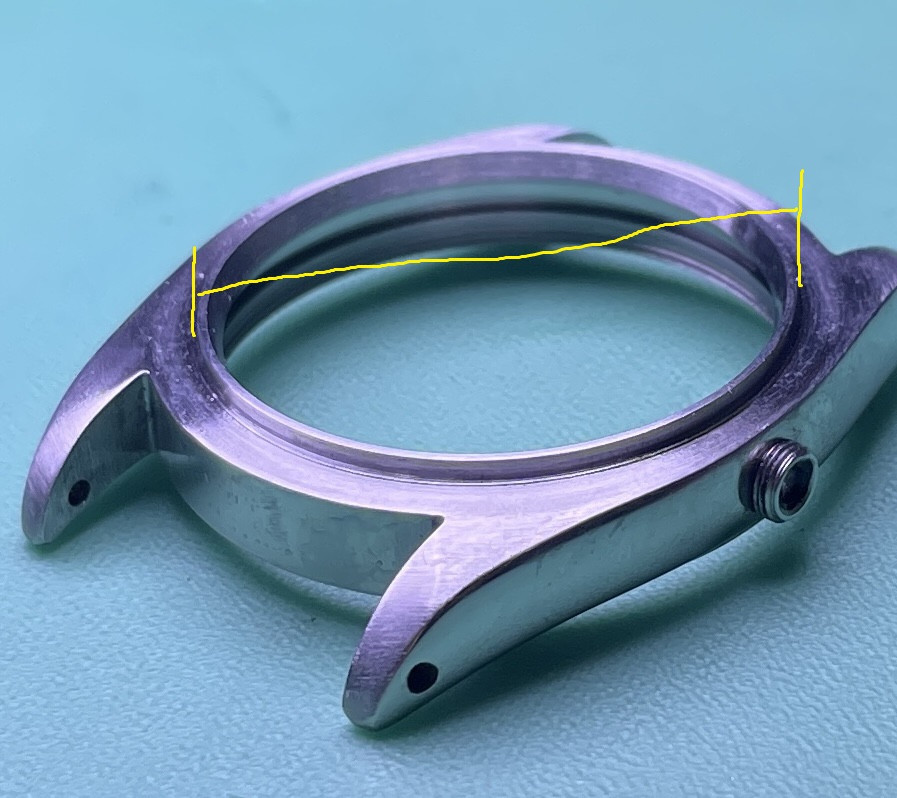

On the subject of reducing the height of the lugs of the Raffles case to better match the 1016 one of the safest ways is to use the spining sandpaper method.

