-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

Building a 5513 - Tutorial

- Thread starter Megahz1

- Start date

@dpd3672

I am glad people are starting to build their own watches. Imo there is too much wrong stuff with raffles 5513 case set. I do not even know if it takes gen spec plexi. Bezel is completely off not only in assembly but also shape. Most importantly you won’t find any good dial which will fit. It might be an ok case if you just want to try shaping, but I am sure that after actually wearing it you will end up looking for something better. Nevertheless share your results here so everyone can have a look at multiple options!

I am glad people are starting to build their own watches. Imo there is too much wrong stuff with raffles 5513 case set. I do not even know if it takes gen spec plexi. Bezel is completely off not only in assembly but also shape. Most importantly you won’t find any good dial which will fit. It might be an ok case if you just want to try shaping, but I am sure that after actually wearing it you will end up looking for something better. Nevertheless share your results here so everyone can have a look at multiple options!

- 13/10/16

- 4,025

- 2,672

- 113

if you have a dremel and a workstation, you are basically set

It has been long since I had so much fun

great job for a first try my fellow countryman

now you're in the rabbit hole but don't need to worry as fun is never ending ...

I joined the game years ago and I still have a lot of fun as there's always new chords to learn and new songs to play

Does this means the Raffles dials are not great?@dpd3672

I am glad people are starting to build their own watches. Imo there is too much wrong stuff with raffles 5513 case set. I do not even know if it takes gen spec plexi. Bezel is completely off not only in assembly but also shape. Most importantly you won’t find any good dial which will fit. It might be an ok case if you just want to try shaping, but I am sure that after actually wearing it you will end up looking for something better. Nevertheless share your results here so everyone can have a look at multiple options!

- 13/10/16

- 4,025

- 2,672

- 113

Does this means the Raffles dials are not great?

Some are great and some not ...

In any case most of Raffles 5513 dials are 29mm and won't fit in a JKF case ... if I'm true the only 5513 Raffles 26mm dial is a milsub ...

Some are great and some not ...

In any case most of Raffles 5513 dials are 29mm and won't fit in a JKF case ... if I'm true the only 5513 Raffles 26mm dial is a milsub ...

any idea where I can source decent dials in that price range?

you need to order the "custom print" option, yes?@Karbon74 I think the best budget option is Helenarou. Yuki is also ok but pricier and less quality.

that makes the dial at about $135 ?

No write to the email and ask for it, it is much cheaper like $80 + shipping iircyou need to order the "custom print" option, yes?

that makes the dial at about $135 ?

oh. that changes everythingNo write to the email and ask for it, it is much cheaper like $80 + shipping iirc

- 13/10/16

- 4,025

- 2,672

- 113

You can make the spring at little bit more curved ... it should work.

Maybe you'll have to sand it down to enlarge the interior diameter.

If nothing of this works you can source better bezel springs on eBay.

So, I'm actually done with version 1 by now; will still use the therad and share my experience before I show the finished clock here. It can remain exciting.

