Hey Guys,

I was approached with a challenge the other day and Ive slept on it and I think I have a plan , but wanted to see what you guys thought and if I missed any snags as I have not done any decal dials to date .

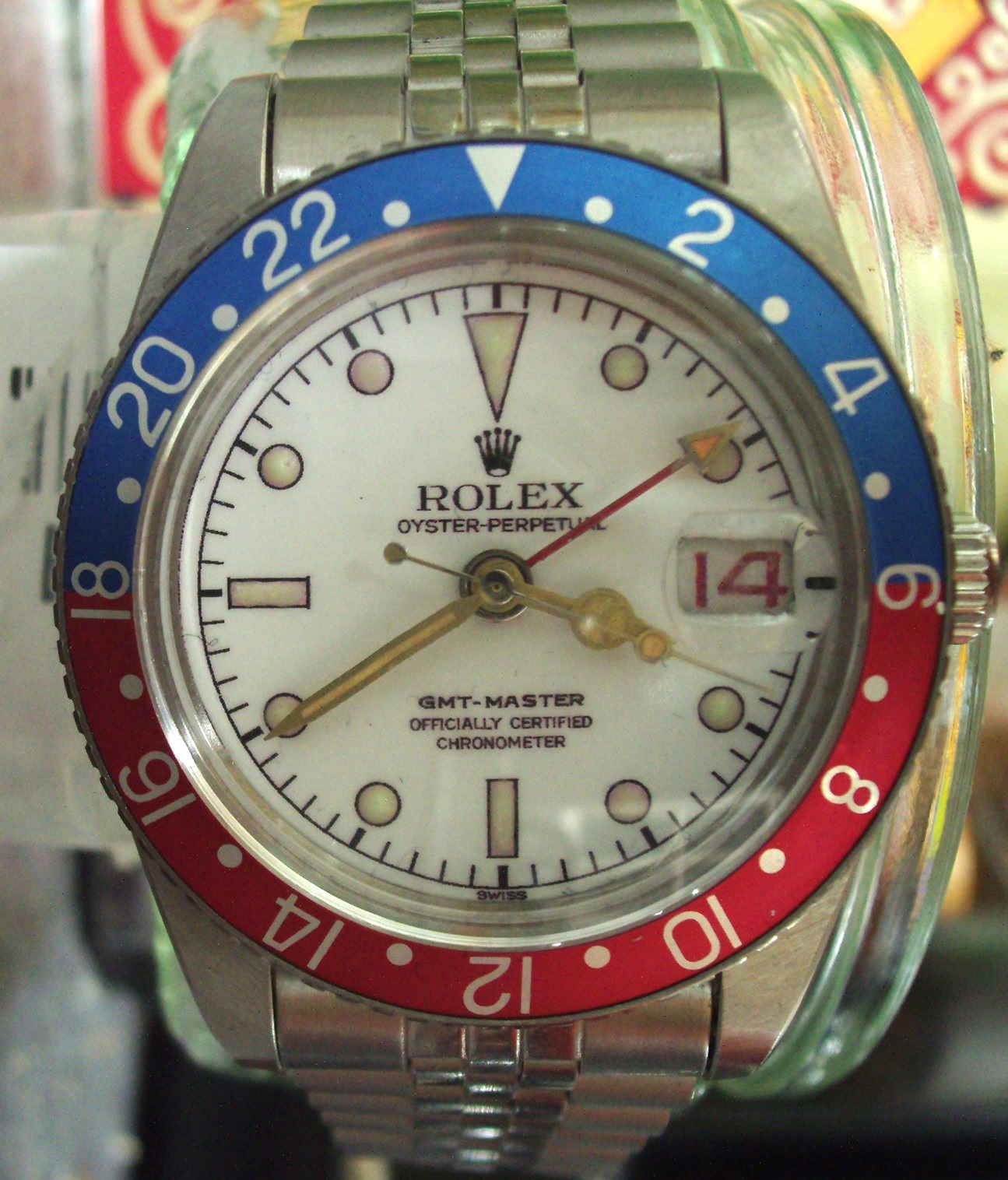

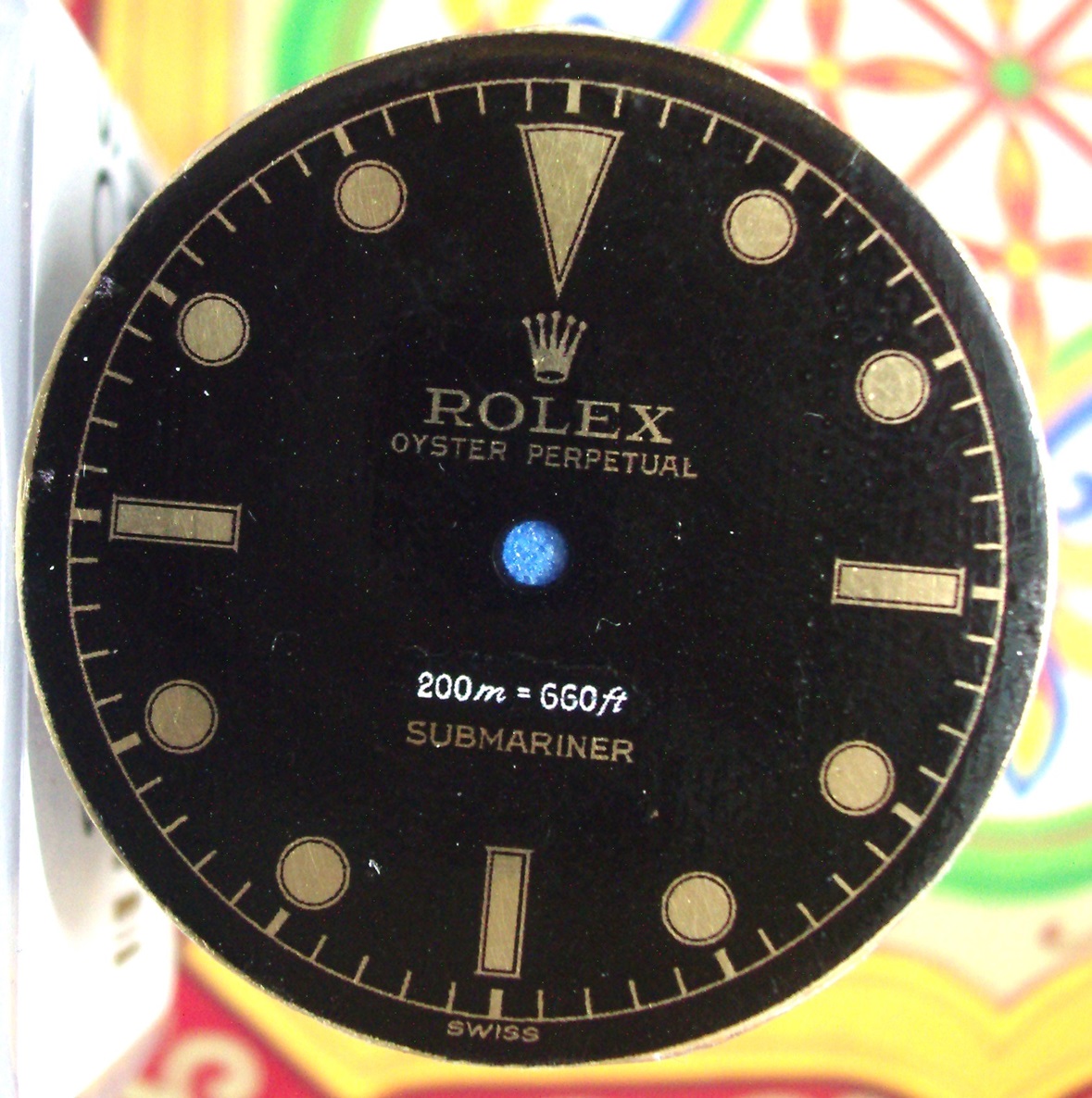

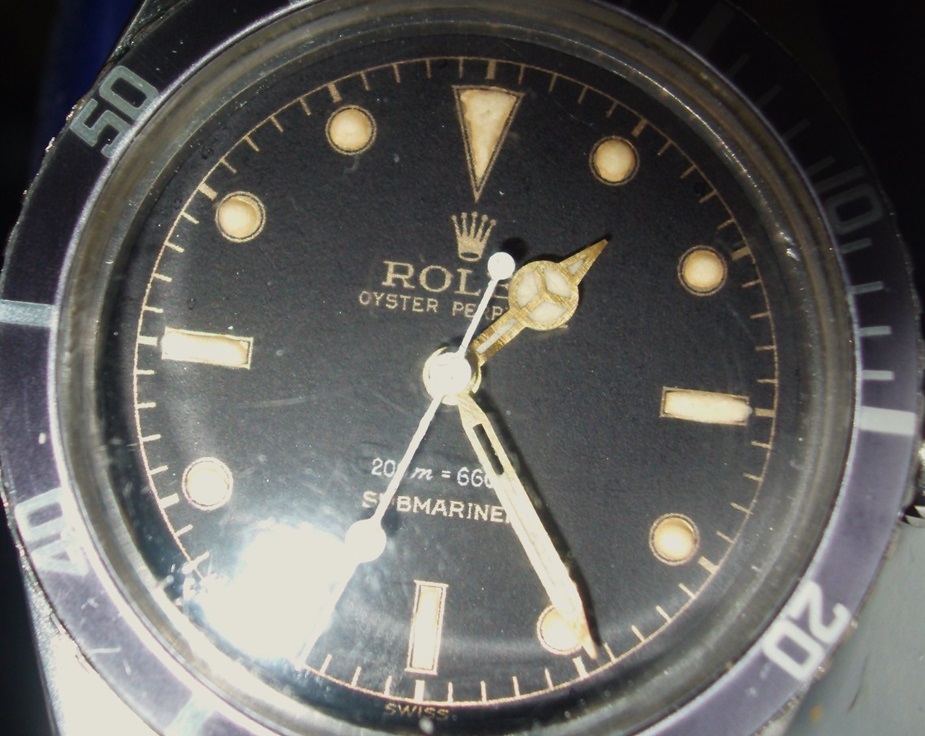

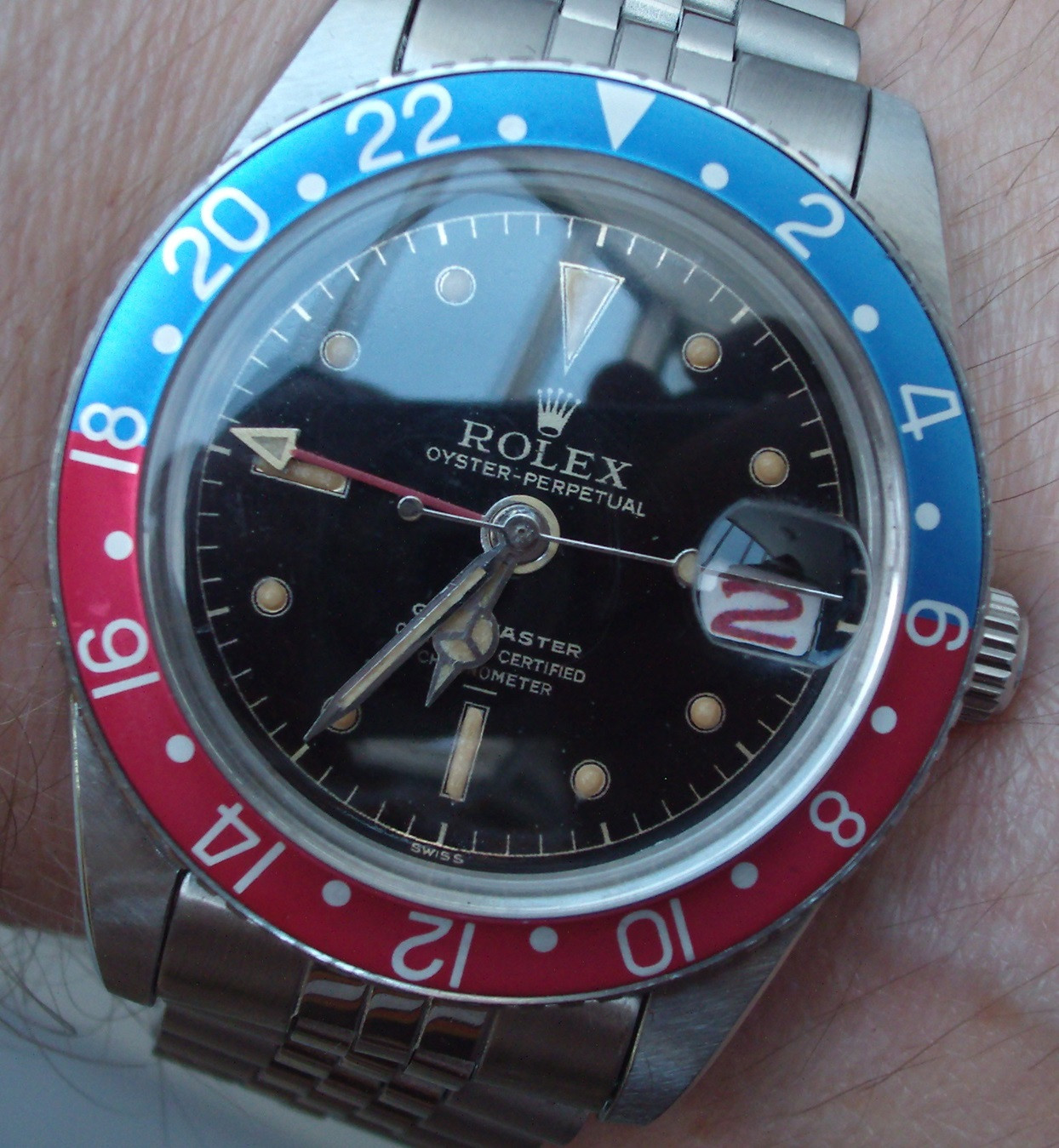

To build this. tropical and all....

preferably a nipple dial.

my thoughts were to buy a gold bluesy sub from a TD

Remove dial

remove indices.

strip and polish dial plate to base metal.

apply air brush paints in an aquamarine violet blueish . this colour makes me thirsty . all nice colours should make you thirsty.

the print out in gold print (or as close as you can get with an ink jet printer. only the text

apply decal over dial plate to seal in air brushed colors

giving the dial a gloss finish from the decal

re apply indices and install back onto watch.

It may not look gen but it will give off the same vibes and appearance I think especially with the polished plate and semi transparent air brush paints allowing the sun to dance off the polished metal underneath.

Thoughts? what am I missing here..?