A very interesting project crossed my bench this week... The rep community has recently been blessed with two new GMT movements: the SH3285 (based on the VR3235), and the DD3285 (based on the VS3235). I have no qualms stating that the VS3235 is one on the best clone movements I've ever had the pleasure of working on (the other being the Dandong 4130 Daytona movement).

Unfortunately, there is currently no large date plate version of the DD3285... this means that for all the Explorer II lovers out there, there's no DD3285 powered Explorer available. However, there is a large date plate version of the SH3285 which is found in the new GMF v5 Explorer II. So this week I had the pleasure of trying to build a hybrid movement with an SH3285 date plate on top of a DD3285 movement. It turns out that it's possible, but not without a few mods to make things fit together snugly.

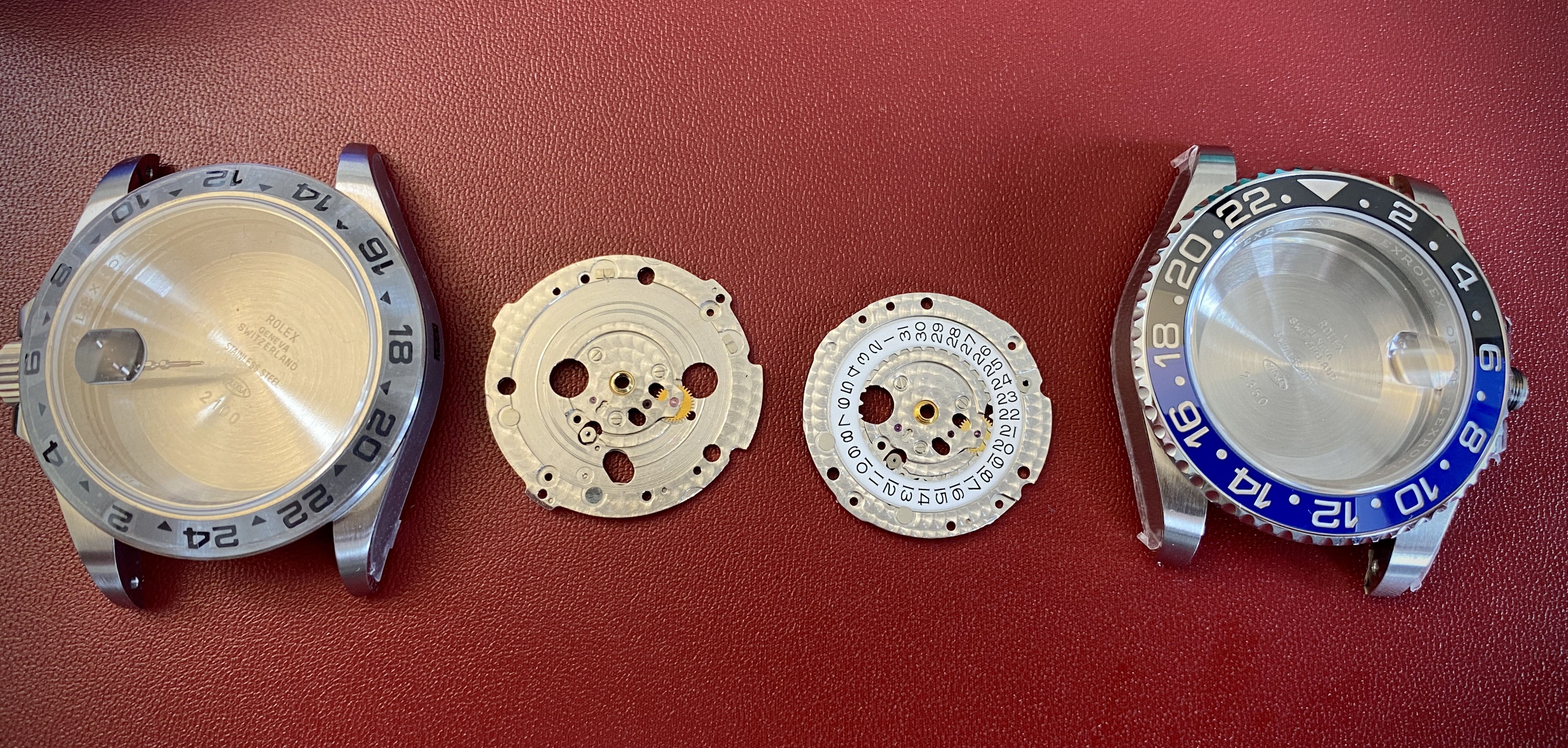

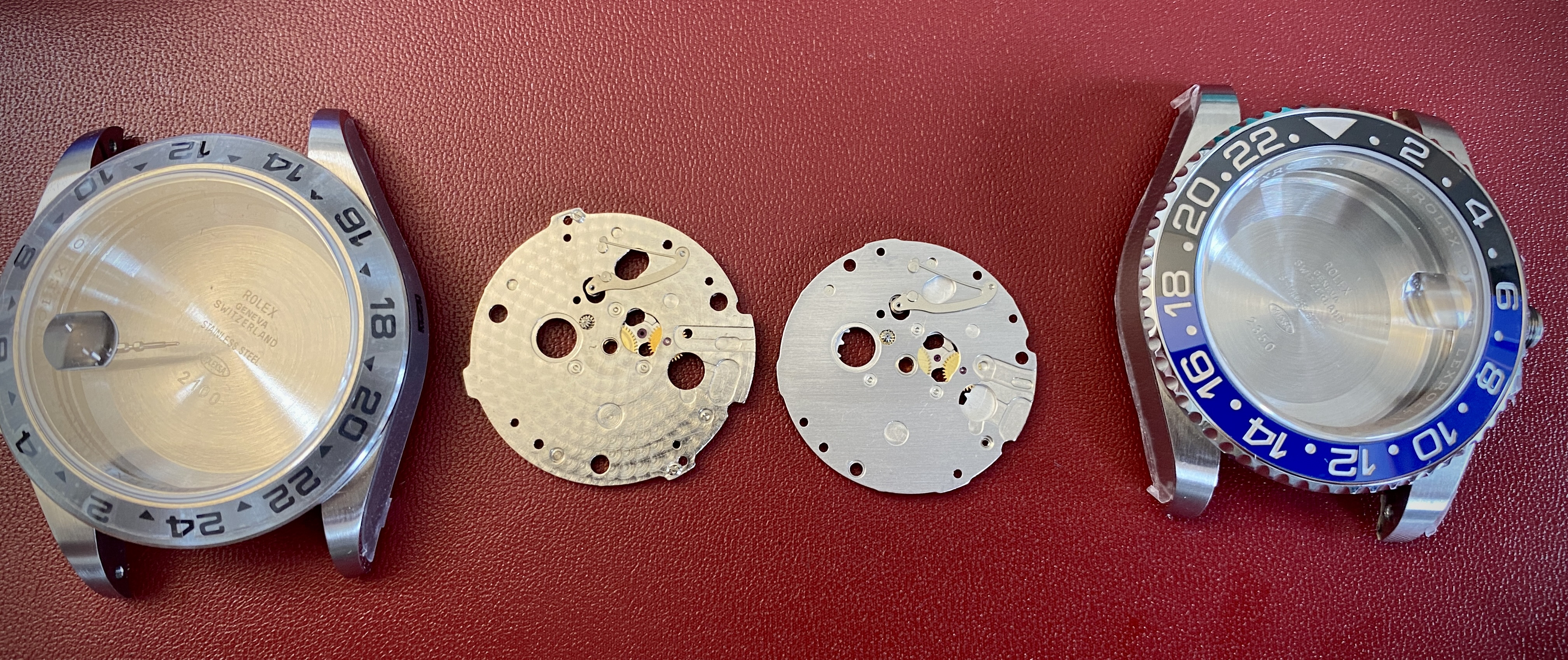

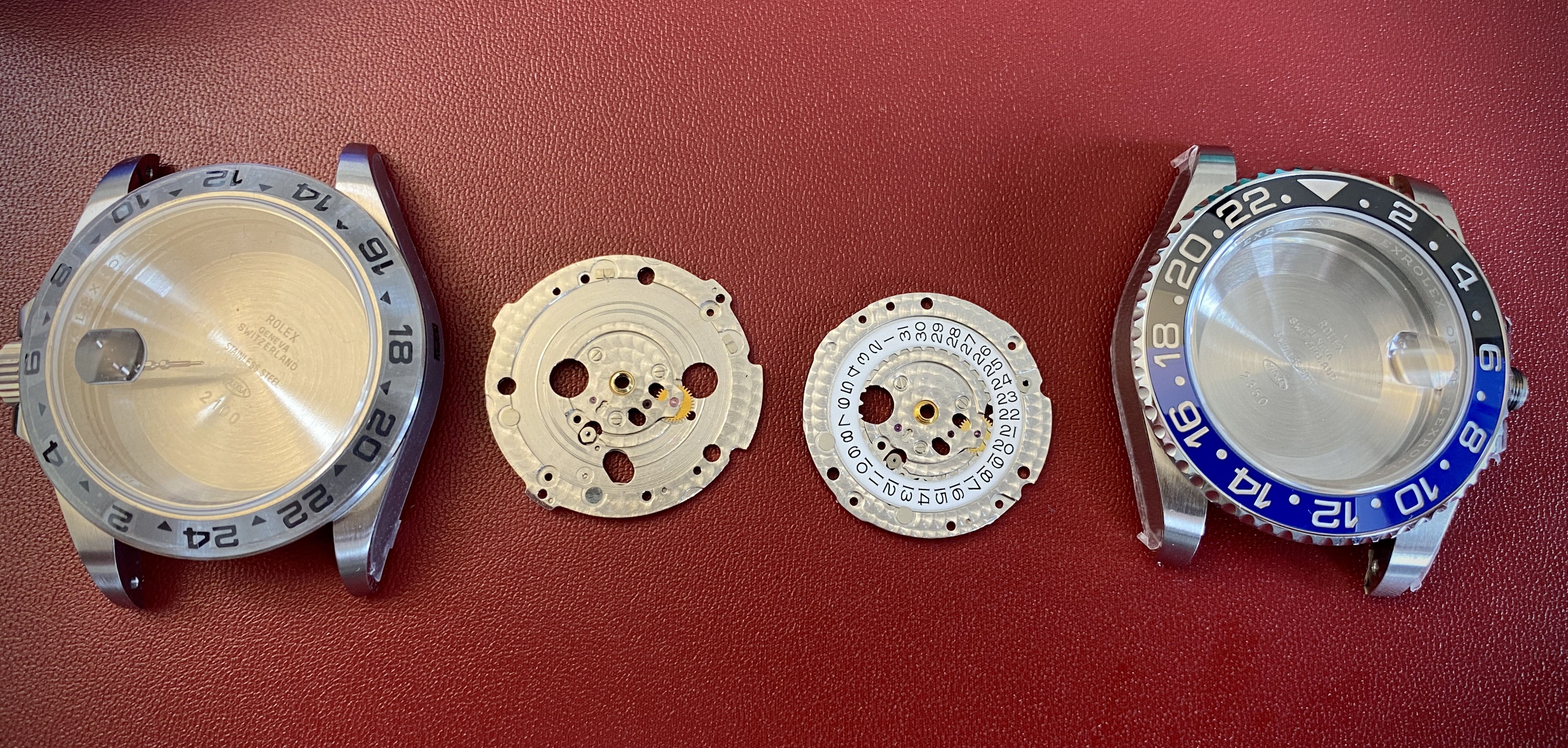

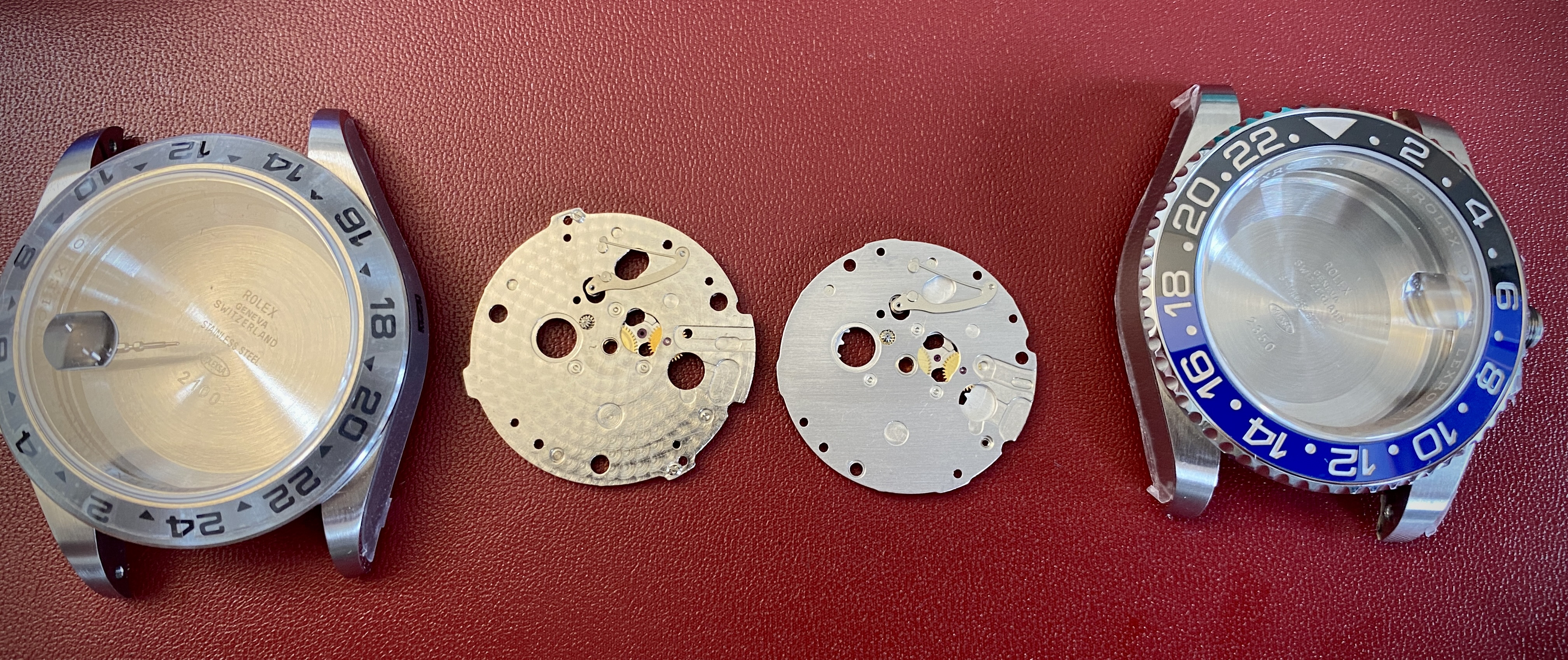

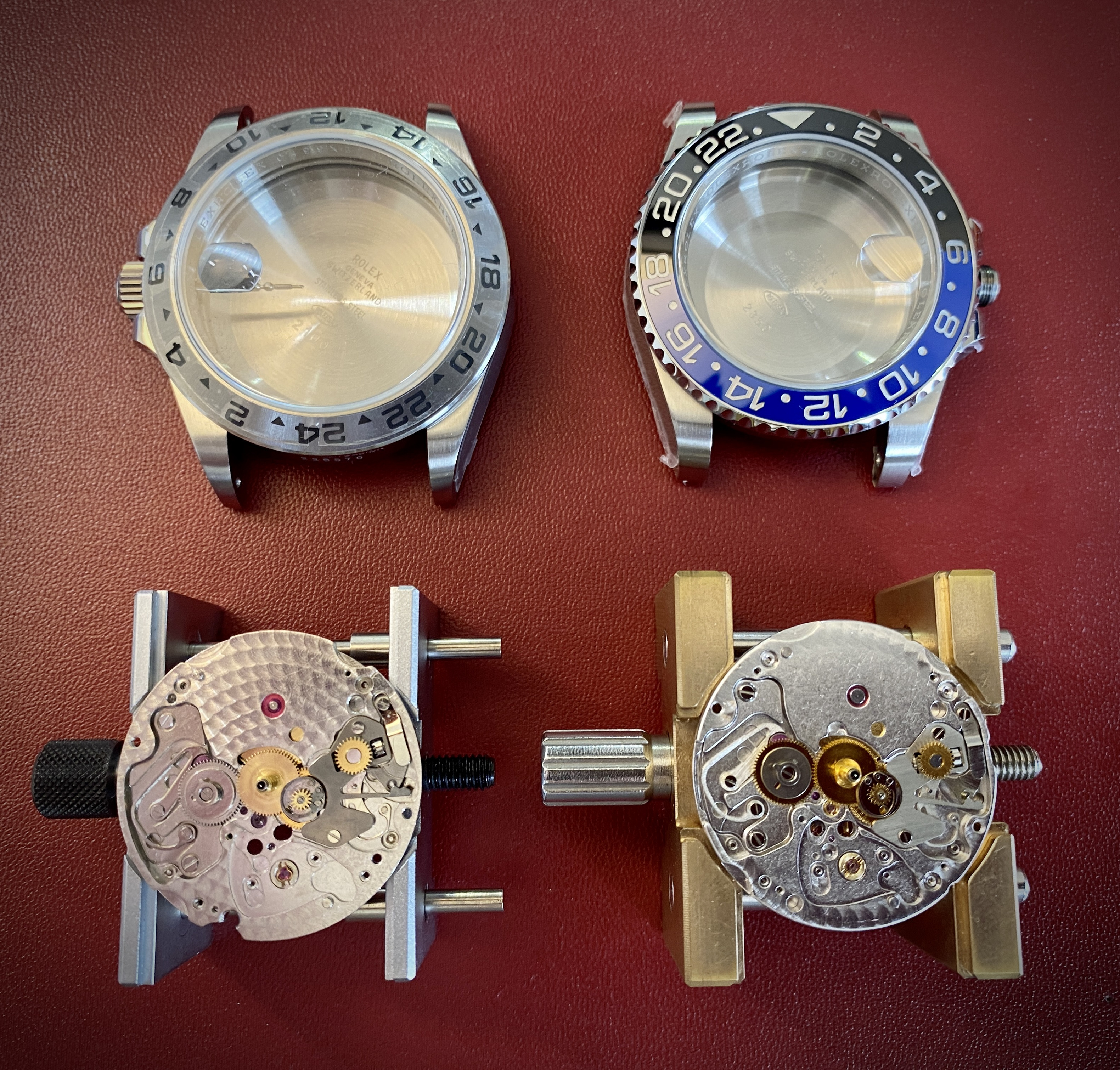

So where do we start? Well, we'll start with the GMF v5 and the CF GMT from which we'll be pulling the donor DD3285 movement. The stuff on the left of the photo is the GMF v5 and the SH3285 movement. The stuff on the right is the CF GMT with the DD3285.

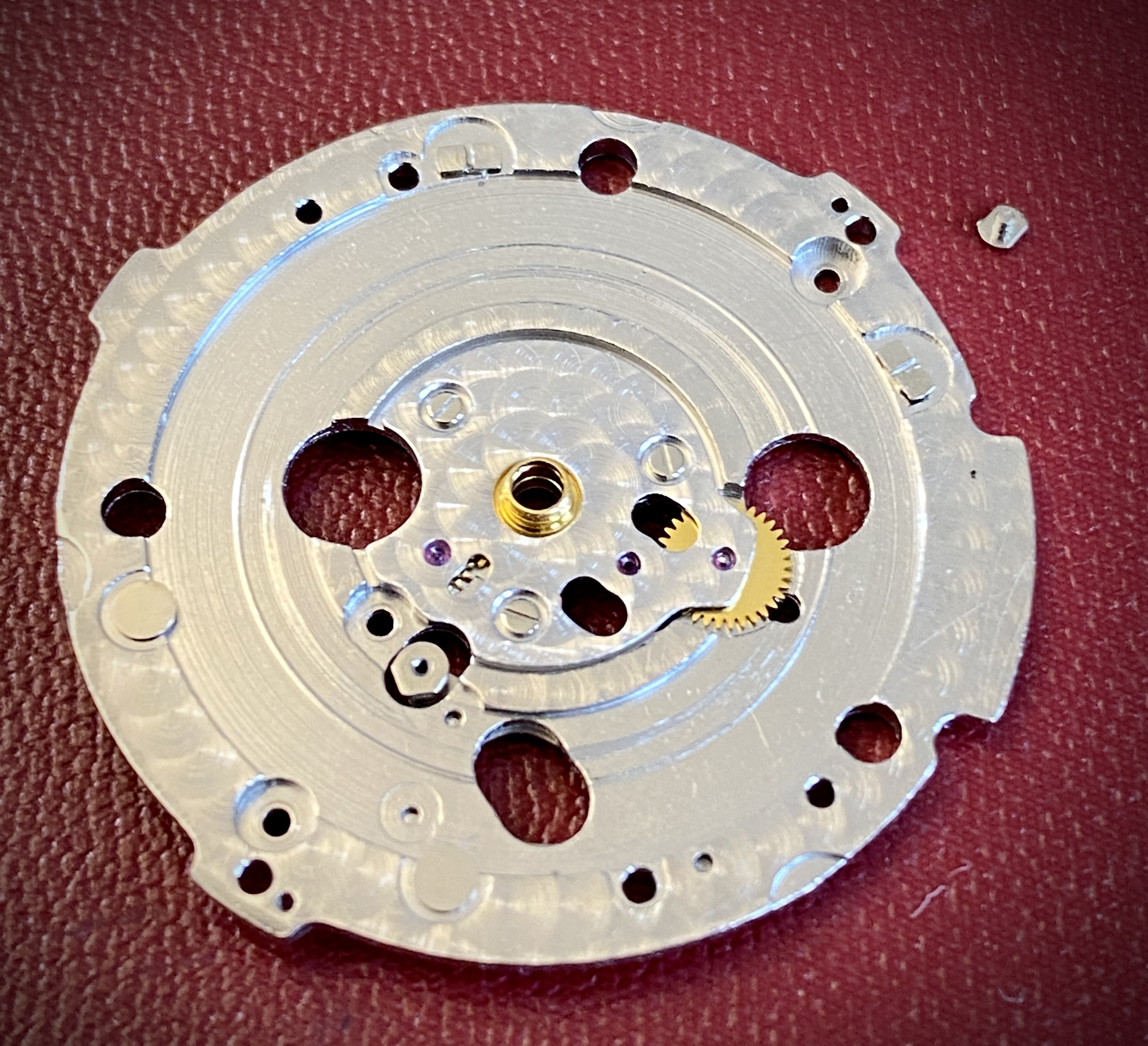

Unlike the VR3235 which has a 3135 style dial side, the SH3285 has a 3235 style dial side, so at this stage I was hoping that it would a simple case of part swapping to get the movement I wanted. Looking at both the top and bottom of the date plates, it certainly seems like they're very similar. NB: they both have exactly the same thickness too.

