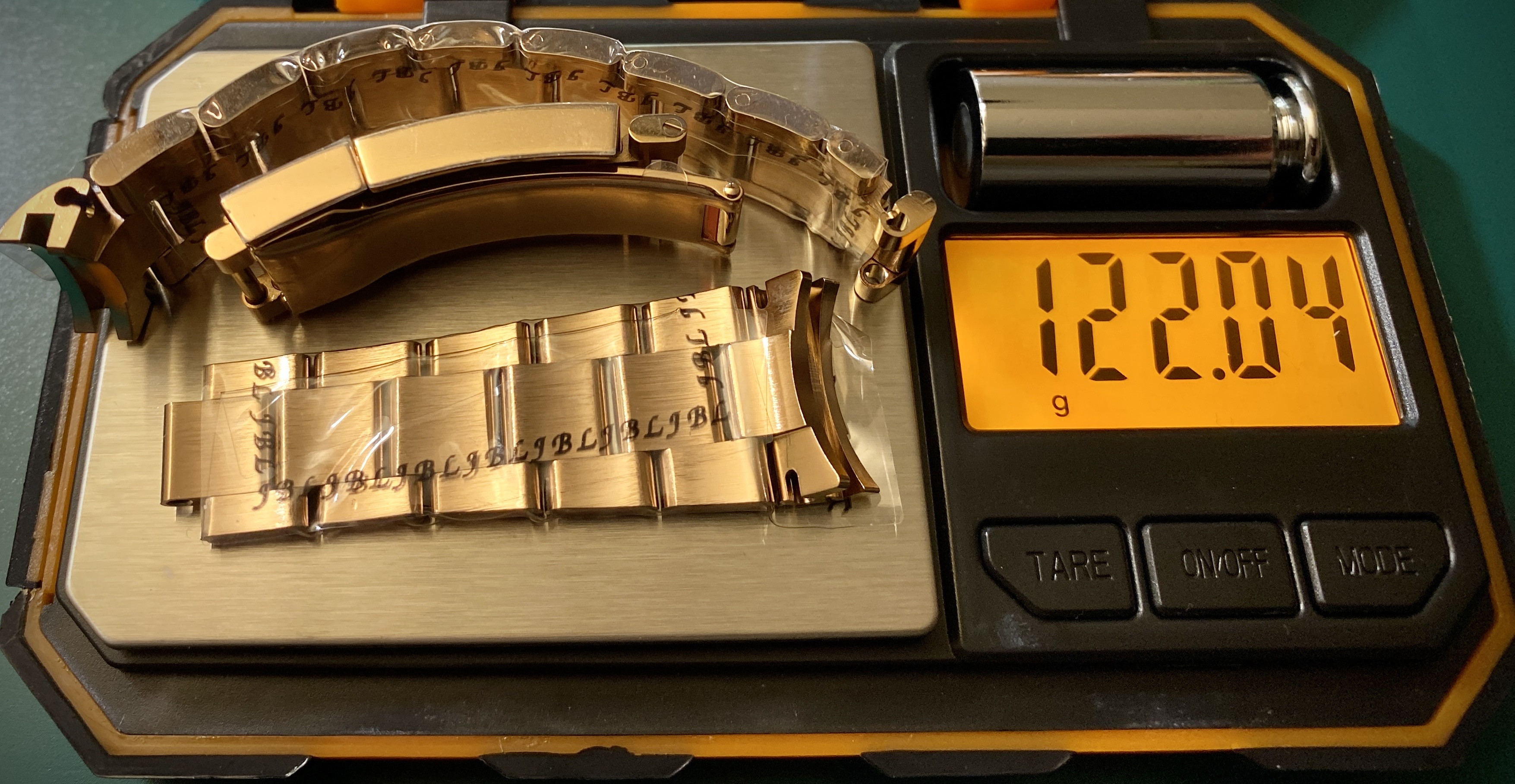

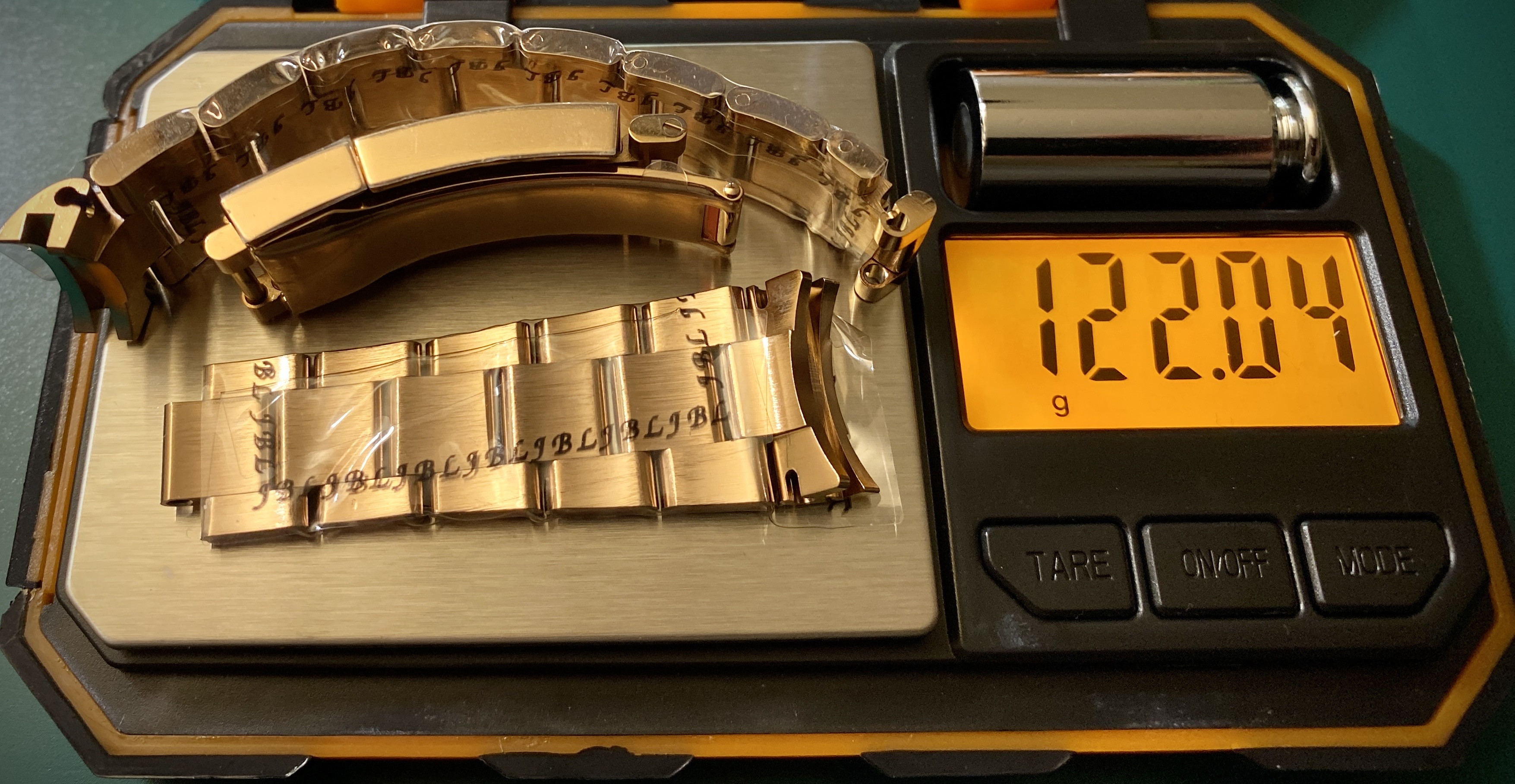

After transferring over the movement and installing the crystal and bezel, the new watch weighs 226g. (NB: my scale maxes out at 200g, so I had to weigh the bracelet and movement separately).

