Ah I see I misunderstood the question. Everything here is good stuff. Personally I use a lathe tool with a 3" circular sanding pad and a mini belt sander for rough shaping. For more intricate work I use a 1" circular sanding pad for the Dremel. 120 grit for rough shaping and 400-600 when I get nervous about chewing too hard on the metal. Swiss Pattern files for crownguards. Polishing I do mostly by hand with sheets of sandpaper all the way up to 10000 grit and finish on the cotton wheel. Vintage pieces I usually stop at 10000 or the black polishing compound to not get it too brightly polished.some use hand files but it's super long and painful. Plus for good results you need good files like Vallorbe

I use a dremel and the compatible workstation. If you take Dremel take the 42xx you will need the variable speed.

The workstation is a must. for lug drill and also to hold the tool for shaping

then personally I use 120 grit sanding drums for rough shaping and quickly move to 200-400 for fine shaping. Some prefer to do 400 directly. It's longer but you reduce the risk of having "shadows" due to uneven sanding.

You still need hand files for the CH insides though...

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

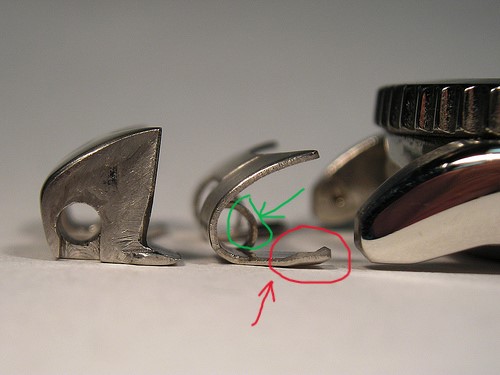

Yes , try modding them to get them to fit. how do they not fit?so do you think I can modify the 580? or better to just buy a 280?

several thingsYes , try modding them to get them to fit. how do they not fit?

1. the tangs below don't fit snug with the underside of the lugs. big gap

2. the holder holes don't seem to align with the lug holes

3. the edge that meet the case is not a perfect circular match

It looks feasible but quite a bit of work, plus there is no going back

several things

1. the tangs below don't fit snug with the underside of the lugs. big gap

2. the holder holes don't seem to align with the lug holes

3. the edge that meet the case is not a perfect circular match

It looks feasible but quite a bit of work, plus there is no going back

Where did you get the end links? Gen?

If gen, do not modify

if rep. then you can do some shaping to the shape and bend the tabs on the underside to get a tighter fit on the case.

if the holder holes dont line up with the lug holes then you may have to break the holder rings off on the end link to make it aline properly.

you may need to shape the inner curve, do last after getting the end link to fit closer as desired.

or just buy 455b end links and they will fit right .

