-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

BP Re-Releases 5-Digit Submariners with VR3135

- Thread starter mclarendude

- Start date

hollywoodrollie

Getting To Know The Place

- 12/12/23

- 46

- 81

- 18

Indeed, I ordered one just recently. Don't assume that it will come with VR3186. The TDs still have old BP stock and I had to ask and insist on getting the new one because they would have otherwise shipped the one with the asian clone movt.Many of the BPs do still come with SA3186’s. Easily identified by the silver on the red reversing wheels.

Good news is, when that dies you just swap in a VR3186.

Those cases tend to have the much wider chamfers as well.

I would sayWhat are you saying Mr. Hayek, that I shouldn't get the 16610, to late to the game?

If you want a fair priced and nice watch

- it is still a great deal.

When you want a good OOTB and wear it like it is - go for it. Still great value.

If you are planning small mods on it… it can be tricky as we all now know (different batches / different used parts and so on)

To start a Franken project with a bunch of Gen parts = it is still the wrong base in my opinion.

It depends on you.

To wear it and enjoy it as it is - I personally still would go for it.

- 12/3/18

- 37,543

- 80,249

- 113

Bro if you can remove the whole autowind assembly (leave rotor attached) and check crown winding, you may be able to identify the issue. If it is the autowind assembly it could be a quick easy fix with a homemade cleaning.Ordered end of Jan, it has the VR movement.

Unfortunately it does have a fault where it will not wind from the crown, so will need to service at some point.

Shame as the timekeeping is excellent.

another way to straighten a slightly bent bezel is using a crystal press.Hy

Yes they all did bro. You have to remove the crystal from the inside, then you can get the insert out, then fish the wire out.

How to remove a bezel attached by a wire clip

Sorry this happened to you, you're in good company heh. Sure looks like they did what you said - put a VR into an old model case.

On a positive note I have straightened a few metal bezels, including a gen with a stout narrow board and a rubber hammer.

Place the insert on a perfectly level surface to ID the offending sector. Place that sector over the edge of the board and beat on it with the hammer. You can clamp the bezel and board to a bench but I've done it freehand.

The bezels are pretty tough and can take a good beating. Rinse and repeat til it's level again. Be patient and keep at it, sometimes you can bend too far in the other direction, etc. This has worked for me more than once, though IDK how it will impact the plating. If the bezel is already shot you have nothing to lose.

muiramas

Aristocrat

- 18/1/17

- 6,105

- 8,133

- 113

I’ll take a look tomorrow - it may be because it was fully wound and going against the clutch, I never try and turn a crown with any force. But I recall when I got it, the winding was stiffer than the VSF movements I have.Bro if you can remove the whole autowind assembly (leave rotor attached) and check crown winding, you may be able to identify the issue. If it is the autowind assembly it could be a quick easy fix with a homemade cleaning.

Overall, I’m delighted with this watch. I’ve just finished smoothing the bracelet off, an ultrasound clean, a once over with renaissance wax. Looks and feels great.

Last edited:

- 12/3/18

- 37,543

- 80,249

- 113

Just these 2 screws to get the autowind + rotor off if you haven't fooled with one recently.I’ll take a look tomorrow - it may be because it was fully wound and going against the clutch, I never try and turn a crown with any force. But I recall when I got it, the winding was stiffer than the VSF movements I have.

Overall, I’m delighted with this watch. I’ve just finished smoothing the bracelet off, an ultrasound clean, a once over with renaissance wax. Looks and feels great.

If your crown winding returns to normal, you've found the issue and a clean and relube of the removed parts should fix them. You can use Naphtha (lighter fluid) in a jar for cleaning then rinse with alcohol. Put the jar in an ultrasound if available. I can post lube instructions if it comes to that.