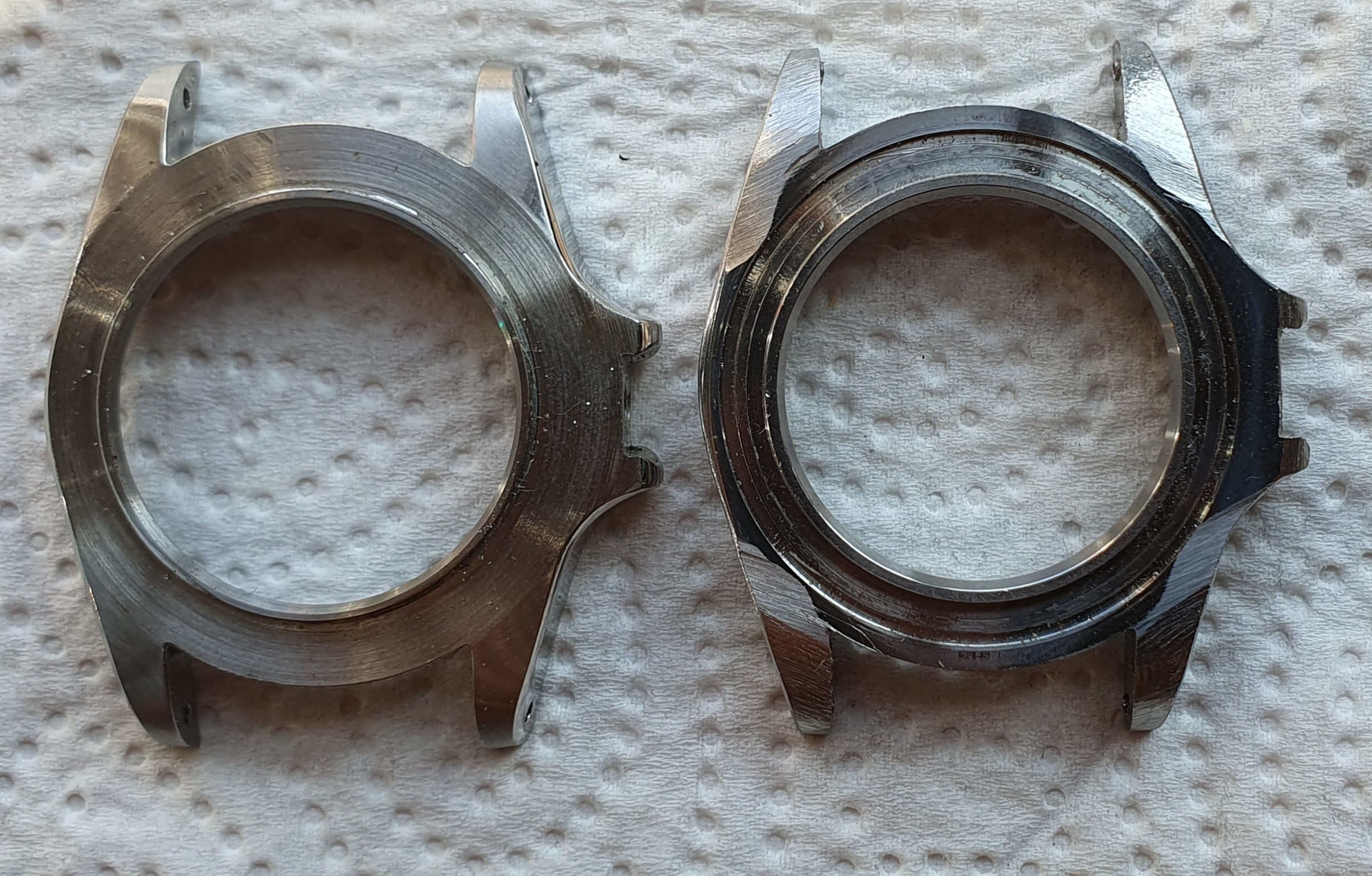

I prefer to use a file for my metalwork. Personally, I feel better about the work. Maybe it's because of my education as a metalworker. As @Megahz1 recommended, I looked at various photos on the internet of a GEN 5513 for the adjustments to the midcase. I also had a 1680 midcase from milk that I can use as a model. Here are a few pictures:

Left: milk case

Right: JKF case

As @Megahz1 has pointed out, the luge on the JFK case are too wide. The second picture also shows that they are too high. That all has to go!

Here you can see a picture were I removed some material with the file. It lookes painful and the file and the file leaves deep marks.

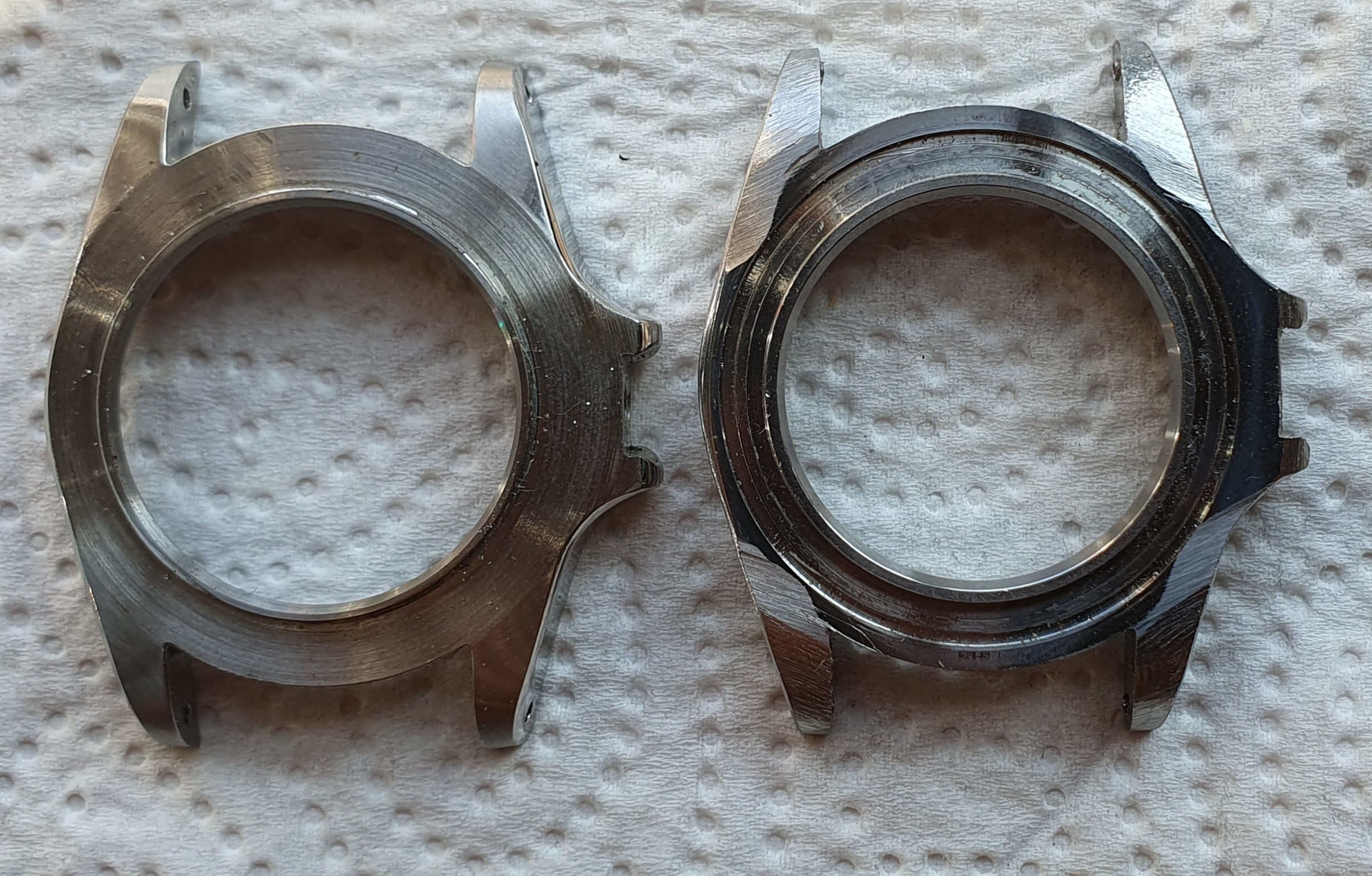

After 2 hours work the shape of the case looks like this.

Left: JKF case

Right: milk case

And from the top.

Left: milk case

Right: JKF case

To get the surface smooth and polished again, I worked with different sandpapers. I started with 280, 400, 600, 1000 and 3000. From 600, the sandpaper was wetted. In the end I used the polishing machine again - but that wasn't really necessary.

I prefer to use a file for my metalwork. Personally, I feel better about the work. Maybe it's because of my education as a metalworker. As @Megahz1 recommended, I looked at various photos on the internet of a GEN 5513 for the adjustments to the midcase. I also had a 1680 midcase from milk that I can use as a model. Here are a few pictures:

Left: milk case

Right: JKF case

As @Megahz1 has pointed out, the luge on the JFK case are too wide. The second picture also shows that they are too high. That all has to go!

Here you can see a picture were I removed some material with the file. It lookes painful and the file and the file leaves deep marks.

After 2 hours work the shape of the case looks like this.

Left: JKF case

Right: milk case

And from the top.

Left: milk case

Right: JKF case

To get the surface smooth and polished again, I worked with different sandpapers. I started with 280, 400, 600, 1000 and 3000. From 600, the sandpaper was wetted. In the end I used the polishing machine again - but that wasn't really necessary.

I bought some 5513 dials here a few weeks ago. So now I have the choice between 3 dials for the setup.

left: supplied JFK

middle: yuki

right: another JFK

I am not 100% convinced of any dial. Personally, I am a fan of colourful watches and so I chose the yuki. For the hands I go with some from Ali. They are compatible to eta movements and already in a yellow color. For my opinion it lookes a bit boring. What do you think?

left: supplied JFK

middle: yuki

right: another JFK

I am not 100% convinced of any dial. Personally, I am a fan of colourful watches and so I chose the yuki. For the hands I go with some from Ali. They are compatible to eta movements and already in a yellow color. For my opinion it lookes a bit boring. What do you think?

@matzemedia I think you did a great job! Unfortunately Milk's case has the wrong diameter afaik. I personally did not touch the top of the lugs at the moment; they are a little bit fat, but curved decently. I would suggest going for a better dial since you put a lot of effort into the case.

Nevertheless great work, keep posting!

Nevertheless great work, keep posting!

you need to give some eld texture to the dial.I bought some 5513 dials here a few weeks ago. So now I have the choice between 3 dials for the setup.

left: supplied JFK

middle: yuki

right: another JFK

I am not 100% convinced of any dial. Personally, I am a fan of colourful watches and so I chose the yuki. For the hands I go with some from Ali. They are compatible to eta movements and already in a yellow color. For my opinion it lookes a bit boring. What do you think?

my current plan is the uneven textured dial effet with sprayed mat transparent varnish

@Megahz1 @369mafia do you know how to make spider dials? could not find how

OK, I'll have to find another solution for the dial. Maybe I'll relume the dots for now. But for now, here is an update of the assembled JKF.

I bleached the insert slightly. After 5 hours, the colour didn't change any more - but I like it that way for now. The crown is unchanged - the original JKF. I have nothing to complain about.

The movement is currently the Asian 2836. Somewhere in my spare parts box I still have an ETA movement with 21,000 bpm. I'll get it in working order again this winter.

Here some images

I bleached the insert slightly. After 5 hours, the colour didn't change any more - but I like it that way for now. The crown is unchanged - the original JKF. I have nothing to complain about.

The movement is currently the Asian 2836. Somewhere in my spare parts box I still have an ETA movement with 21,000 bpm. I'll get it in working order again this winter.

Here some images