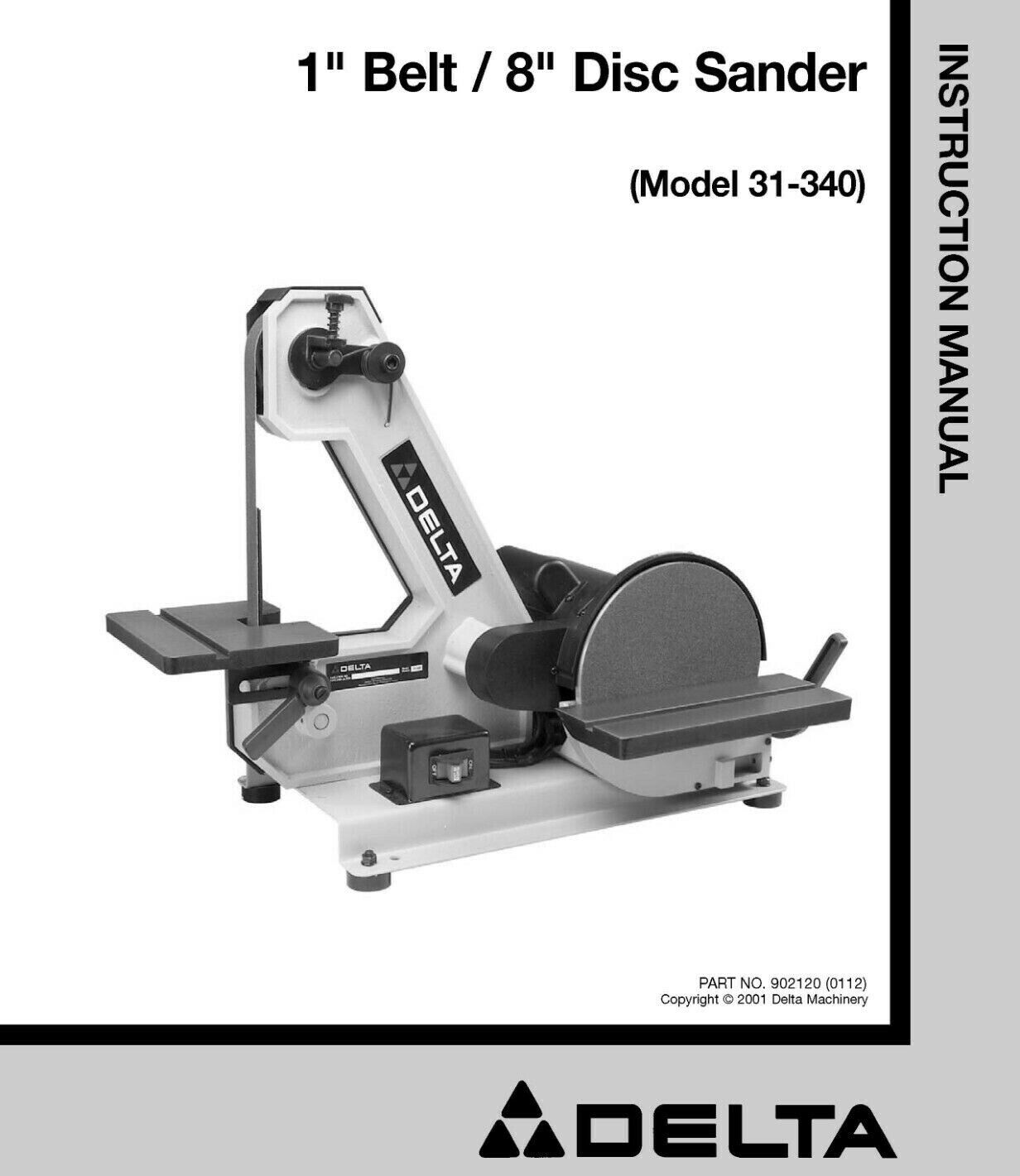

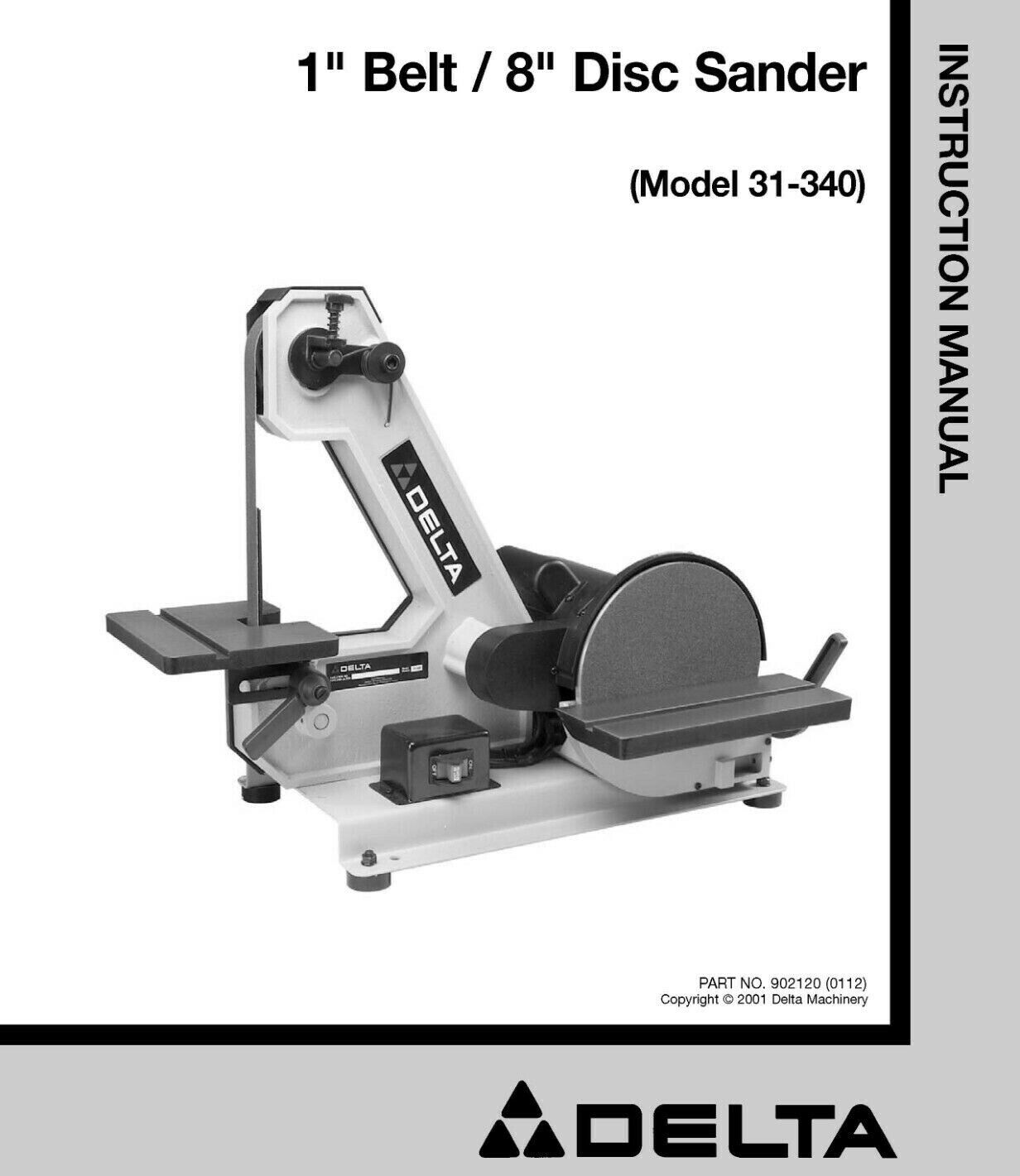

It just occurred to me that a lot of my old woodworking tools might get rescued from the workshop and pressed into service. I've been using a dremel and hand files/paper, but I have one of these and a proper drill press that could be doing so much more...Ah I see I misunderstood the question. Everything here is good stuff. Personally I use a lathe tool with a 3" circular sanding pad and a mini belt sander for rough shaping. For more intricate work I use a 1" circular sanding pad for the Dremel. 120 grit for rough shaping and 400-600 when I get nervous about chewing too hard on the metal. Swiss Pattern files for crownguards. Polishing I do mostly by hand with sheets of sandpaper all the way up to 10000 grit and finish on the cotton wheel. Vintage pieces I usually stop at 10000 or the black polishing compound to not get it too brightly polished.

I use this so rarely, I actually forgot I had it.

they come from the Raffles rivet and also a spare 580 that I also ordered from Raffles.Where did you get the end links? Gen?

If gen, do not modify

if rep. then you can do some shaping to the shape and bend the tabs on the underside to get a tighter fit on the case.