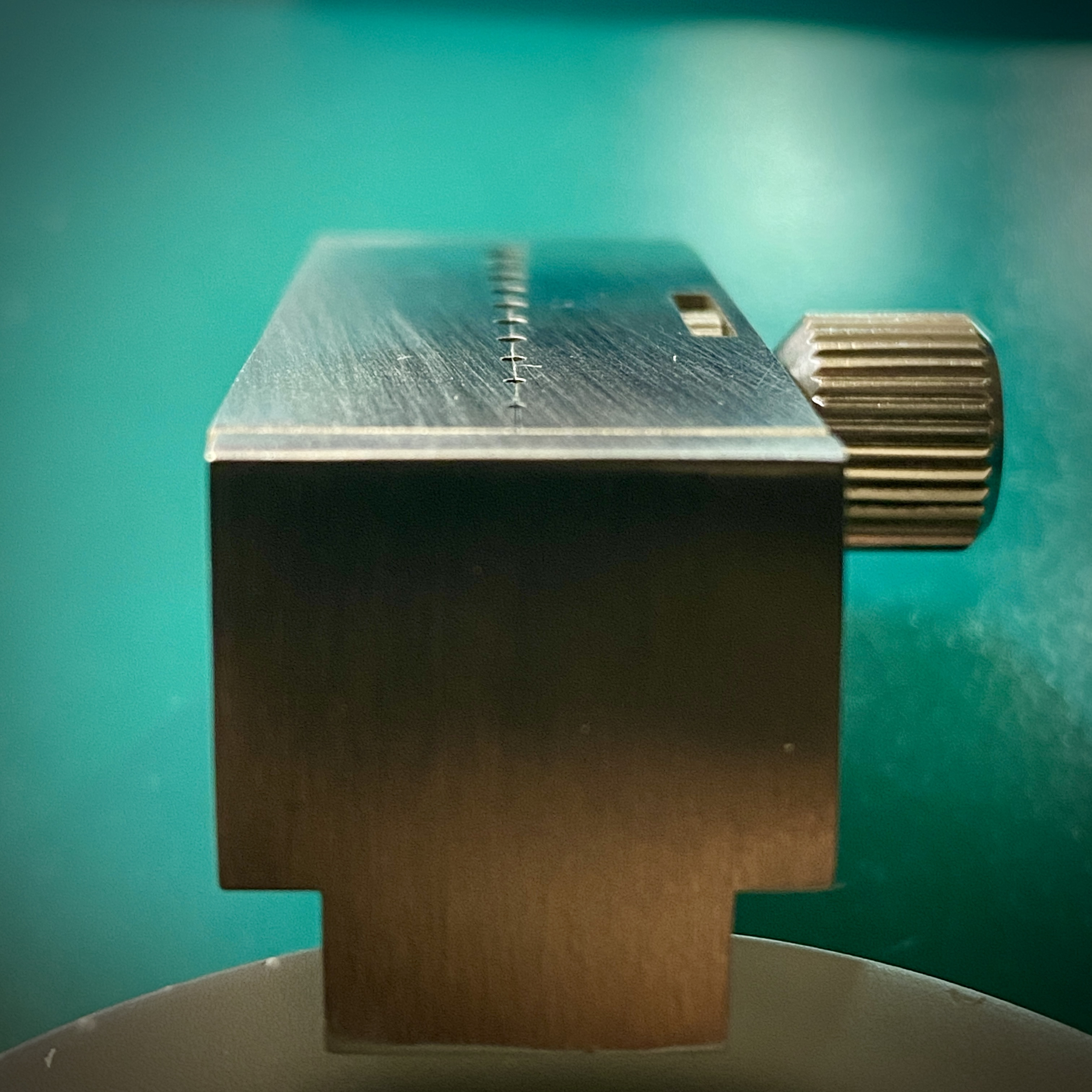

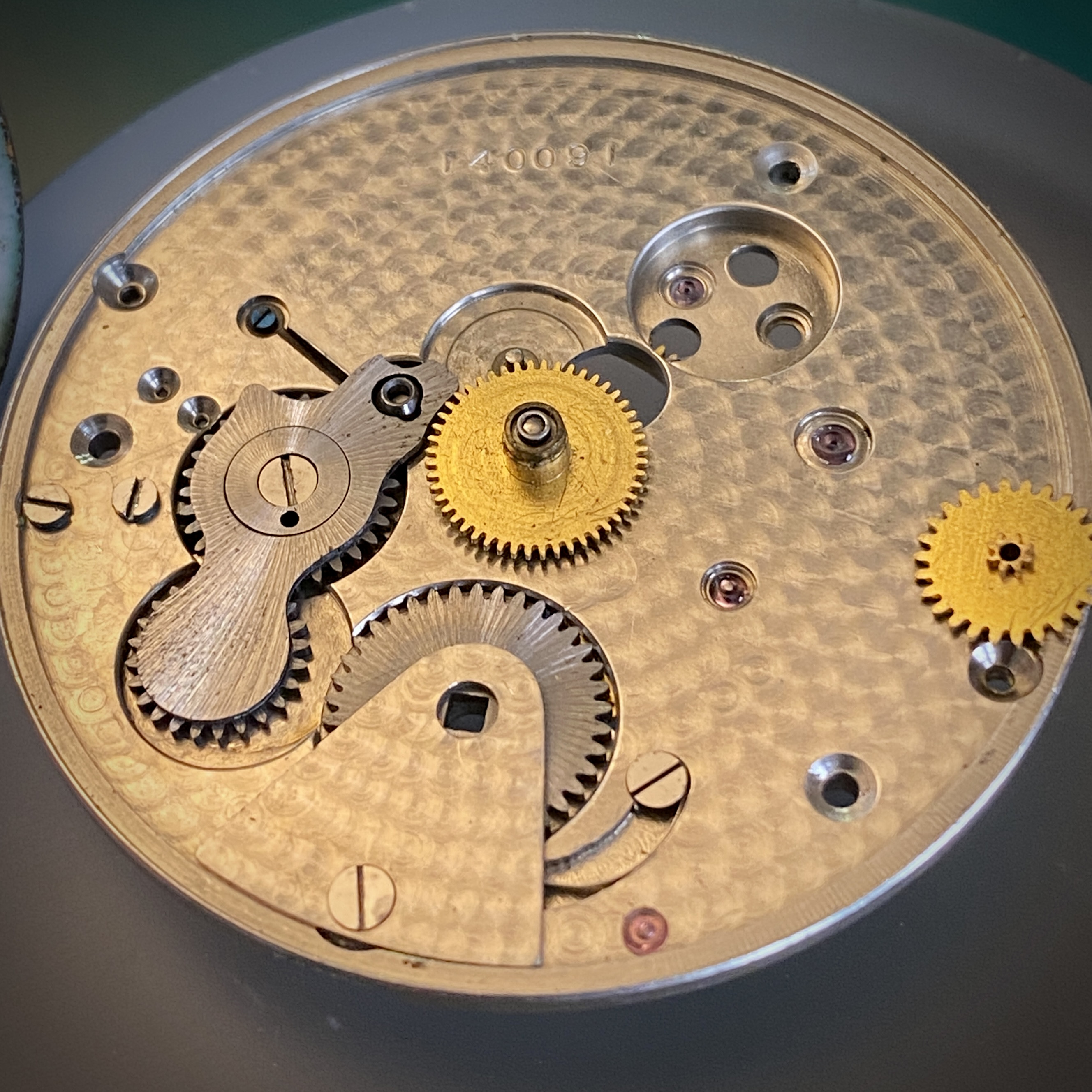

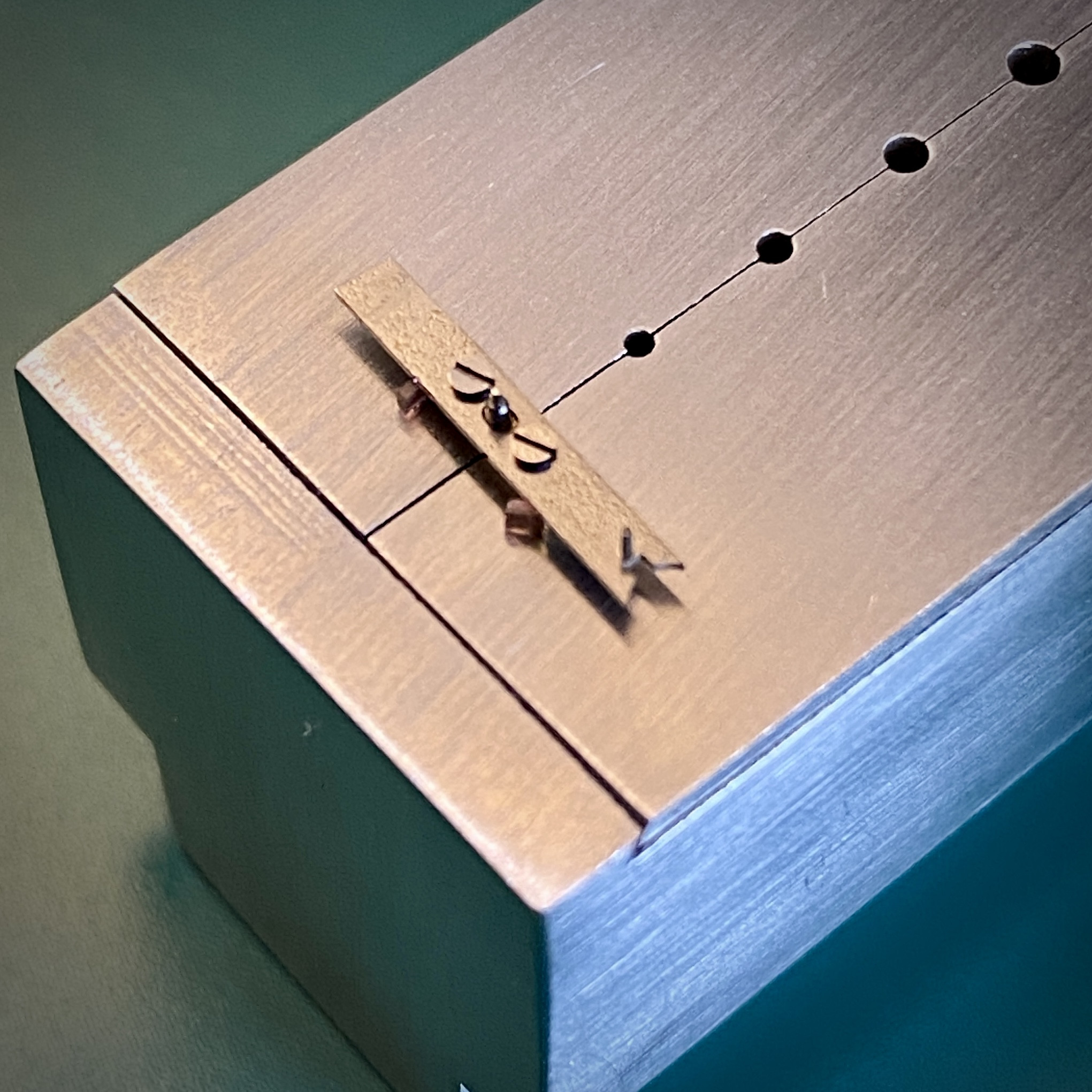

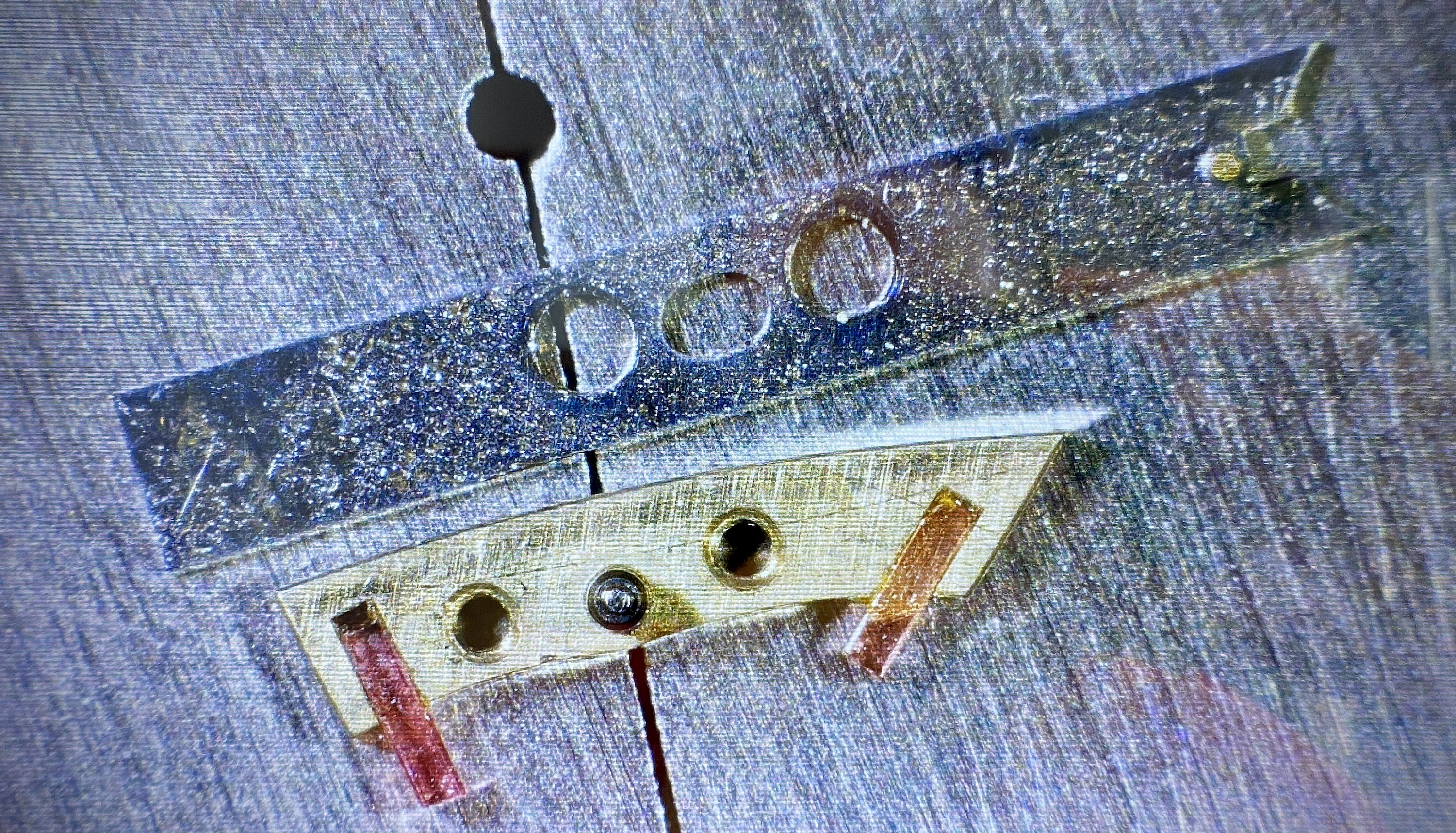