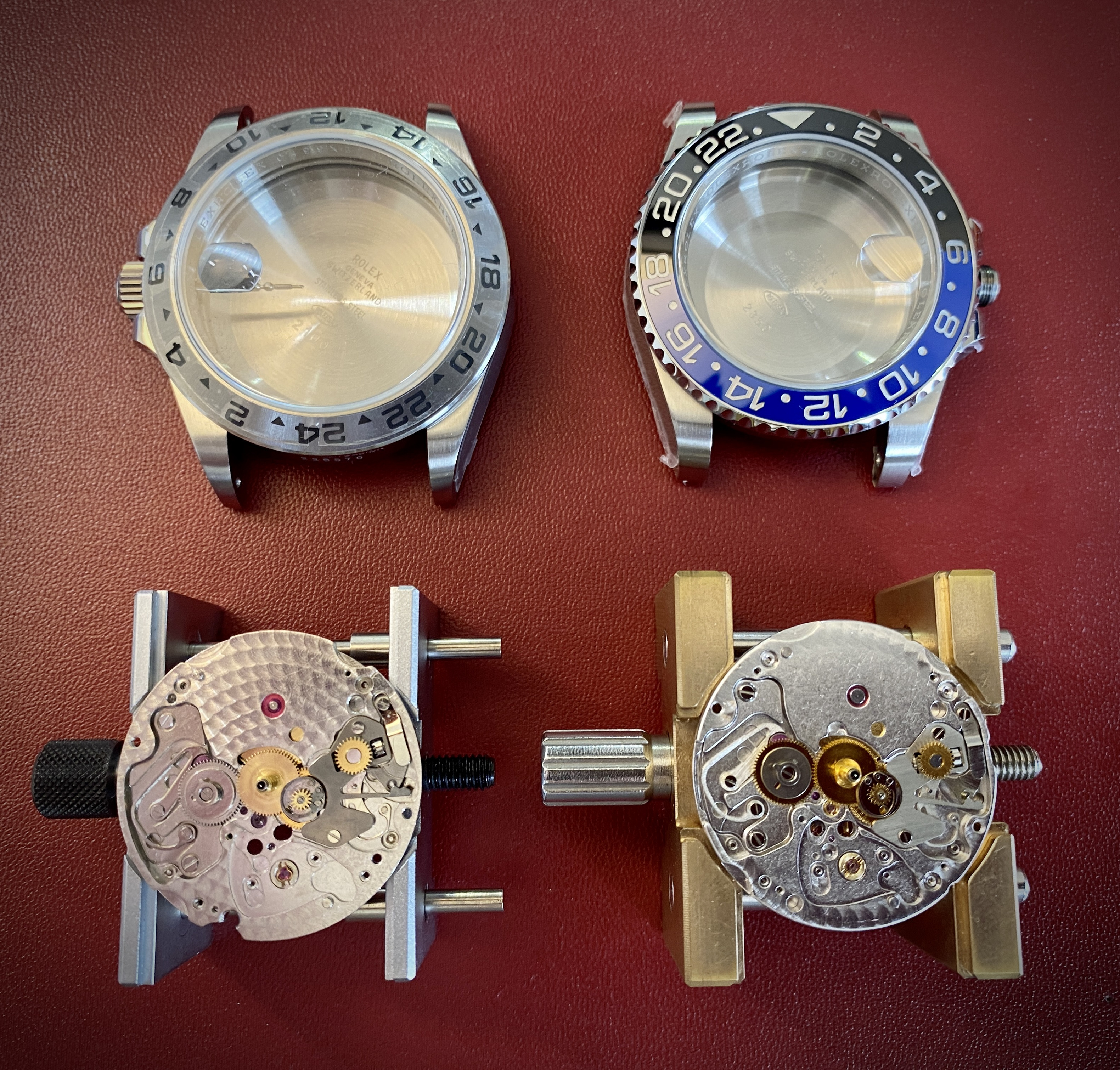

Looking at the movements themselves on the dial side, the SH3285 (left) and the DD3285 (right) do look like they're the same design. But that just means that any differences we run into will be small and potentially hard to find.

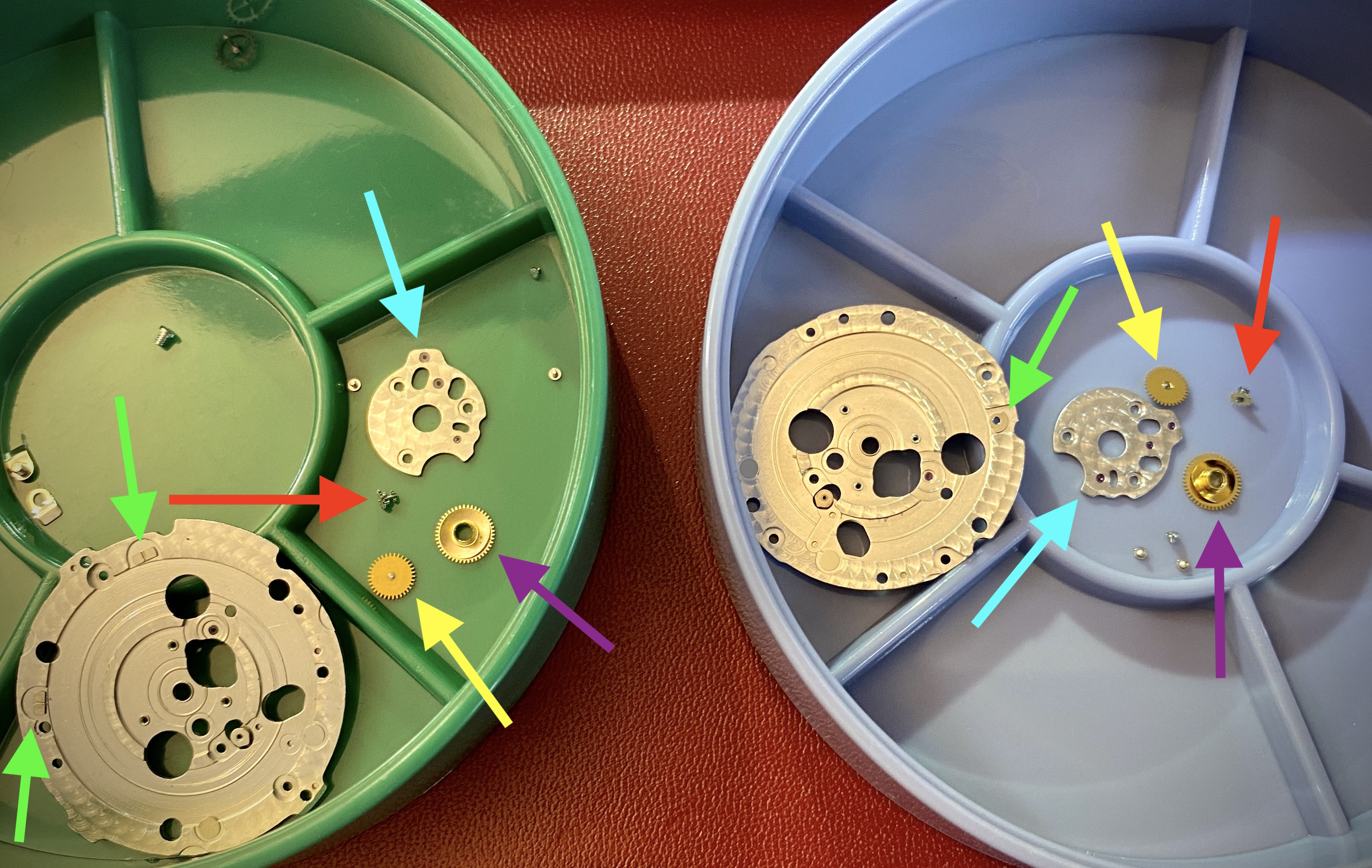

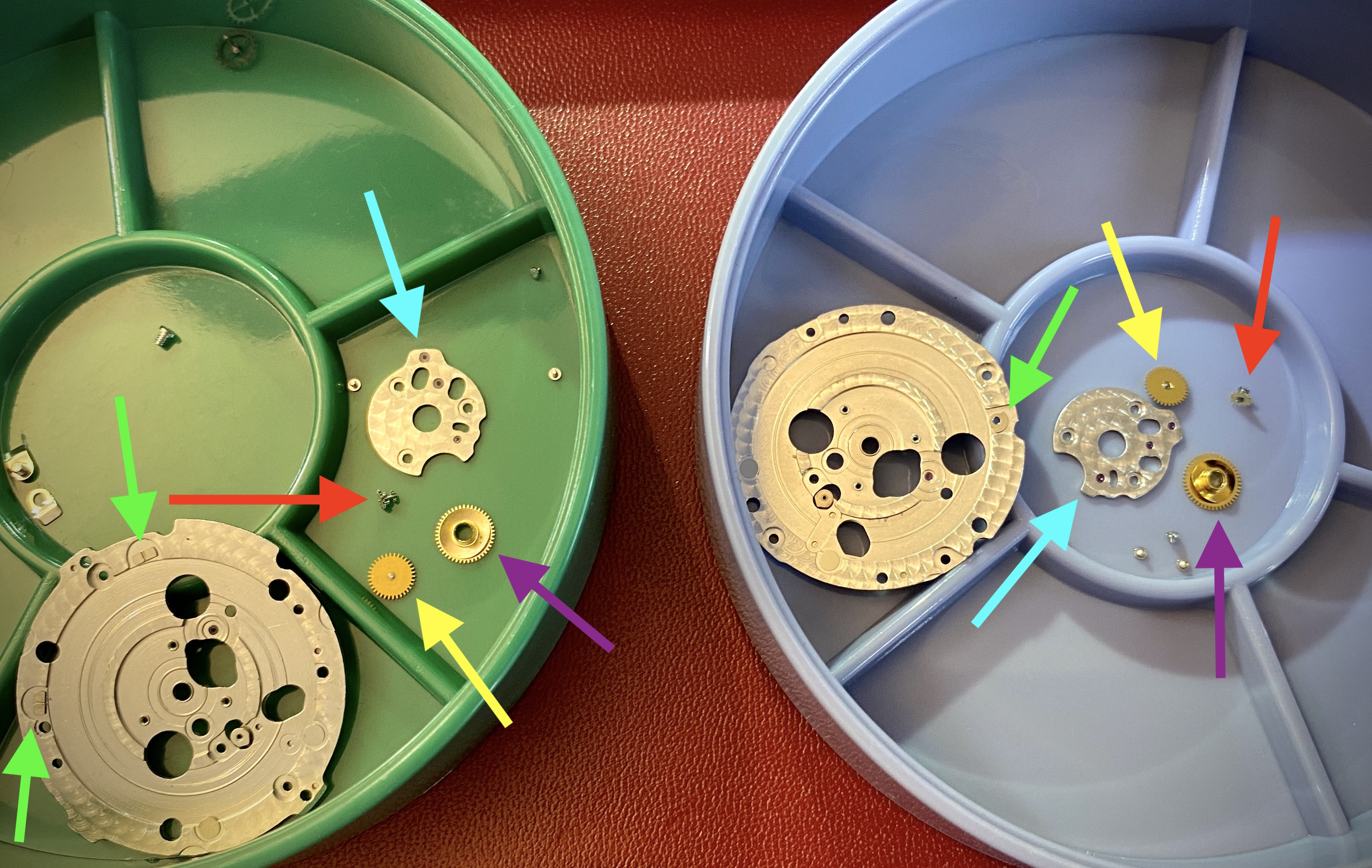

At this point it's probably a good idea to name all the parts we're dealing with here:

- Date plate (green arrow pointing to the different styles of date wheel retention clips... I actually the prefer the style on the SH3285 on the left).

- Hour wheel (purple arrow)... these appear to be identical between the SH and DD 3285.

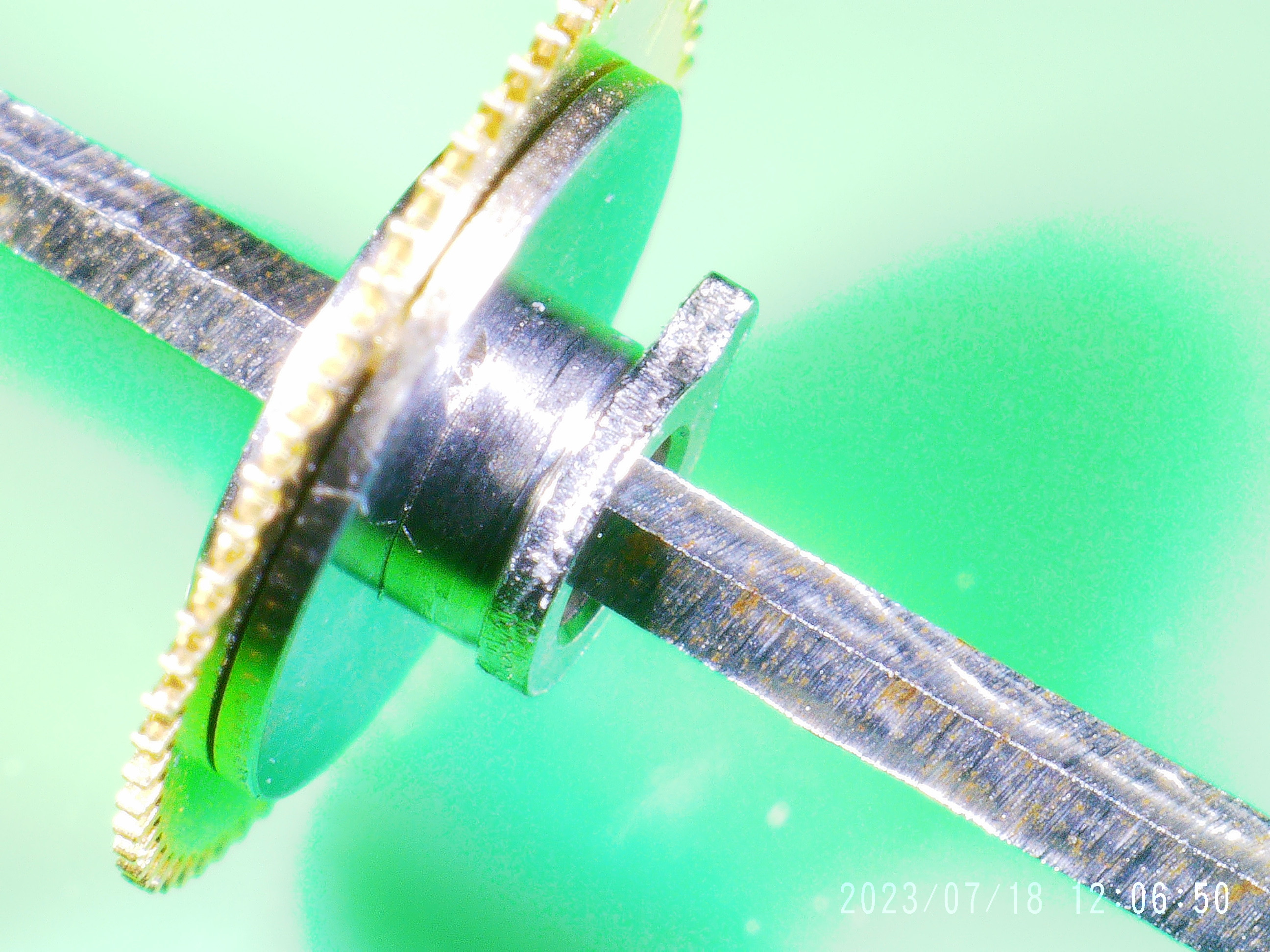

- Hour jumping intermediate wheel (yellow arrow). These are functionally similar, except the DD version has smaller pivots than the SH version. This means that we have to use the SH version of this part in the hybrid since the DD version will flop around in the larger jewel hole of the SH date plate.

