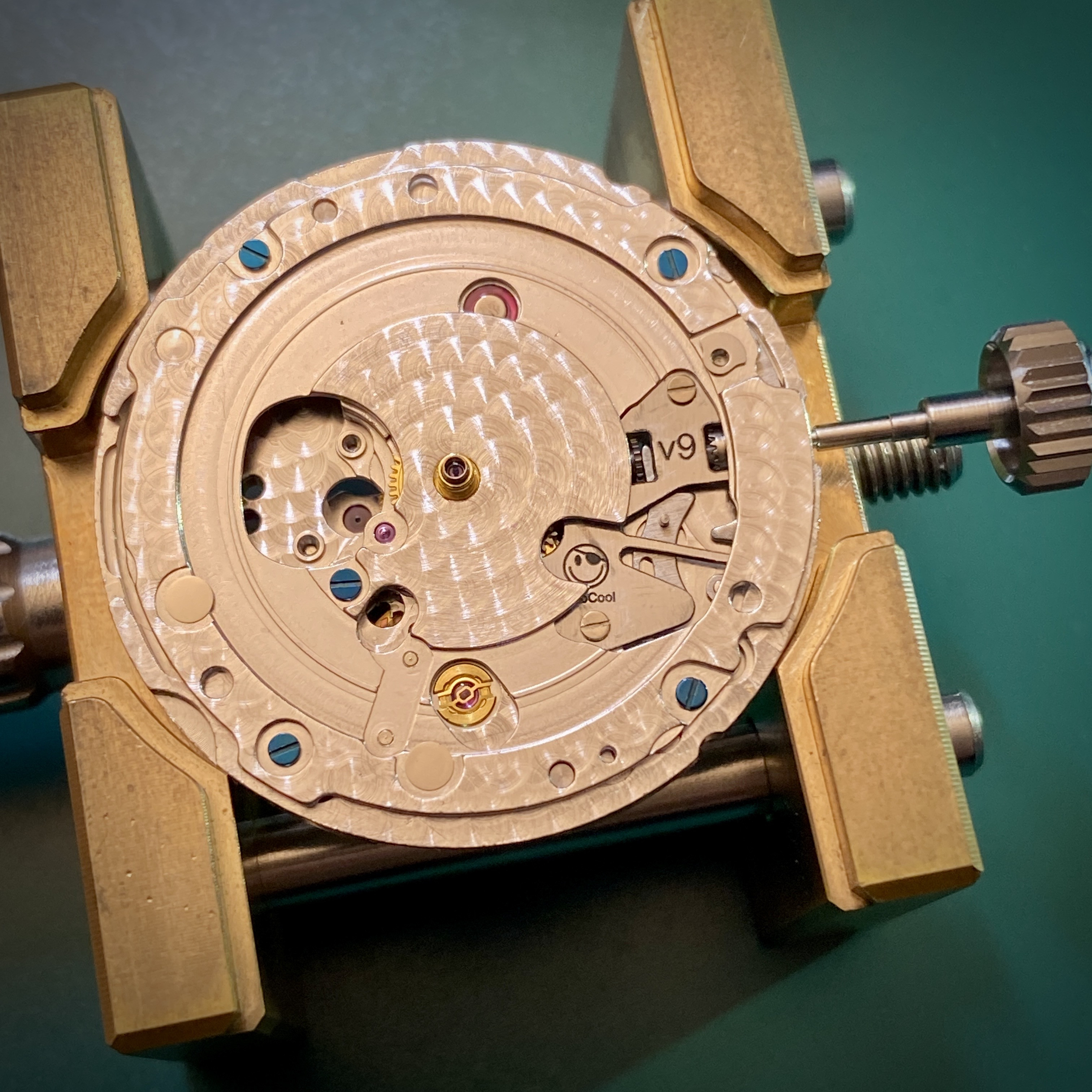

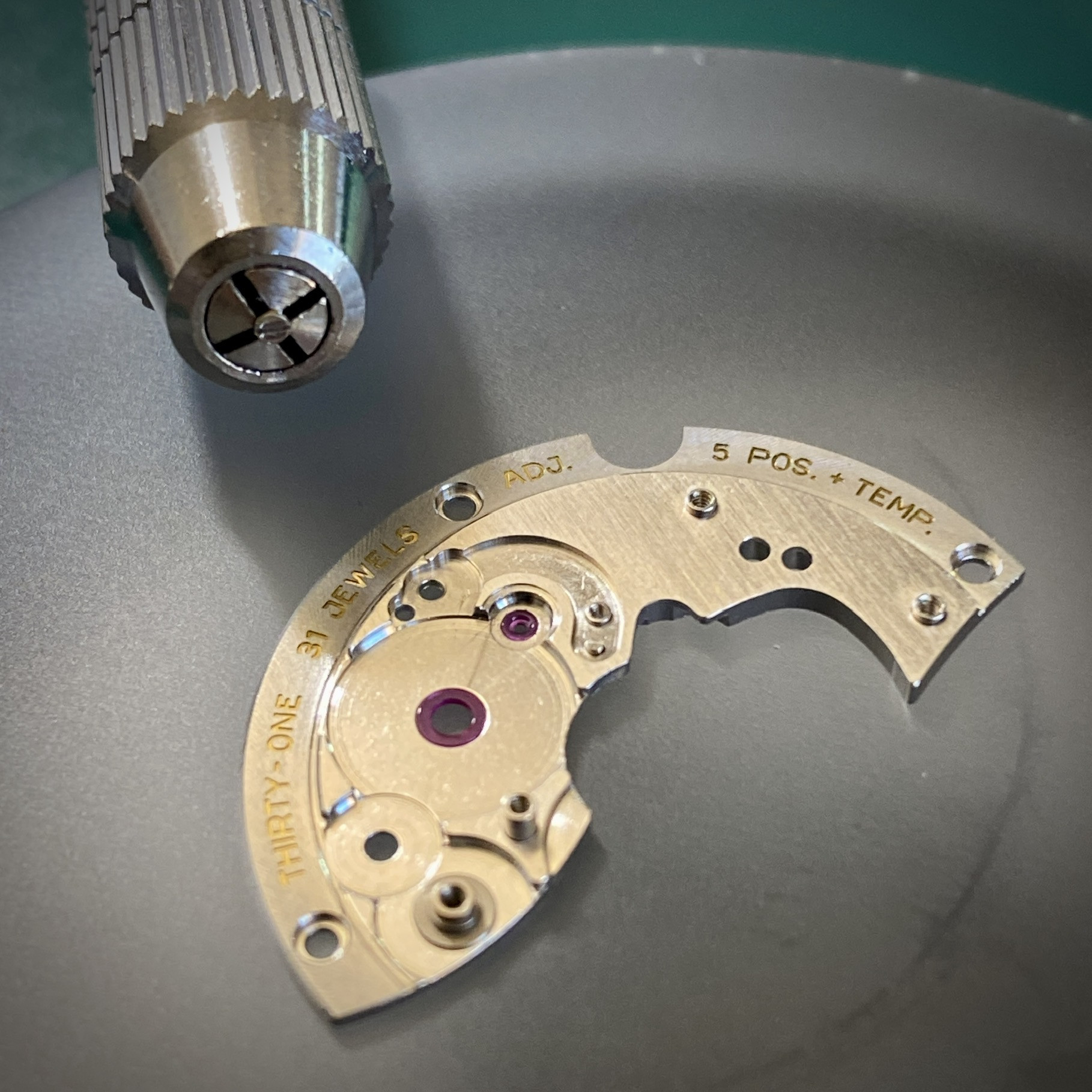

A little more work on the 3230 setting lever spring project. I have a watch in on my bench for a service at the moment, and I'm going to be installing one of