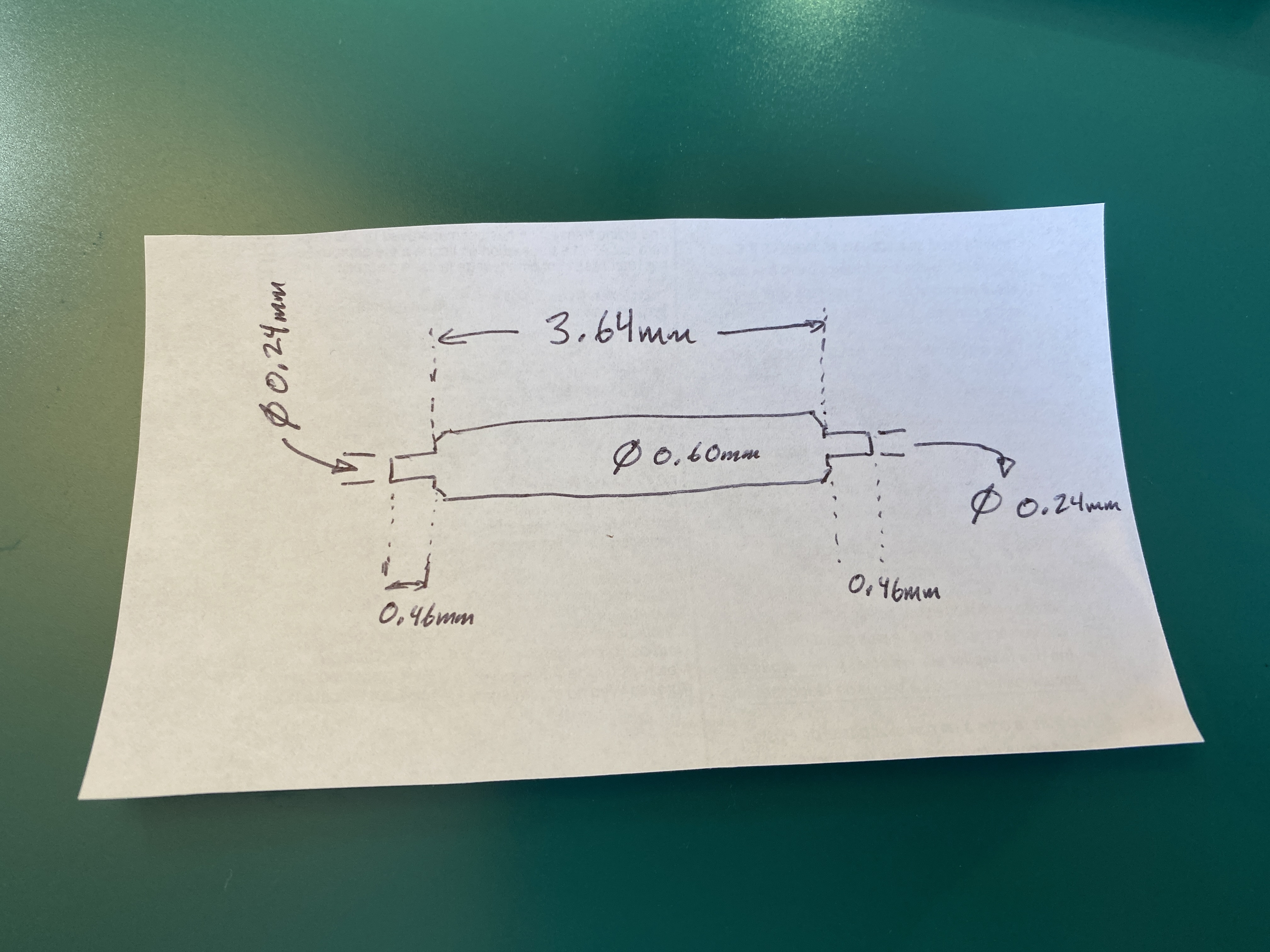

And I’m using the old CF bezel which has an interesting hollow channel machined in the back. I haven’t worked on enough metal bezel Daytonas to know if this is standard or not. My first thought was that the channel could be used to house a tungsten copper weighted slug to further increase the weight of the watch.

