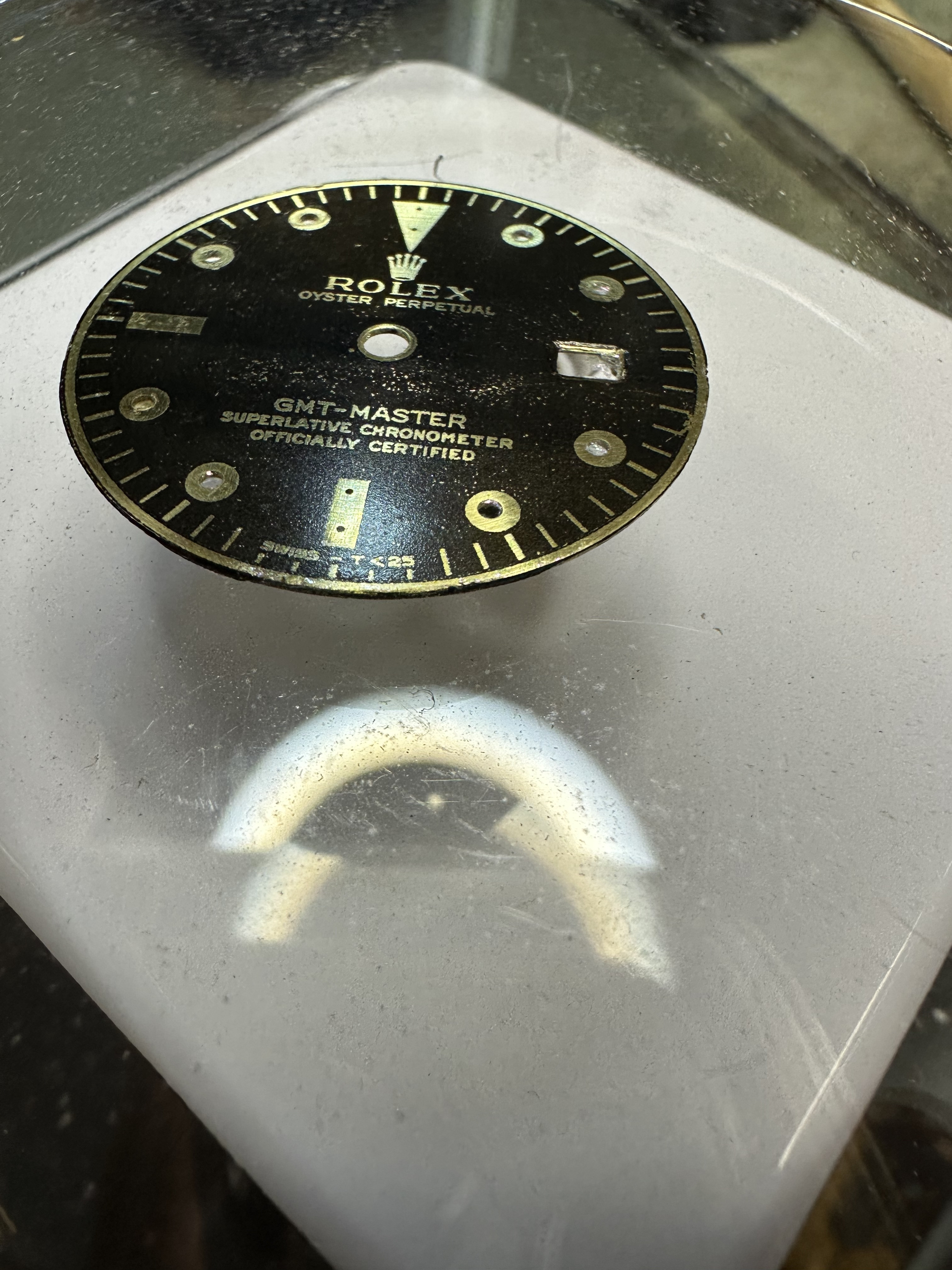

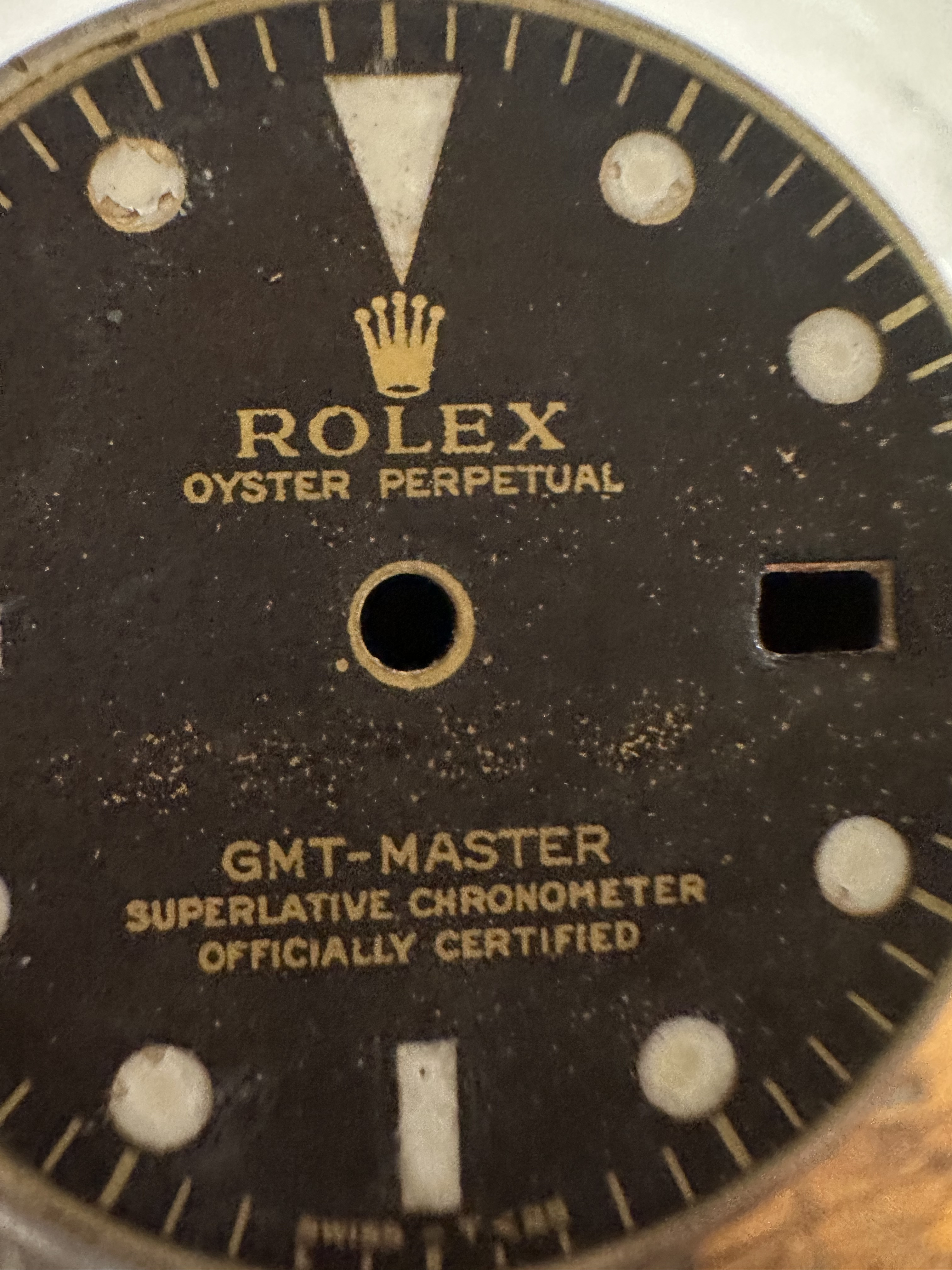

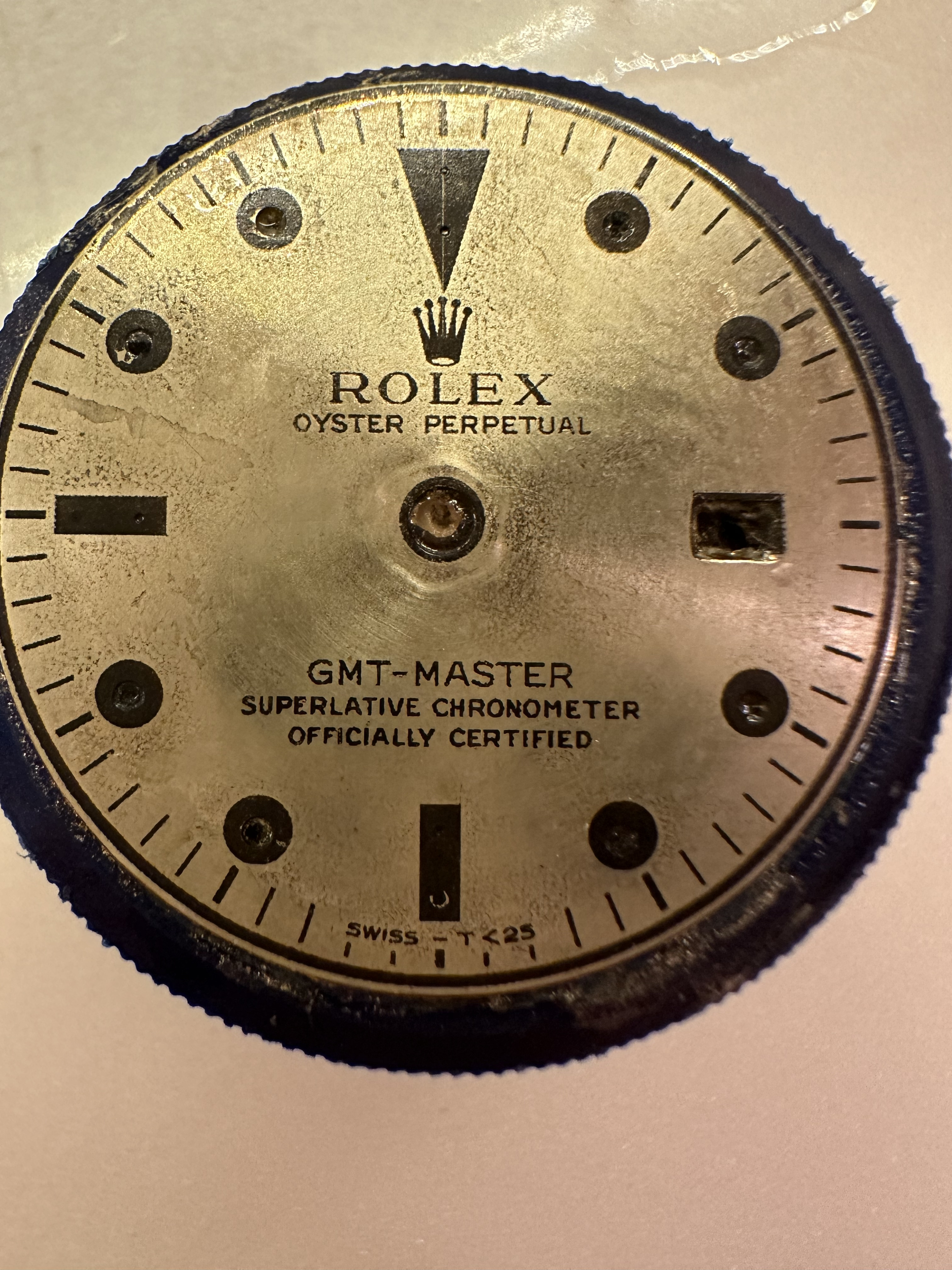

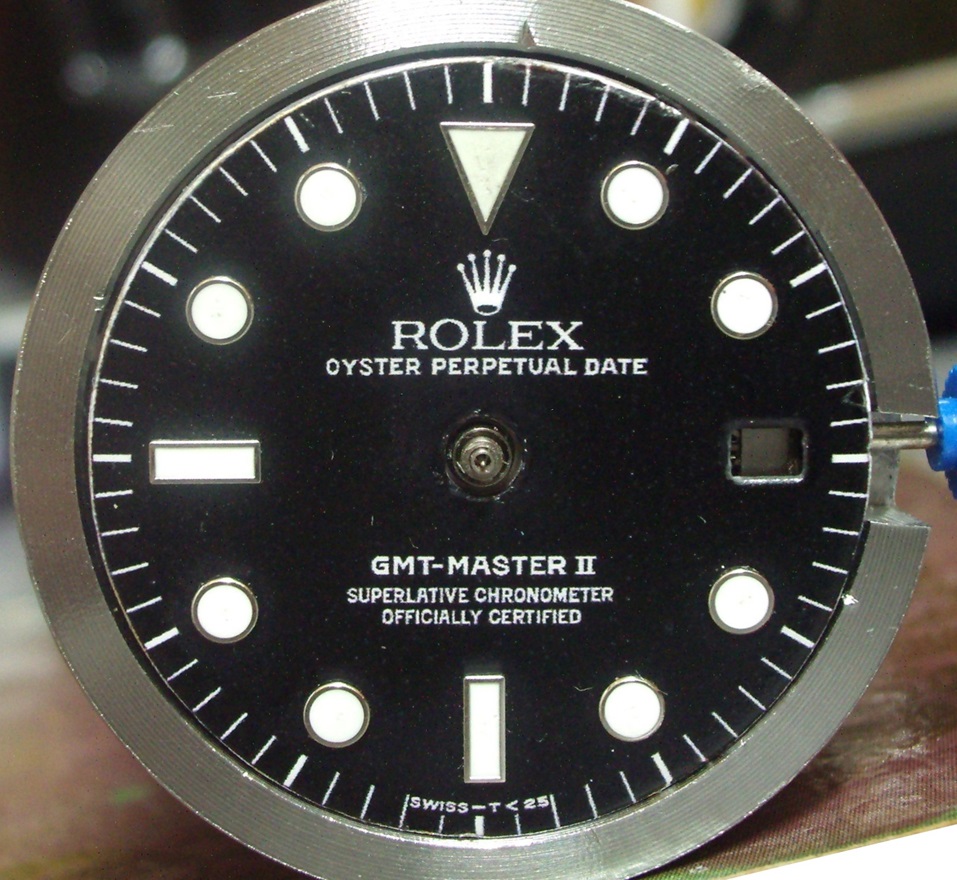

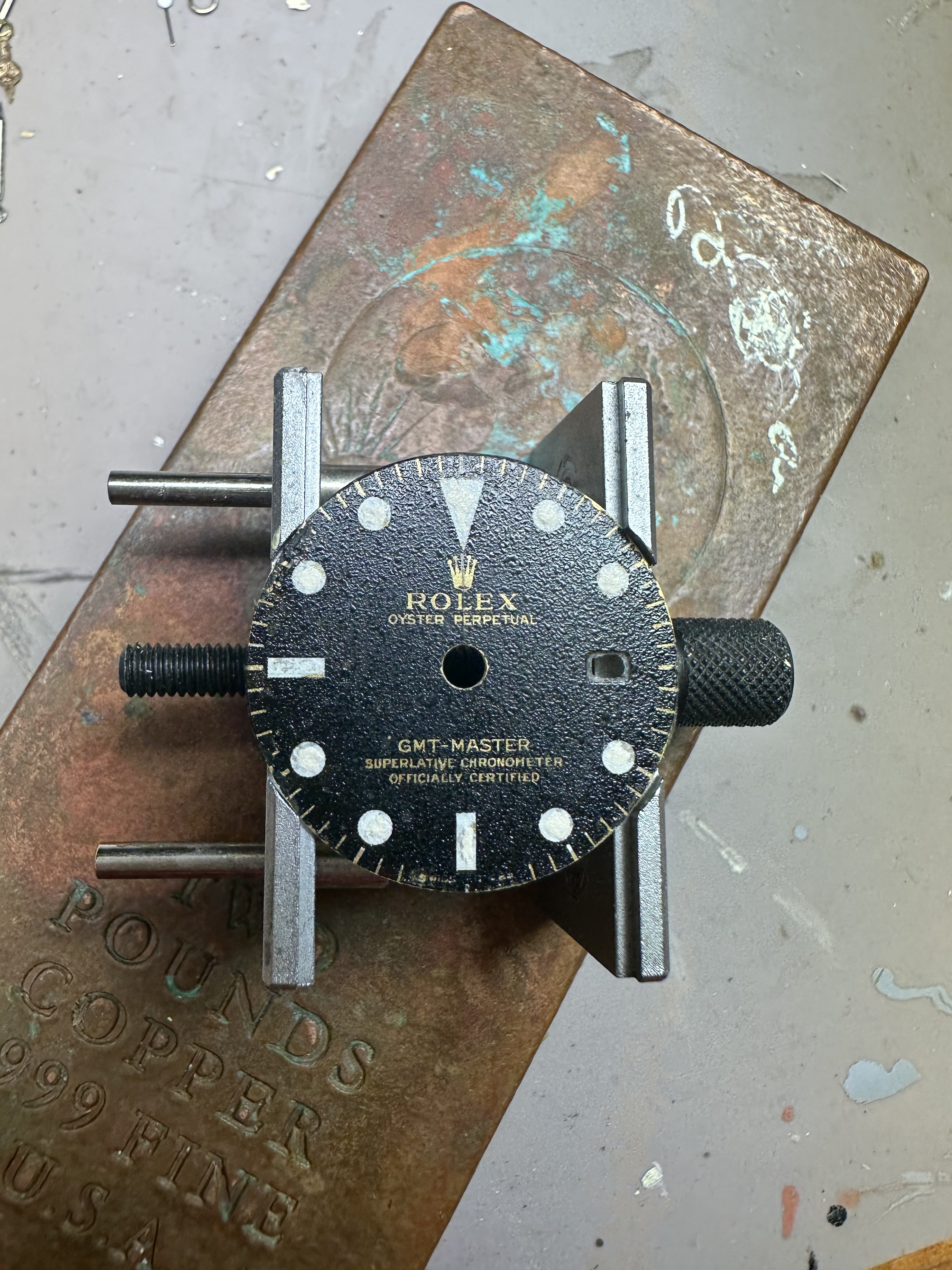

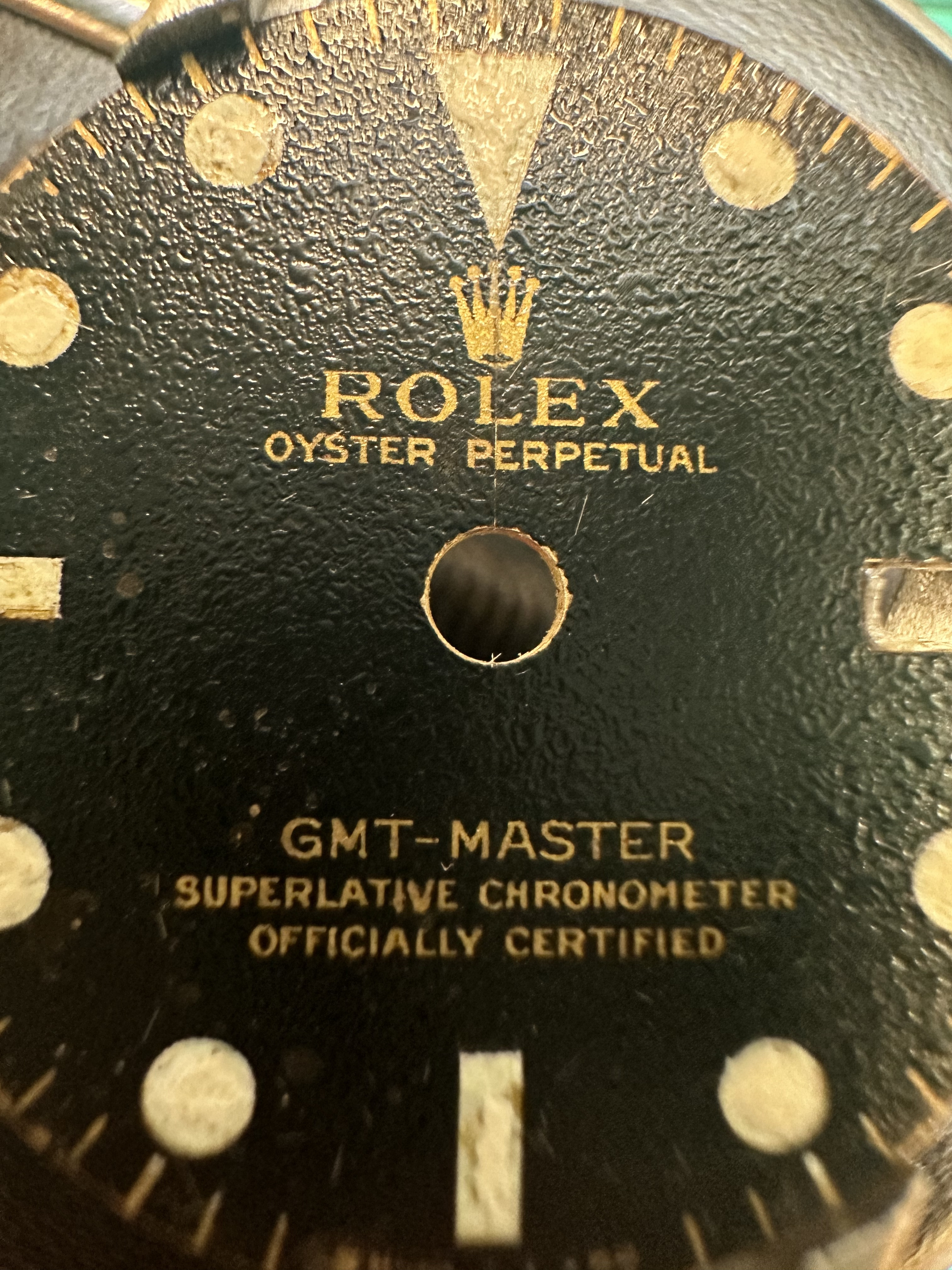

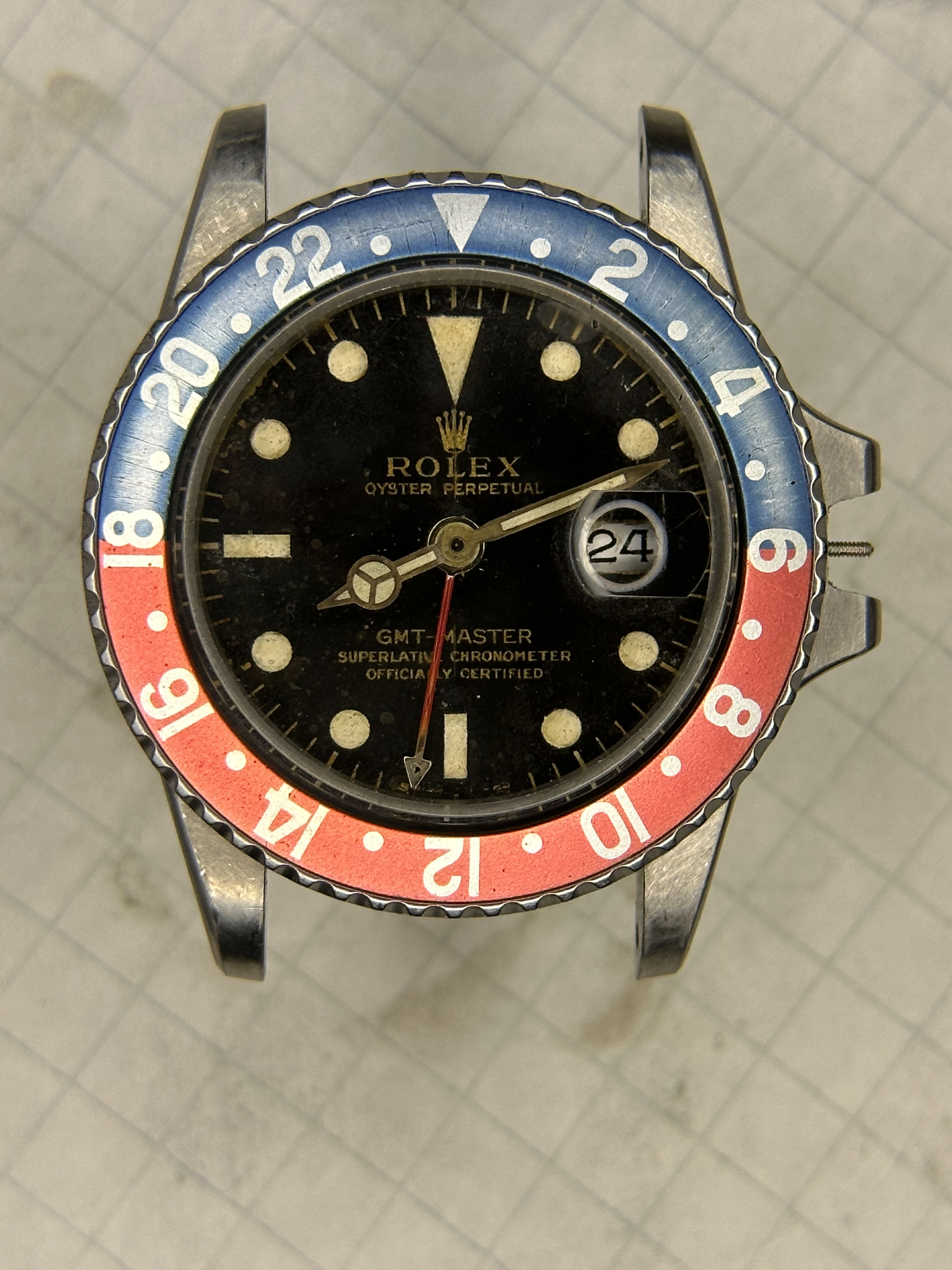

Just an update. I'm still using this dial to build a watch. Anything before I forget how the assembly is even supposed to work. Still undecided with hands, final lume, un-aged date disc, bezel, case shape, and more. But I'm somewhat impressed a watch is coming together. Here's a close-up of how crappy it looks under magnification, and another one or two in a case under a lamp with decent light.I hate to admit it, but couldn't give up on the Sunnyscopa sheets I still had left. I inadvertently spilled the glue various times when the bag hadn't properly sealed, so I still have a few sheets with no binder to use. Decided to try some Liquitex gloss medium, which is "almost" the same as clear acrylic waterbased paint.

It came out okay, but it's much thicker and doesn't have any noticeable benefits from the glue Sunnyscopa comes with. I decided to apply white acrylic before to have a sharp white base for the lume, and the final result was great for having a white base, but it really lost the beauty of a mirror polished gilt dial. With that, I misted the final result with a strong clear. It's much more textured than I want, but a clean white base for lume was the goal here.

Many, many issues, but I'm happy to finally be close to throwing something new on my wrist.

[url=https://clickpix.org/image/FE22366E-BA8F-4F43-89F6-A7943AB2E64F.hL5CTv]

[url=https://clickpix.org/image/FE22366E-BA8F-4F43-89F6-A7943AB2E64F.hL5CTv]