I am still in two minds about doing the nails&stone treatment.

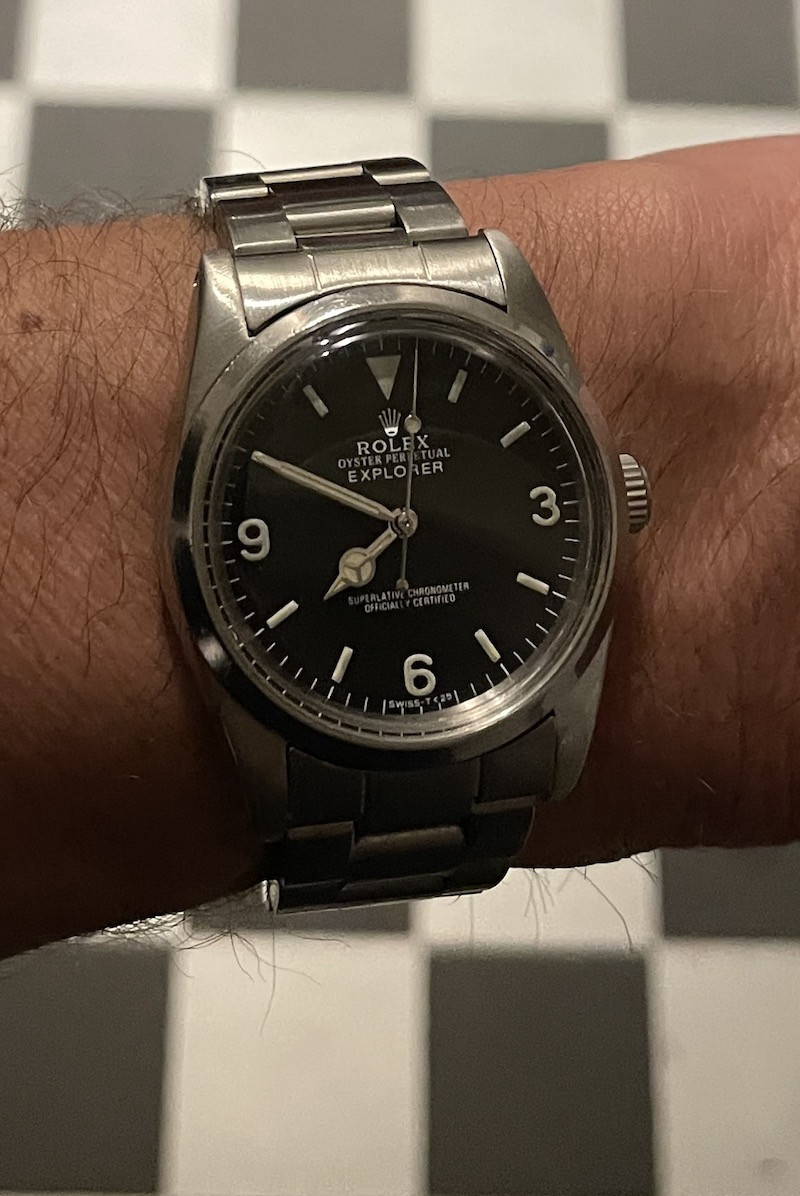

I decided to do a NOS look first so that I did not get lazy and sloppy, in order to fix the shape in my mind. I still feel there are a few symmetry issues, but mostly the lugs now "feel right" if you see what I mean

Best drillstarted the case work with the lug drilling

I snapped 3 bits

seems that the Raffles steel is stronger than the JKF

started the case work with the lug drilling

I snapped 3 bits

seems that the Raffles steel is stronger than the JKF

Best drill bits for stainless steel that I have found are made of cobalt. This has probably been covered here before but just in case...In my experience, cobalt drill bits cut light years better than any other drill bit I've used. No contest. I'd love to hear other's experiences. I've broken many drill bits in my time but I've never broken a cobalt bit drilling a watch case. With good lube, they cut like butter. My go to lubrication is BOELUBE, developed by Boeing for the aircraft industry. Pretty sure other lubes would work fine too. It's just what I prefer.started the case work with the lug drilling

I snapped 3 bits

seems that the Raffles steel is stronger than the JKF

This thread is fantastic. This and the gilt dial thread, to name a few favorites. Amazing community freely sharing processes and progress. Good old R & D.

Thank you all