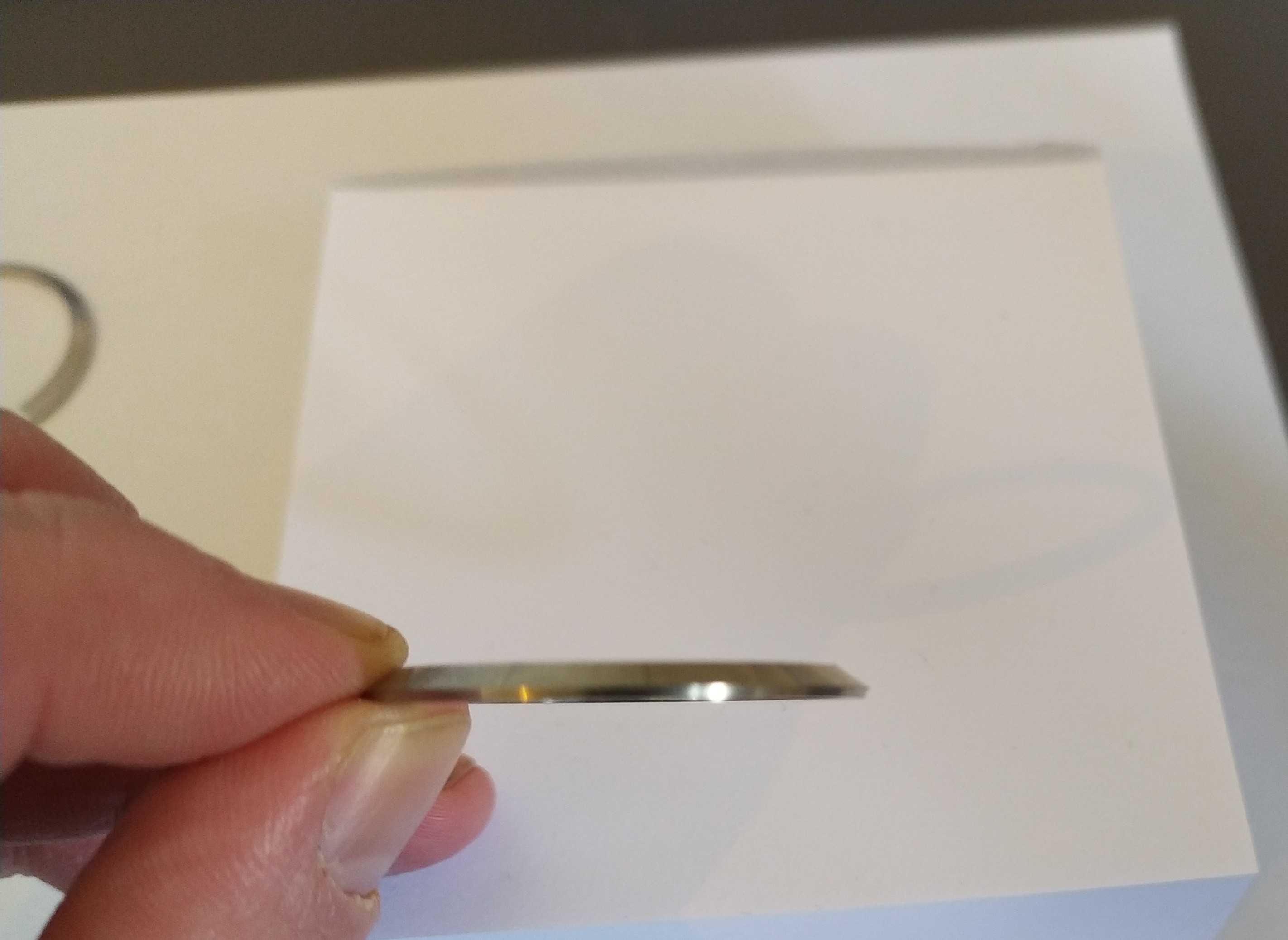

Did you have those made or are those from 1016L they look good...nice crisp edge

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

- 20/4/21

- 185

- 292

- 63

I had them made after a CAD model i made myselfDid you have those made or are those from 1016L they look good...nice crisp edge

Whoa… nice! Can you tell us about the cases, and especially the engraving!?

- 20/4/21

- 185

- 292

- 63

I probably have written about that already but i really like the curve and side profile of your case. Do you have any tips?

- 20/4/21

- 185

- 292

- 63

SureWhoa… nice! Can you tell us about the cases, and especially the engraving!?

