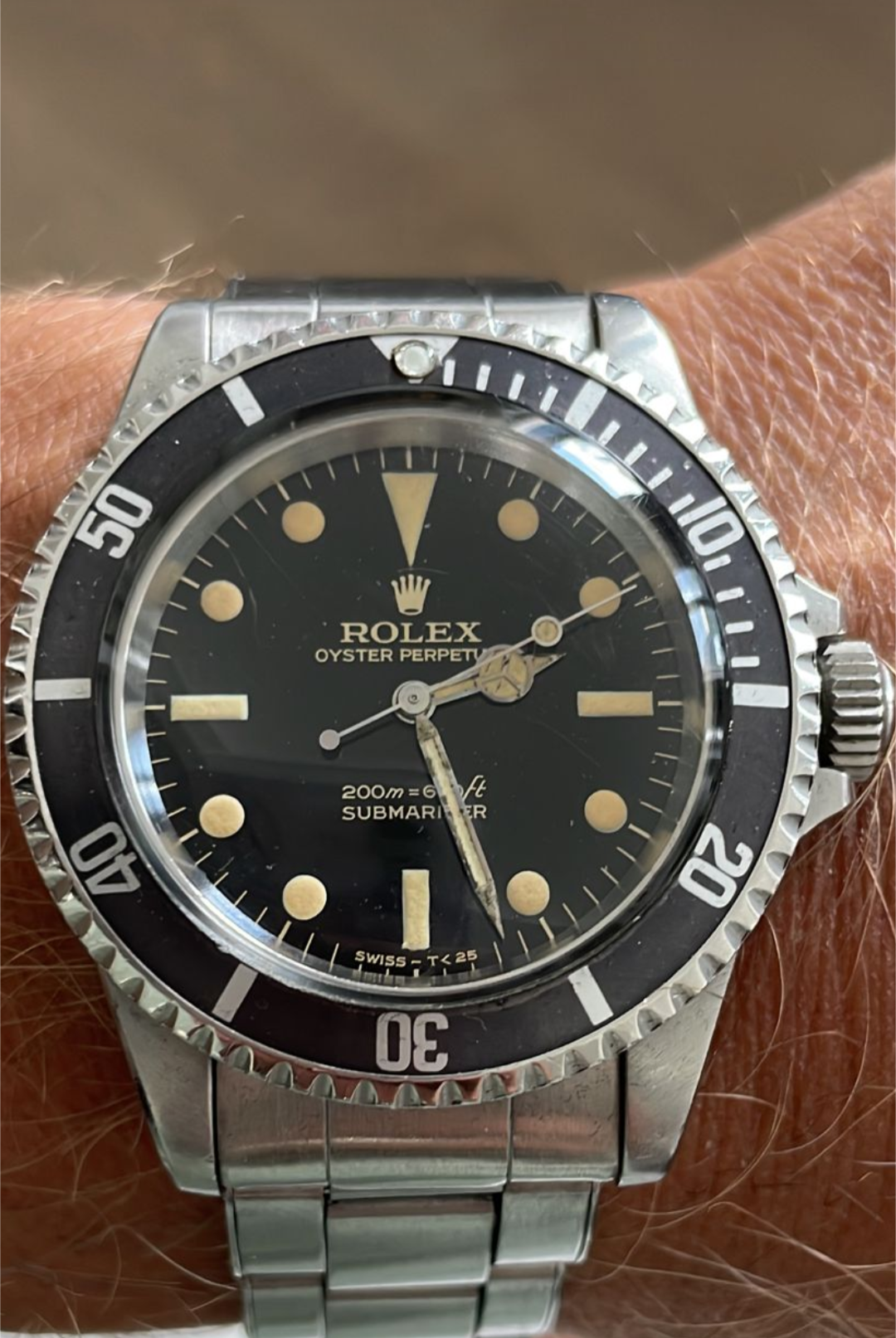

I'd like to ask a general question towards those that are still using Sunnyscopa. I've had plenty of great results, but I still never know with 100% certainty how it will turn out until the bandage is ripped off.