if the holder holes dont line up with the lug holes then you may have to break the holder rings off on the end link to make it aline properly.

you may need to shape the inner curve, do last after getting the end link to fit closer as desired.

or just buy 455b end links and they will fit right .

25$ so it's alright. better indeed to buy 455b buy it's going to take 3 weeks from Raffles to get here

Did you reshape the lugs or case shape in any way? If so, the end links might need some adjustment to fit correctly.several things

1. the tangs below don't fit snug with the underside of the lugs. big gap

2. the holder holes don't seem to align with the lug holes

3. the edge that meet the case is not a perfect circular match

It looks feasible but quite a bit of work, plus there is no going back

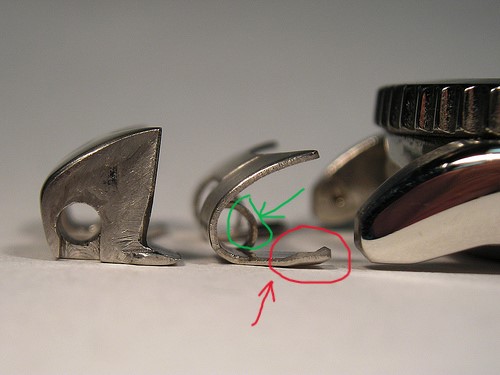

The "tangs" (I'm not sure what the proper name is, so I'll go with yours, lol) are designed to put some tension between the part against the case and the bottom of the lug, but if you altered the lug profile, they'll need to be bent "up" a bit. They're in the picture in RED

It's also possible the area in green might need to be opened up or modified slightly if a different size spring bar is used, or if the spring bar hold wasn't drilled exactly centered.