Last edited:

muiramas

Aristocrat

- 18/1/17

- 6,105

- 8,133

- 113

Lol, I think you overestimate my abilities KJ! I did a few tinkerings during Covid, and realised that I did not have the attributes needed to do such things. If I can replace the batteries in my kids toy’s without losing the screws I feel proud! Turns out it was fully wound yesterday, the winding action isn’t the best I’ve ever had - a little stiff and feels like it’s slipping, so once the honeymoon is over, I’ll send it off to someone who knows what they are doing for a service.Just these 2 screws to get the autowind + rotor off if you haven't fooled with one recently.

If your crown winding returns to normal, you've found the issue and a clean and relube of the removed parts should fix them. You can use Naphtha (lighter fluid) in a jar for cleaning then rinse with alcohol. Put the jar in an ultrasound if available. I can post lube instructions if it comes to that.

It will definitely be OOTB for me. I’m waiting for the TDs to return after CNY.I would say

If you want a fair priced and nice watch

- it is still a great deal.

When you want a good OOTB and wear it like it is - go for it. Still great value.

If you are planning small mods on it… it can be tricky as we all now know (different batches / different used parts and so on)

To start a Franken project with a bunch of Gen parts = it is still the wrong base in my opinion.

It depends on you.

To wear it and enjoy it as it is - I personally still would go for it.

This is the original SH3135 From like 10 years ago. You can tell by the silver teeth on the red wheels. This is exactly why I told the TD I wanted a movement shot to prove it’s a VR.I recently had a 5-digit BP arrive on my bench. The owner bought it recently, specifically because it was supposed to have the VR3135 movement. When I opened the case I didn’t see a VR3135 inside.

This isn’t a 3135 clone that I’ve seen (nor have I documented it in my comprehensive guide), but the shock setting (red) and beat adjustor (blue) of the movement pictured above look the same as those found on the old SA3186 (time bomb) GMT movement. Note the rounded end of the beat adjustor and steel cup of the shock setting.

A vr3135 movement has a squared off end to the beat adjustor and has a brass cup for the shock setting.

I’m not sure if this is a known issue or the result of an error on the part of the buyer or seller. But I figured this was worth sharing. The person who bought this watch before sending it to me for service is not naïve, so I think a “movement check” wouldn’t be a bad idea for anyone buying one of these watches going forward.

Last edited:

I bent the hell out of my bezel trying to take it off. I wasn’t expecting a wire in there. It’s supposed to be the new one. The bezel was easy to bend back flat by hand And fairly easy to reinstall. After removing the crystal with a press, and bezel insert with a razor blade, there is no way to fish the wire out on mine. The gap is about 0.5mm all the way around. Very tight tolerances. I’ll never pull the bezel off again On this watch. I’m shocked that I got it 100% flat and rotates perfectly. I want to order a two tone blue but I think I’ll wait a bit for them to burn through any old remaining stock haha.another way to straighten a slightly bent bezel is using a crystal press.

- 12/3/18

- 37,543

- 80,249

- 113

You can get to the wire if you insert a narrow screwdriver blade in one side. This moves all of the gap to one side.I bent the hell out of my bezel trying to take it off. I wasn’t expecting a wire in there. It’s supposed to be the new one. The bezel was easy to bend back flat by hand And fairly easy to reinstall. After removing the crystal with a press, and bezel insert with a razor blade, there is no way to fish the wire out on mine. The gap is about 0.5mm all the way around. Very tight tolerances. I’ll never pull the bezel off again On this watch. I’m shocked that I got it 100% flat and rotates perfectly. I want to order a two tone blue but I think I’ll wait a bit for them to burn through any old remaining stock haha.

From another thread:

BTW in case you (or others) are wondering how you can get a wire clip bezel off, here are two ways. Both methods require the insert to be removed before the bezel comes off the watch.

Note: If the bezel is seemingly impossible to remove, it probably has a wire clip!

1. Remove the movement and press the crystal out from the inside. This will allow access to the inner perimeter of the insert where it can be carefully pried up. Then find an end of the wire clip and coax it out where it can be grabbed with pliers and pulled out a segment at a time. This method is common and much more feasible with a 5 digit rep where there is no separate crystal retaining ring. That part is usually built into the case on 5 digit wire clip models. On 6 digit models, sometimes the crystal won't press out from inside due to a strong retaining ring.