- Date intermediate pinion (red arrow)... these parts appear to be identical between the SH and DD 3285. Nonetheless, I used the SH version of this part in the hybrid.

- Date plate bridge (cyan arrow)... Due to the larger pivot on the SH Hour jumping intermediate wheel, we need to use the SH version of this part in the hybrid.

Summary: we're using all the SH 3285 date plate parts for our hybrid since the DD versions of some parts have the wrong sized pivots, and swapping jewels doesn't gain us anything.

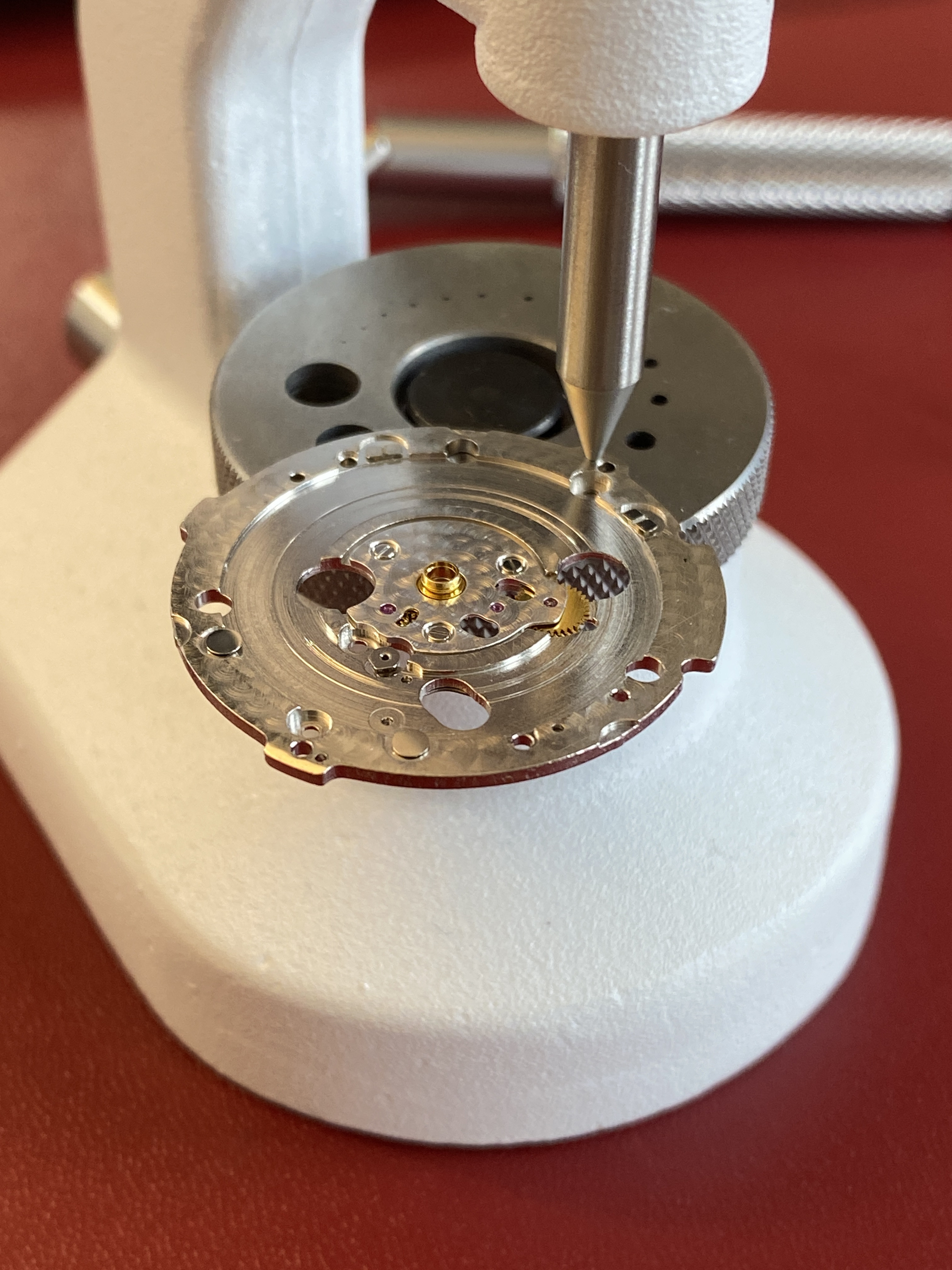

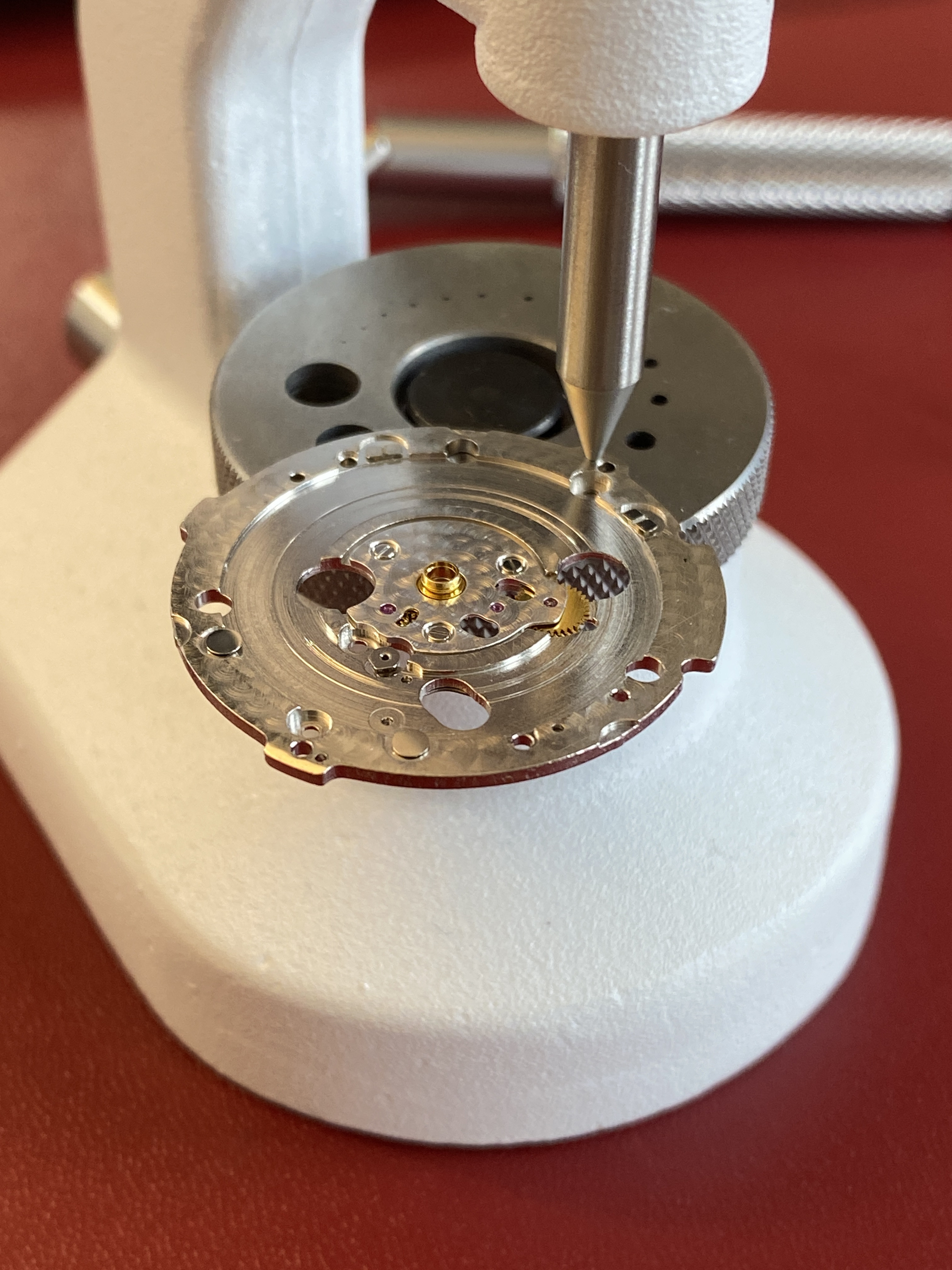

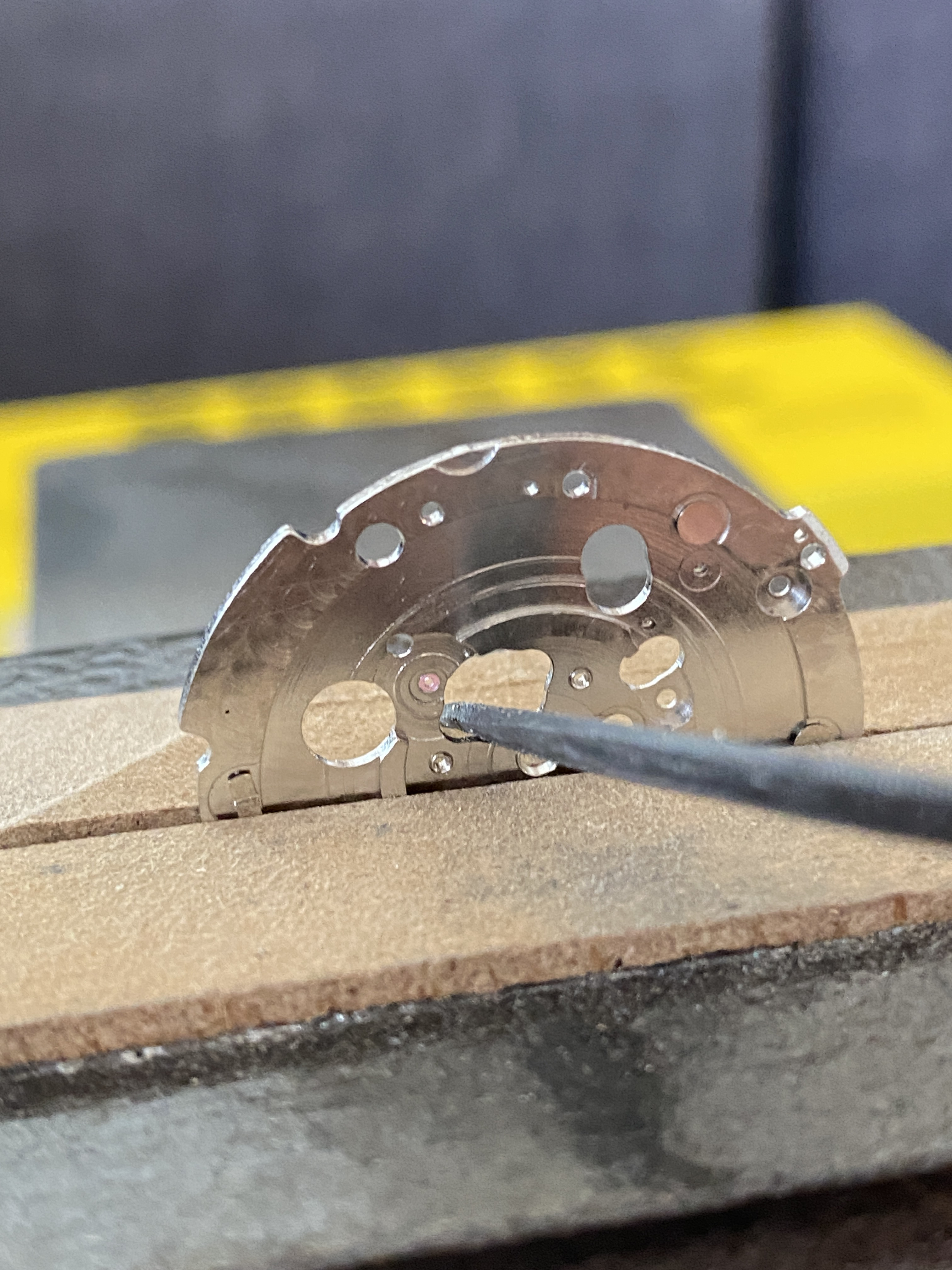

The first fitment issue we come up against is that the SH date plate has dial foot holes, and eccentric screws to grab the dial feet. Unfortunately the DD movement mainplate doesn't have the necessary clearance for these eccentric screws, so we'll have to remove them. This means we'll have to secure the dial with dial dots or glue, but that's not unexpected in a build like this. These locking screws are easy to push out using a staking set.