I always seem to keep trying it when I'm waiting on something, so I might as well ask...

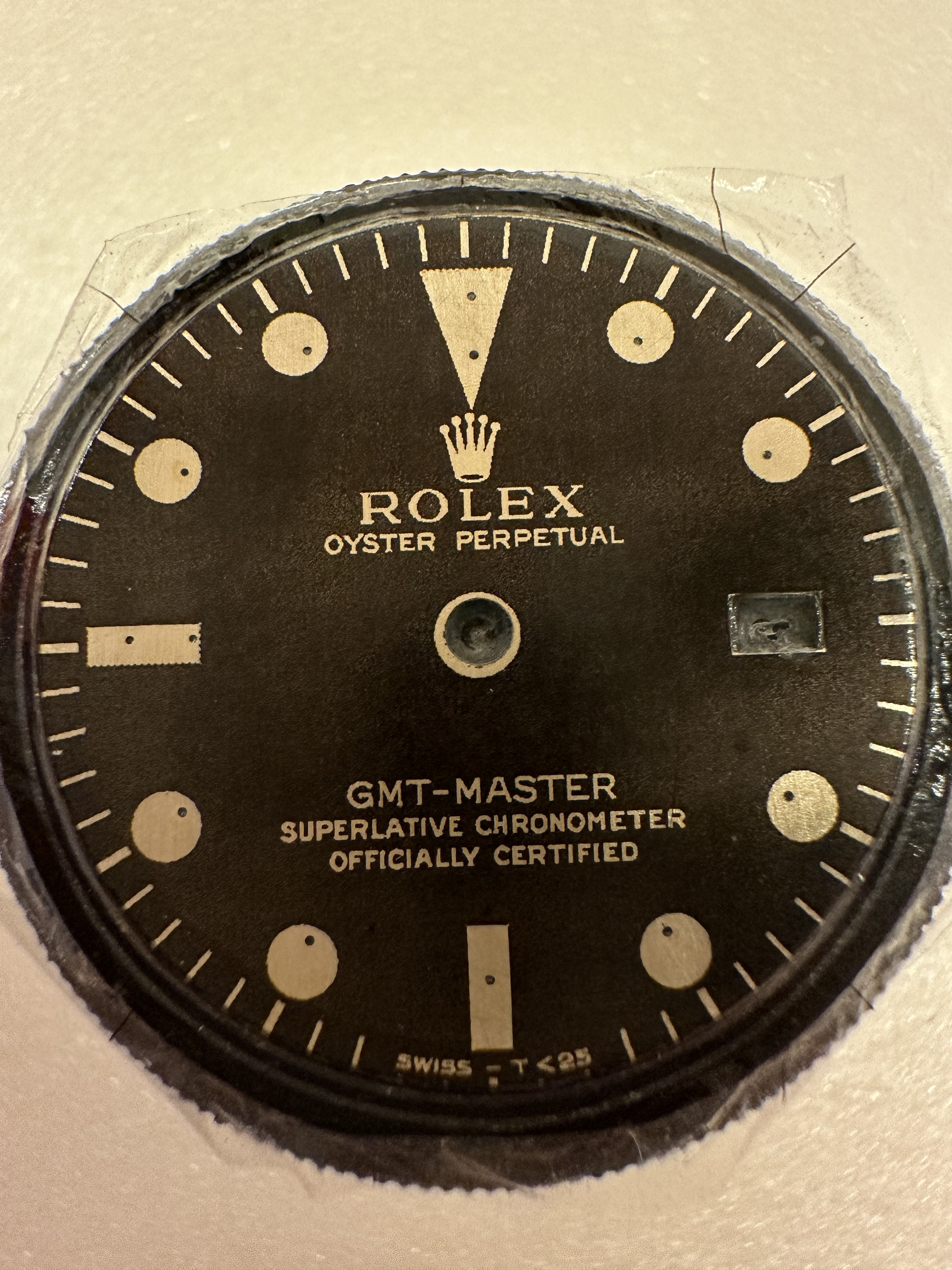

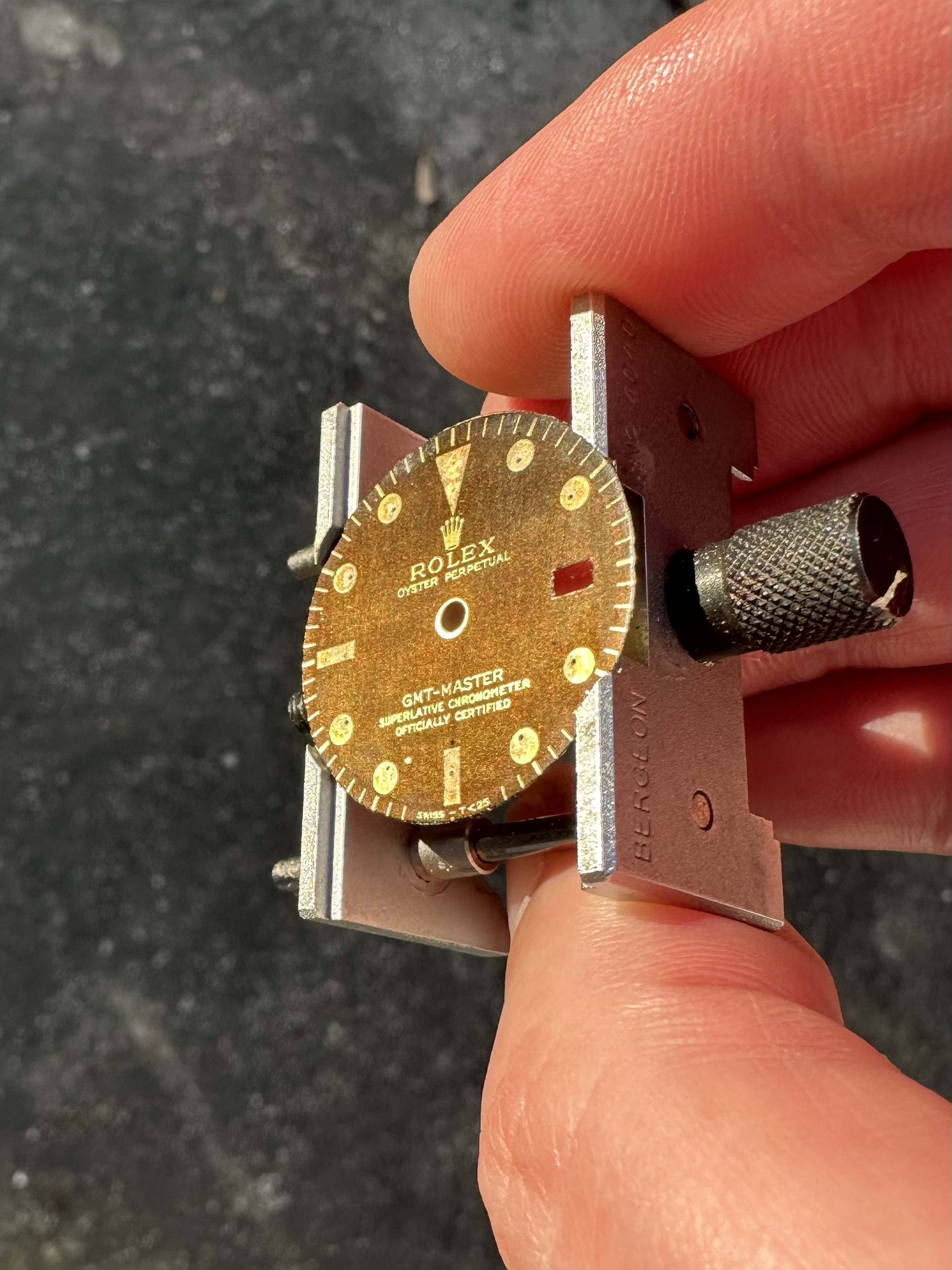

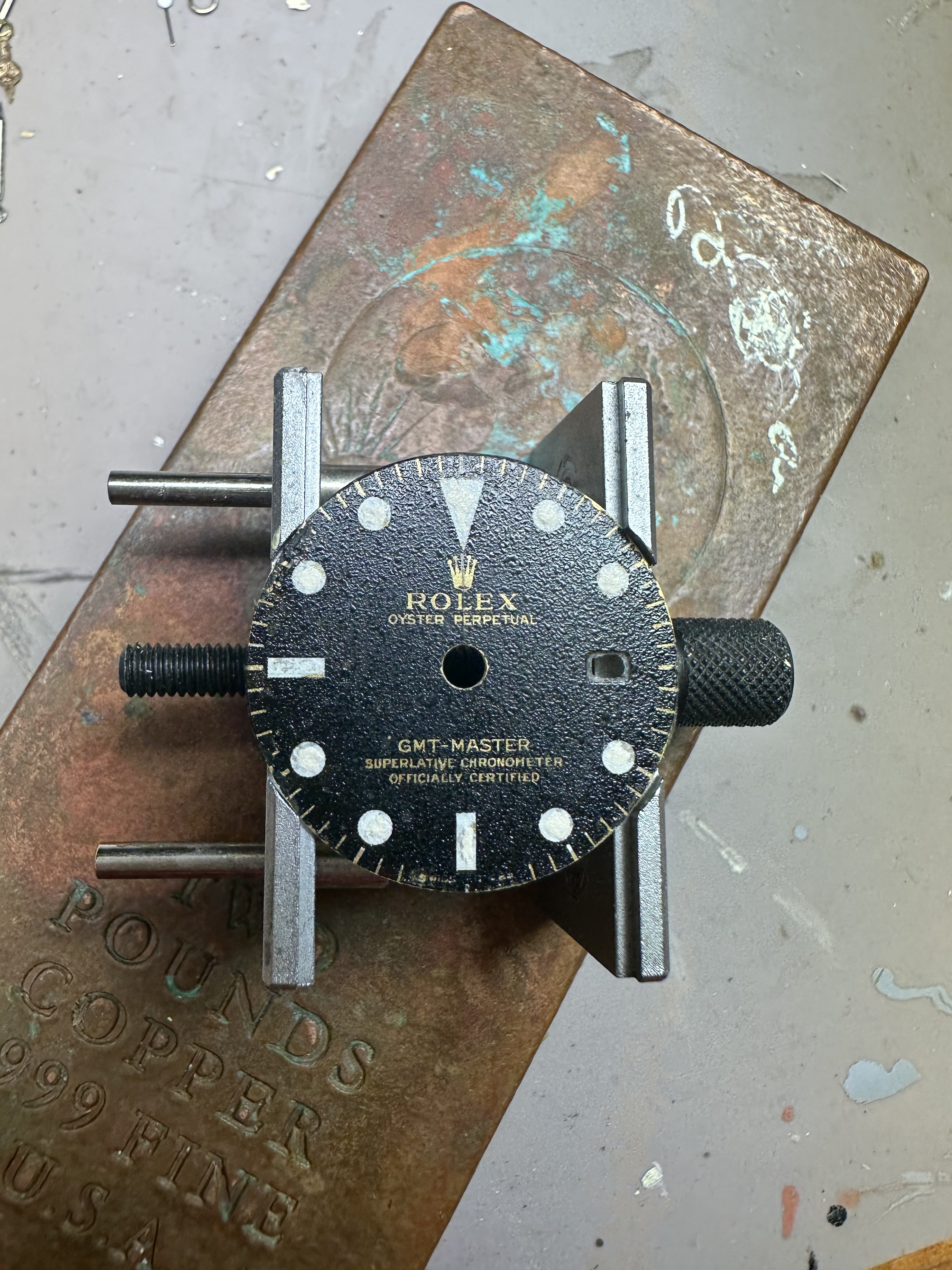

