-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

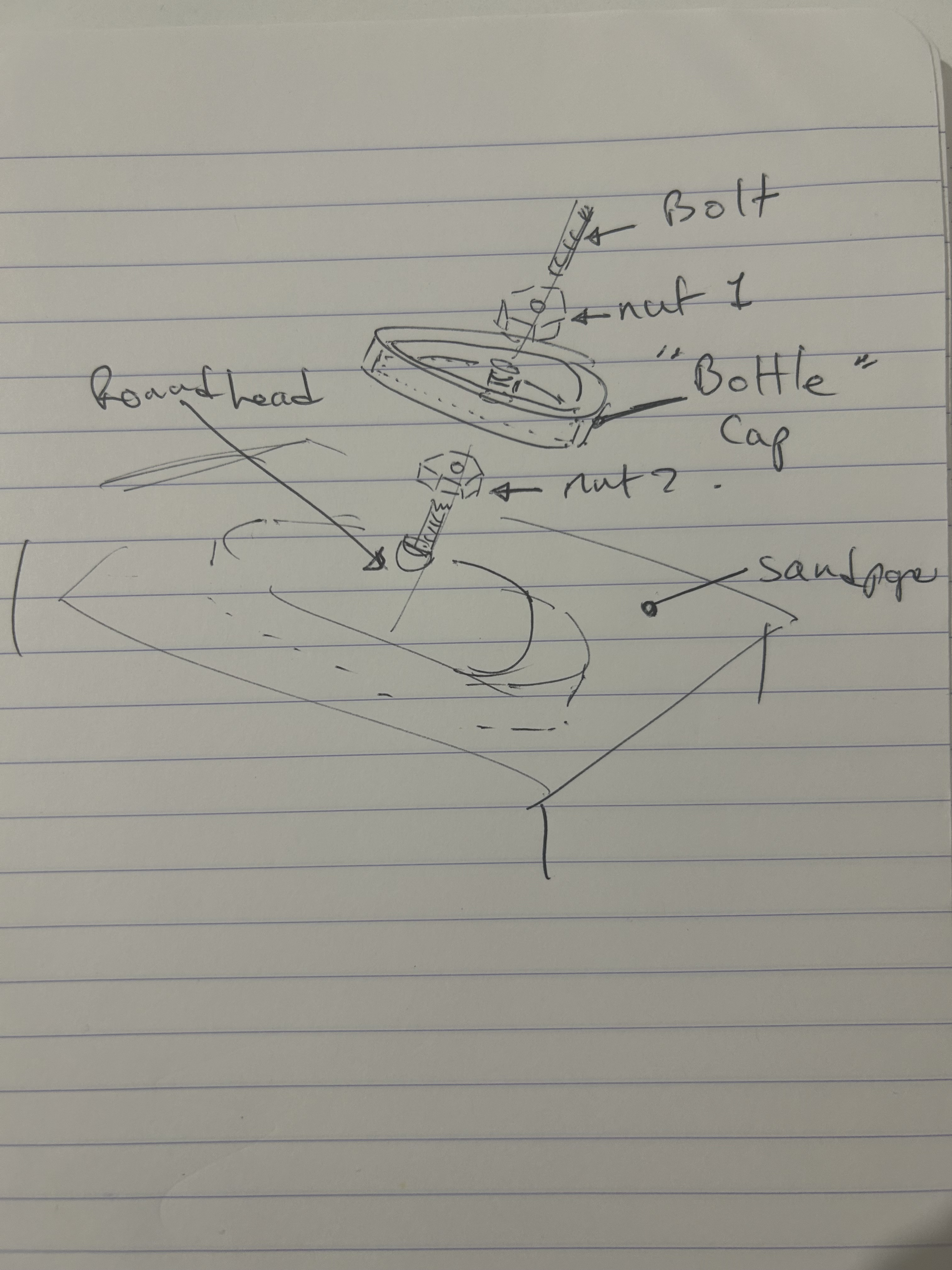

I'm actually thinking there's potential to make a rough "lathe" using a drill press, drill press vice, and that jig. You'd need a sacrificial case back that you wouldn't mind drilling a hole perfectly centered in, but then you could mount the case to the drill press and (on low speed, of course) rotate the case to do shaping.

Maybe I'll experiment with some of the $20 AliX cases before I try it on something pricey and Vietnamese, lol.

Maybe I'll experiment with some of the $20 AliX cases before I try it on something pricey and Vietnamese, lol.