So the bezzels are made from 316L by a firm here in germany. I made the CAD drawing myself in a painstaking process of measuring fotos online and finding compromises in sizes. The bezzles are designed to emulate the original ones but are made for t21 crystals so a few angles and measures had to be shiftet for optioma (in my opinion) esthetic outcomes. T22 will probably follow in the future.

The case is a raffles saphire case that is heavily modified. maybe a little bit too much on the flanks as i think 1016Ls are very pleasing. Drilled lugholes, drilled, retapped crowntube with gen crown. Its a lot of filing, looking, measuring and polishing.

The engravings were done by @newest dude on the forum ;-)

In preparation for my first build, I've been butchering some of the cheaper watches I have here. What I'm really struggling with is the placing of the seconds hand.

Is this just a case of practice? Any tips?

Is this just a case of practice? Any tips?

Are you holding it with tweezers or small piece of Rodico?In preparation for my first build, I've been butchering some of the cheaper watches I have here. What I'm really struggling with is the placing of the seconds hand.

Is this just a case of practice? Any tips?

I find that Rodico method works much better.

Use a pointy piece of blutac or rodico to hold the second hand with left hand, and tweezers in right hand for finesse.In preparation for my first build, I've been butchering some of the cheaper watches I have here. What I'm really struggling with is the placing of the seconds hand.

Is this just a case of practice? Any tips?

Prayer and profanity also seem to help...as do threats, begging, resignation...and blind-arse luck

Helpful, thank you. Few words have been said this evening but got there in the endUse a pointy piece of blutac or rodico to hold the second hand with left hand, and tweezers in right hand for finesse.

Prayer and profanity also seem to help...as do threats, begging, resignation...and blind-arse luck

In preparation for my first build, I've been butchering some of the cheaper watches I have here. What I'm really struggling with is the placing of the seconds hand.

Is this just a case of practice? Any tips?

Rodico for the seconds hand…any hand actually

my additional advice:

1. Get yourself some movement holders. Heavy metal ones are more stable

2. Buy a small tray that you put on the side of the silicone mat. get in the habit of never leaving a tool on the mat.

Ah this is helpful, thank you. Found myself dropping tools all over the place. It was honestly one of the most amateur endeavours I've put myself though, quite embarrassed. If someone was watching me they'd be laughing.Rodico for the seconds hand…any hand actually

my additional advice:

1. Get yourself some movement holders. Heavy metal ones are more stable

2. Buy a small tray that you put on the side of the silicone mat. get in the habit of never leaving a tool on the mat.

Perhaps it time that you lot flexed your "build" setups in one photo so I can start to tweak mine

Set up a "factory" in my basement this week, with stations for 3D printing, laser and drag engraving, cutting, grinding, sanding, and lathe-ing. It's encroaching on my gym, but the tools involved in this hobby are getting bigger and bigger, lol. It's also a lot more organized than the workbench I was using, that was overflowing with various pieces/parts of the machines we use.

And I still have a lot of my office dedicated to assembly, repair, luming, and aging.

And came up with a new project...I found a nice label maker on Amazon that prints on clear labels. I'm going to start putting little labels inside my case backs (or on the outside of my case backs, haven't decided yet) with identifying features for each watch...Factory, movement, parts, modifications, etc. It should make things easier if and when I ever decide to sell something.

I'm thinking a small label that says something like "Gen case-Raffles dial-Yuki hands-Clark crystal-gen crown" or similar. Or maybe just a code that corresponds to a spreadsheet with the details for each watch.

Let's face it, many of us are long past the "This is a Noob Submariner" stage, and falling down the "This is a gen case with a Mochacha dial and Tudor hands with a Vietnam bezel, Athaya crown and tube, Sternkreuz high dome T19 with case work by Kilowattore and a gen ETA movement serviced by me, etc."

Frankly, it would be easier, sometimes, just taking on a second job and going all gen, lol.

And I still have a lot of my office dedicated to assembly, repair, luming, and aging.

And came up with a new project...I found a nice label maker on Amazon that prints on clear labels. I'm going to start putting little labels inside my case backs (or on the outside of my case backs, haven't decided yet) with identifying features for each watch...Factory, movement, parts, modifications, etc. It should make things easier if and when I ever decide to sell something.

I'm thinking a small label that says something like "Gen case-Raffles dial-Yuki hands-Clark crystal-gen crown" or similar. Or maybe just a code that corresponds to a spreadsheet with the details for each watch.

Let's face it, many of us are long past the "This is a Noob Submariner" stage, and falling down the "This is a gen case with a Mochacha dial and Tudor hands with a Vietnam bezel, Athaya crown and tube, Sternkreuz high dome T19 with case work by Kilowattore and a gen ETA movement serviced by me, etc."