2. If the crystal won't press out from inside, you have to remove the insert from above. I have on occasion managed to keep an insert intact while doing this. Tape up the crystal and use it as a fulcrum for a thin new razor blade. Put the blade corner under the insert and carefully work it around, loosening it up. Sometimes you can lift it up enough to get progressively thicker pry tools underneath it and work it up and out. More often, the insert will chip or crack so you can just piece it out with less concern. If you don't care about the old insert you can just crack it at a weak marker point initially and dig it out.

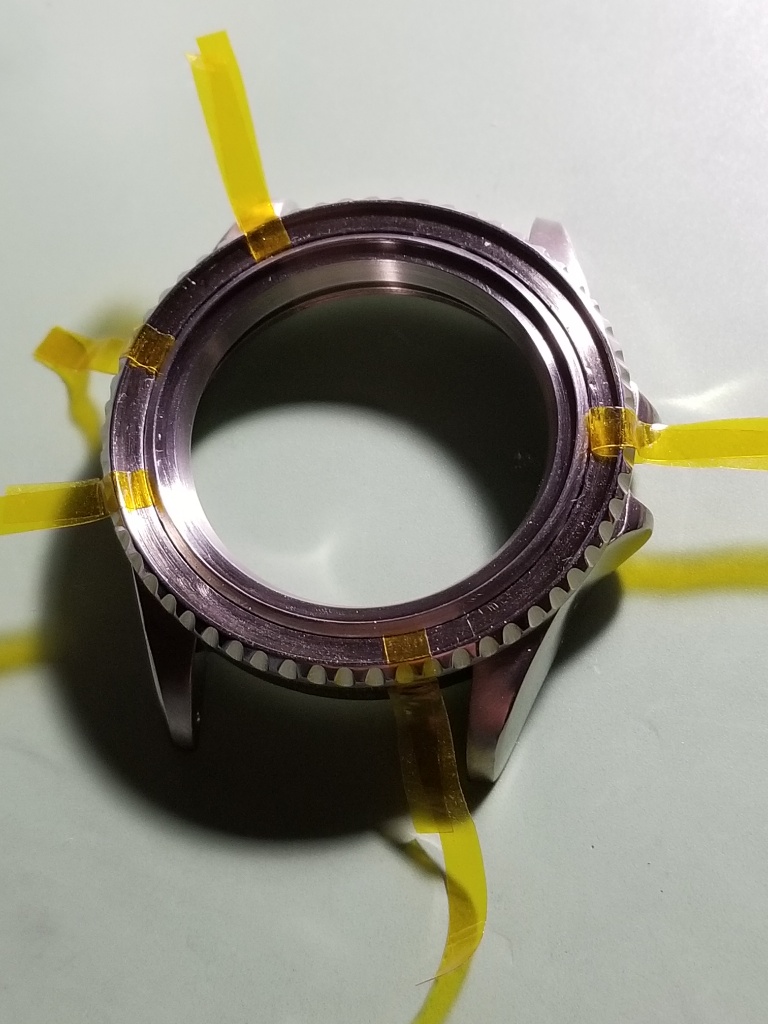

Here are some pics of a 5 digit. On this one the gap to access the wire clip was so narrow I had to hammer a screwdriver in to open it up enough to grab the wire. It's usually not that tight. It was doing this that made me wonder how these are assembled because previously reassemblies were done by feeding the wire clip back into the gap one segment at a time. I saw that you could tape the wire clip into the groove, set the bezel in place, then cut the tape and pull it away. Yellow bracelet tape works really well for this task because it sticks to itself and is very strong laterally. Also it is super smooth on top so it slides out easily.