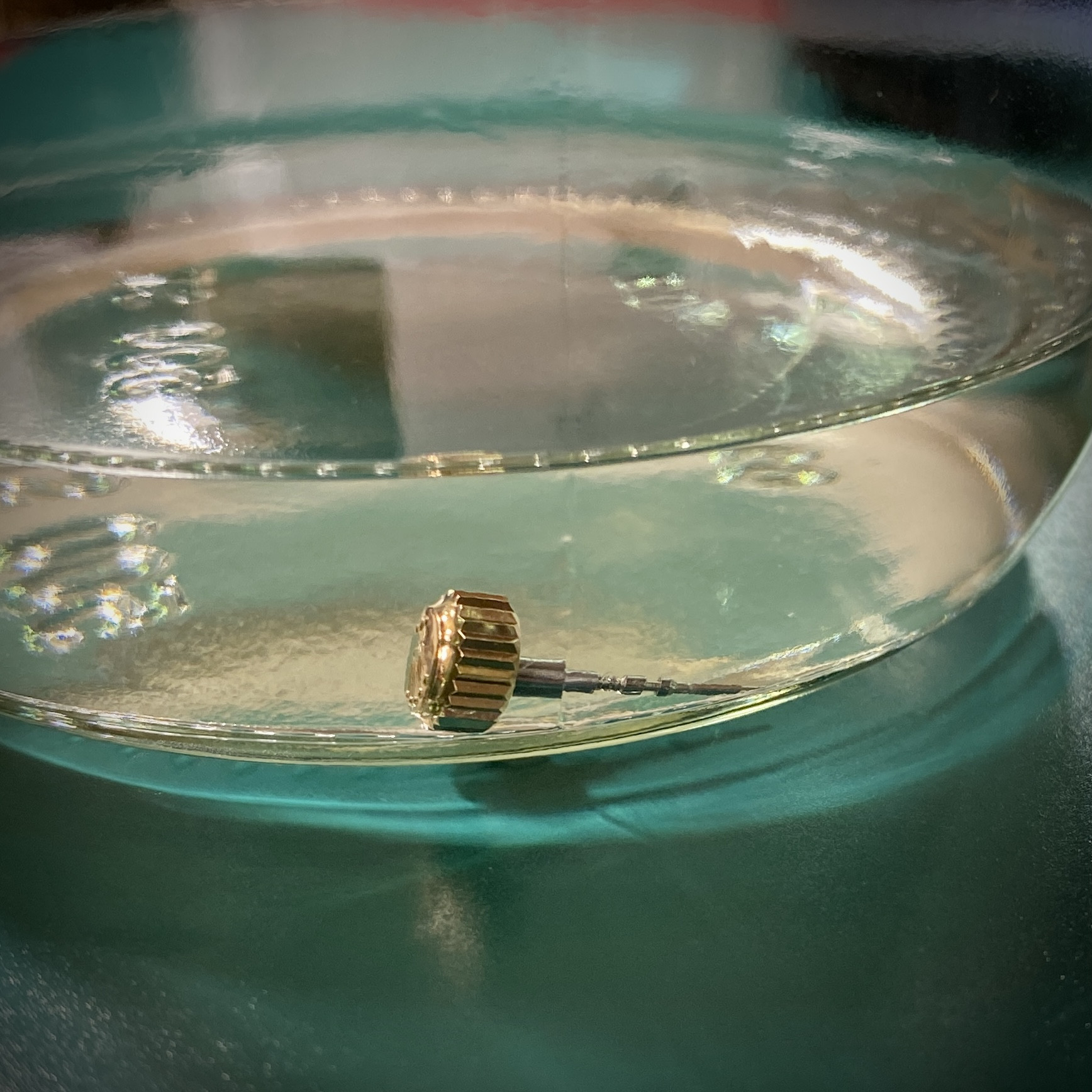

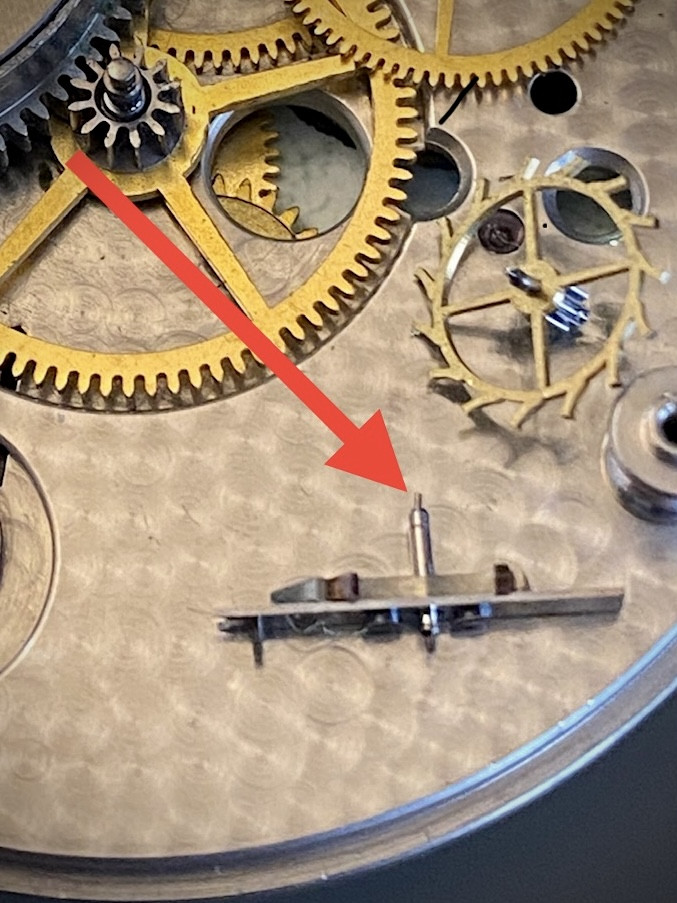

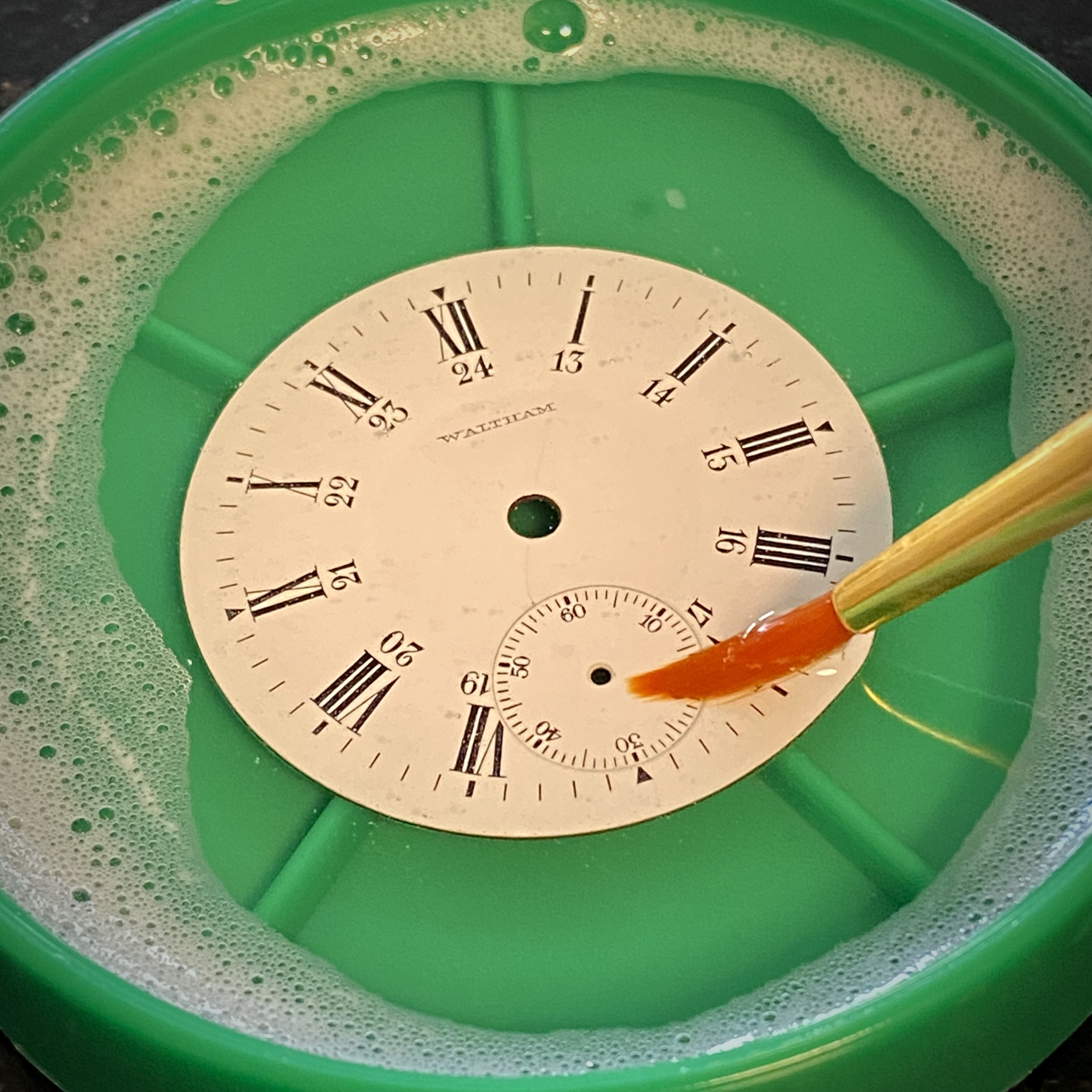

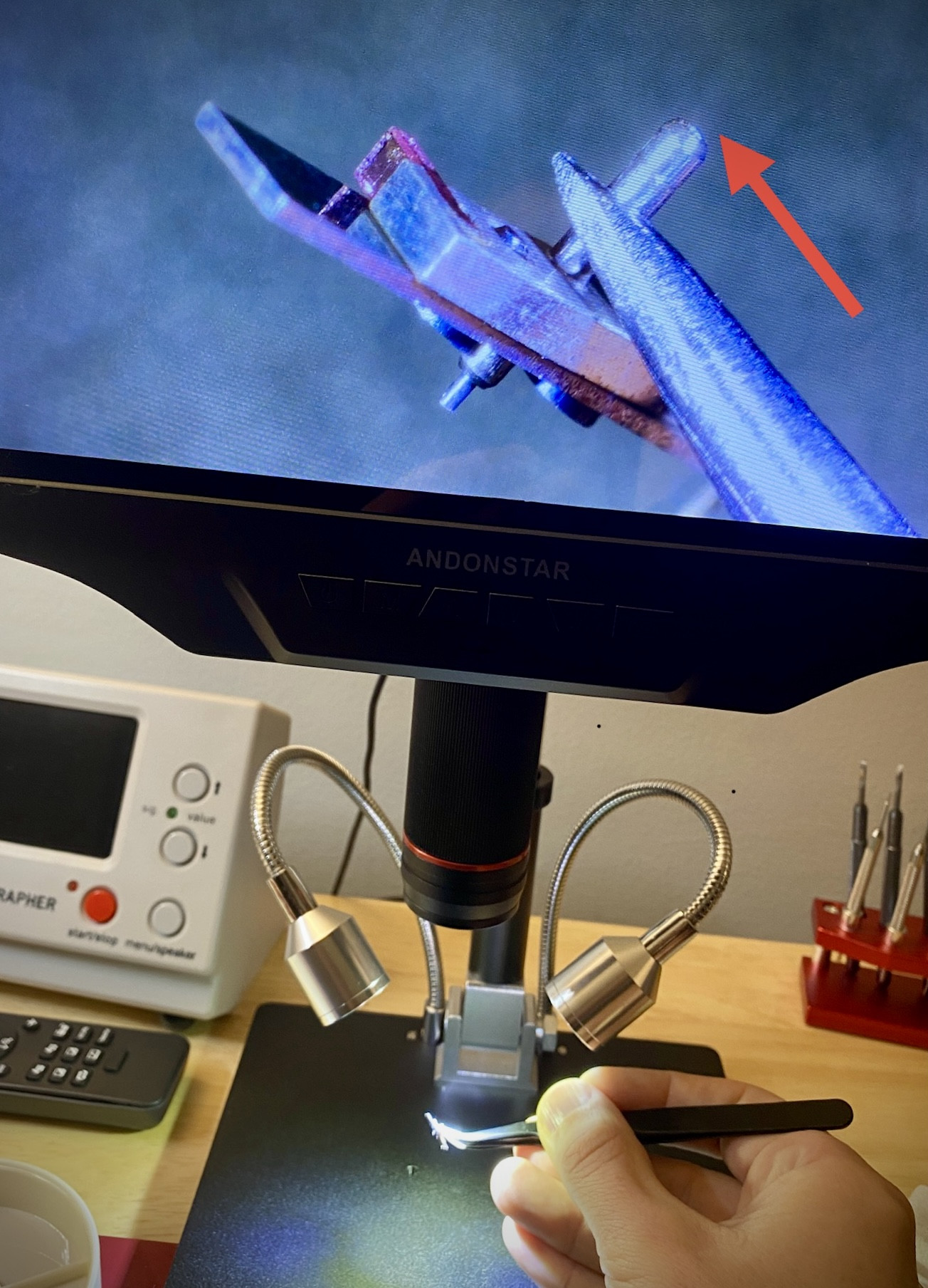

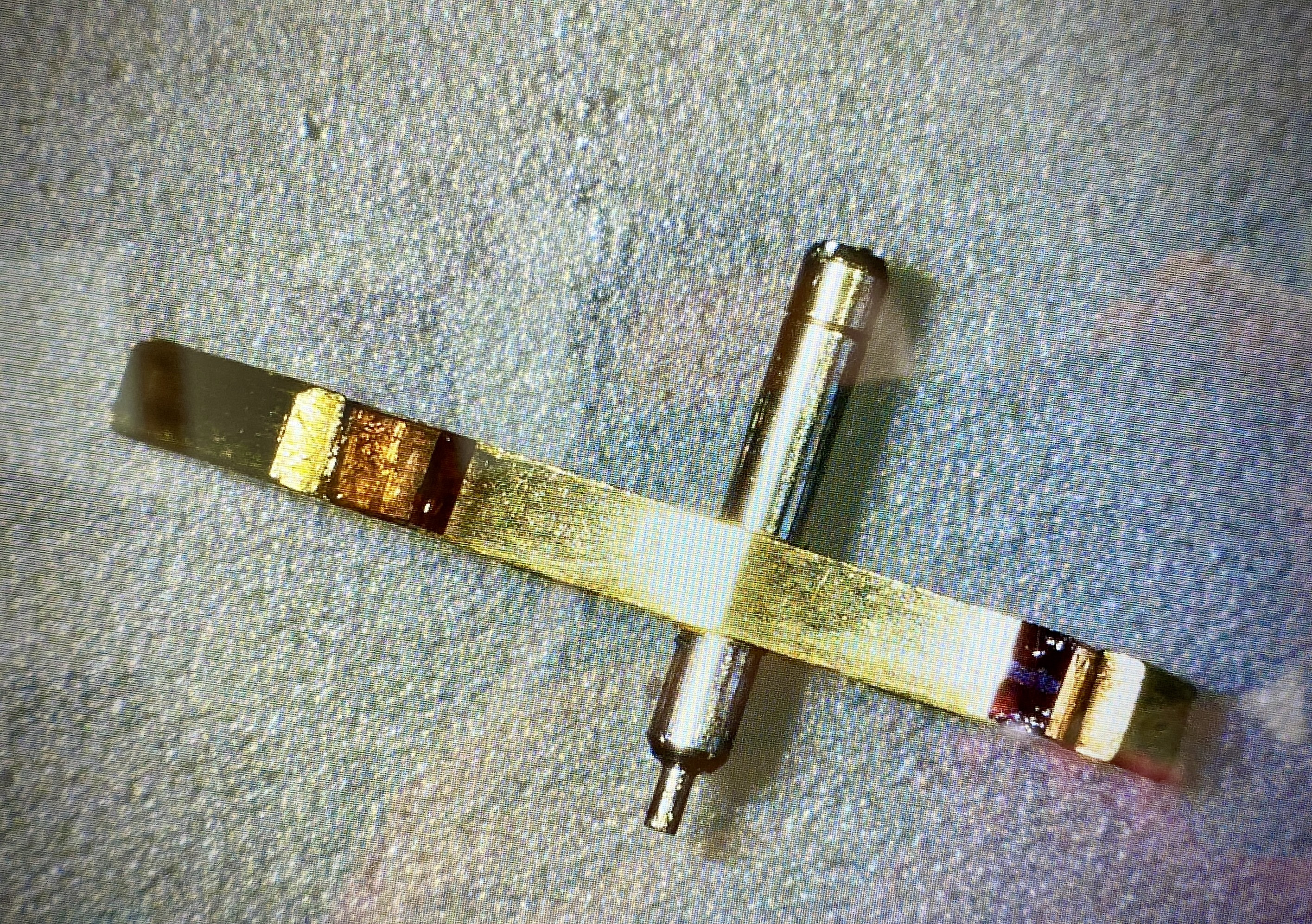

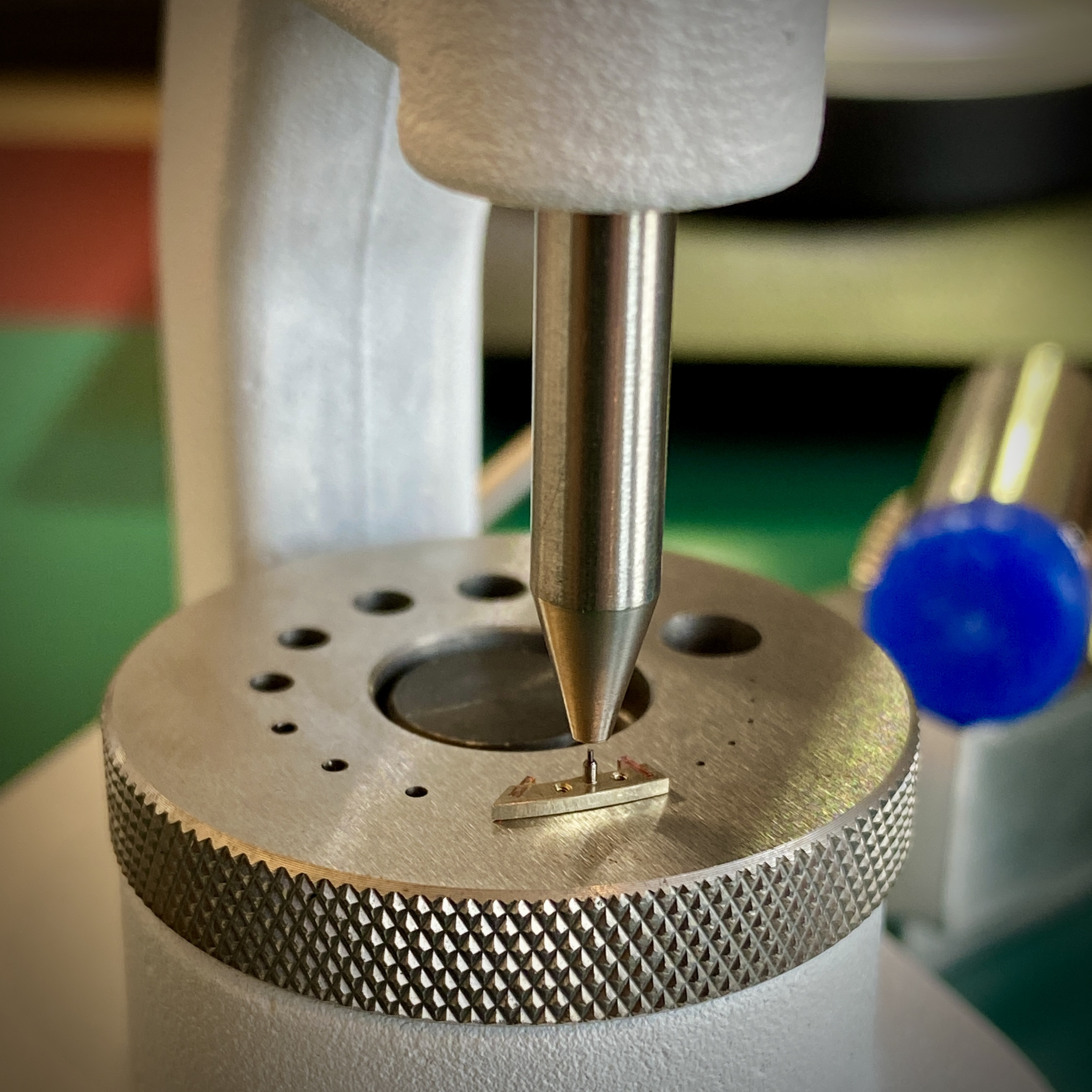

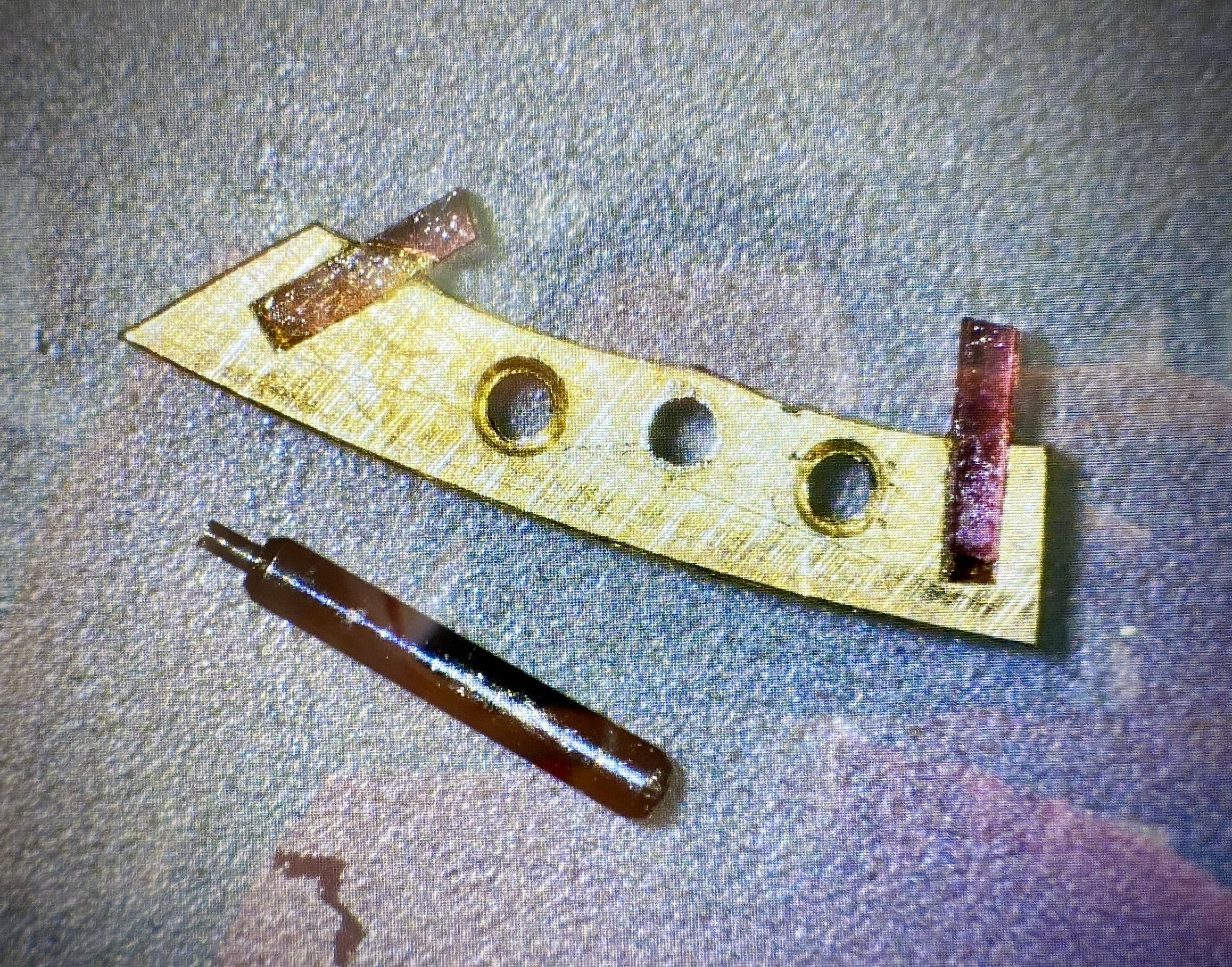

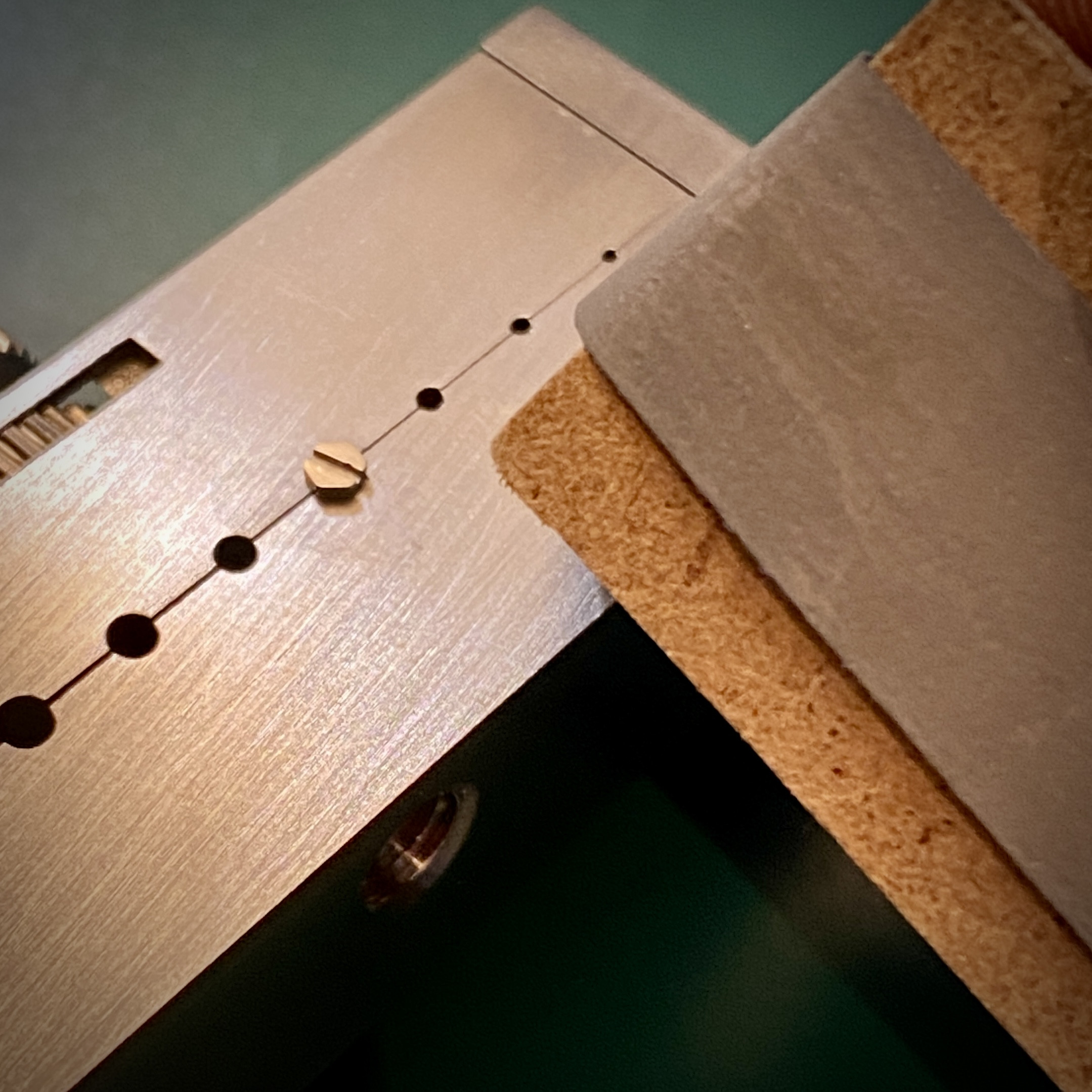

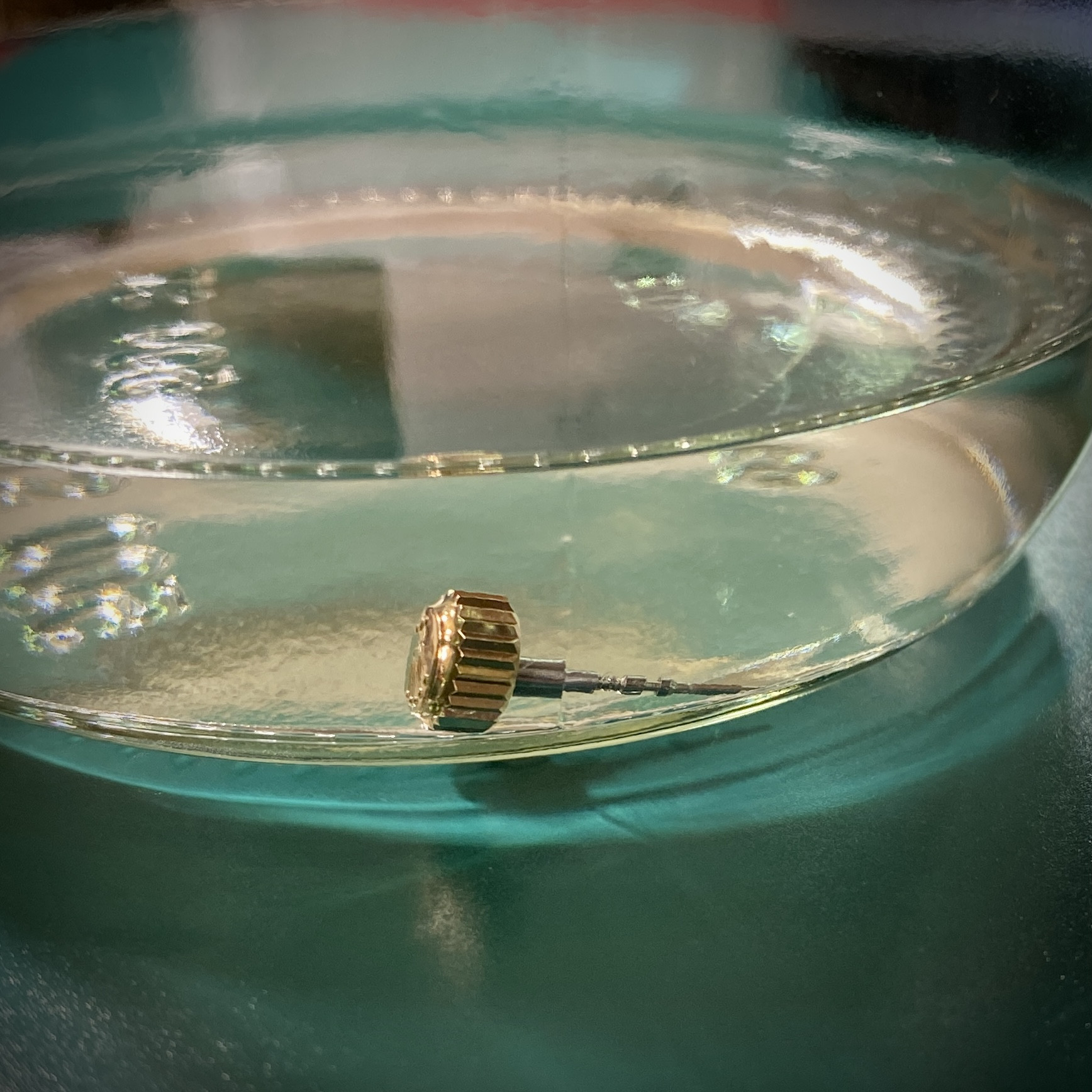

Unfortunately I wasn’t able to finish the build since the movement stem was (what looked like) epoxy glued into the crown. There was clear glue visible on the stem threads. A little bit of loctite is required to keep the stem and crown from coming apart, but loctite is designed to release; epoxy is not. I’m soaking the stem

And crown in acetone overnight to see if that helps separate the parts.

After transferring over the movement and installing the crystal and bezel, the new watch weighs 226g. (NB: my scale maxes out at 200g, so I had to weigh the bracelet and movement separately).

And I’m using the old CF bezel which has an interesting hollow channel machined in the back. I haven’t worked on enough metal bezel Daytonas to know if this is standard or not. My first thought was that the channel could be used to house a tungsten copper weighted slug to further increase the weight of the watch.

Unfortunately I wasn’t able to finish the build since the movement stem was (what looked like) epoxy glued into the crown. There was clear glue visible on the stem threads. A little bit of loctite is required to keep the stem and crown from coming apart, but loctite is designed to release; epoxy is not. I’m soaking the stem

And crown in acetone overnight to see if that helps separate the parts.