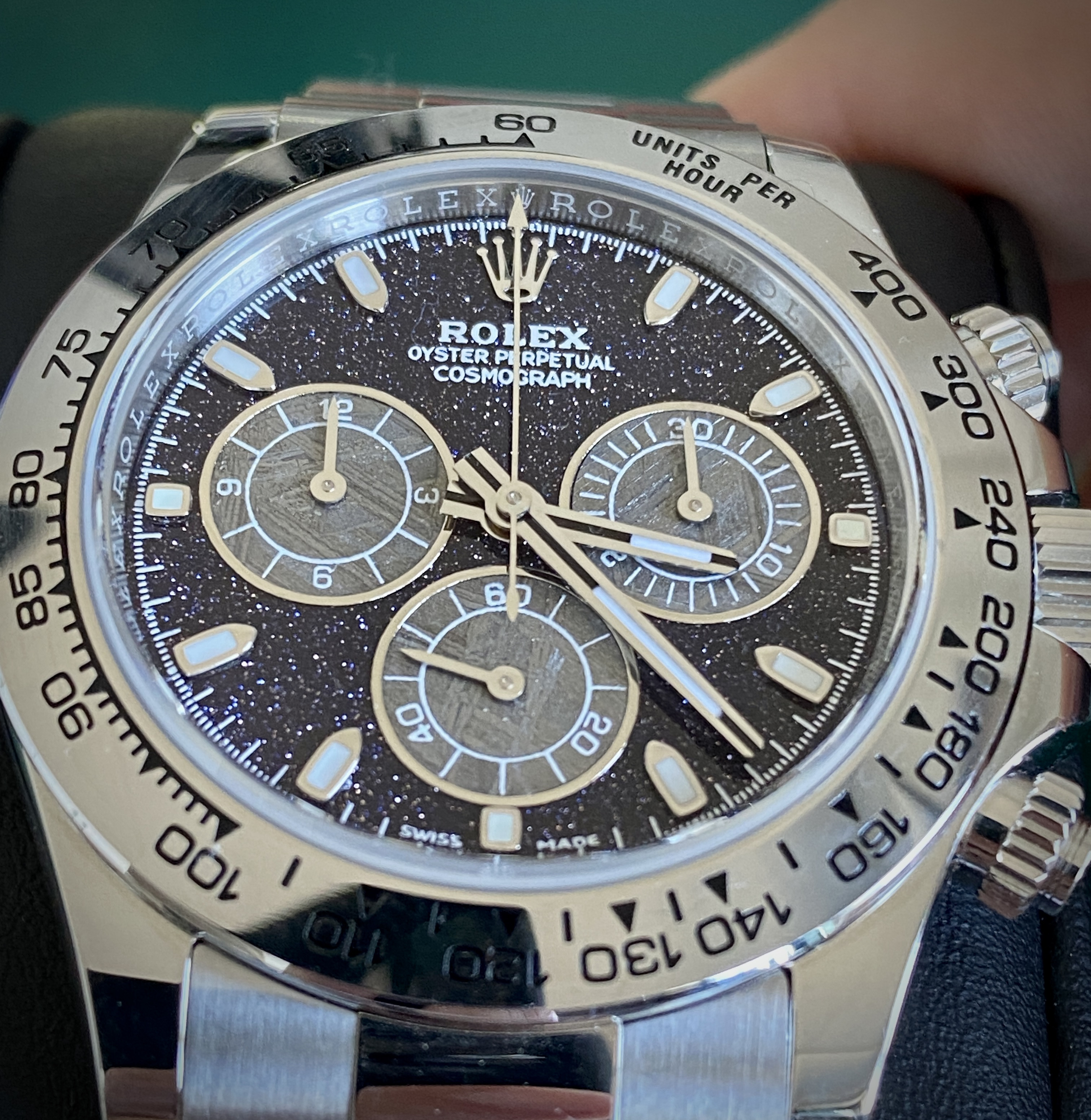

I did a fun personal build this week... I recently picked up one of

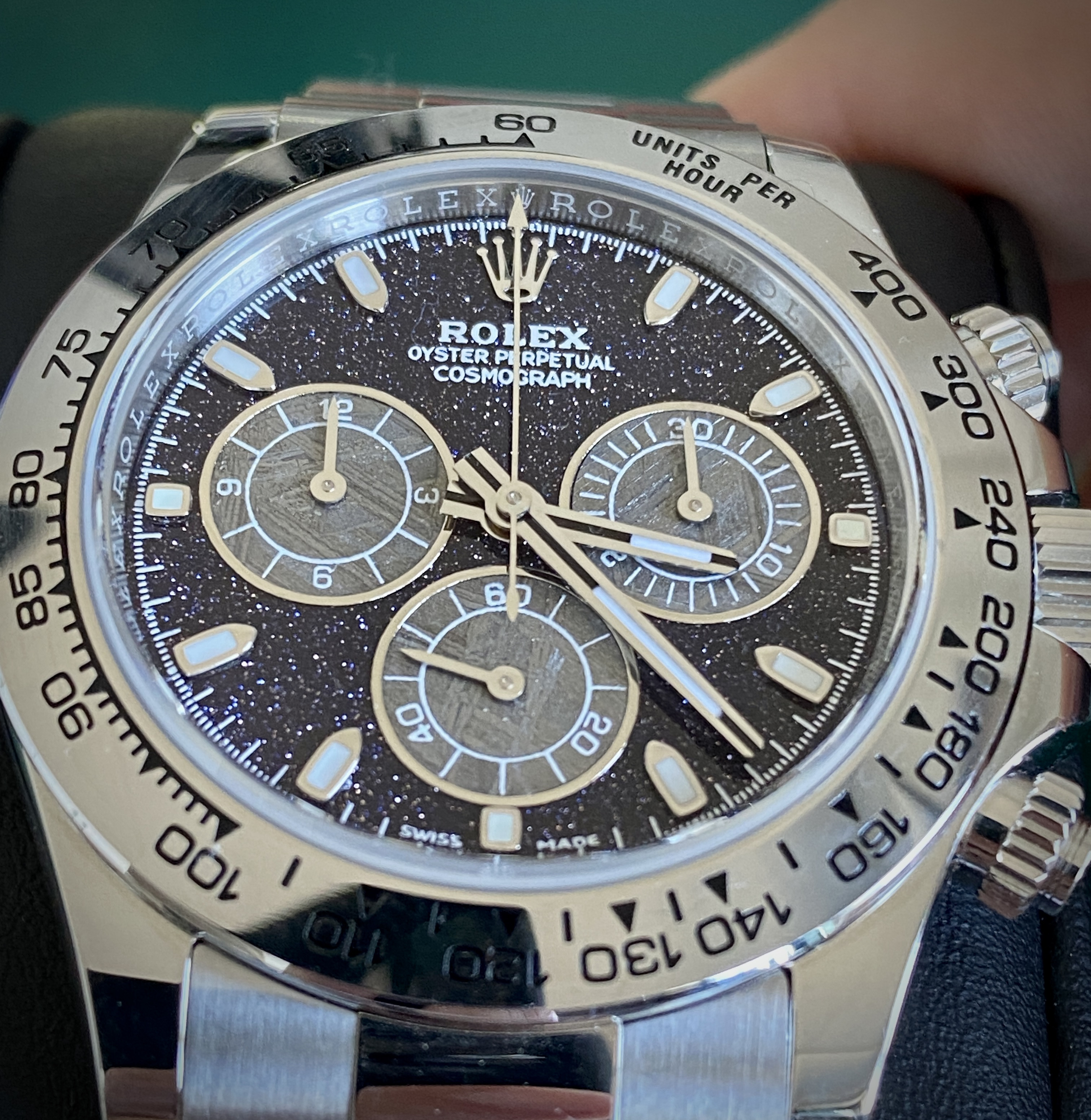

@Oascom's custom aventurine & meteorite Daytona dials.