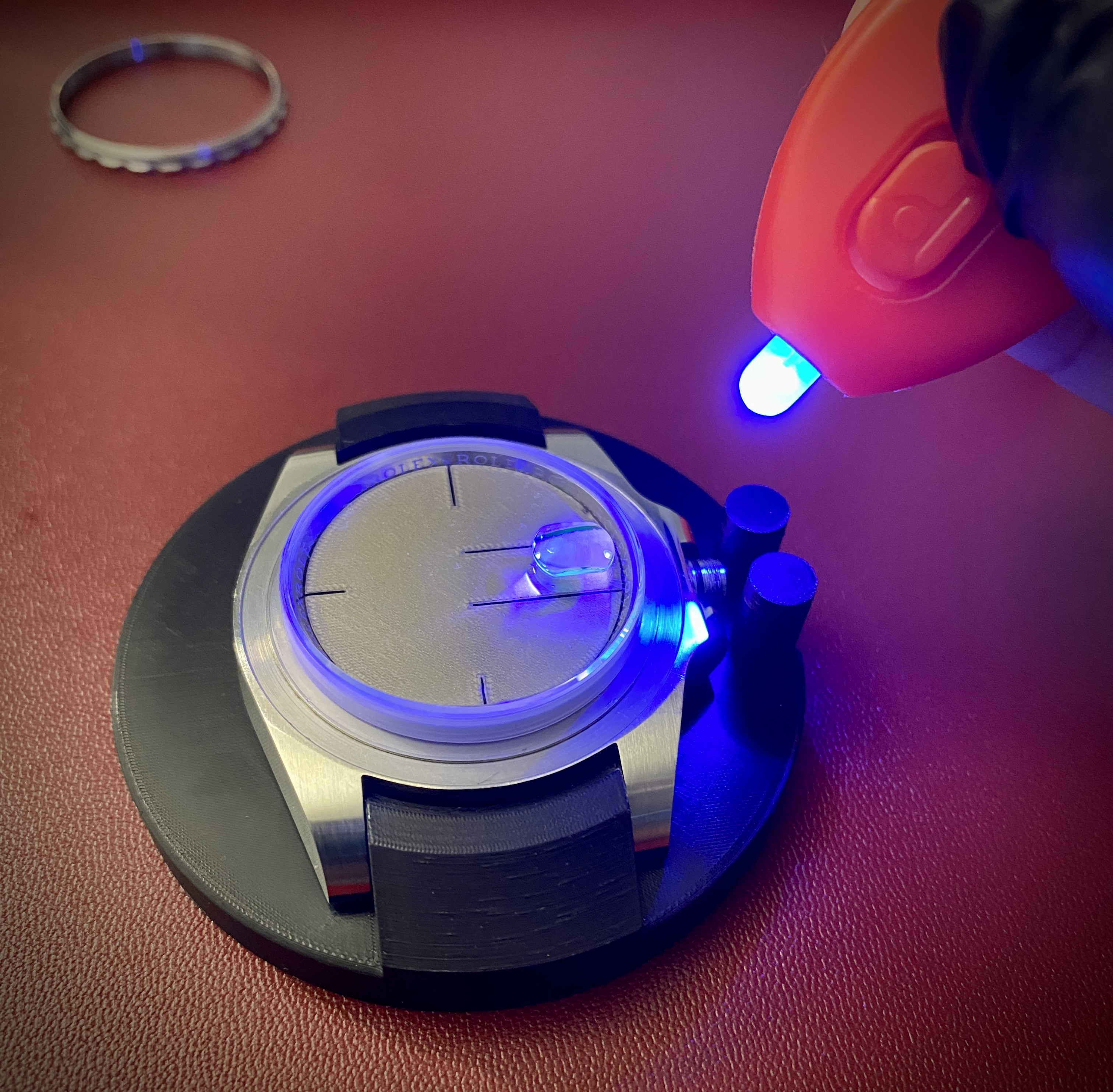

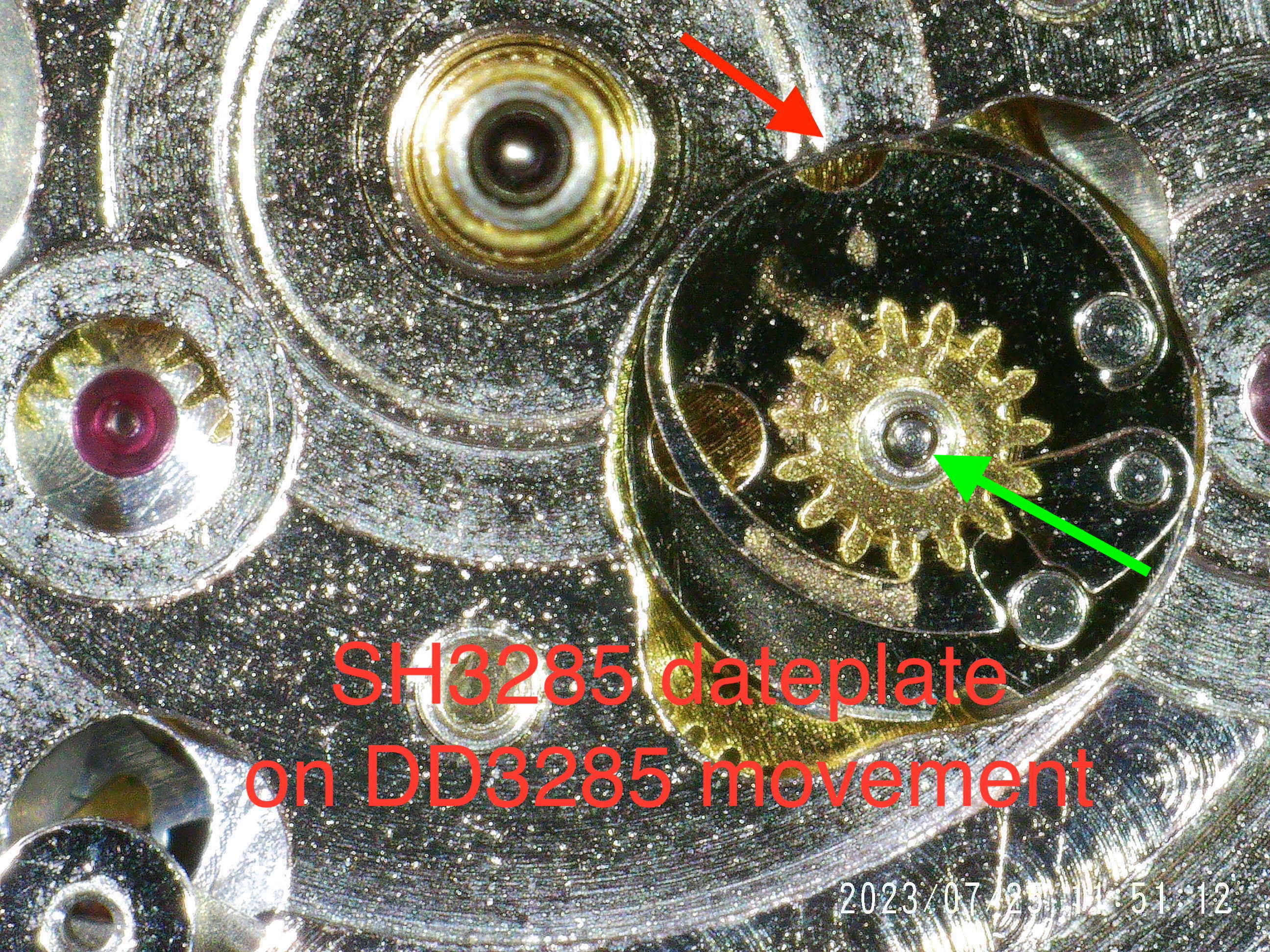

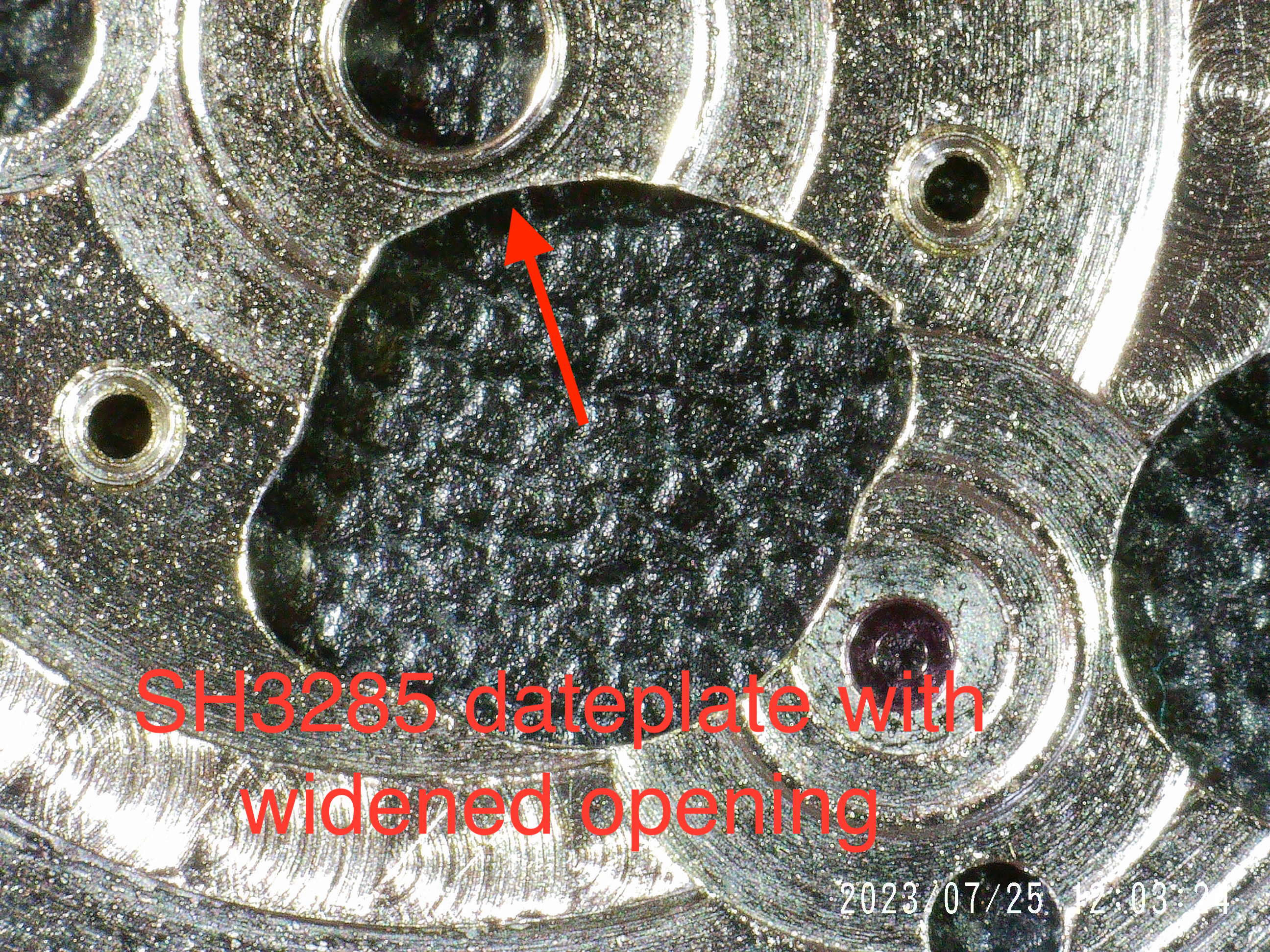

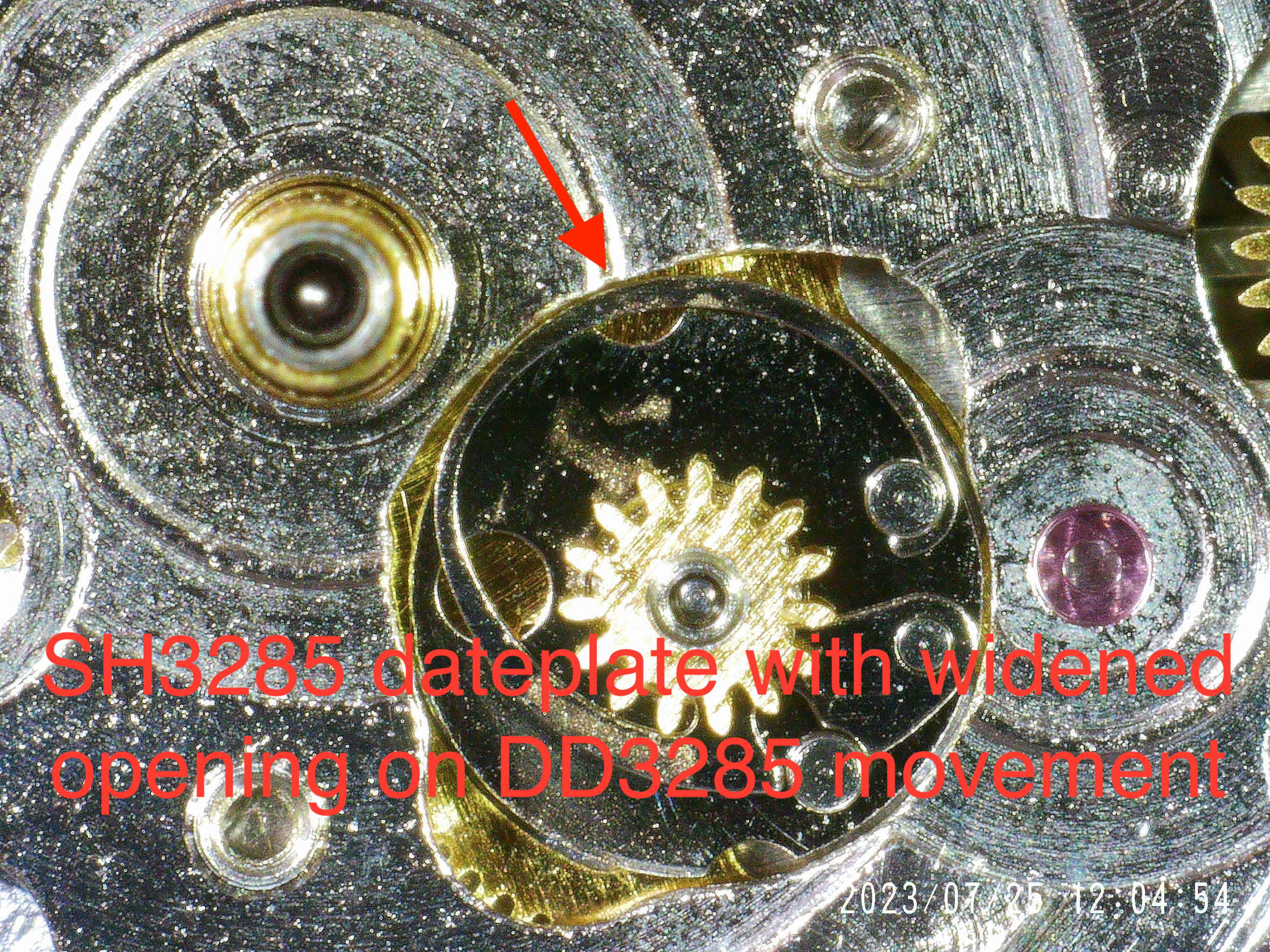

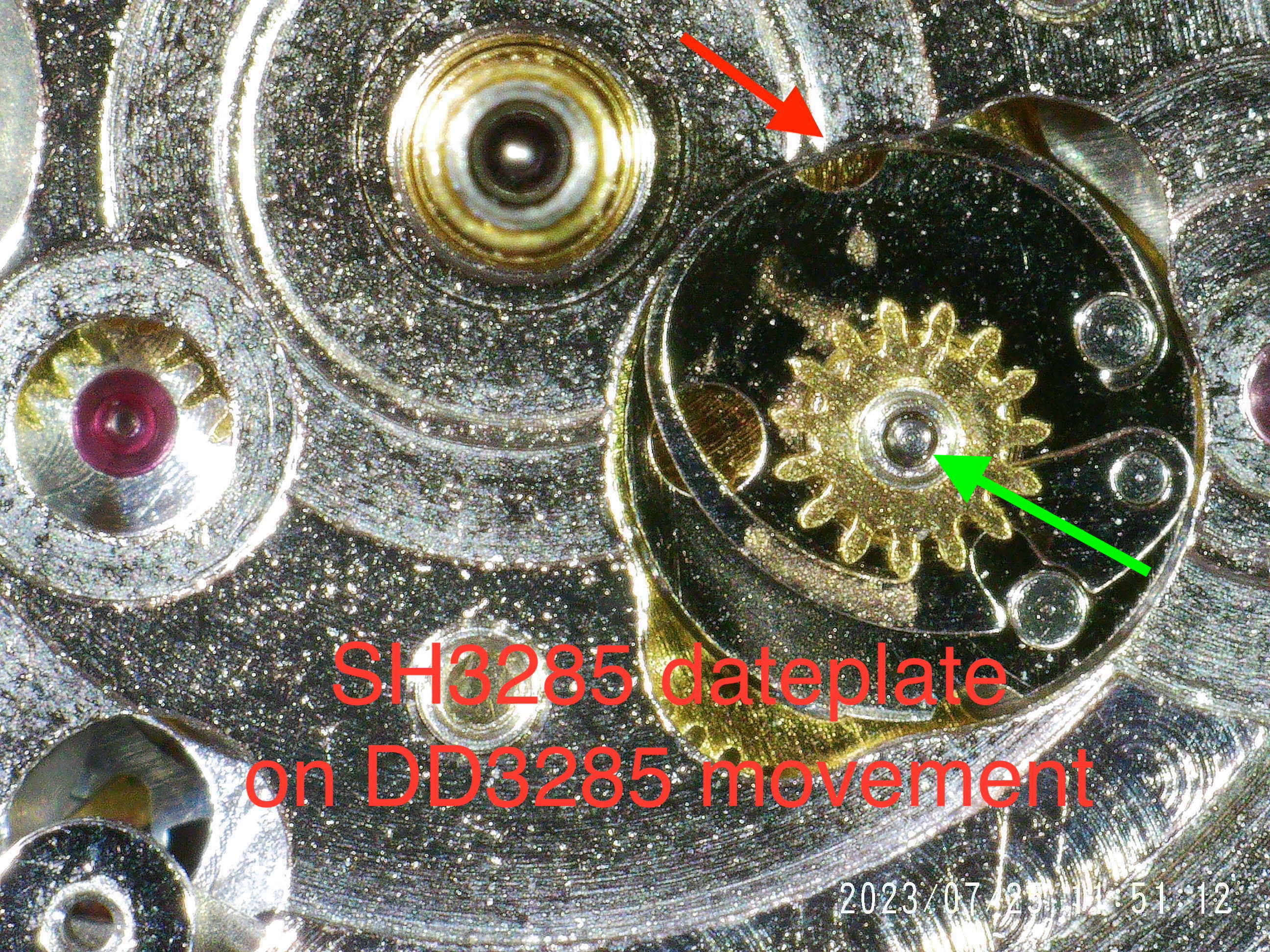

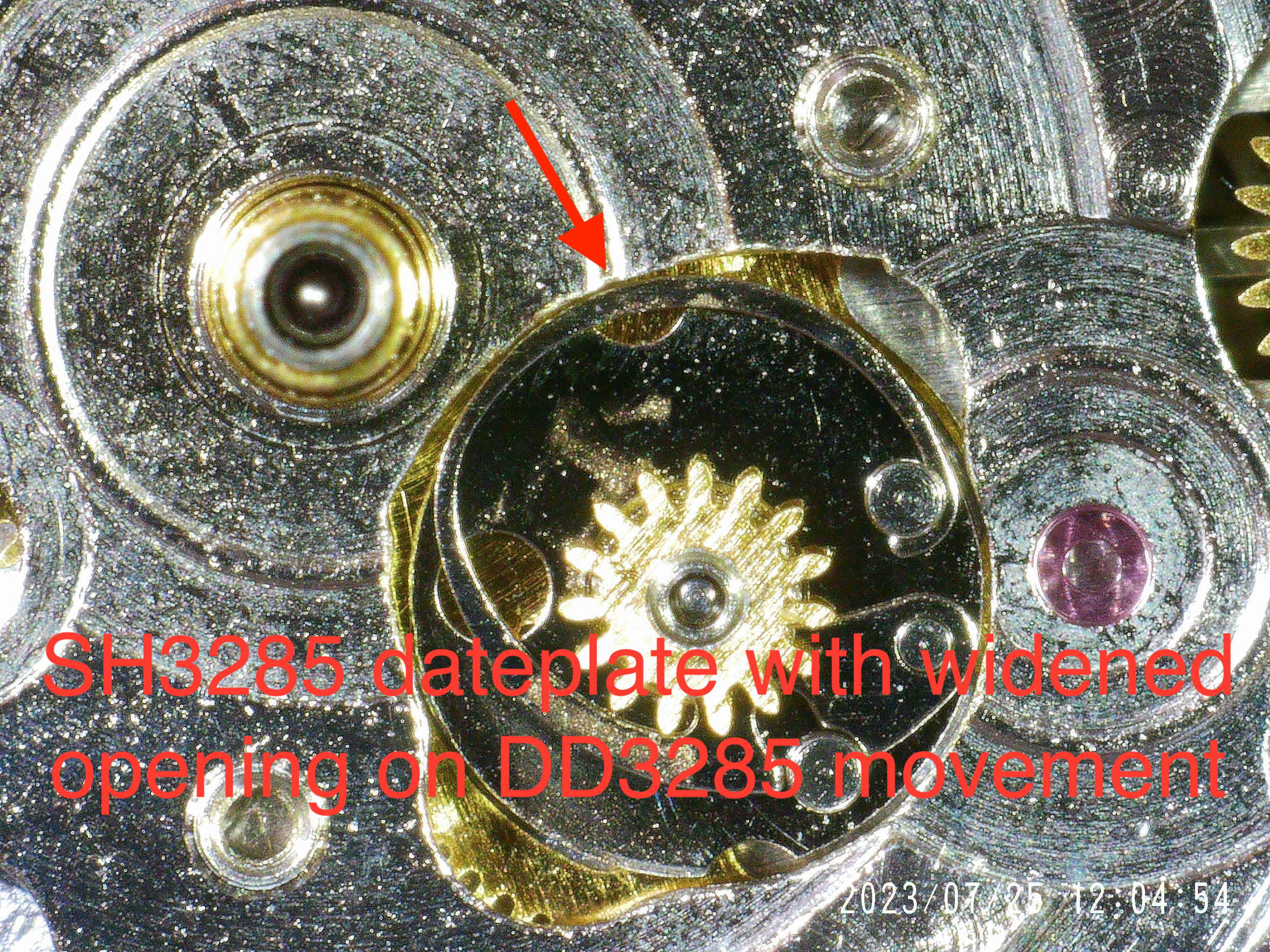

The next clearance issue is with the hole in the SH dateplate for the hour hand jumping mechanism. I'm not sure if the spring is larger on the DD movement, or if maybe it's just placed in a slightly different position, but for some reason the dateplate sat high on the arm of the hour jumping spring when I placed it on the DD movement (red arrow).

