Thanks to all this incredible information on this forum, I recently completed a very basic 1016 build. I realise that this thread is full of incredible, accurate reps, but I just thought I'd detail it here in case it helps another newbie at any point.

It was the first ever watch I've built, and I had absolutely no experience. I'm quite pleased with how it turned out all things considered. I've got hold of a WSO bezel, so I hope to have another go at a more accurate one once I gain a bit more experience!

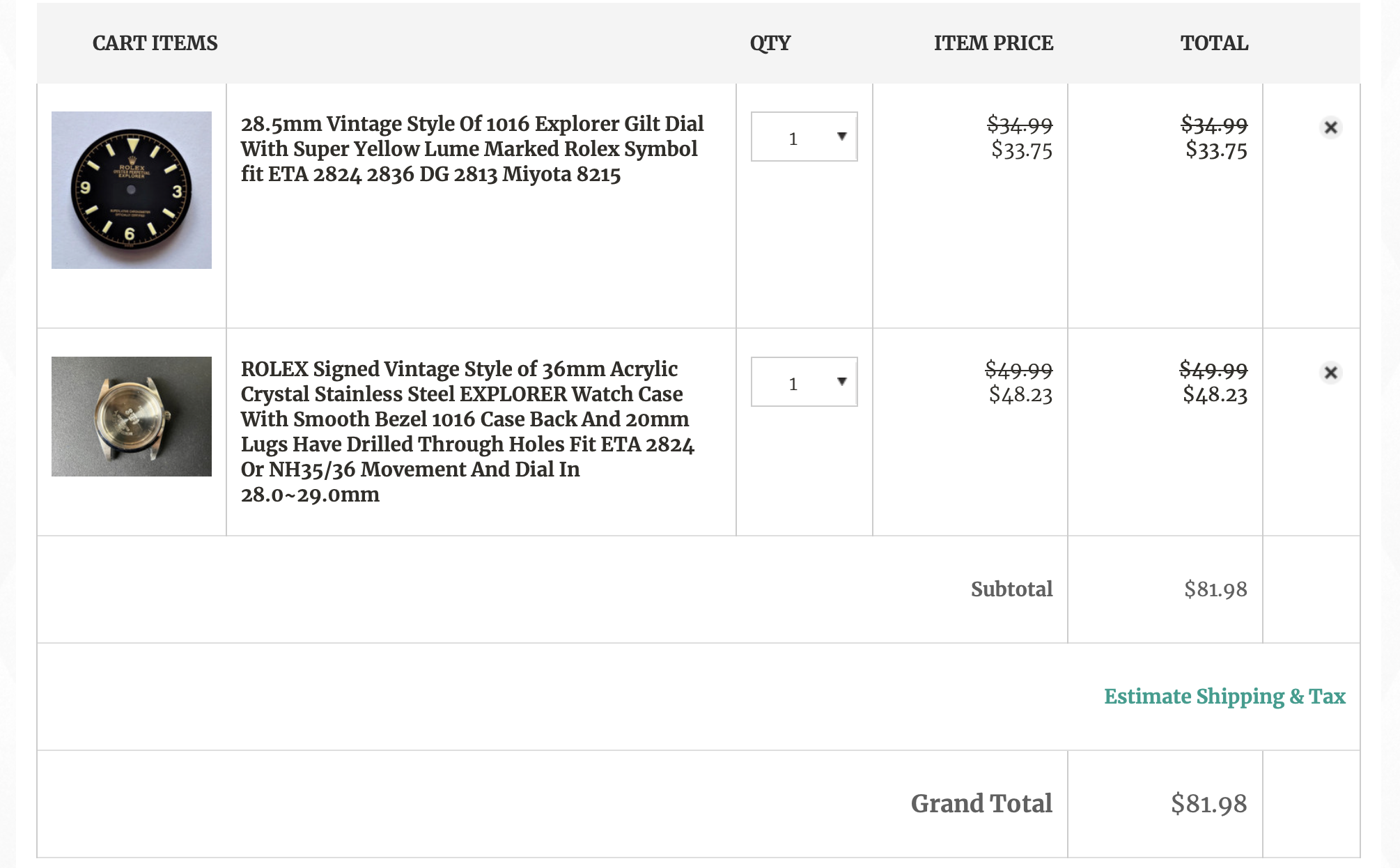

Anyway, it was just a Raffles / Cousins build with no case modification.

I bought the case and dial from Raffles. I went for the acrylic as sapphire just didn't feel right. When I do the more accurate build, I'll go for the sapphire, as I understand the crystal is easier to remove and replace with the T21 crystal.

I bought an NH38 movement and hands from Cousins. The seconds hand was a bit of a problem. Cousins seem to sell the correct style hand in both a 12.5mm x 0.2mm option and a 14mm x 0.21mm option. Luckily I ordered both.

I knew that NH movement seconds hands were tricky, but I absolutely could not get the 0.2mm one to sit on the post at all. I tried for literally hours! The 0.21mm one fit perfectly after only a handful of goes, so I ended up trimming the tip with a pair of nail scissors so it was more like 13mm long.

Cousins code for the 12.5 x 02.mm hands, which I found too tight: H58752

Cousins code for the 14 x 0.21mm hands, which I trimmed the end of: H58754

Cousins code for the hour and minute hands: H58731

I aged the hands and the lume on the dial both by baking on damp coffee grounds at 160C for 10 minutes and with Tamiya weathering paints that I got from Amazon. I wasn't quite brave enough to bake the dial, so I just attacked it with a bit of weathering paint on the lume. I removed the dial feet, filed the nubs smooth and attached the dial to the movement with a couple of dabs of silicon.