Frankly, it would be easier, sometimes, just taking on a second job and going all gen, lol.

Last edited:

We gotta see the lab once you its all set up sounds awesome!!Set up a "factory" in my basement this week, with stations for 3D printing, laser and drag engraving, cutting, grinding, sanding, and lathe-ing. It's encroaching on my gym, but the tools involved in this hobby are getting bigger and bigger, lol. It's also a lot more organized than the workbench I was using, that was overflowing with various pieces/parts of the machines we use.

And I still have a lot of my office dedicated to assembly, repair, luming, and aging.

And came up with a new project...I found a nice label maker on Amazon that prints on clear labels. I'm going to start putting little labels inside my case backs (or on the outside of my case backs, haven't decided yet) with identifying features for each watch...Factory, movement, parts, modifications, etc. It should make things easier if and when I ever decide to sell something.

I'm thinking a small label that says something like "Gen case-Raffles dial-Yuki hands-Clark crystal-gen crown" or similar. Or maybe just a code that corresponds to a spreadsheet with the details for each watch.

Let's face it, many of us are long past the "This is a Noob Submariner" stage, and falling down the "This is a gen case with a Mochacha dial and Tudor hands with a Vietnam bezel, Athaya crown and tube, Sternkreuz high dome T19 with case work by Kilowattore and a gen ETA movement serviced by me, etc."

Frankly, it would be easier, sometimes, just taking on a second job and going all gen, lol.

I've still got to clean up the cables that are running everywhere, but it's basically up and running, just a little sloppy. I'll take some photos tonight.We gotta see the lab once you its all set up sounds awesome!!

I'm thinking a small label that says something like "Gen case-Raffles dial-Yuki hands-Clark crystal-gen crown" or similar. Or maybe just a code that corresponds to a spreadsheet with the details for each watch.

I would recommend the spreadsheet approach, with a printed serial number put into each caseback, which would be similar to setting up your own archives matching the serial number of each watch to the records regarding its production. Otherwise you will go down the rabbit hole of microprinting, researching the best glues for the labels, etc. Not worth it for your purpose. Don't ask me how I know.

seriously sounds incredible! congrats man, jealously doesn't cut it!Set up a "factory" in my basement this week, with stations for 3D printing, laser and drag engraving, cutting, grinding, sanding, and lathe-ing. It's encroaching on my gym, but the tools involved in this hobby are getting bigger and bigger, lol. It's also a lot more organized than the workbench I was using, that was overflowing with various pieces/parts of the machines we use.

And I still have a lot of my office dedicated to assembly, repair, luming, and aging.

And came up with a new project...I found a nice label maker on Amazon that prints on clear labels. I'm going to start putting little labels inside my case backs (or on the outside of my case backs, haven't decided yet) with identifying features for each watch...Factory, movement, parts, modifications, etc. It should make things easier if and when I ever decide to sell something.

I'm thinking a small label that says something like "Gen case-Raffles dial-Yuki hands-Clark crystal-gen crown" or similar. Or maybe just a code that corresponds to a spreadsheet with the details for each watch.

Let's face it, many of us are long past the "This is a Noob Submariner" stage, and falling down the "This is a gen case with a Mochacha dial and Tudor hands with a Vietnam bezel, Athaya crown and tube, Sternkreuz high dome T19 with case work by Kilowattore and a gen ETA movement serviced by me, etc."

Frankly, it would be easier, sometimes, just taking on a second job and going all gen, lol.

I have a good idea of what its going to be like and I am going to feel like a kid in a candy story.I've still got to clean up the cables that are running everywhere, but it's basically up and running, just a little sloppy. I'll take some photos tonight.

but if it doesn't at least somewhat resemble Doc Browns Lab. I will be slightly disappointed , especially If I am not greeted at the door by a man with a science hat and a bath robe . no pressure tho D

Currently, I have little stickers on the backs of my builds, but they're very simple, mostly so in a year I'll be able to tell one very similar build from another. As the builds get more complicated, it's getting harder to remember what parts went into everything.I would recommend the spreadsheet approach, with a printed serial number put into each caseback, which would be similar to setting up your own archives matching the serial number of each watch to the records regarding its production. Otherwise you will go down the rabbit hole of microprinting, researching the best glues for the labels, etc. Not worth it for your purpose. Don't ask me how I know.

This is recent, Gen case and Yuki dial and hands, but already getting fuzzy on the little parts, lol.

Last edited: