- 12/3/18

- 37,544

- 80,345

- 113

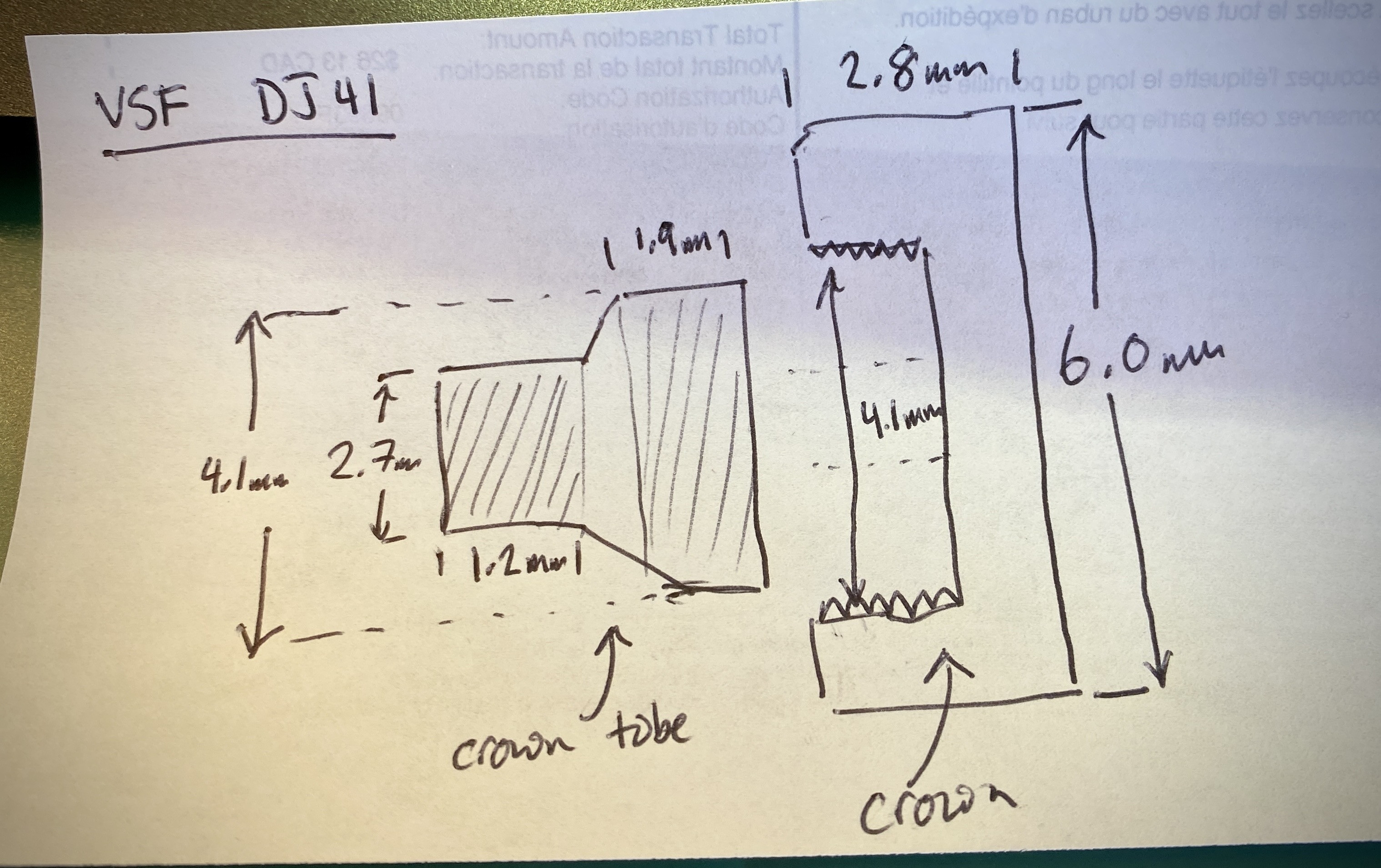

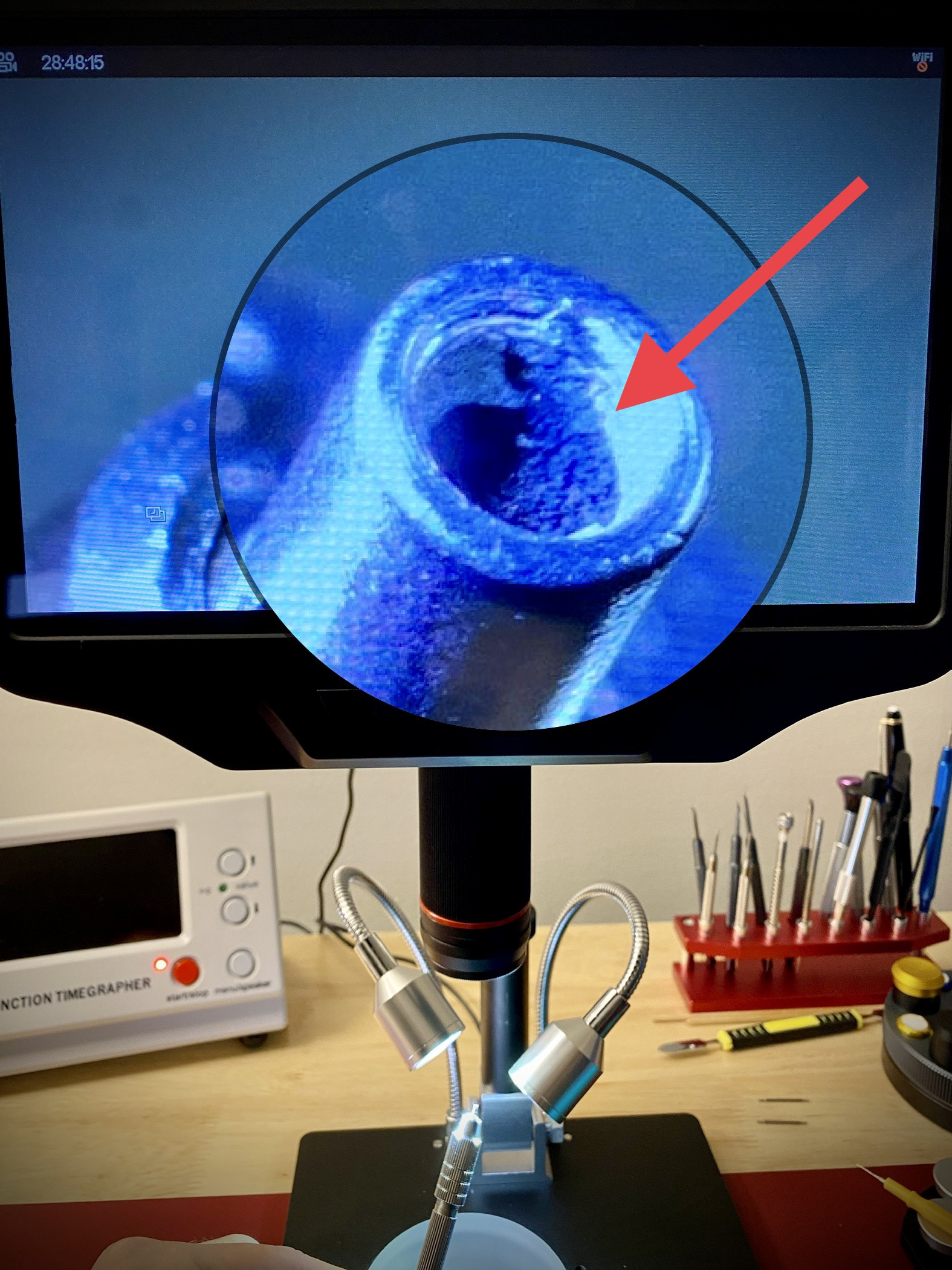

Besides a gen gasket being being thicker and denser than a CLEAN gasket, Your pic of its profile points out another reason a gen gasket won't fit under the retaining ring without some width shaving.Thanks KJ... that confirms it that Deep is using a gen style edge profile, and CF v1 was a non-gen profile.

The crystal indent where the gasket has to go blocks it from seating fully. AND that CLEAN crystal indent is too tall and not the right shape to fit a gen-spec gasket properly either. Another cheap shortcut by CLEAN, smh.