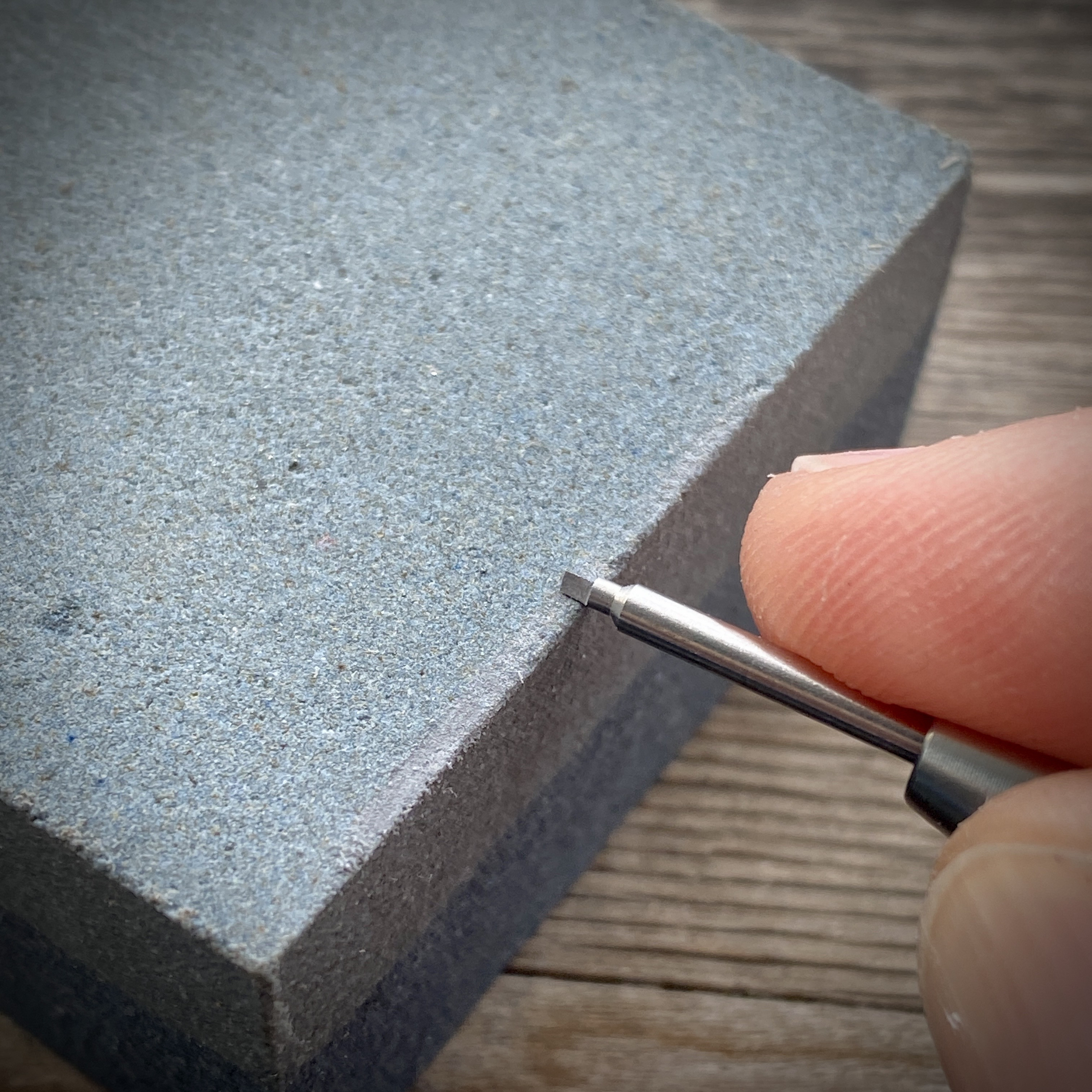

@xZeroCoolx's laser cut parts into it for testing. ZeroCool and I are still working out the final production process for this part (it should be widely available soon), but at the moment I'm still hand finishing the laser cut parts with sand paper up to 3000 grit. Then I'm cleaning the part in an ultrasonic cleaner to remove any residual grit from the hand finishing. But as a final step, ZeroCool suggested that we passivate the metal to ensure that there's the lowest possible chance of corrosion developing.

I've never passivated stainless steel before (although I have used benzotetratriazol as a passivator / corrosion inhibitor for the coolant in my custom PC cooling loop). But unlike passivating copper in a liquid cooling loop, passivating stainless steel is different. The stainless steel we're using (304 SS) is:

- 17.5% to 19.5% Chromium

- 8% to 10.5% Nickel

- 2% Manganese

- 1% Silicon

- Trace amounts (<0.1%) of Nitrogen, Carbon, Phosphorus, and Sulfur

- Balance of Iron

The way that stainless steel is passivated is to immerse the part in either Nitric or Citric acid to dissolve away any free iron on the surface of the part, leaving the surface of the part as Chromium and Nickel which both quickly form a protective oxide patina.