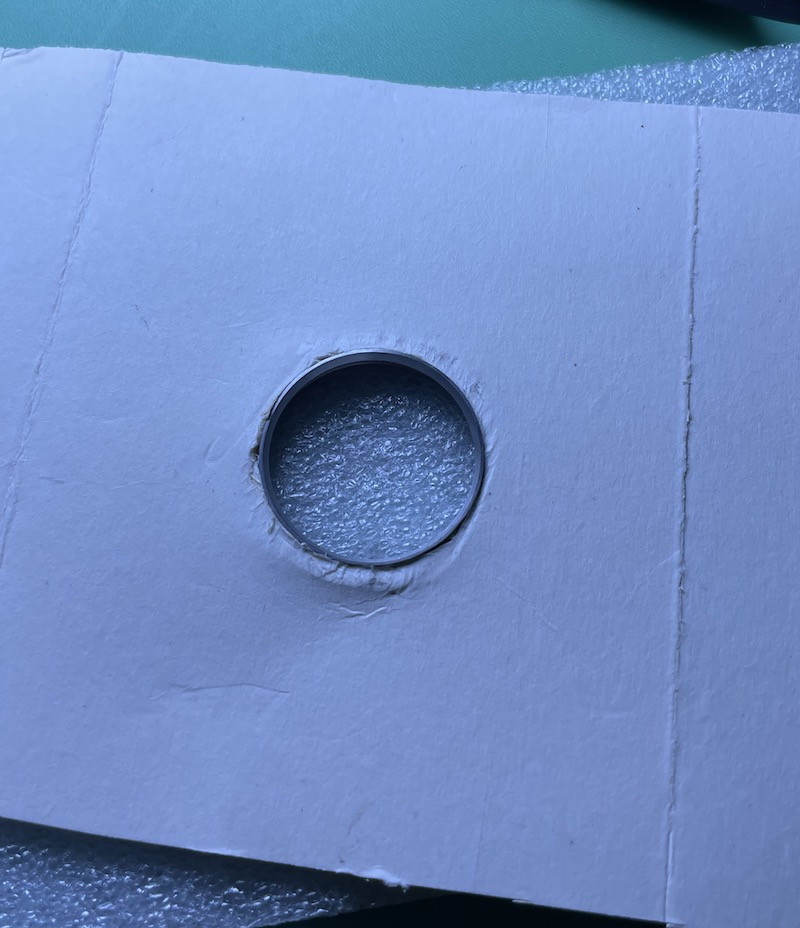

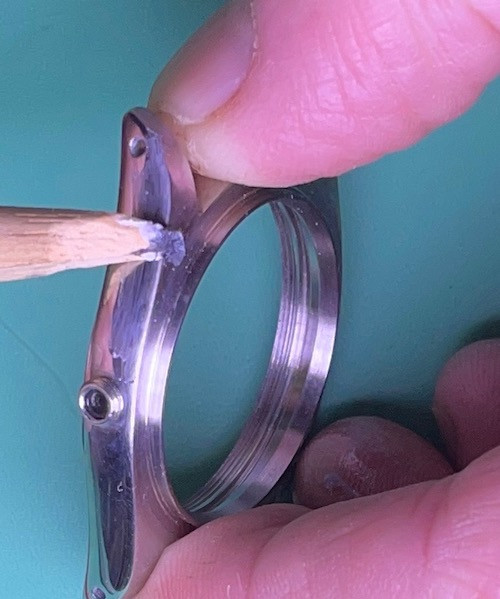

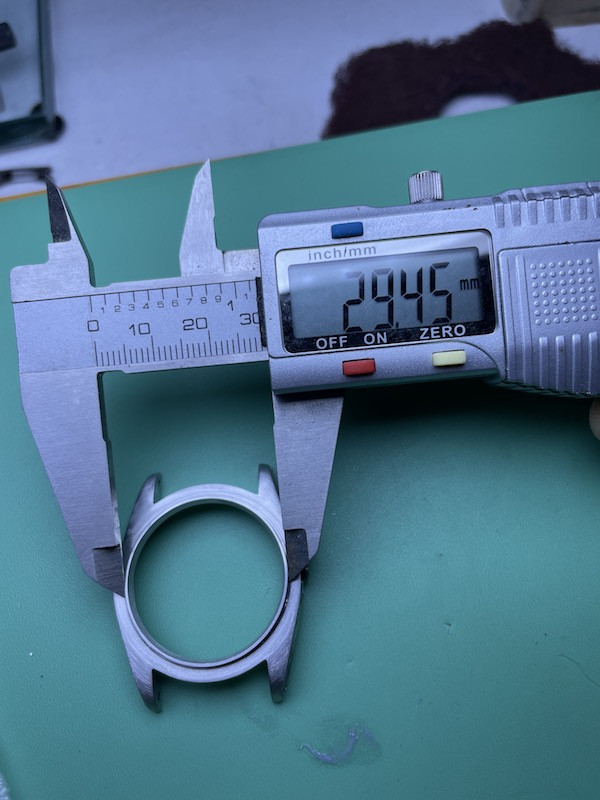

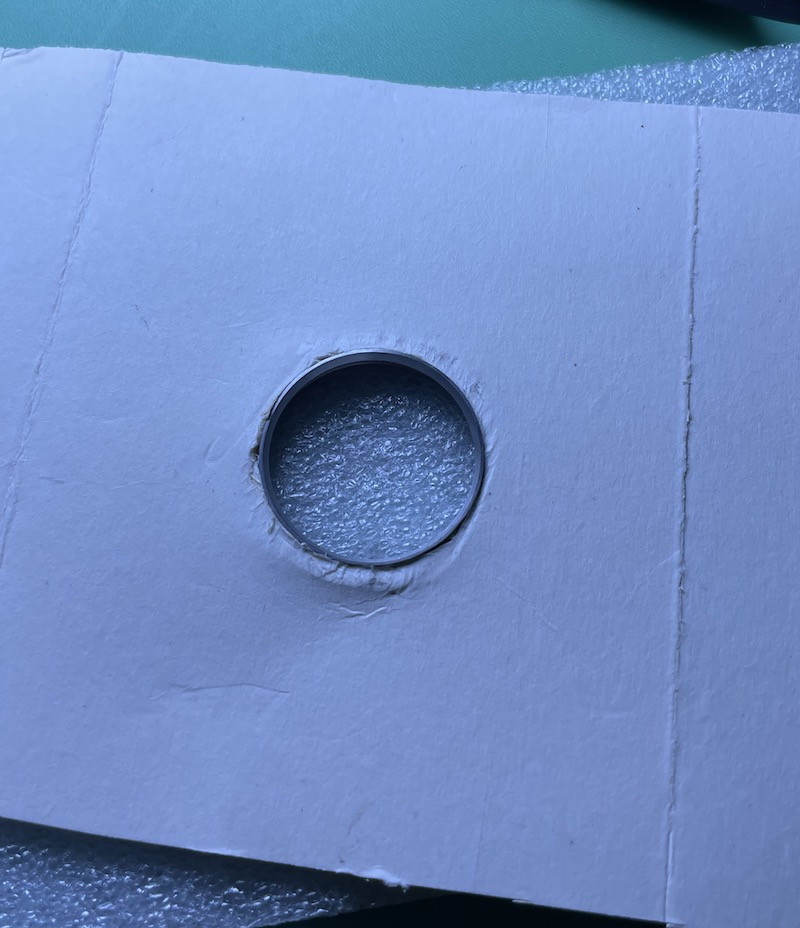

Cut an aperture in some card and some 240 Grit wet and dry paper and place them togther. Ensure the holes in both are just larger than the rehaut but not too large.