Everything fit together pretty well and I was surprised at how good a fit the NH movement was in the Raffles case just by pushing it in!

Anyway, it's not perfect. Here's the stuff I learned that I'd think about and probably do differently next time:

I'd probably go for the dial with the white lume rather than the yellow. Since the hands are white, I think it would make it easier to get them to match better after aging if they both started from being the same colour.

The dial isn't *perfectly* straight - it's tilted a couple of degrees off. I was really careful when attaching it to line everything up with the winding stem, but I think I probably should have put it in the case with the winding stem in and crown screwed down as well before leaving it to dry to check its position, but equally I'm not even convinced this would be possible to do before the silicon dried. I'm not sure whether I can rectify this, or whether it would have been better to use dial dots rather than silicon. Actually, having typed that out, I think dial dots are probably the way forward!

After reading these whole 60-odd pages of detail about 1016s, the small details that I didn't think would bother me are starting to bother me, so I'm sure it's only a matter of time until I do another build! I think I might have a go at a vintage datejust first, though, as at least I should be able to use the dial feet onto an ETA clone for that, and it's the lining up the dial that's causing me to hold back on doing another build like this one.

Anyway, as I said, I'm quite pleased for a first attempt and I certainly couldn't have done it without all the fantastic information on these pages, so thank you! And if you're on the fence about giving this a go yourself, go for it! It's nowhere near as bad as I thought it might be!

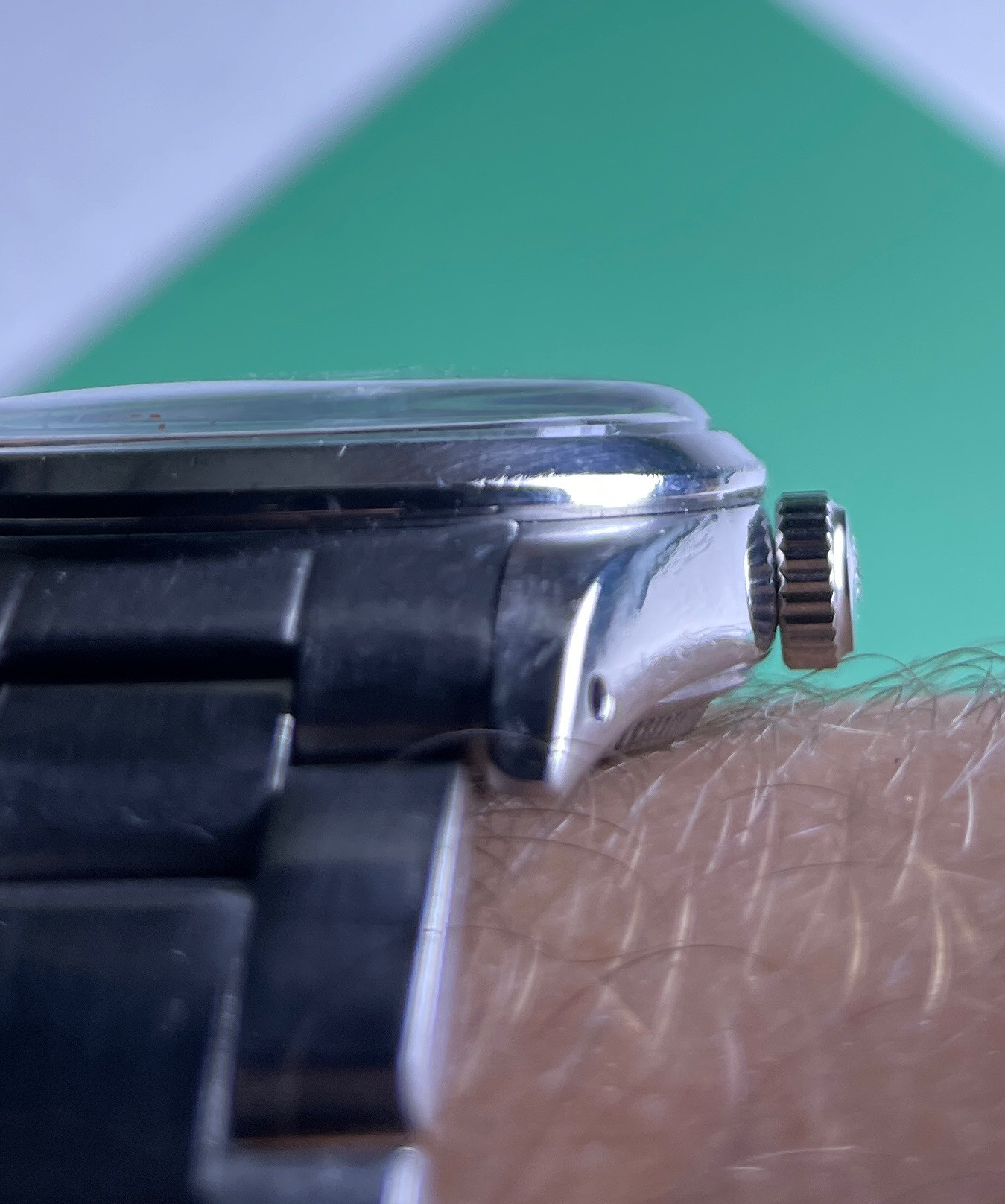

A quick picture showing my pathetic noodle-wrists, which is why vintage 36mm watches are where I'm at!