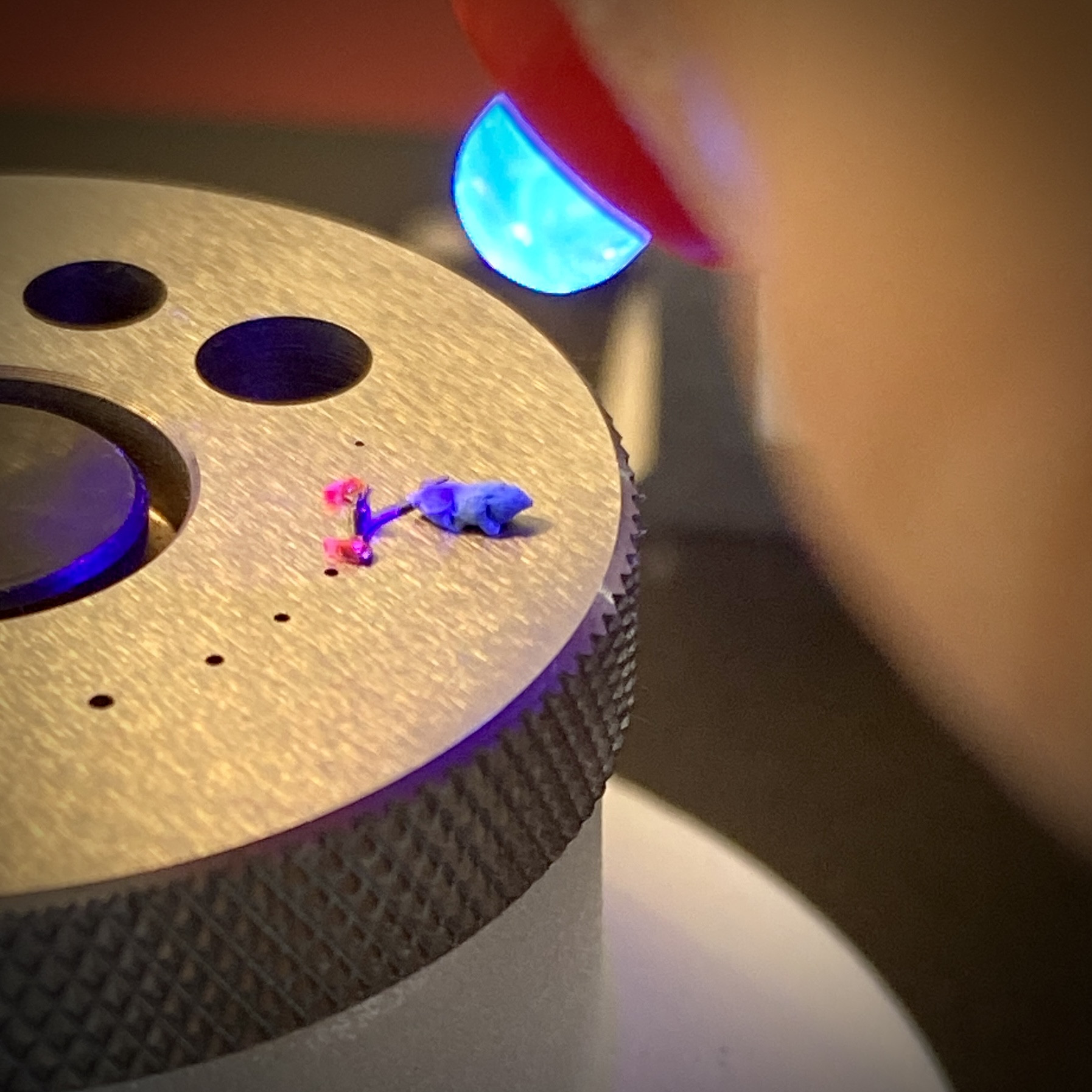

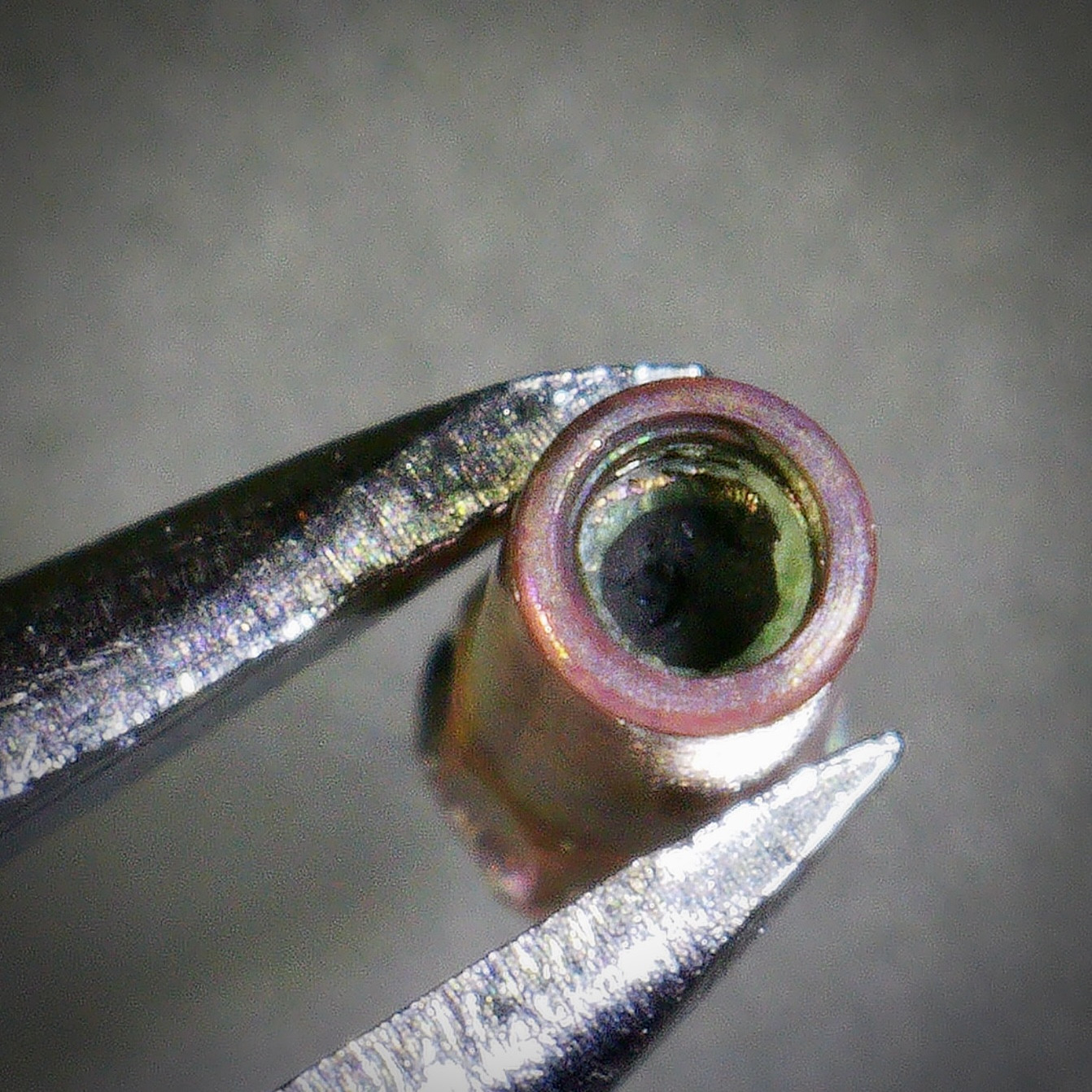

My DIY method was to first degrease the part using 99.9% IPA as a first bath, then after drying the part, using a second bath of Acetone to remove any oils that might have made it onto the part from my fingers during the hand finishing. Then I prepared a concentrated solution of citric acid at 50C and left the part in the solution for 20 minutes. Below is a time lapse of the part in the bath. It's not terribly exciting, but you can see that initially there were a lot of bubbles as the surface iron was eaten away by the acid, but then the bubble formation rate decreased and eventually slowed to a stop. Hopefully this means that all the of surface iron has been removed.