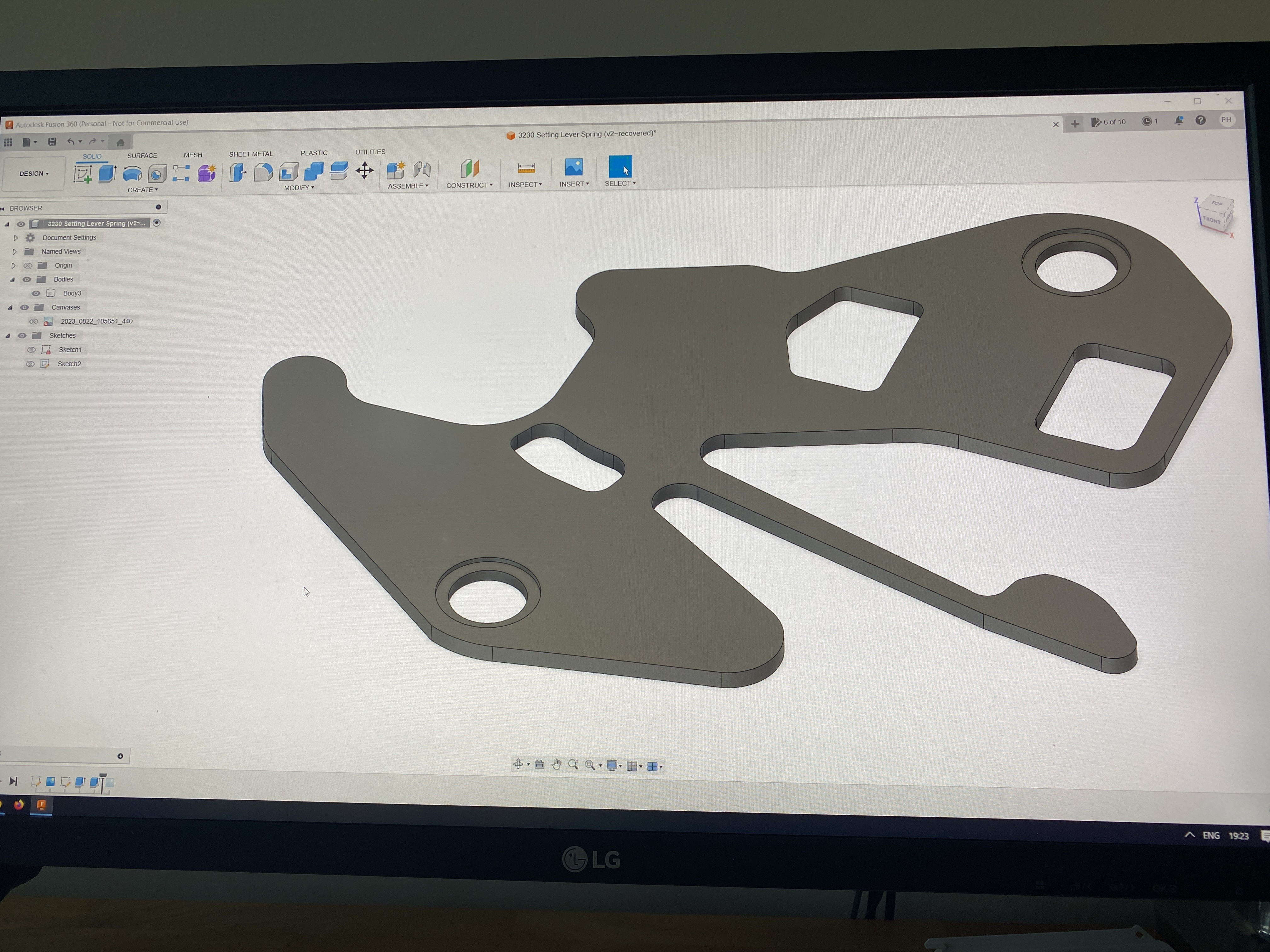

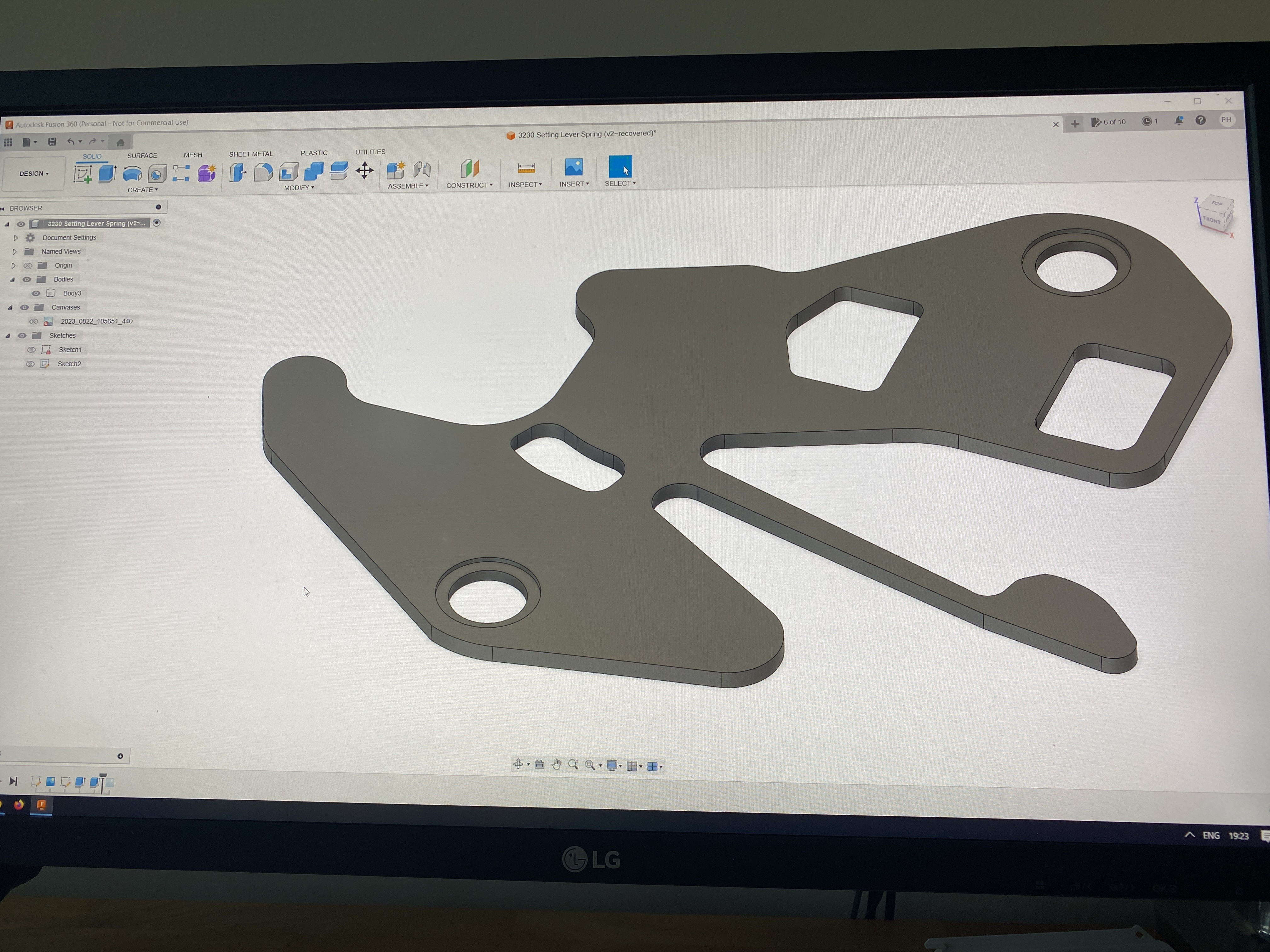

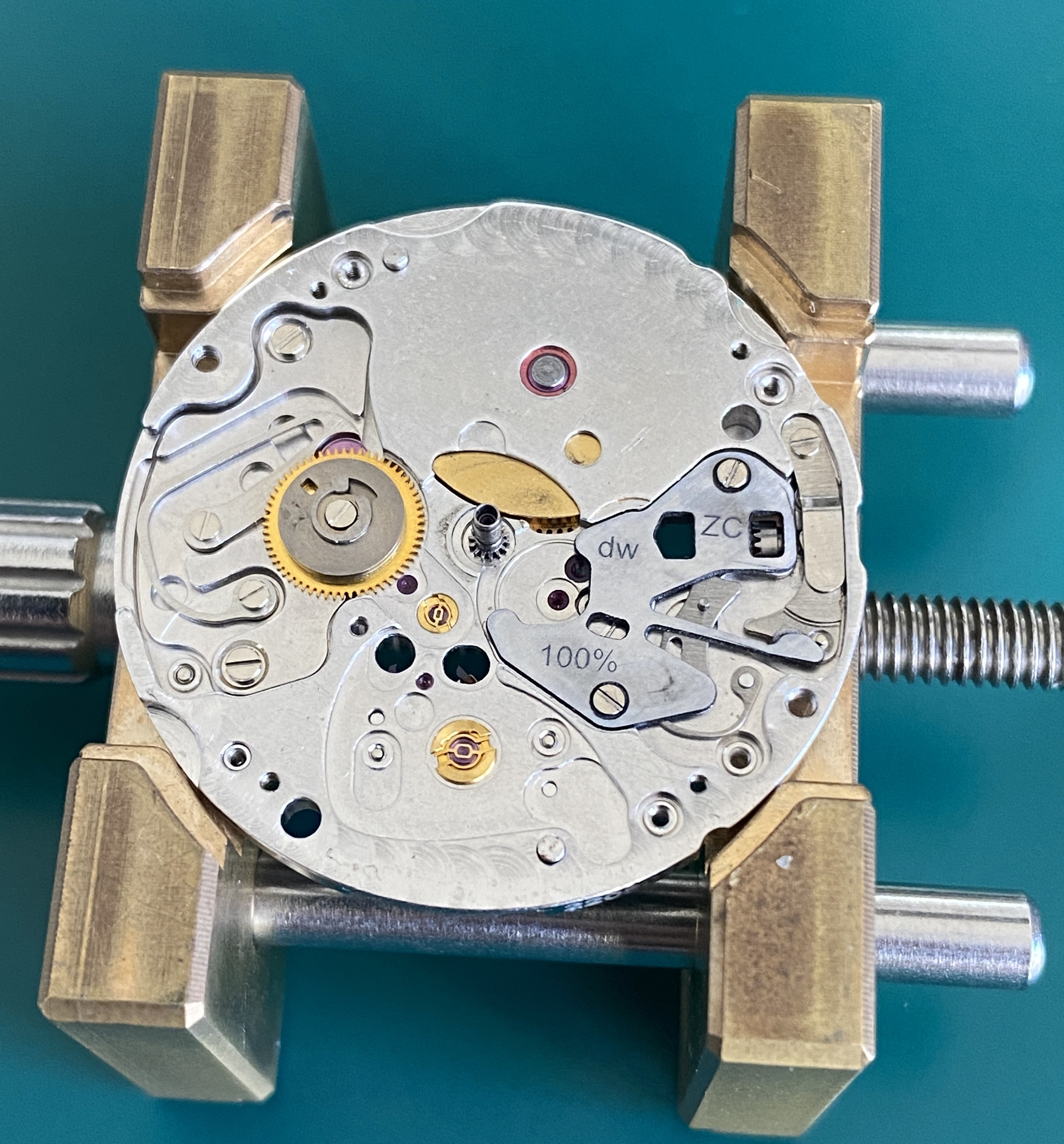

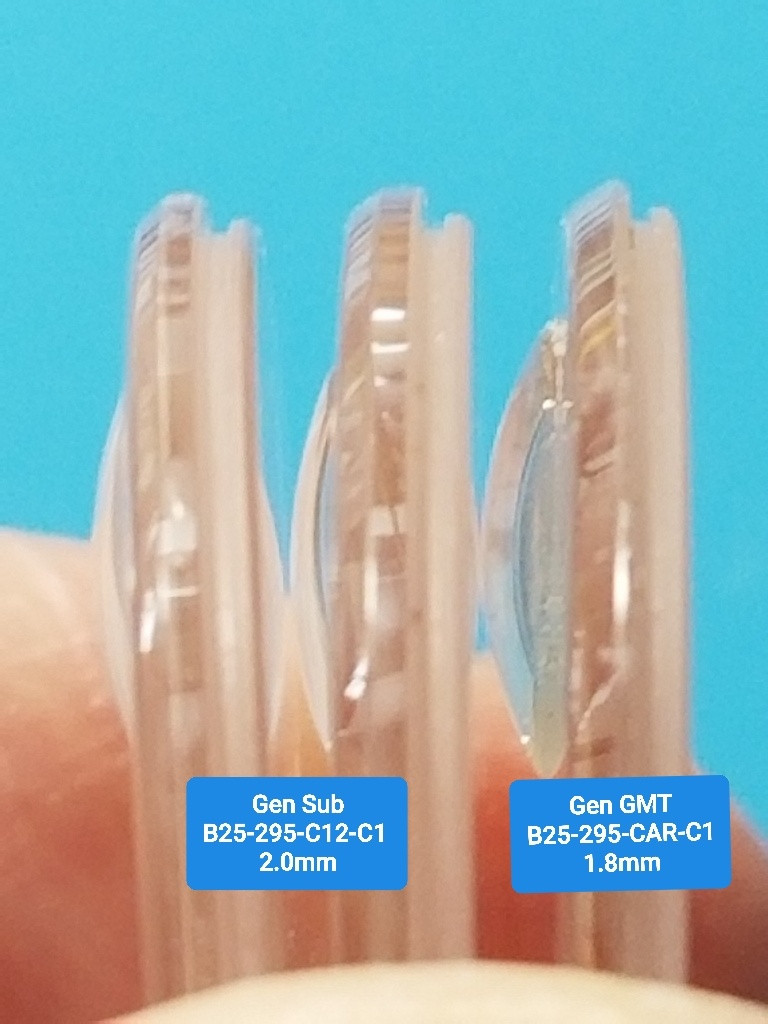

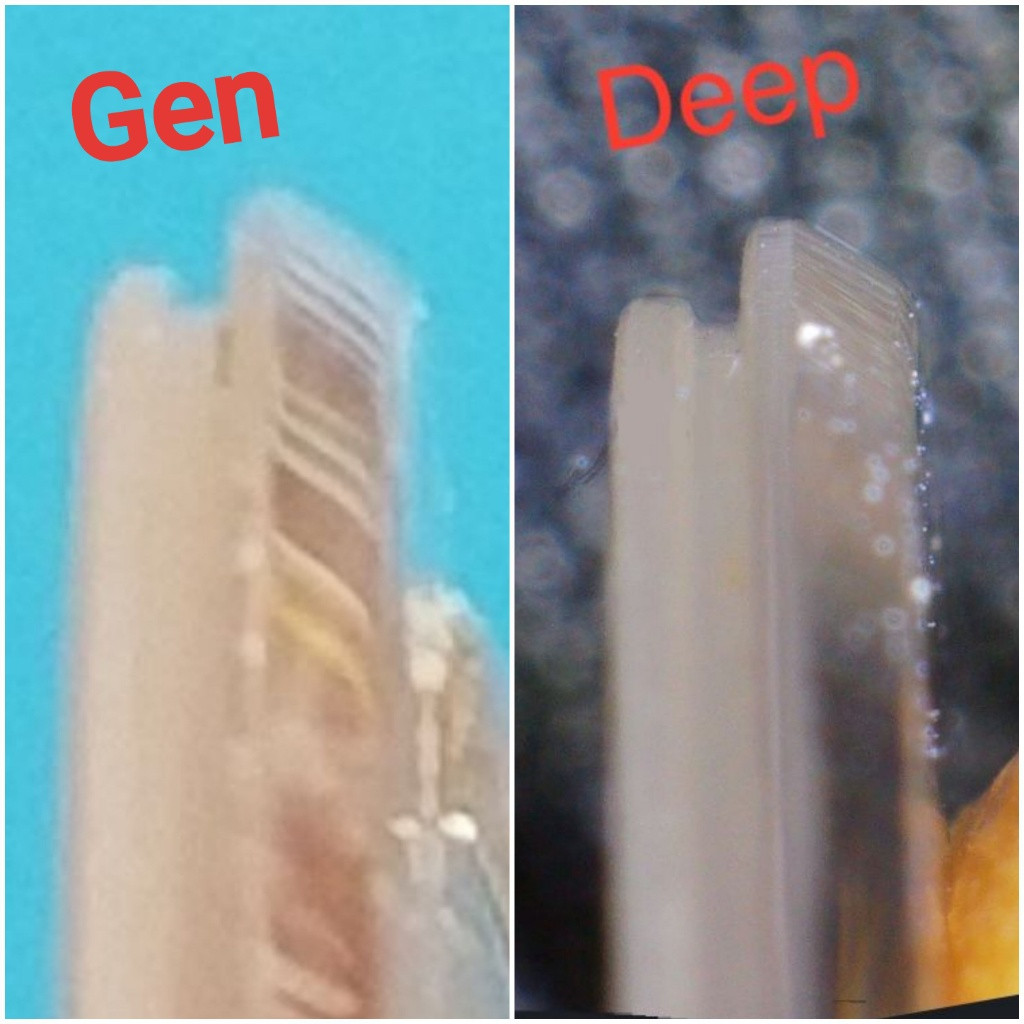

I've had a BTF 116509 in my watch box that has had very little wrist time, and I thought I'd try making a custom piece-unique Daytona. After giving the DD4130 a full service, I secured the new dial on the movement with two dots of 5 minute epoxy (Oascom's dials don't have dial feet). The fit and alignment was perfect.

With the hands pressed on, I was starting to get very excited. The way the aventurine sparkles really goes with the "Cosmograph" theme of the original Daytona naming. The iron-nickel crystals of the meteorite sub-dials just add to the space theme of this build.