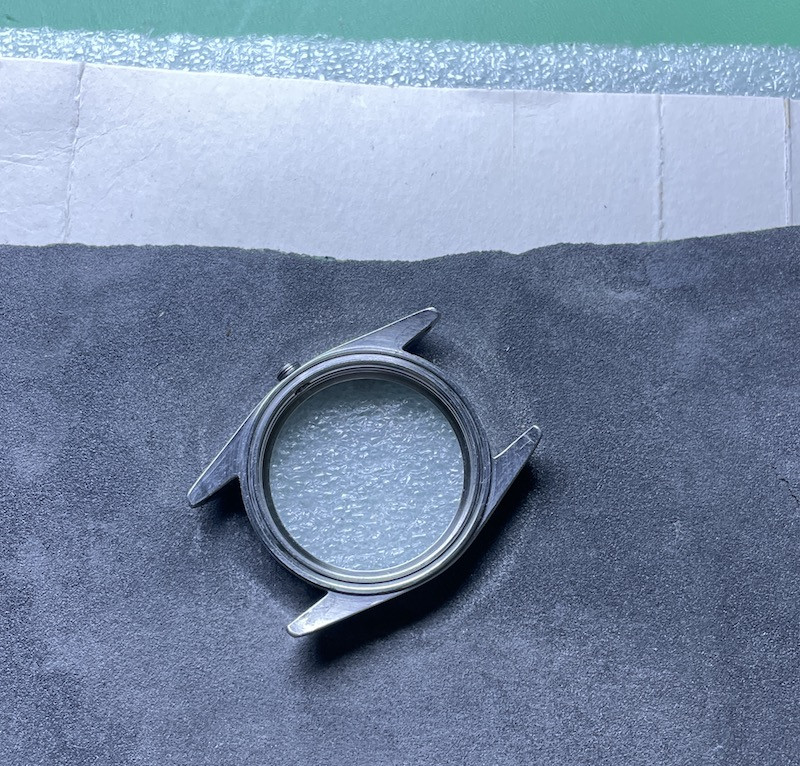

Place the case - after cleaning it thouroughly to avoid clogging - face down on the sandpaper and ensure the holes are correct size and the case fits snugly in to them. There should be minimum sideshake (sorry!) Basically make sure it's tight in there and isn't going to jump out mid-spin and damage the top of the rehaut.

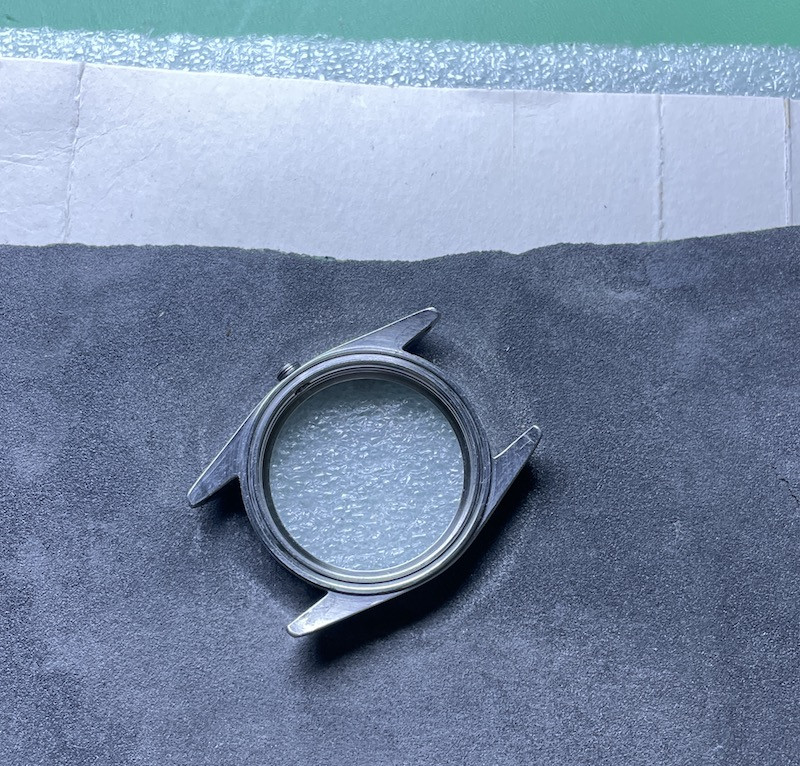

Stand standing up and over at the bench and apply finger and thumb downward pressure on the case trying to keep the case spiining as levelly as possible.

Give it a few spins and inspect the work. Keep going until you start to see what you want.

In the first spin I use some foam - approx 5mm thick to allow the sandpaper to "give" a little and mould around the fall off of the lugs ensuring uniform sanding of the whole lug.

When I'm satisfied with meat-removal I'll then replace that thicker foam with a piece thinner - about 2 mm - this is what finishes the top of the lugs nice and flat as if lathed - or that's the idea.