- 13/10/16

- 3,981

- 2,587

- 113

That one was made using water-based acrylic spray paint ...

Now we're talking. What type of white base were you using before? Looks like you fixed the issues you were having with your previous white attempt(s)?

Maybe you were using acrylic water-based first, and then using a solvent-based rattle can "melted" the coats together??? If so, how long did you wait for the paint to dry?

Was it a lacquer or an enamel?

Looks very promising to me, and it appears to have none of the issues you mentioned before. Would love to know the changes you made.

Beautiful as always!That one was made using water-based acrylic spray paint ...

Beautiful as always!

That gives me a lot of questions:

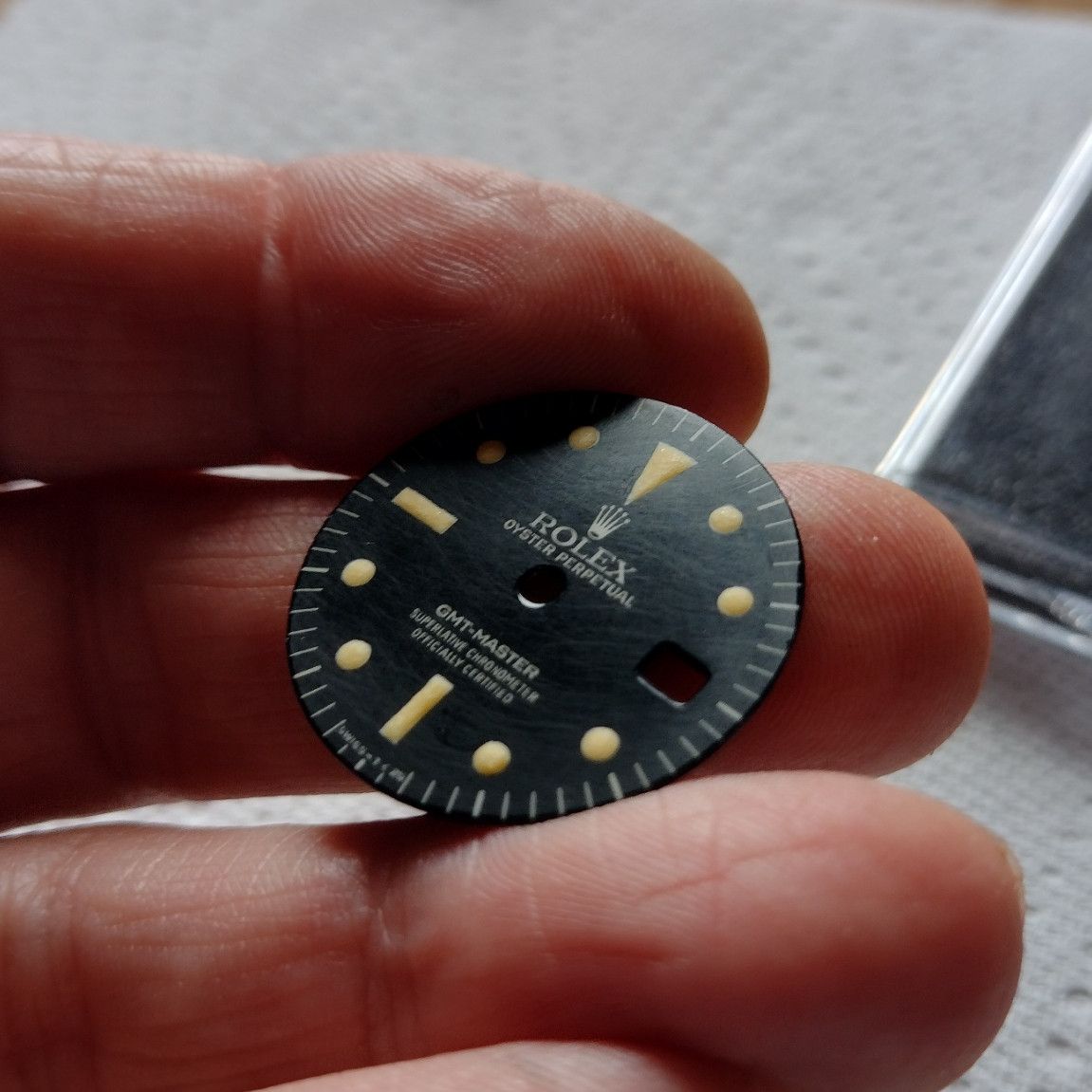

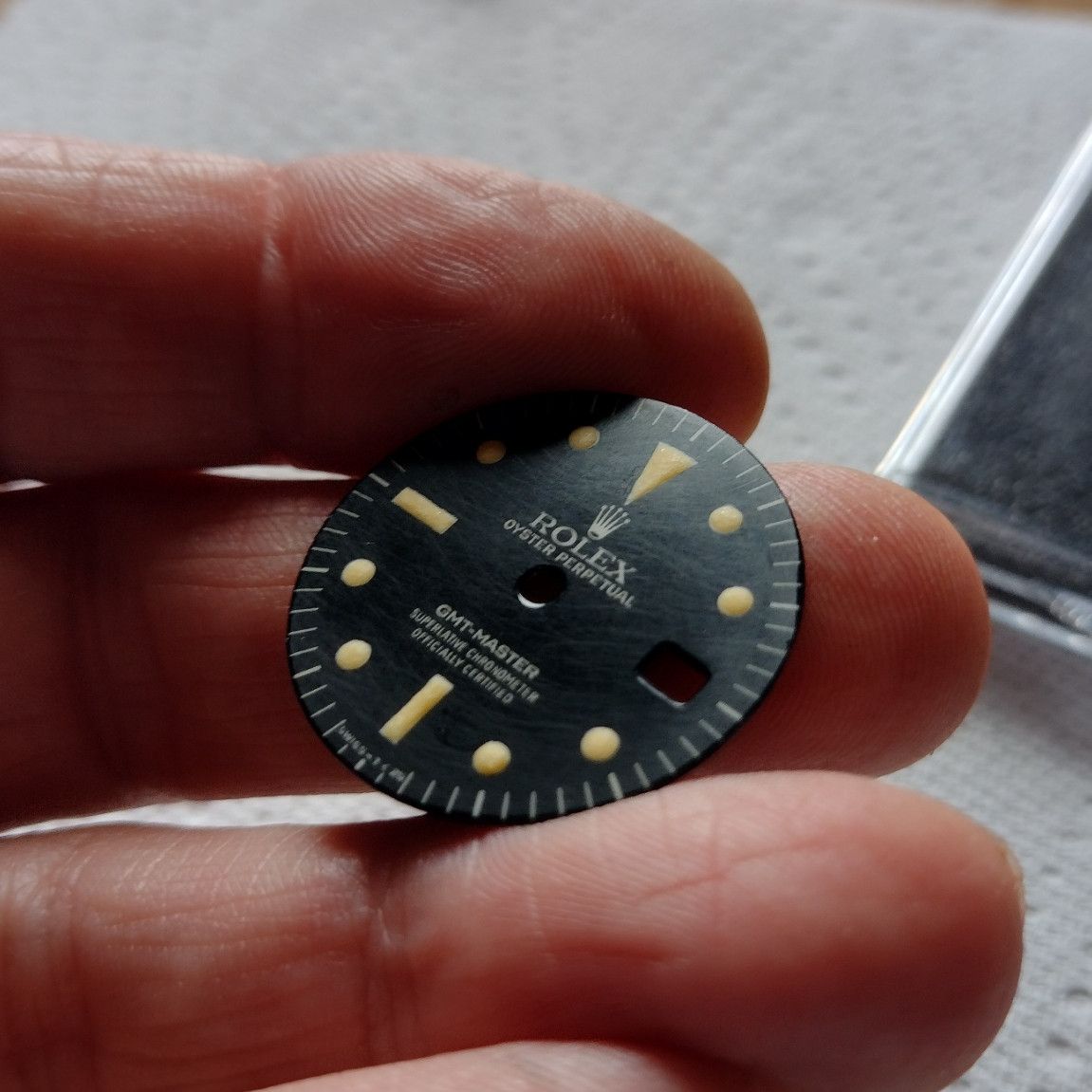

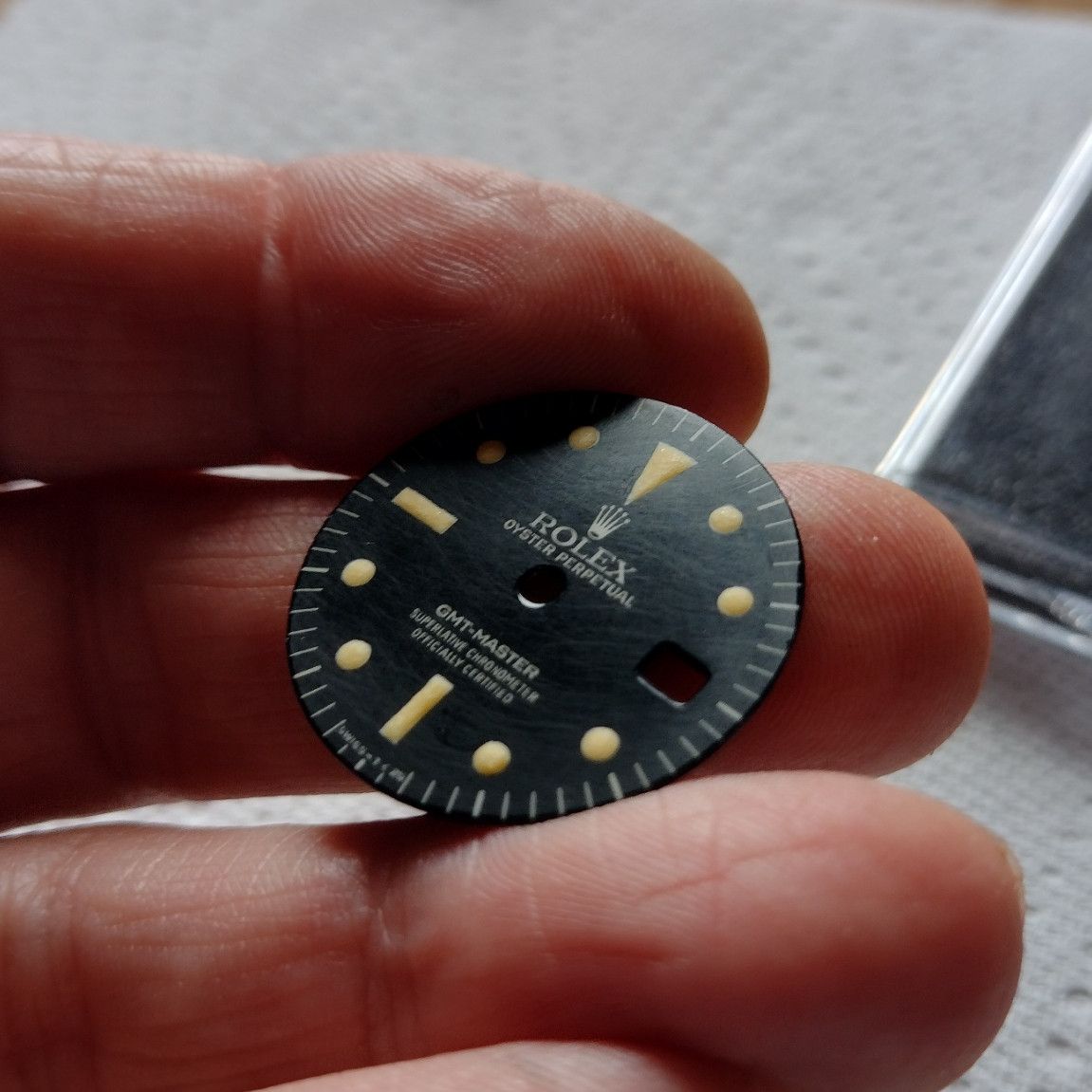

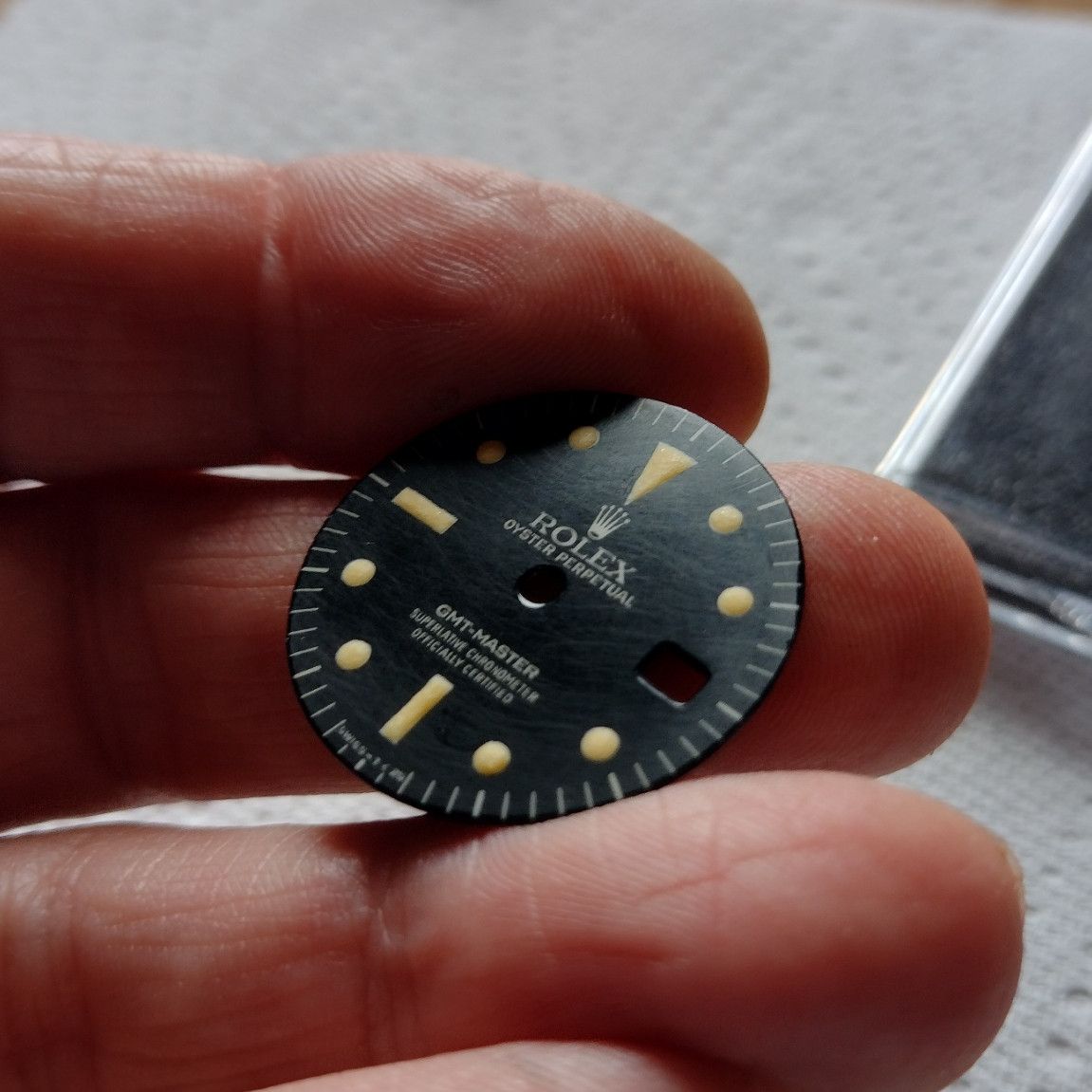

What type of dial is it? A matt or gilt dial?

How did you get the white/silver text so nice? Is it white toner or a black decail over a blanc brass dial?

Oh so much questions: i which to book a workshop from you ;-)

Am I looking at the wrong photos? I don't see a Long E.Thank you

It's a 1675 GMT Mark I matte dial ... hence the "long E"

The text is white and made using black toner transfer on a white dial.