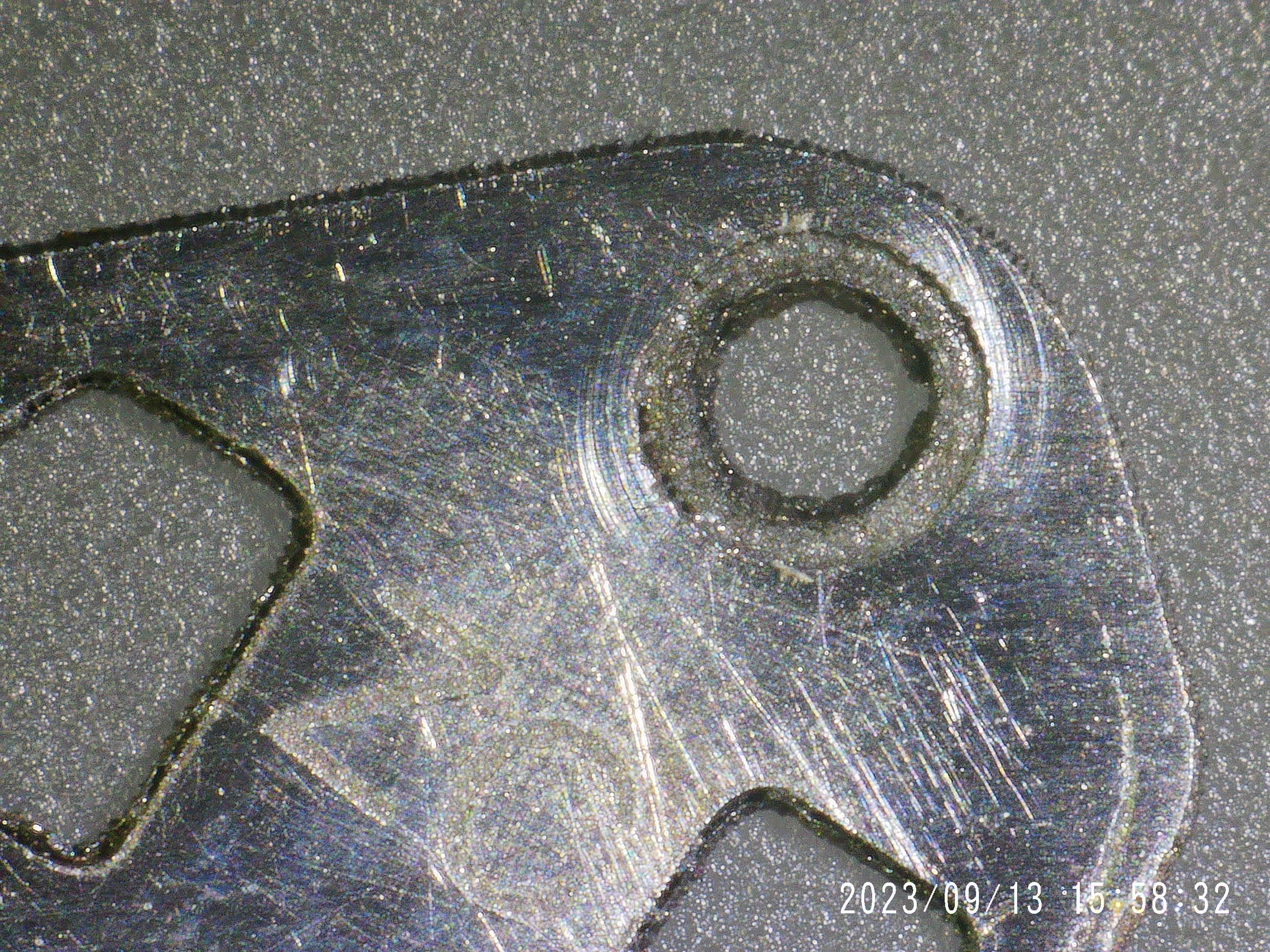

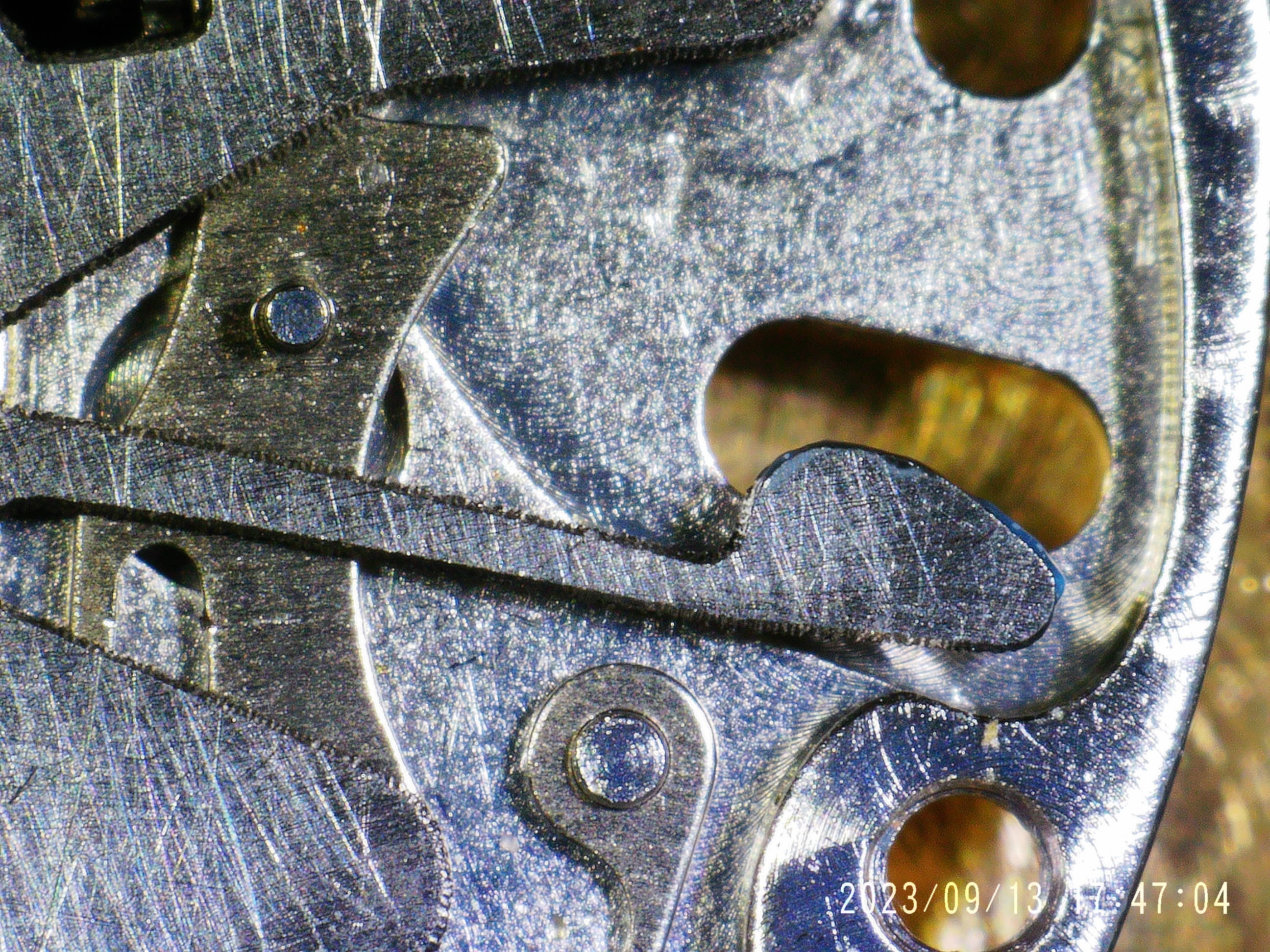

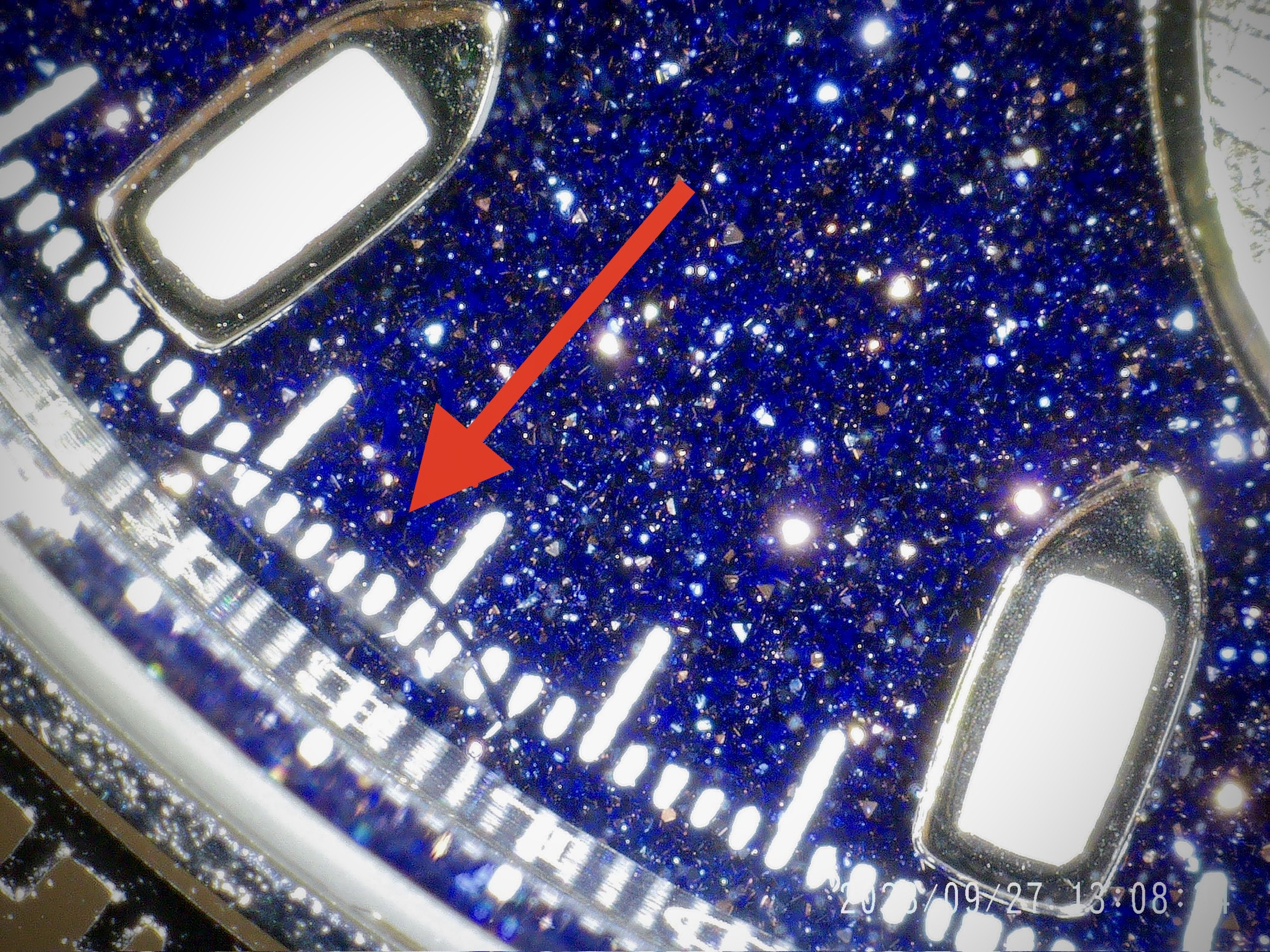

But as I was securing the movement + dial into the case with the case clamps, I heard a "crack"... I hadn't applied must torque to the case clamp screws, so I was surprised. When I flipped the watch and inspected it under the microscope, I saw a crack in the aventurine running in a half moon shape through the minute track.