Also of note, the pivot on the DD hour jumping mechanism is smaller than the version on the SH movement (green arrow). This will mean that there will be a small amount of play in the hour jumping mechanism. I didn't end up replacing the jewel in the SH date plate with one that had a smaller hole because the slop was very minimal and everything functioned properly. But this might be something that's wroth doing if there are issues in the future.

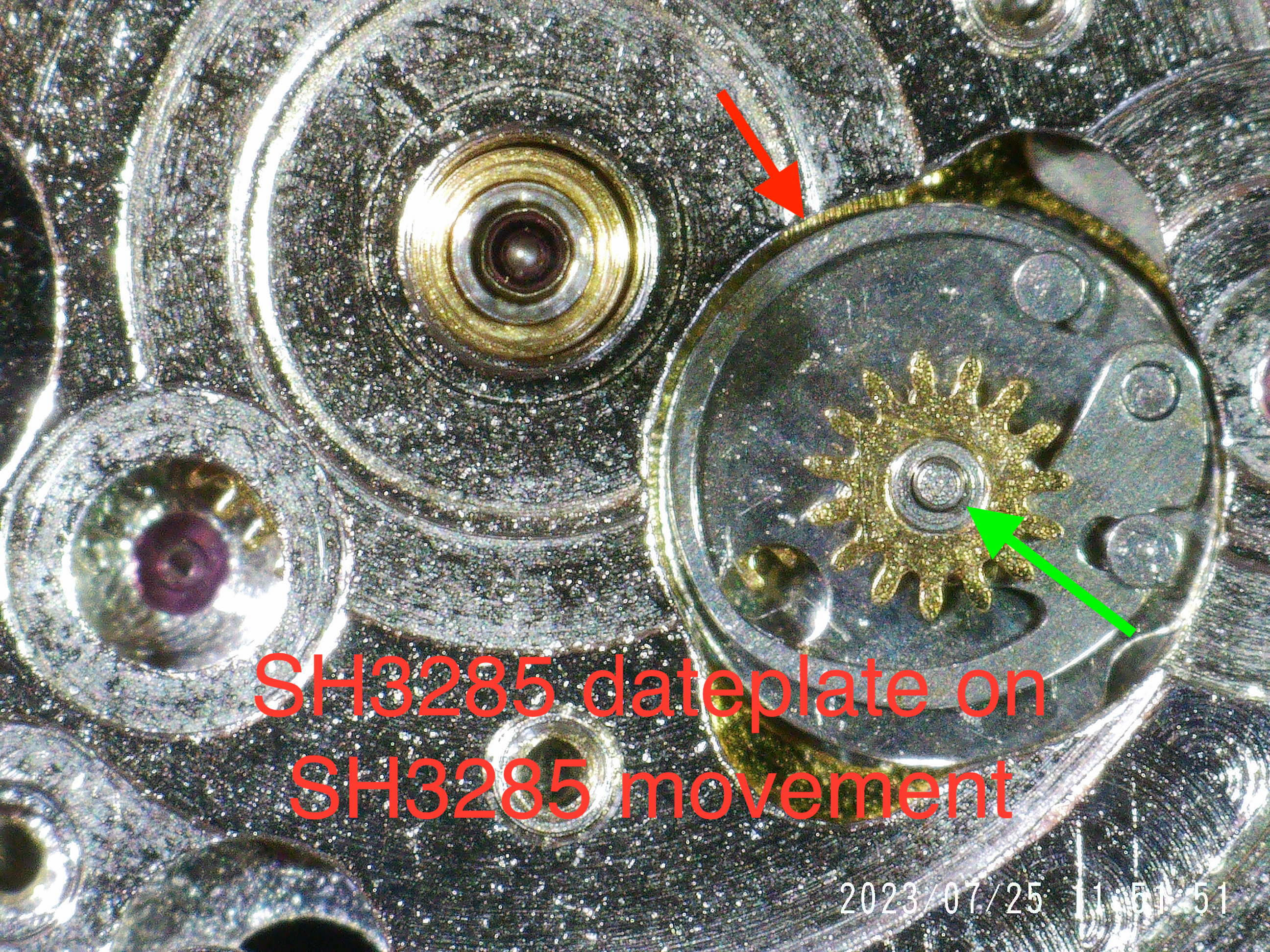

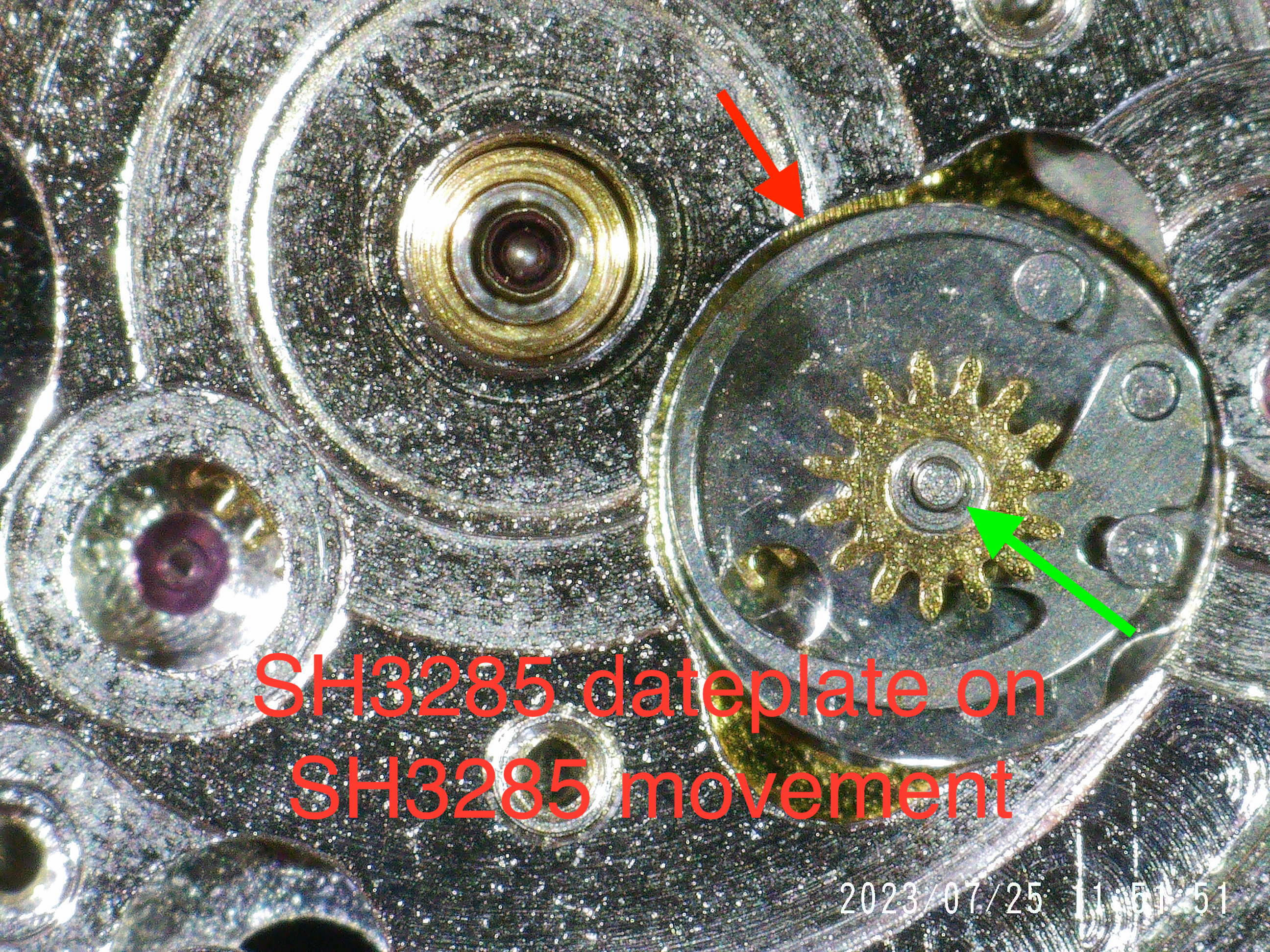

For reference here's the SH dateplate on the SH movement. You can see how the date jumping spring clears the hole in the date plate easily (red arrow). And you can see the larger pivot on the SH version of the hour hand jumping mechanism (green arrow).

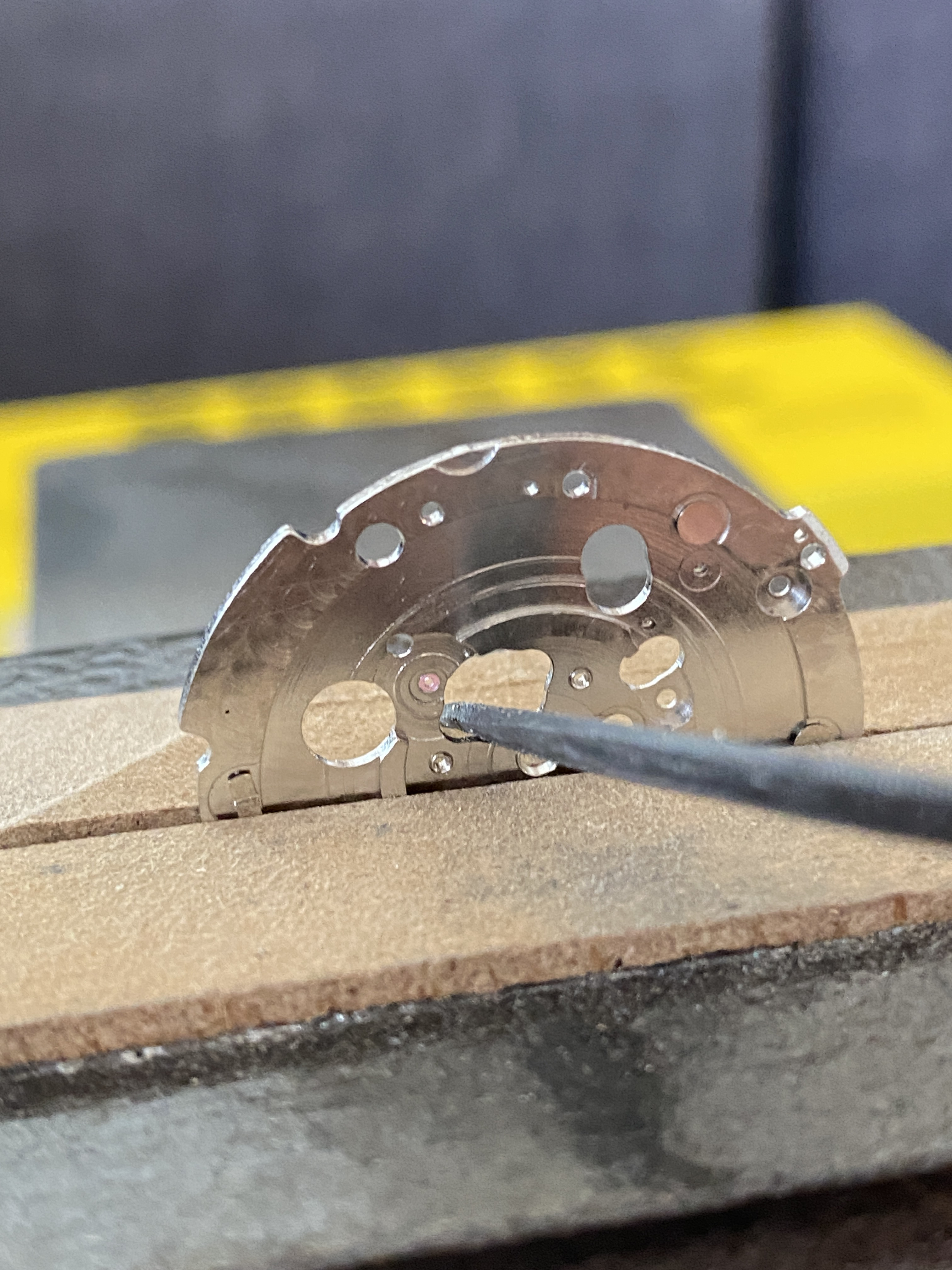

My solution to the date plate clearance issue was to simply hold the SH date plate in soft jaws of my vise, and use a file to open the hole up slightly. When I was done with the file I used some 1000 grit sand paper to remove any burrs that the file might have left. And obviously I washed the date plate to remove any debris from the process before every test fitting.