Possibly the last of that sort as this week I'll "dip my toes" in white printing on matte black ... fingers crossed

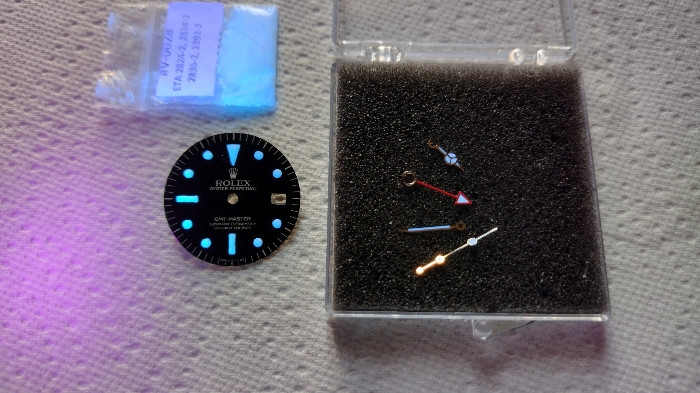

The lume reaction to UV is a bit too muchI tried to mimic the reaction of the zinc sulfite lume which was still used on early GMT matte dials.

I'm still on a "test phase" playing with green and blue fluorescence (not phosphorescence) and all the shades in the between.

At the moment I have no idea on how to get a purple one (some old gilt dials have it) but I'm stubborn so I will find.

I don't have the time to push the tests much further, but from January 2025 I'll be working 100% on dials and watches, so I'll be able to explore new solutions.

Am I looking at the wrong photos? I don't see a Long E.

I assume you are looking for tips from @manodeoro since his technique is perfected. But I'll give you some ideas that may help. Try to leave a little arm sticking out in one part of circle so you can have a small section that is easier to grab the film.I'm starting to get the hang of putting my decal on. My first difficulty is removing the transparent film after baking. I cut almost flush with the dial and it's hard enough to grab the film, but it's easier to put it on and to get rid of the air. When I remove the film, I often get a little bit of paint with it. When the background is white, you lose several days to start again... Do you have a tip?