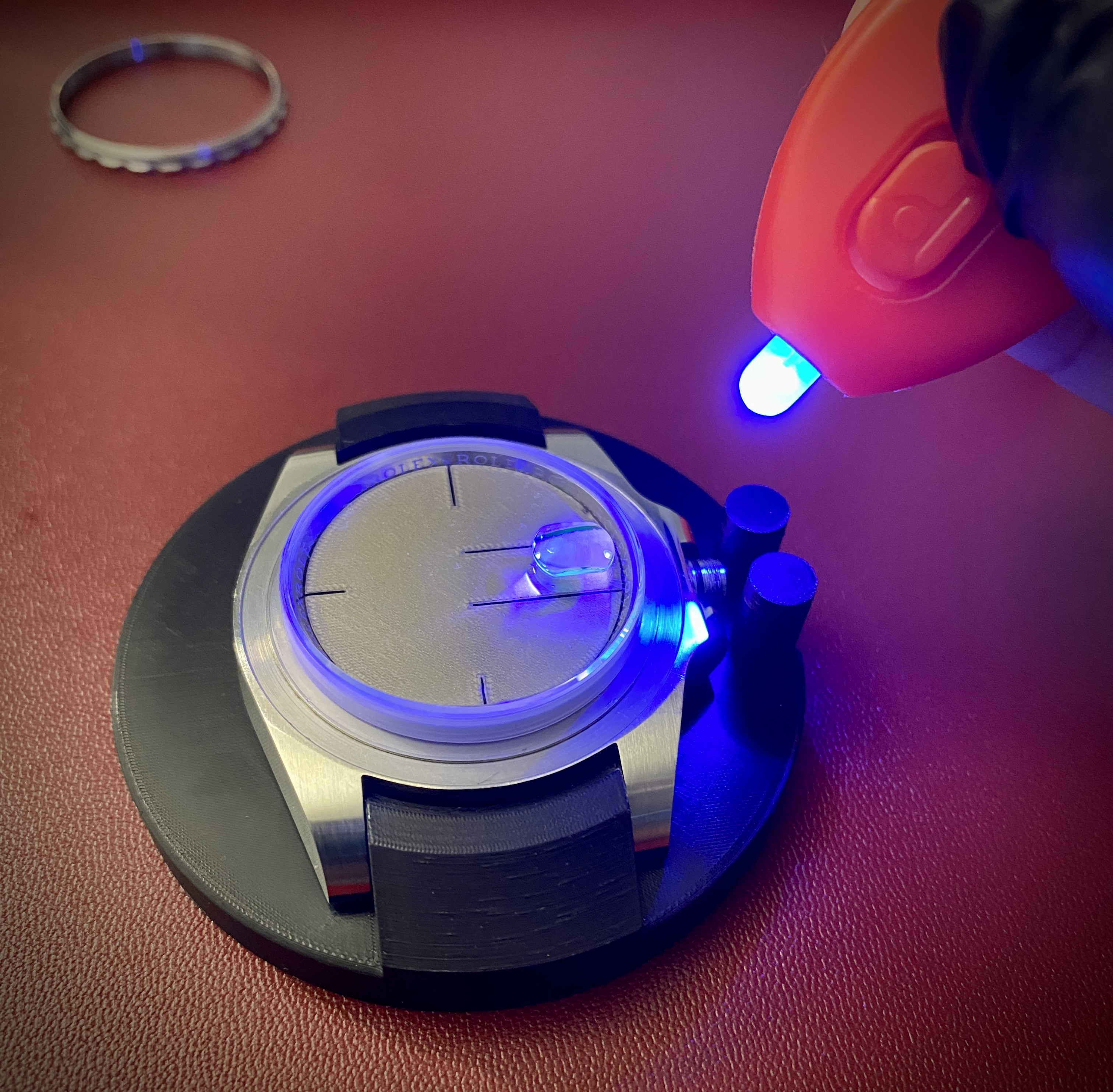

I knew that a stone dial would be brittle but I was surprised nonetheless. After a few messages back and forth with Oascom to discuss how the dial could be repaired, we came up with a plan to use optically clear UV glue to shut the gap and to use the movement as a jig for the procedure.

Fortunately the crack was over a part of the movement that was full height, and the crack hadn't gone clean through the dial, so it was a simple matter to apply a thin film of UV glue to the seam and then use a probe to squeeze the two sides