I have banned myself from my watchmaking bench after "having dinner". Some of my greatest and most tragic mistakes in watchmaking have ocurred there "after dinner"i will make a drawing later after dinner

- 20/4/21

- 186

- 293

- 63

Is this just for even lugs right? or is this intended for reducing the overall height of the midcase?

If you can get precise enough, you might be able to shave the flat area around the rehaut, but with this McGuyer level technique, you will hit the sidewallIs this just for even lugs right? or is this intended for reducing the overall height of the midcase?

A lathe gives the precision to work this

On Ali they go for 500-600 for the ones that can work steel

For my "Spinning Sandpaper" Technique - this is purely to take the height of the lugs down to a reasonable 1016 height.Is this just for even lugs right? or is this intended for reducing the overall height of the midcase?

It's really designed - with the holes in the sandpaper and card and pressed down on the foam pad - BY HAND - to "neglect" the area immediately beneath the foot of the rehaut and to approx 3 mm out - and for good reason; That needs to be perfectly flat - just in case there's been some shinangins with different acrylics, altered bezels - and glue is necessary for waterproofing.

It's the next best thing to lathe work that I could dream up and I like the fact that it's under the hand and not in a chuck. I'm currently without lathe at present but one coming soon - but even if it was here - I'd opt to do this by hand I think.

google up "three jaw chuck"it would be cool to have a "chuck" that fit in the dial seat of the case that can attach to a drill to spin the case set on the paper block

It's really a hand-finishing technique.it would be cool to have a "chuck" that fit in the dial seat of the case that can attach to a drill to spin the case set on the paper block

You need that feedback through the fingers to inform where to evenly apply the pressure and it's only the work of 20 minutes or so. You're in direct contact with the work.

Spinning a drill up at 500 RPM with the case held possibly non-concentrically and you've only got to slip and you take a bite out of one corner of the lugs and things go wild.

I have a variable speed drill which allows more control of rpm and but I agree its key to have the hand contact on itIt's really a hand-finishing technique.

You need that feedback through the fingers to inform where to evenly apply the pressure and it's only the work of 20 minutes or so. You're in direct contact with the work.

Spinning a drill up at 500 RPM with the case held possibly non-concentrically and you've only got to slip and you take a bite out of one corner of the lugs and things go wild.

I was thinking of mounting it in something like this or a drill press to insure its level to the surface and then we should get an even pattern around the thickest part of the case set. and then fine tune the outter edges. how much are we taking off the top of the lugs anyway??

that would work well to hold the mid case solid. this can then also be used to modify bezels too like I did on my 5513 to shape the underside of the bezel , or reduce the dia - off topic lolgoogle up "three jaw chuck"

automatico

Known Member

- 5/10/11

- 123

- 253

- 63

"Sadly I do not have 1.3mm drilled lugs - just the stock Raffles holes."

You can use oem spec spring bars made for Rlx Datejust 1600 and 16000 watches when using a case that has regular size lug holes bored all the way through the lugs.

The 1600/16000 spring bar tips are fairly long compared to generic type spring bars and they will pass through the lugs farther.

They look a little bit better imho.

On 34mm 'Explorers' you can use Rlx 1500, 6694 etc. oem spec spring bars.

The 34mm Explorers, (Air King base with 19mm lug spacing) had smaller diameter spring bars same as 34mm dress watches.

You can use oem spec spring bars made for Rlx Datejust 1600 and 16000 watches when using a case that has regular size lug holes bored all the way through the lugs.

The 1600/16000 spring bar tips are fairly long compared to generic type spring bars and they will pass through the lugs farther.

They look a little bit better imho.

On 34mm 'Explorers' you can use Rlx 1500, 6694 etc. oem spec spring bars.

The 34mm Explorers, (Air King base with 19mm lug spacing) had smaller diameter spring bars same as 34mm dress watches.

Thanks! Must be so much gold hiding in the 100+ pages in this thread.DIALS VECTOR - Google Drive

drive.google.com

MODEL NUMBERS VECTOR - Google Drive

drive.google.com

SERIAL NUMBERS VECTOR - Google Drive

drive.google.com

Our resident Romulan/ Picard Hybrid made an Index to celebrate our 100th page a little while ago;Thanks! Must be so much gold hiding in the 100+ pages in this thread.

Check it out.

Are we truly ready for a "Post your 1016 with your Avatar" thread?