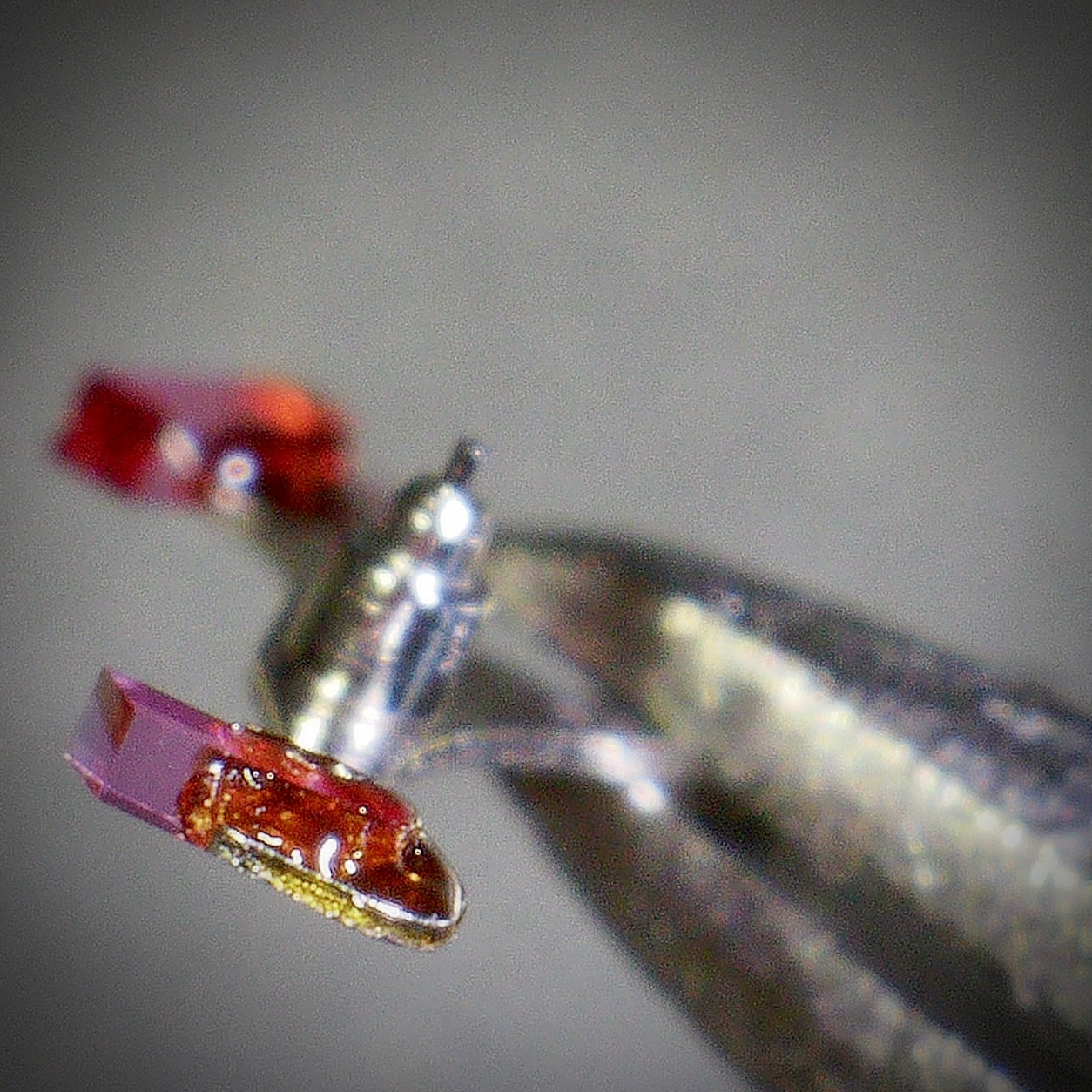

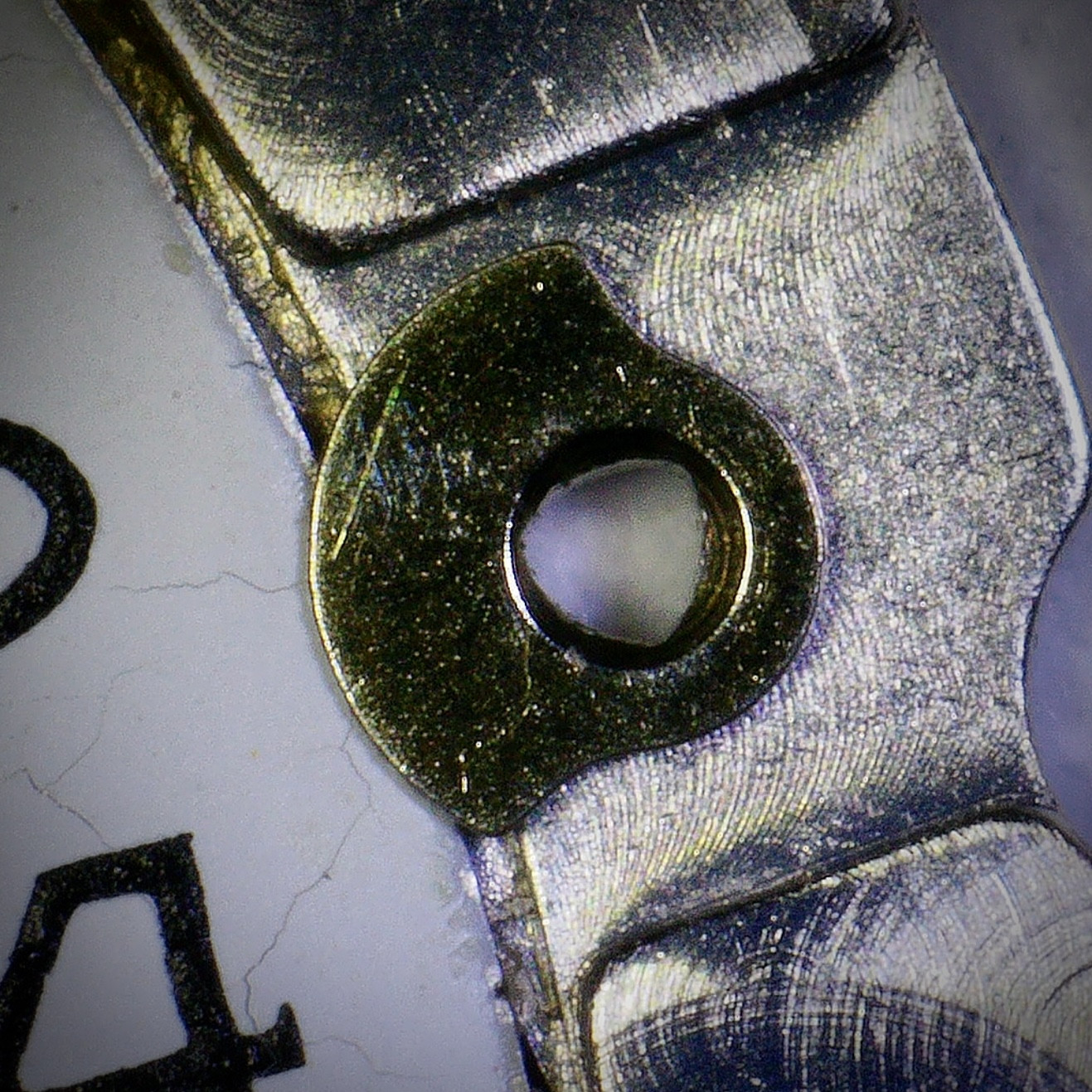

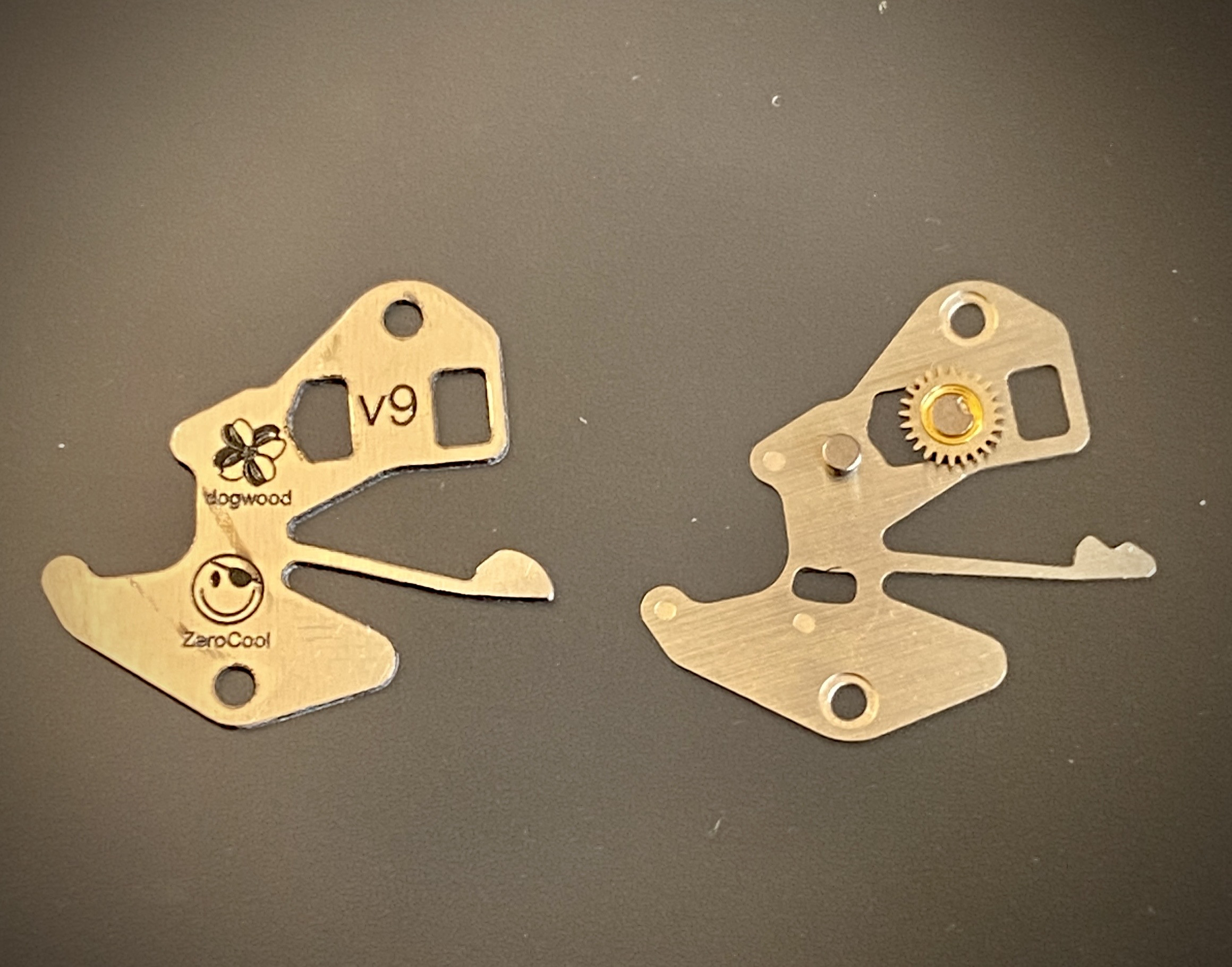

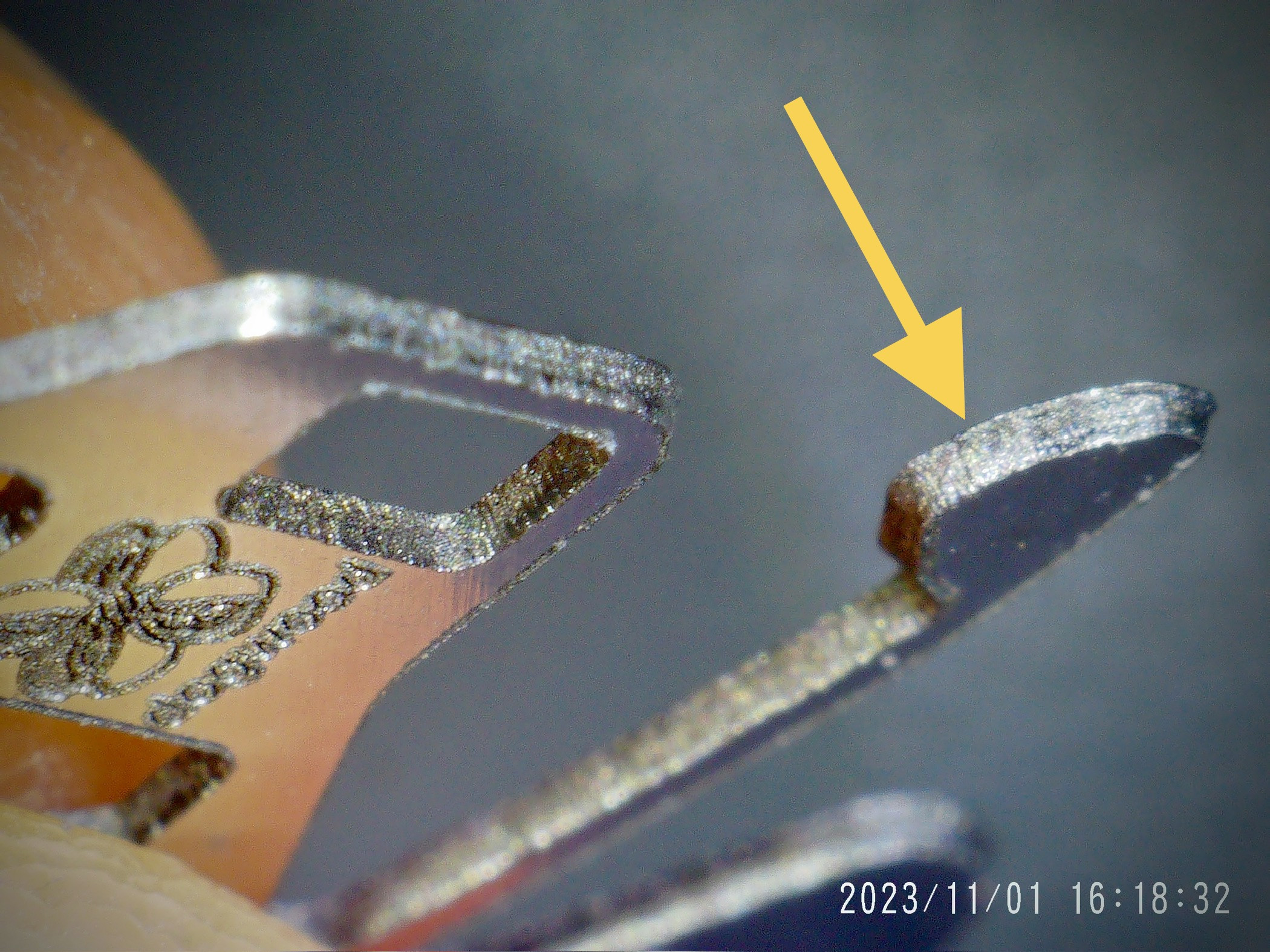

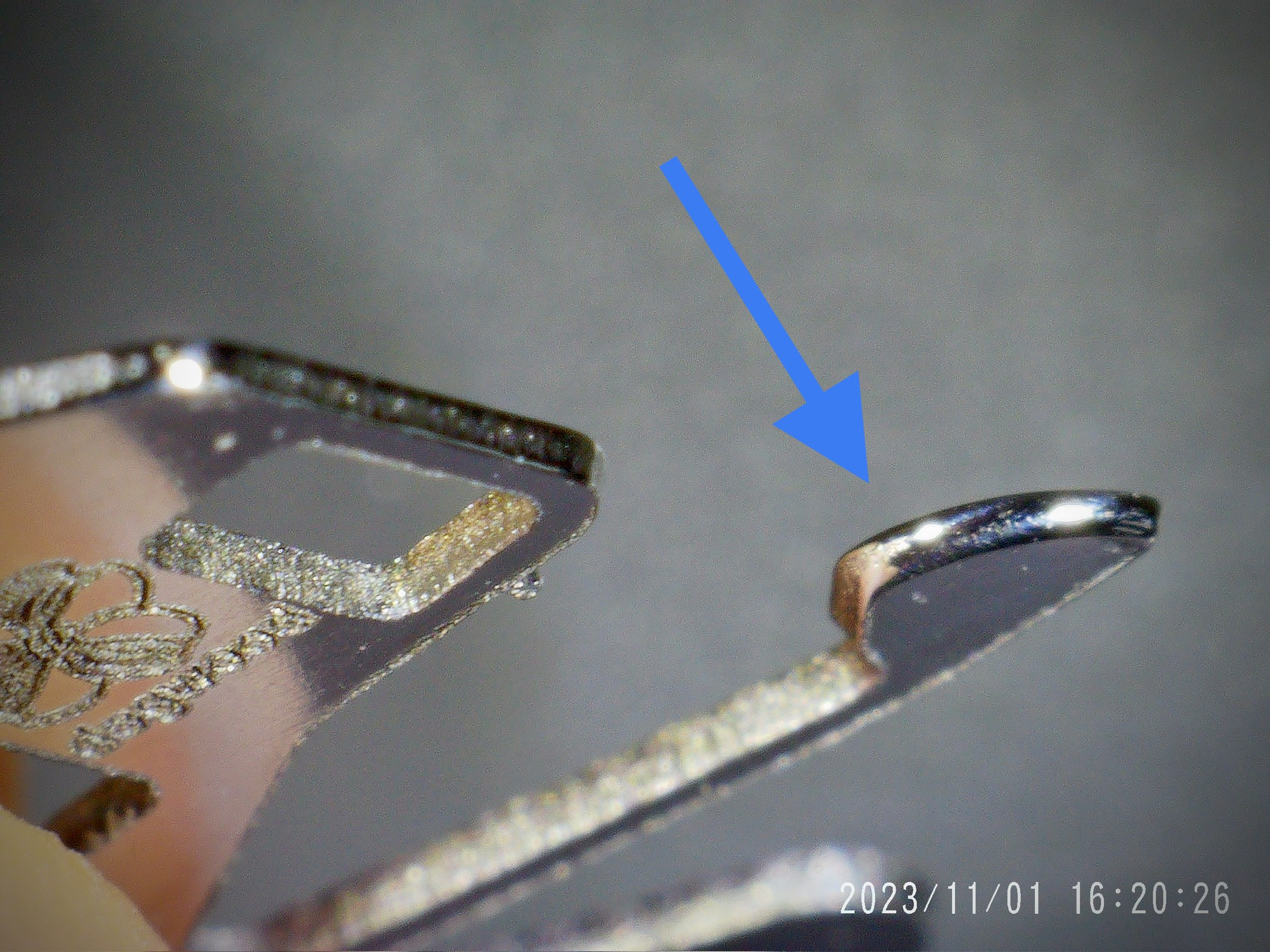

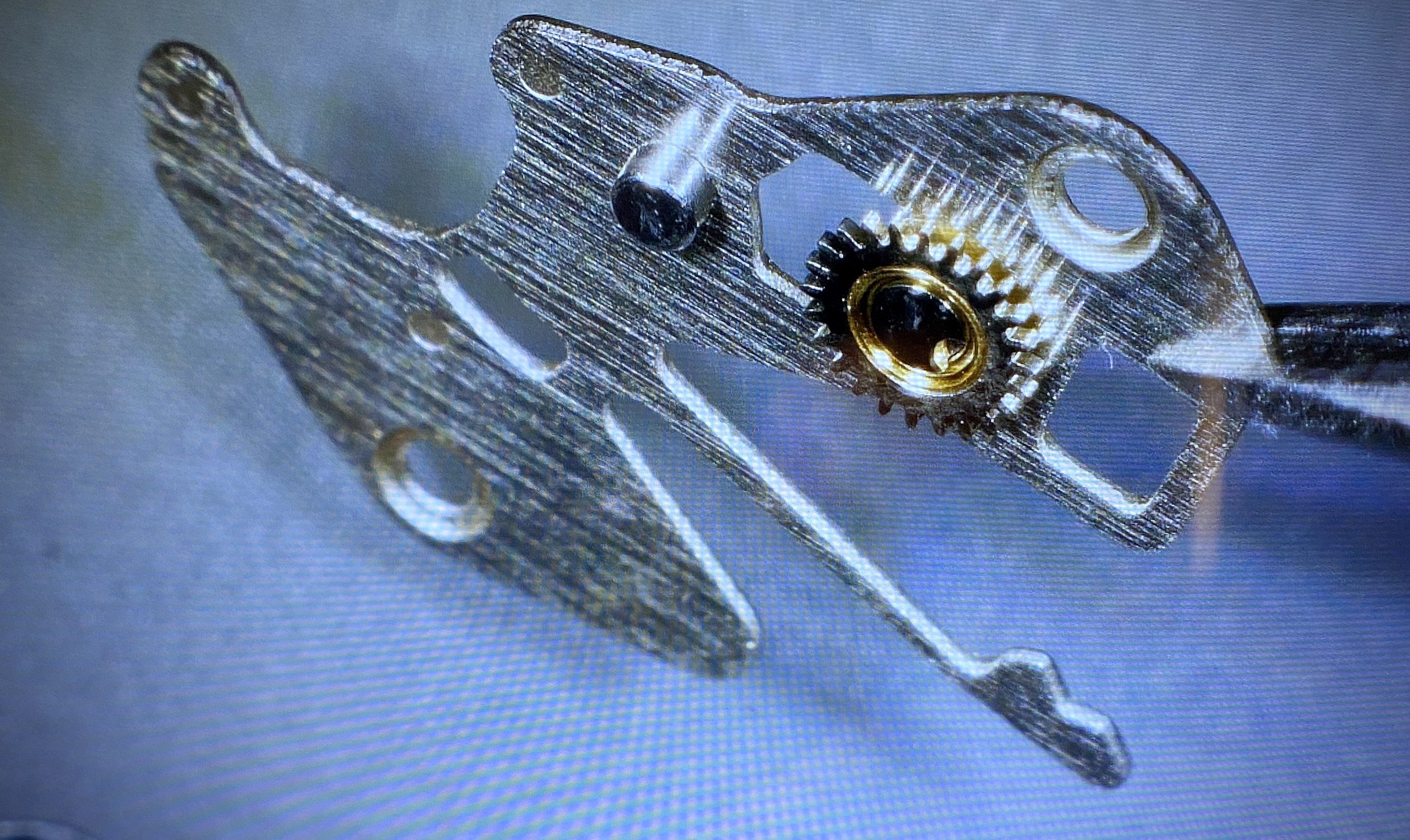

Here's the finished part, and for comparison the stock Dandong part at the same magnification.

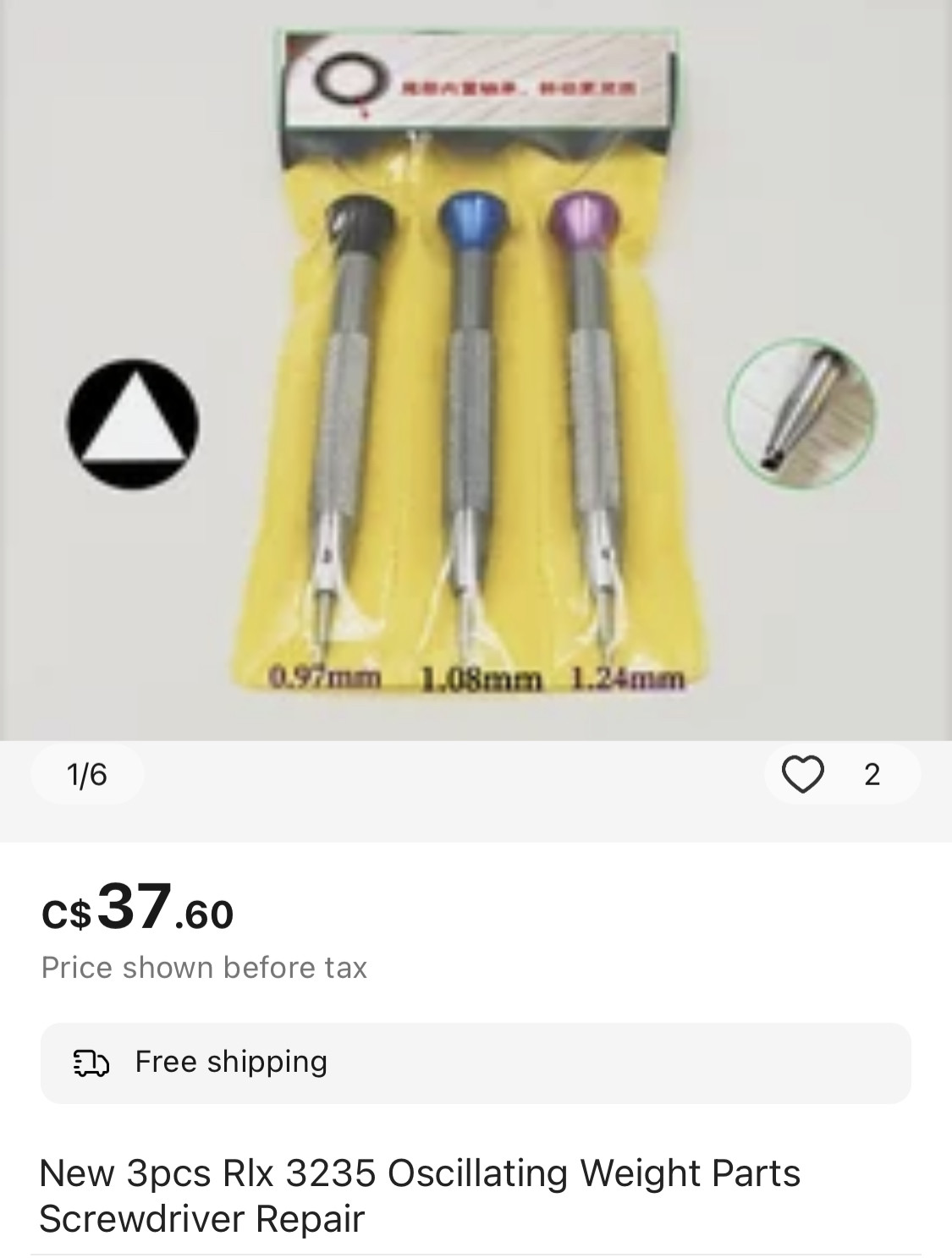

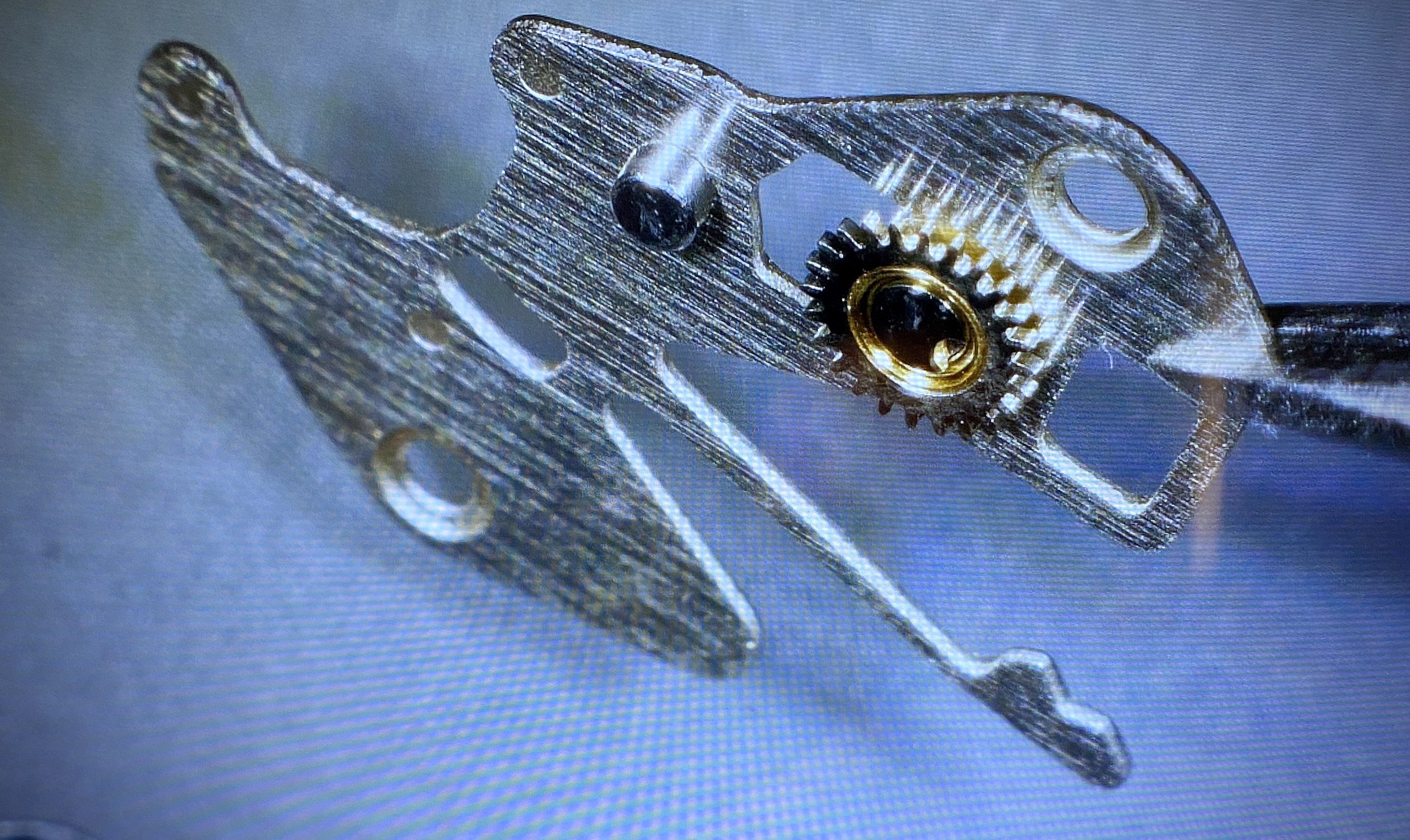

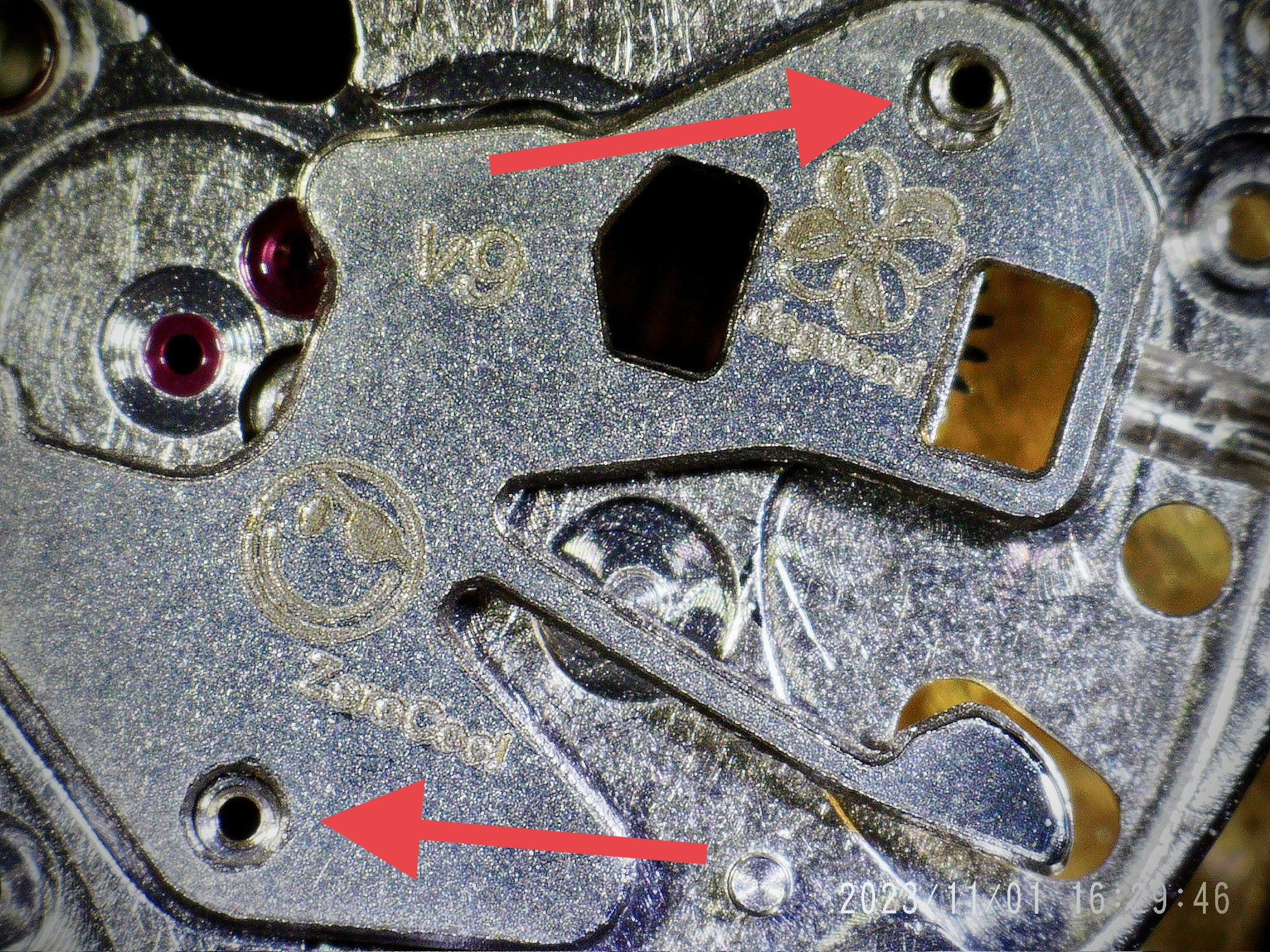

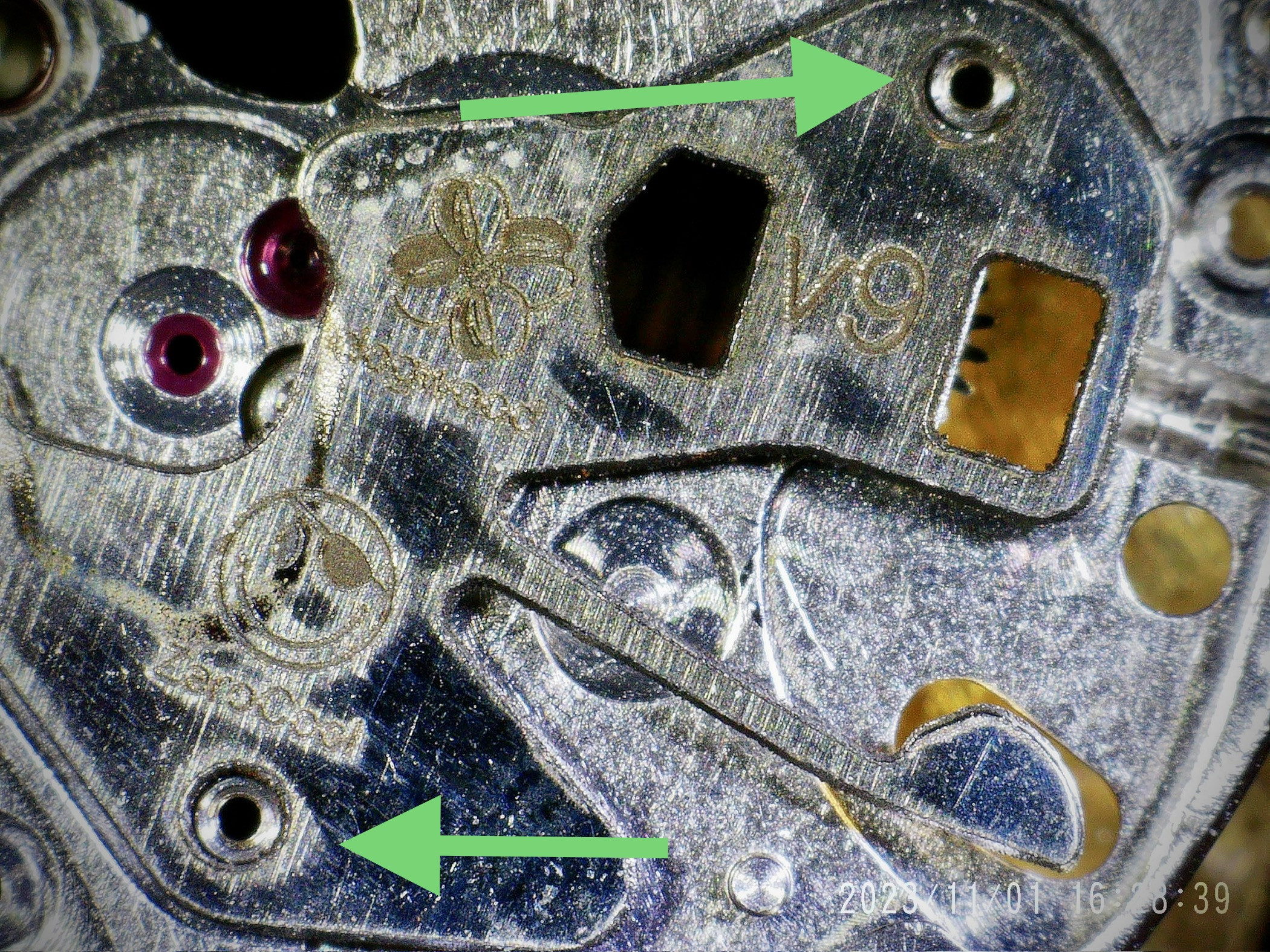

In order to get these parts widely available, we need to develop a way of finishing the edge profile of the part to be as smooth as possible without having to hand finish the each individual part. ZeroCool has been doing a LOT of testing on this, and we might have a method involving a rock tumbler and a combination of grits that effectively deburrs and smooths the edge profile. It's not a fast process, but it might be a "hands free" process, which is what we're looking for. The pic below is from ZeroCool and shows the casualties of production testing...

We've also looked into stamping the parts since they're thin sheet metal parts... I even ran the calculations for 0.25mm 304 stainless, and for our part geometry the force required for stamping would only about about 750kg, which would be easy enough to generate on a manual arbor press. But stamping requires precision tools and dies to be made. I contacted a few tool and die makers, but the cost would be high, and I was warned that 1) the tool may not last that long because the long skinny spring arm is quite thin, so the tool that punches it out may break after very few actuations; and 2) stamped parts don't have very good edge finishes since the sheet metal both shears, but also tears. The way to solve the tearing problem with stamping is to do an operation called "Fine Blanking" which is where the tool and die are far more complex and the metal parts getting punched are supported by a counter punch as they are sheared. The problem with "fine blanking" is that the tooling costs at least $50K... so that's kind of out of the question. One final option, is production wire electronic discharge machining. Wire EDM is a process where a thin copper wire is threaded through metal and a high voltage is put on the wire, as the wire approaches the stock material a spark jumps across and erodes away the stock material (and the wire, but the wire is cycled through from a large spool, so there's always fresh wire). Wire EDM is the process that produces those amazing metal parts that slide together and have no seam. But Wire EDM is also expensive and offers levels of precision that just aren't required for this part. But is doesn't have the HUGE upfront costs of tooling that fine blanking does.

Anyway... TLDR: the VS3230 setting lever spring project is progressing and hopefully soon these parts will be available to the community.