together as I applied the UV LED light. (I didn't get any pictures of doing that since it required two hands).

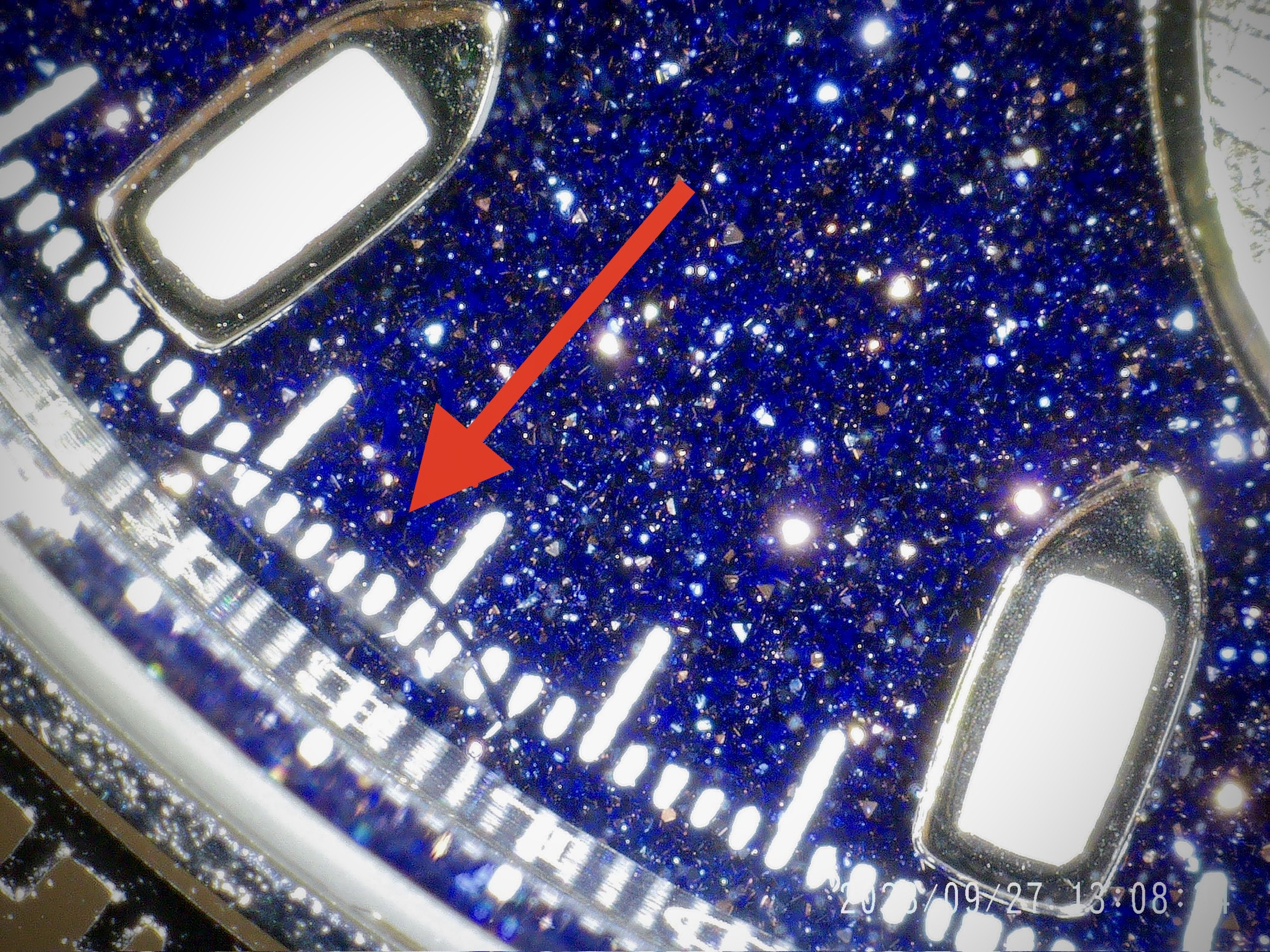

With the dial repaired, I got the movement + dial back into the case. The crack in the printing case be seen in this macro shot on the 39 minute marker, but it's basically invisible to the naked eye.

Pictures really don't do this dial justice. The aventurine sparkles really nicely as it moves through the light. I'm worried that it might be a little too much "bling" for my style. But it was a fun project nonetheless.