If it's any consolation, every single gen bracelet I have with folded end links develops play in this area. The trick is to bend the little tabs a small amount to properly "squeeze" the lugs, if that makes sense.

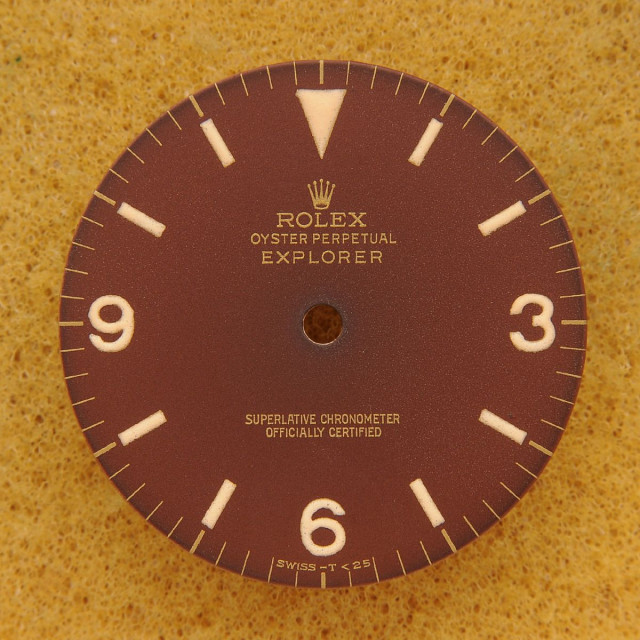

Is that a decal printed gilt dial? I'm just starting to experiment with these myself, but I'm loving the results so far.

I actually repurposed a couple of Raffles dials that I botched and managed to turn them into something more or less usable, lol. I found a store on AliX that sells blanks (literally just brass circles with no holes or dial feet) super cheap, so I've got a lifetime supply incoming in various sizes.

I haven't lumed one yet, but will try that in the next few days to see how it turns out.

That's about the same setup I use. Different brand though. With a drill press as well you're all setIt just occurred to me that a lot of my old woodworking tools might get rescued from the workshop and pressed into service. I've been using a dremel and hand files/paper, but I have one of these and a proper drill press that could be doing so much more...

I use this so rarely, I actually forgot I had it.

Explorer affectionados refer to that end link rattle with great affection as being part of the character of the watch. Part of the ageing.Did you reshape the lugs or case shape in any way? If so, the end links might need some adjustment to fit correctly.

The "tangs" (I'm not sure what the proper name is, so I'll go with yours, lol) are designed to put some tension between the part against the case and the bottom of the lug, but if you altered the lug profile, they'll need to be bent "up" a bit. They're in the picture in RED

It's also possible the area in green might need to be opened up or modified slightly if a different size spring bar is used, or if the spring bar hold wasn't drilled exactly centered.

If it's any consolation, every single gen bracelet I have with folded end links develops play in this area. The trick is to bend the little tabs a small amount to properly "squeeze" the lugs, if that makes sense.

Mine started doing it (opening up a little) after only a few weeks. Now and again I'll use two halves of a clothes peg to nip them a little tighter together.

In some odd way, I'm almost disappointed that I already have something I need for this...half the fun is in gathering the tools and materials, and and setting up the project, lol.That's about the same setup I use. Different brand though. With a drill press as well you're all set

I ordered a 3D printer on Black Friday, and just found out that for not much money, there's a laser engraver add-on that MIGHT work for serial numbers on Raffles cases, lol...

Haha I know exactly what you mean.In some odd way, I'm almost disappointed that I already have something I need for this...half the fun is in gathering the tools and materials, and and setting up the project, lol.