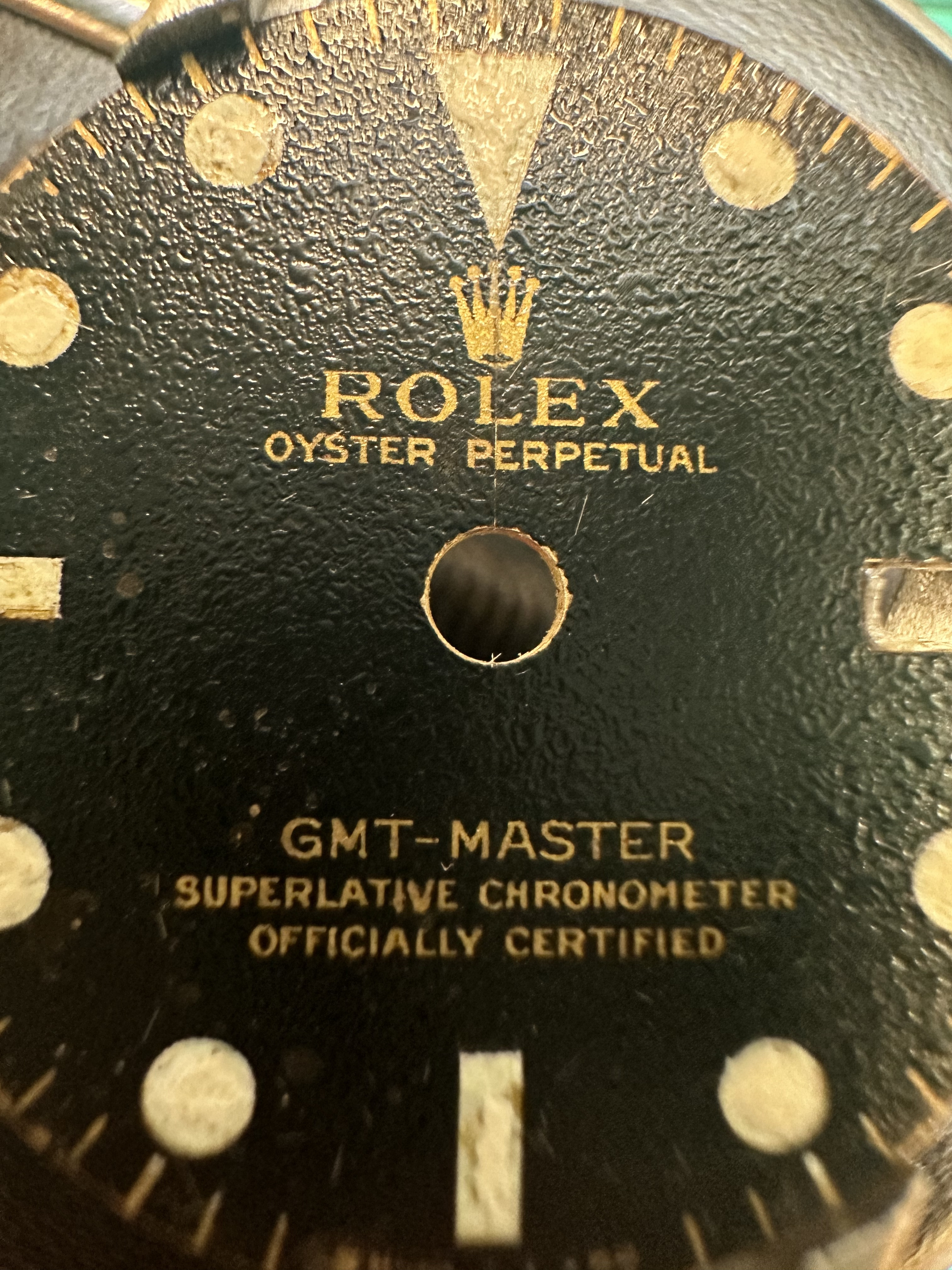

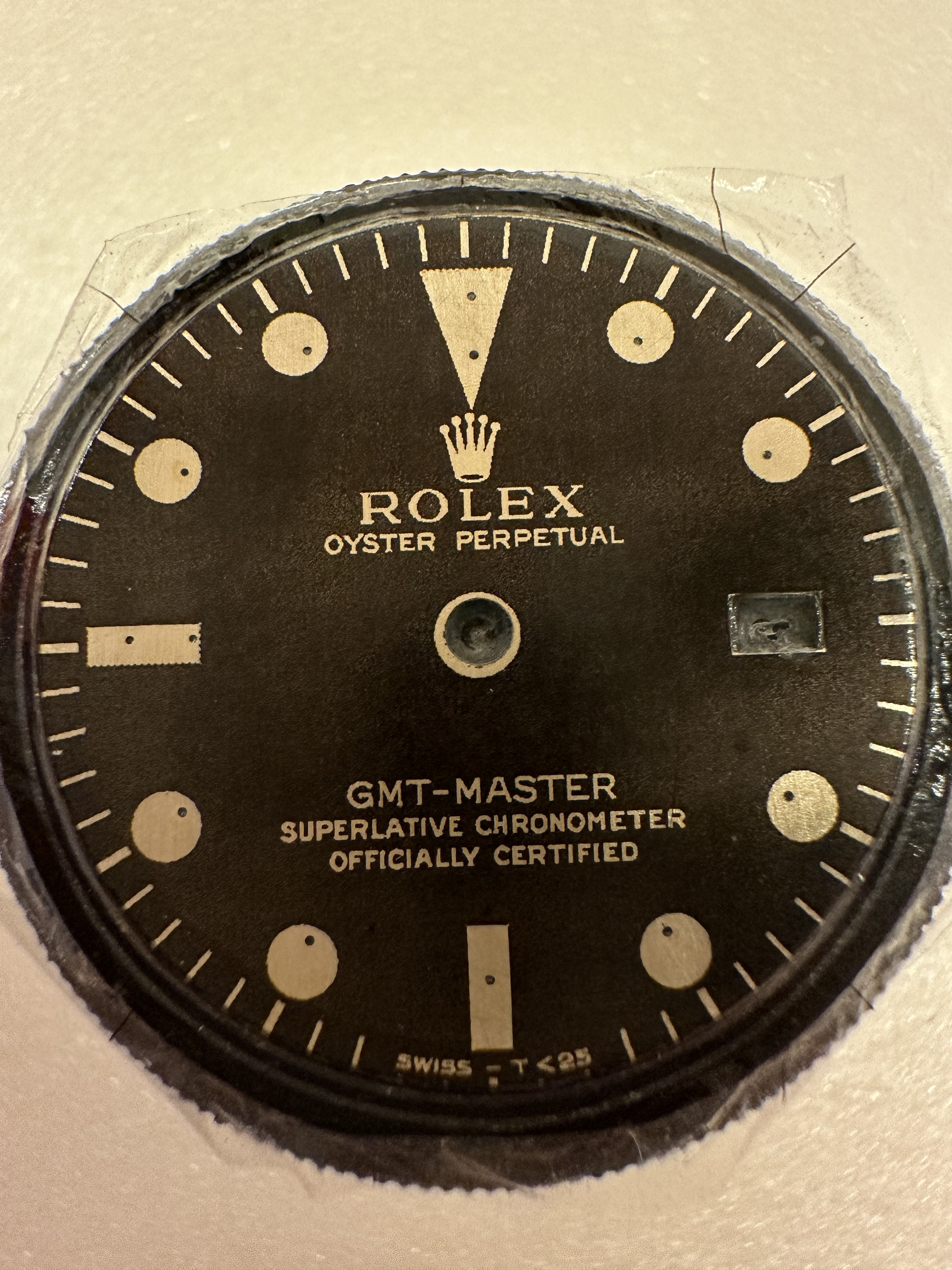

Here's a good print. Dial is clean as a whistle. I heated it up with a hair dryer and avoided a heat sink to avoid under heating. Used a glass vial and a paint brush to continually apply pressure while heating. It's applied well, and there are no smears or smudges.

So, at this point, do you toss it in the oven? If so, what temperature (please specify F or C). I'm certain it will come off clean, but every time I'm sure, I lose something... might be around an edge, date window, who knows?

Again, I know the directions, and I have had great results. I'm asking for others' input. If I knew how to post a survey, that's what I would've done. Again, no wrong answers here. Just asking because I hate the guessing game. Not even sure it's avoidable.