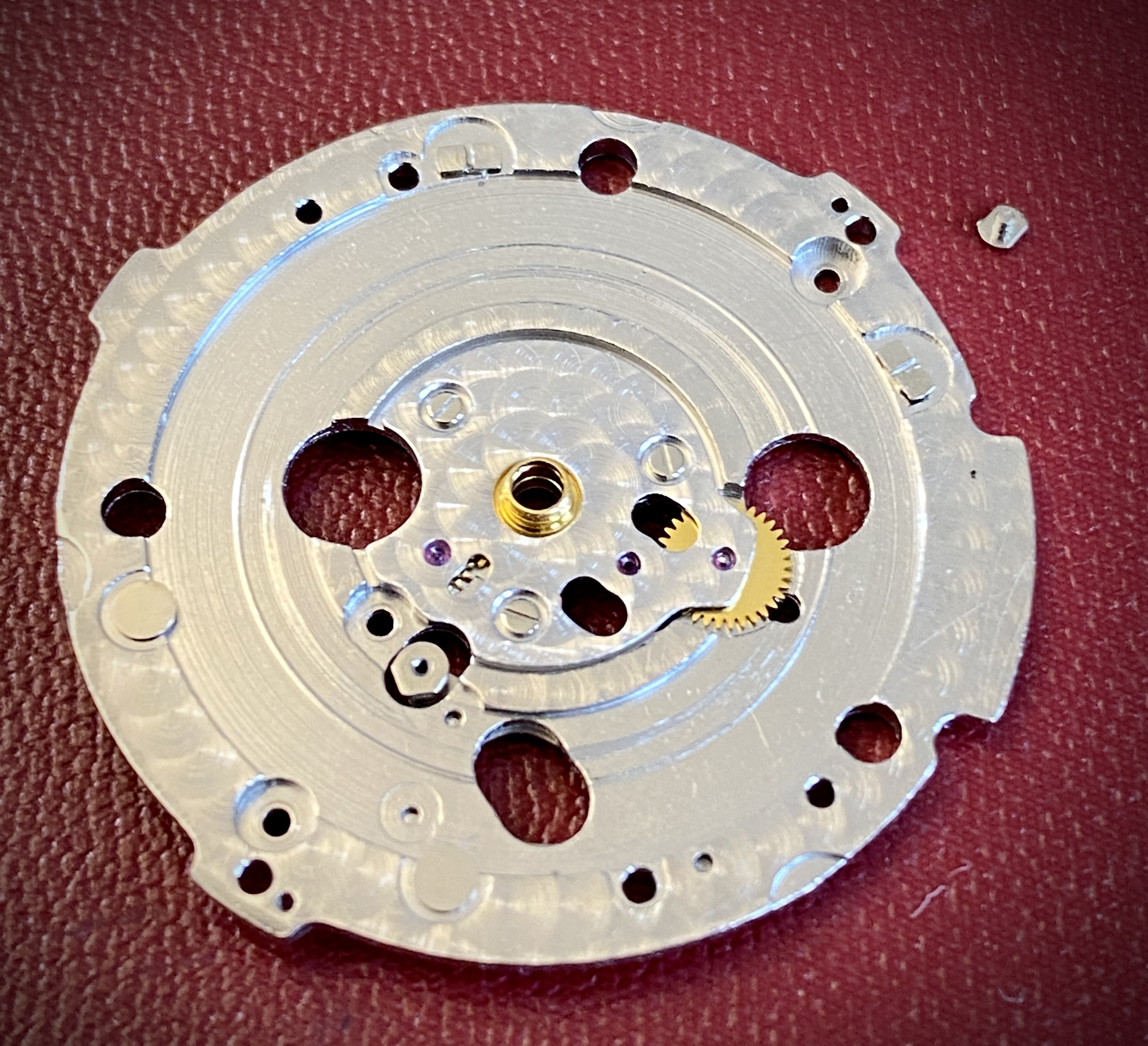

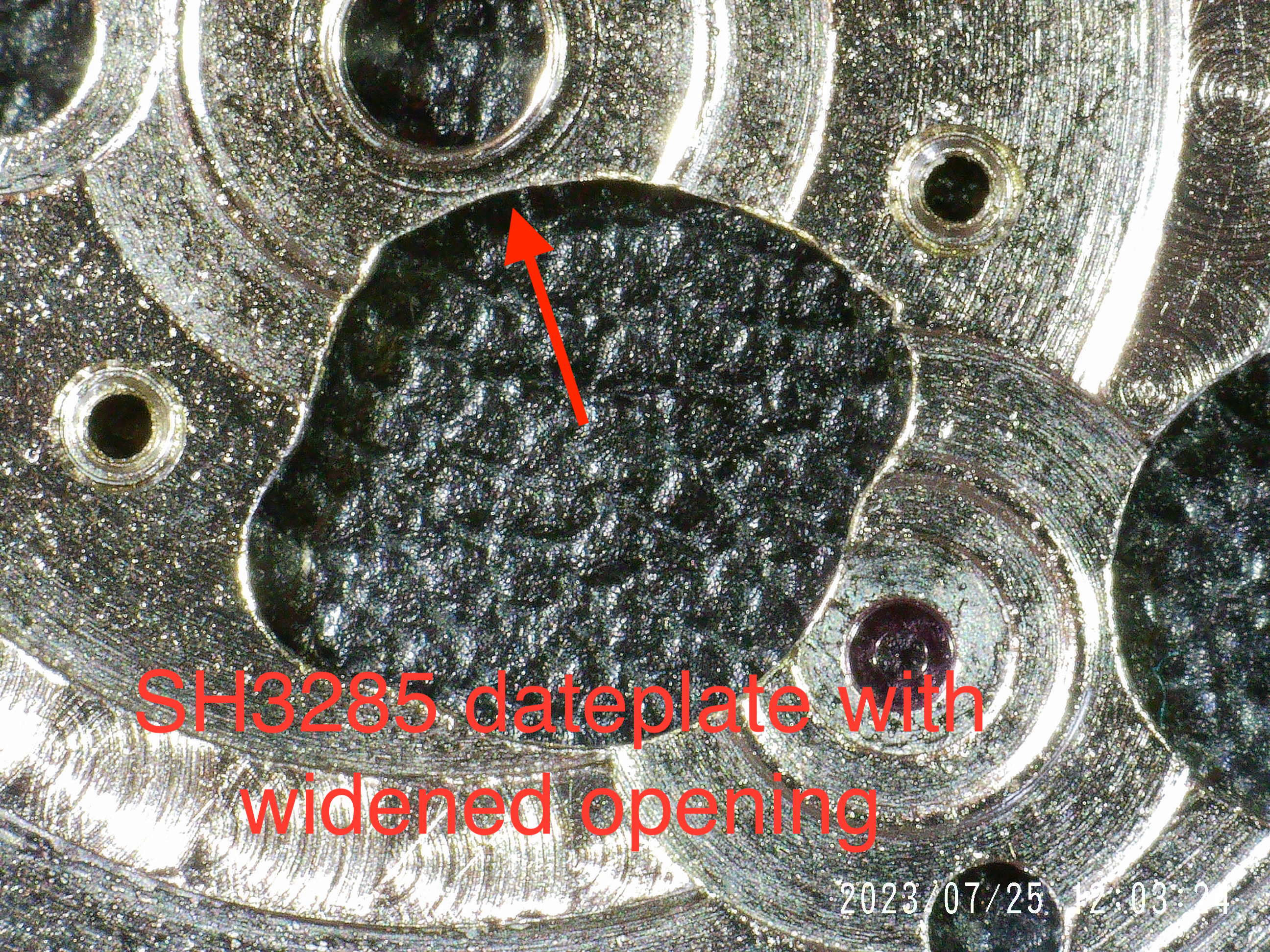

Here's what the SH dateplate looked like after the hole was opened:

With the additional space for the hour hand jumping mechanism in the SH date plate, everything fit together nicely.

I secured everything down and made sure that the teeth on all the wheels and pinions where meshing nicely.

One final modification that was necessary was that the dial feet on the GMF v5 dial needed to be trimmed down by about 1mm in order to not protrude through the SH date plate so far that they hit the DD mainplate.

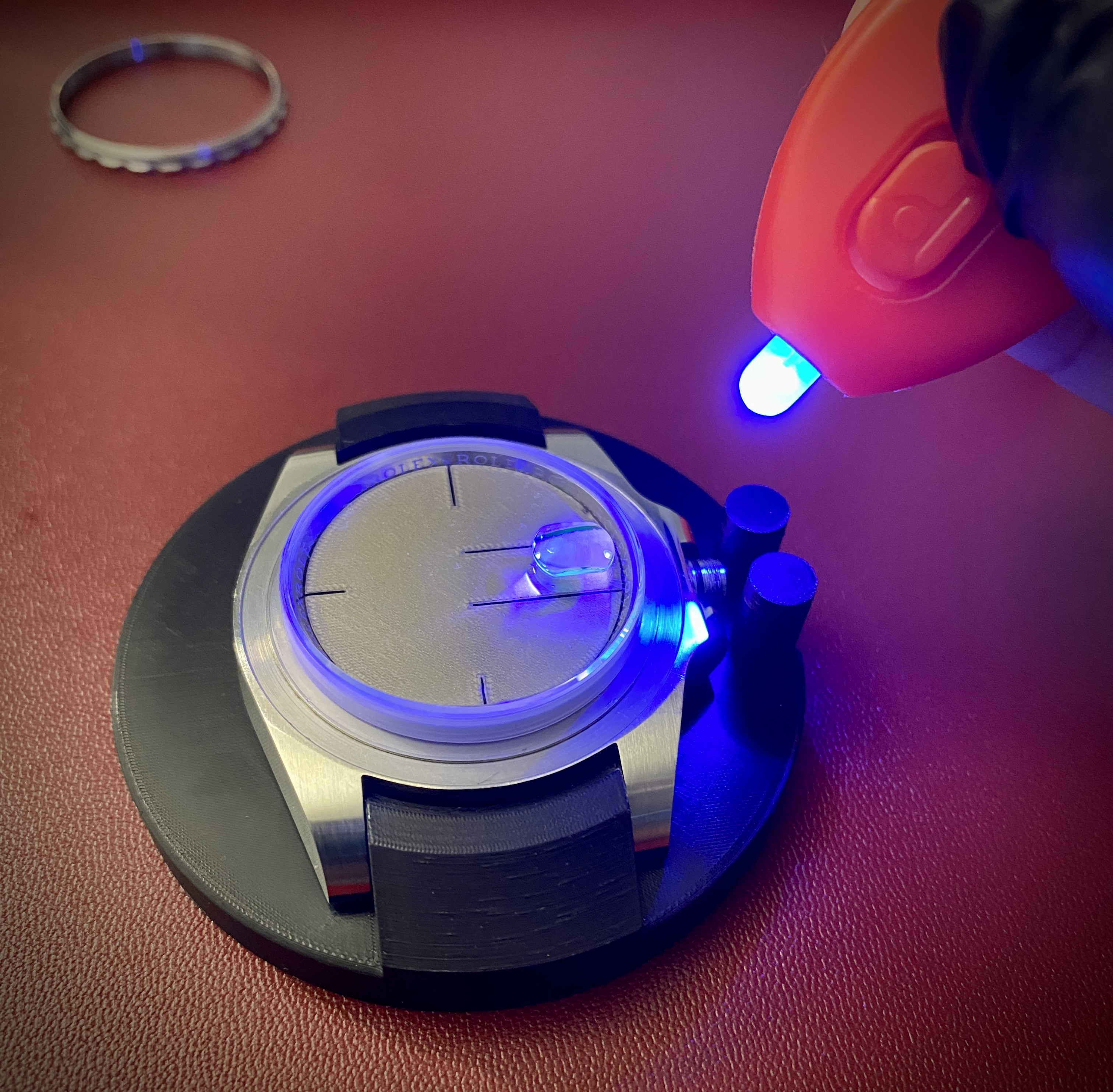

The final test was to glue the dial into place and press on the hands to ensure everything fits together properly... and it does...

There have been rumors of a DD3285 with a large date plate that we might see in a Clean Factory Explorer II... but for anybody interested in a DD3285 powered Explorer II today, there is a solution -- albeit a hybrid where you need a donor movement from a CF GMT.