I ordered a 3D printer on Black Friday, and just found out that for not much money, there's a laser engraver add-on that MIGHT work for serial numbers on Raffles cases, lol...

I've probably done that 25 times on some of my vintage watches over the years. It's a shame the other links aren't as easy to tighten up on old bracelets.Explorer affectionados refer to that end link rattle with great affection as being part of the character of the watch. Part of the ageing.

Mine started doing it (opening up a little) after only a few weeks. Now and again I'll use two halves of a clothes peg to nip them a little tighter together.

When I see people bitching about .005mm SEL gaps in their QC photos, I'll take a look at one of my old Rolex or Omega bracelets and sigh...

Yeah, when we talk about "tells" on rep watches, a lot of people don't realize that perfect, tight bracelets and end links on 30, 40, even 70 year old watches is one of the more obvious ones.

The biggest tell might always be the wearer, but while some of us could conceivably afford a vintage watch as a daily driver in an Explorer or Datejust...or even a Sub, GMT, or Daytona, depending on our finances and how and when we acquired it...almost nobody that works for a living is going to be banging a museum quality vintage Rolex into his desk at the office, or using it on the arm that swings a hammer.

I started into collecting watches when a Sub or a GMT or even a Daytona wasn't terribly expensive...but they were all watches that had been worn every day and showed it (what used to yield a nice discount, and now commands a hefty premium as "patina," lol). A pristine vintage watch doesn't stay that way for long if it's worn, and if it's 50 years old and hasn't been worn, it's either too expensive to wear or a nearly criminal abuse of a rare piece of history.

It either screams "fake" or "this guy is an absolute idiot."

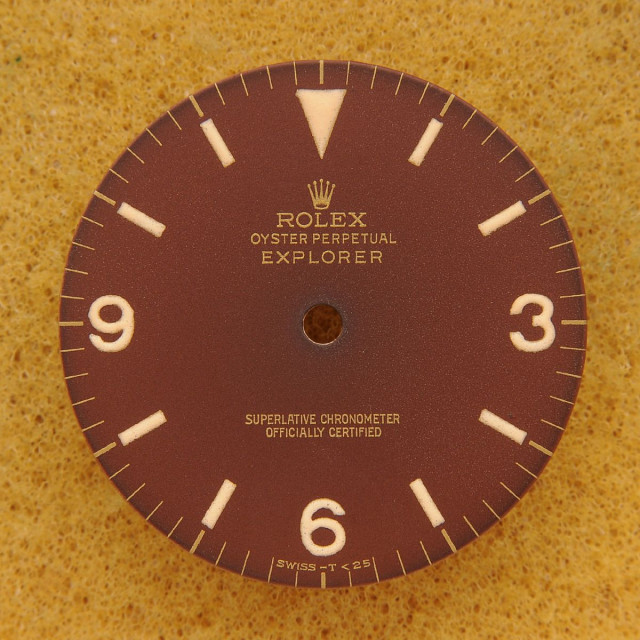

No, that is the raffles tropical dial #1 I had just given it a slight fade with the air brush and translucent black on the edges and around the center hole and then give it a texture with a light coat of matt poly spray finish. I built it for a fellow member who wanted to replicate the ruby tropical dial on a budget , so I was happy to obligeIs that a decal printed gilt dial? I'm just starting to experiment with these myself, but I'm loving the results so far.

I actually repurposed a couple of Raffles dials that I botched and managed to turn them into something more or less usable, lol. I found a store on AliX that sells blanks (literally just brass circles with no holes or dial feet) super cheap, so I've got a lifetime supply incoming in various sizes.

I haven't lumed one yet, but will try that in the next few days to see how it turns out.

the fade is quite subtle on the ruby dial , but my dial work is darker but not very noticeable but still there. exactly what he wanted.

ruby dial :

Air brush...damn, another tool I forgot I had...impulse bought one at Harbor Freight because it was on sale, lol.No, that is the raffles tropical dial #1 I had just given it a slight fade with the air brush and translucent black on the edges and around the center hole and then give it a texture with a light coat of matt poly spray finish. I built it for a fellow member who wanted to replicate the ruby tropical dial on a budget , so I was happy to oblige

the fade is quite subtle on the ruby dial , but my dial work is darker but not very noticeable but still there. exactly what he wanted.

ruby dial :