watcher009

Known Member

- 12/12/17

- 162

- 49

- 28

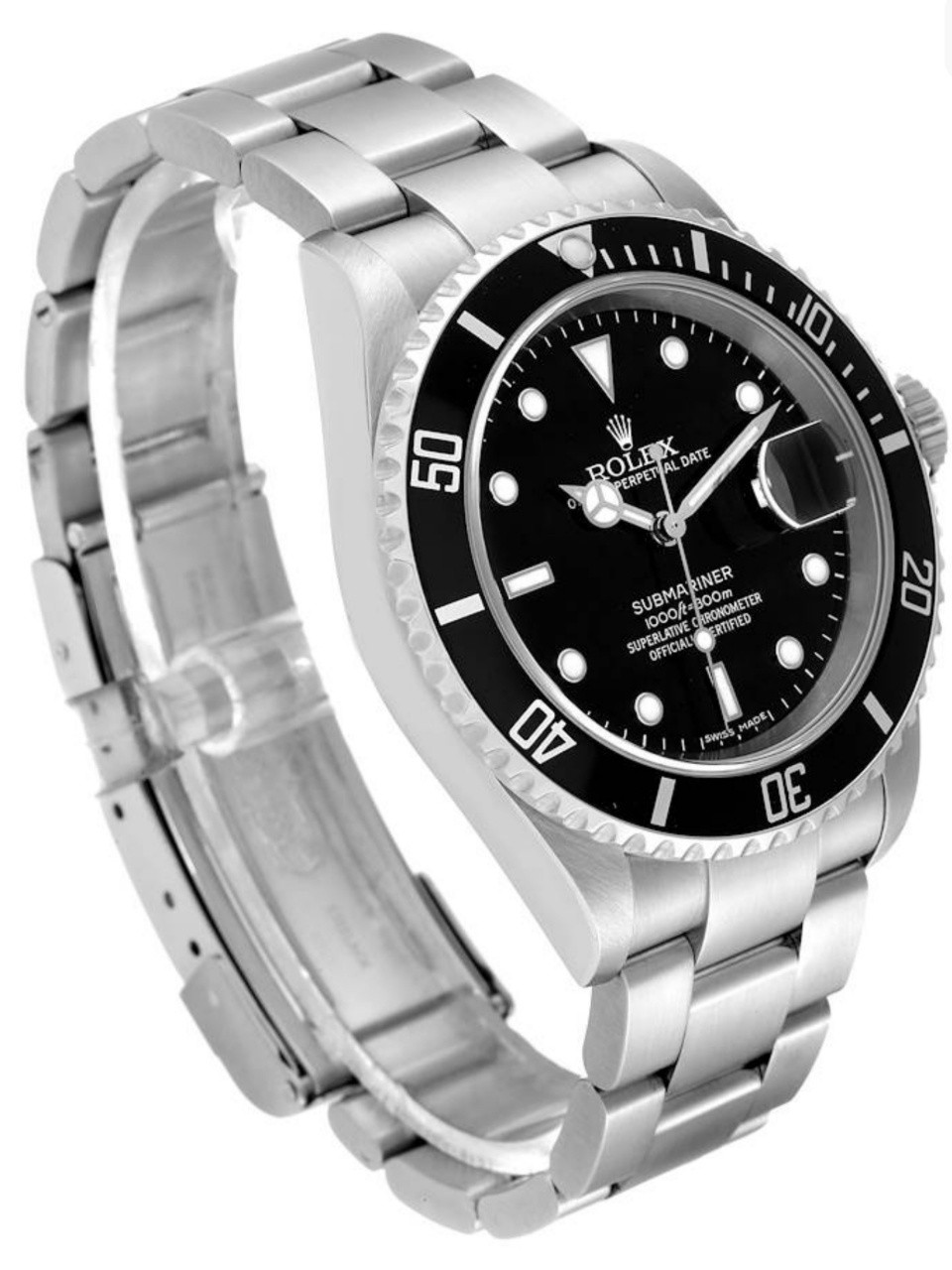

I have one question though. Has rolex changed the polish or the shape of the case when they switched from lug holes to no lug holes? Your gen that you are comparing the BP with is with lug holes. Here below are some more gens with similar BP lugs and polish but all with lug holes. I have not been able to find the same polish or lugs on no lug holes models. The polished finish running all the way to the bottom of the front part of the lug. Now is this because of a change in case shape or just polish? Or am i missing something and my observation is wrong?I think the wide chamfers can be gotten used to. You can see in these pics of the BP 16710 next to my gen that its chamfers are considerably more pronounced than the Sub or the gen. This difference is quite apparent in super close ups but at arm's length is much less noticeable. I never even think about it anymore and have a number of BP Subs and GMTs.