@manodeoro gave me a few tipswhich I only half-applied, I'm a bad student... I'm going to switch to car spray paint, it should handle the heat well. And I'll take your advice and leave some of the film sticking out to make removal easier.

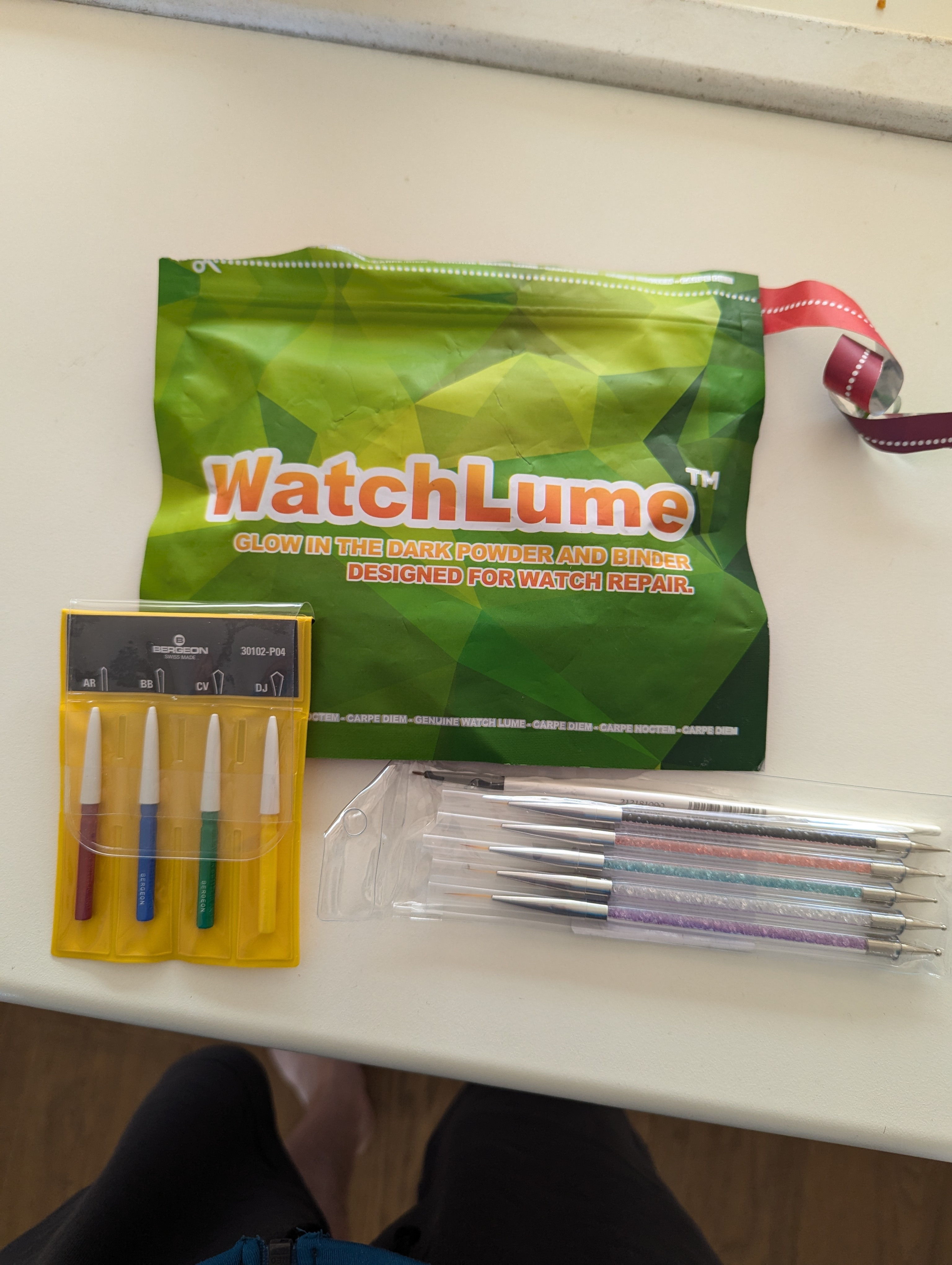

I'm not sure it's a trick we need, but the right tools and the right texture will do the trick. I just left myself with this and I think it should look better, so I'm going to go back to the watchlume, which is a product that's already ready to be installed. I had much better results with it. The problem is that it's not opaque and can only be applied to white.