are you talking about the chamfered edges?I have one question though. Has rolex changed the polish or the shape of the case when they switched from lug holes to no lug holes? Your gen that you are comparing the BP with is with lug holes. Here below are some more gens with similar BP lugs and polish but all with lug holes. I have not been able to find the same polish or lugs on no lug holes models. The polished finish running all the way to the bottom of the front part of the lug. Now is this because of a change in case shape or just polish? Or am i missing something and my observation is wrong?

- 23/6/17

- 2,309

- 2,750

- 113

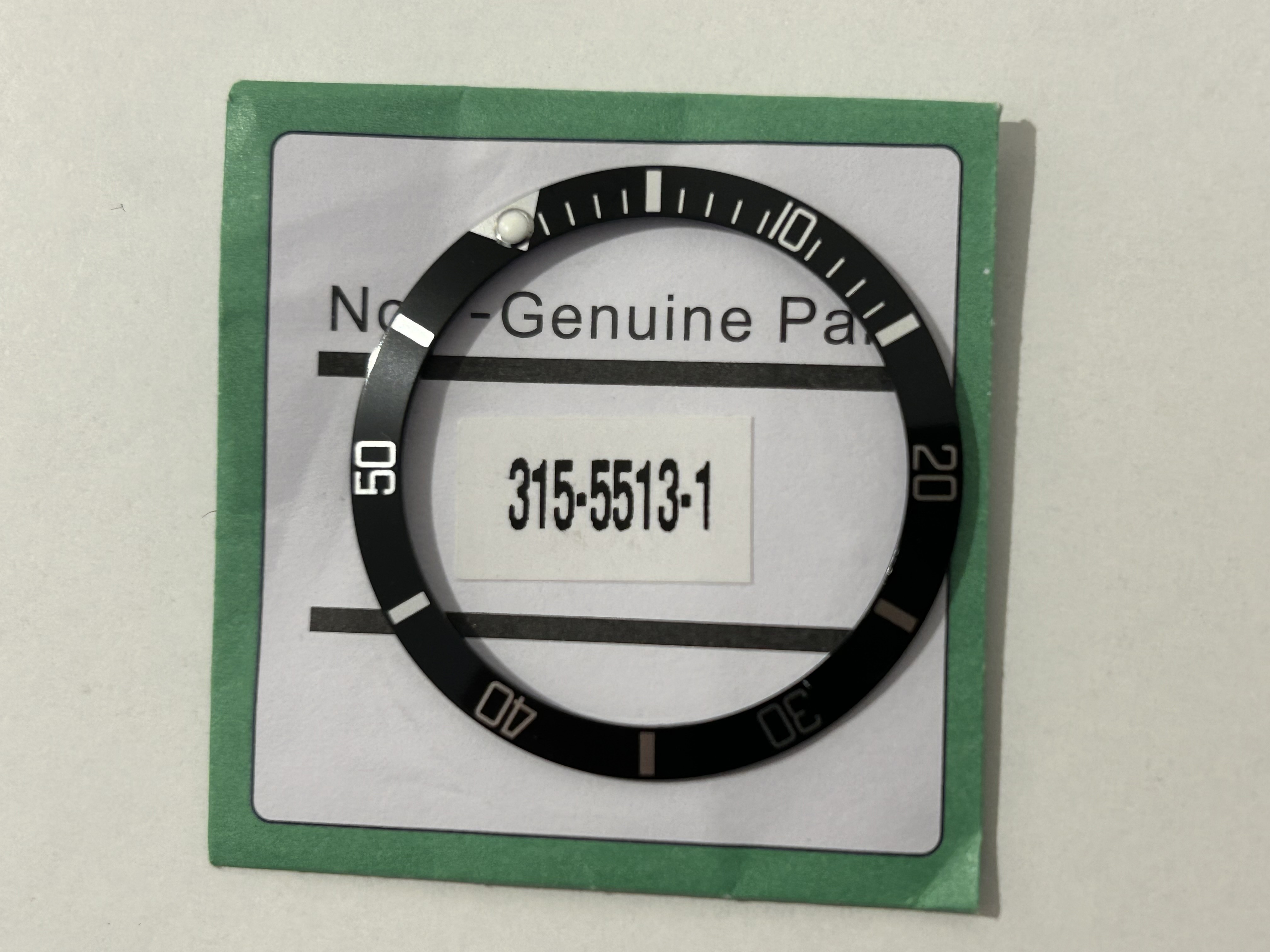

Here we go, after a long search i found some good looking and bloody cheap inserts on taobao. I gave it a try and it held up what i expected. Great insert for a few bucks.

I used the BP pearl as the one one the insert was not good. Insert is perfect sized and snapps strong in place without the need of glue.

I also used a 3D printed ring to press the clamping ring fully down, no the bezel sits also perfect without a gap.

Heres the link to the inserts if someone is interested

I used the BP pearl as the one one the insert was not good. Insert is perfect sized and snapps strong in place without the need of glue.

I also used a 3D printed ring to press the clamping ring fully down, no the bezel sits also perfect without a gap.

Heres the link to the inserts if someone is interested

- 12/3/18

- 37,543

- 80,249

- 113

I have one question though. Has rolex changed the polish or the shape of the case when they switched from lug holes to no lug holes? Your gen that you are comparing the BP with is with lug holes. Here below are some more gens with similar BP lugs and polish but all with lug holes. I have not been able to find the same polish or lugs on no lug holes models. The polished finish running all the way to the bottom of the front part of the lug. Now is this because of a change in case shape or just polish? Or am i missing something and my observation is wrong?

Here is a no holes case with wide chamfers.

You can look at a lot of samples of many watches here, I do a lot of comparisons and window shopping at this site.

Buy Pre-Owned Luxury Watches

Shop pre-owned luxury watches at SwissWatchExpo, Atlanta’s leading used watch dealer.

Pic #3 in each model at the site gives the side angle view

To answer your question, I've read that after the cases are made by CNC, Rolex has a final hand finishing step. So as much as they strive for uniformity there can still be some slight variances depending on who did the final hand polish. I remember a thread on TRF mentioning that as CNC programming and technology etc. improved, the need for the final hand polish may have been reduced or eliminated.

I've seen videos of angled lug brushing being done by machine, it not hard to imagine chamfering being a follow up machine task. So that could explain the evolution to narrower chamfers, all the way to 6 digit models which basically have none.

watcher009

Known Member

- 12/12/17

- 162

- 49

- 28

Thank you so much for the detailed explanation and the link to verfiy..very helpful. Clears my misconceptionHere is a no holes case with wide chamfers.

You can look at a lot of samples of many watches here, I do a lot of comparisons and window shopping at this site.

Buy Pre-Owned Luxury Watches

Shop pre-owned luxury watches at SwissWatchExpo, Atlanta’s leading used watch dealer.www.swisswatchexpo.com

Pic #3 in each model at the site gives the side angle view

To answer your question, I've read that after the cases are made by CNC, Rolex has a final hand finishing step. So as much as they strive for uniformity there can still be some slight variances depending on who did the final hand polish. I remember a thread on TRF mentioning that as CNC programming and technology etc. improved, the need for the final hand polish may have been reduced or eliminated.

I've seen videos of angled lug brushing being done by machine, it not hard to imagine chamfering being a follow up machine task. So that could explain the evolution to narrower chamfers, all the way to 6 digit models which basically have none.