Thank you. I am also pleased with how it came out. probably the most accurate build to date , so far.Beautiful build!

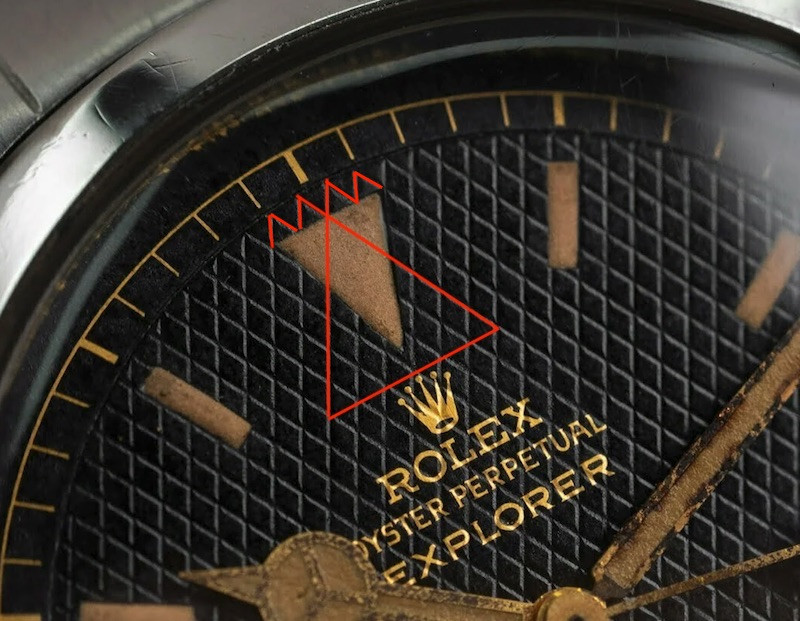

I was actually thinking about the waffle dials and how to replicate them. I hit some brass with a hammer (not watch related) a while back and noticed that the "negative relief" of the face of the hammer was impressed on the watch. Every dent, piece of grit, and imperfection was stamped onto the brass. It's how they used to strike coins back in the day (probably still do, no idea).

Now, trying to avoid another rabbit hole, I'm thinking something like a checkered surface, like they do for gun grips, on the face of a hammer would allow a perfect replication of the gen waffle dial.

Finish the face of a cheap claw hammer from the hardware store with a negative waffle finish (possibly just checker it, or have a gunsmith checker it), 3D print a jig to hold a dial in the proper position, and start stamping out dials by hitting the anvil part of a bench vice. The steel face would be much harder than the brass, so it should last quite a while before the pattern started to get sloppy. I'd assume several hundred dials, at least.

Remembering all the work Manodeoro mentioned perfecting his waffle dials (which for some reason I seem to remember involved multiple layers of waterslide decals, but maybe I'm remembering wrong), this seems like a much simpler (and likely more authentic) process.

Even a series of steel "circles" about 26mm in diameter, with checkering and a 2mm stem to hold the dial should work.

Alternatively, laser engraving the dial blank, or drag engraving it might work just as well. Some micro sol to "melt" the decal into the grooves (or even paint it and laser etch the gilt away) and it should look pretty good. I'm thinking if the dial blank is 285.mm, the area that's "waffled" is inside a 26mm circle, give or take.

The best thing about this hobby is it almost guarantees I'll live to be 100, just because I'm stubborn as hell and I keep getting ideas for new things to try...

I think your on to something. using a press of some sort to create the pattern would be ideal . however it may be difficult to apply the film free decal to the surface with the texture. however I support you going down this rabbit hole. that would be amazing , especially if you went all out and made a template that also presses the markers into the dial plate allowing for that recessed look and easy of lume application.

Yes Mandoreo uses multiple layers of film free decals to create the effect I assume he adds it and then presses the pattern into the ink while its setting for the pattern

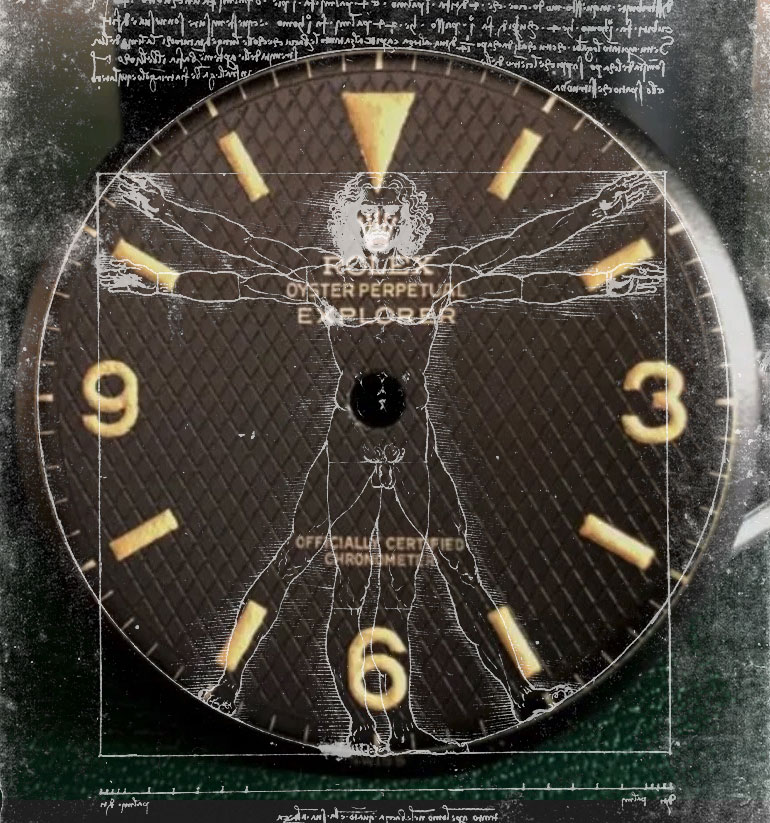

THis MQ dial was the best on offer from 2017-2018 and cost a small fortune $$$ and it was not true gilt dial but the paint used does look pretty good . It was the best and only option at the time. I would say that the Raffles dial is at par with this dial , if anything it edges it out because a year into owing the mq dial the lume started to fall off , I have never had that happen to a raffles dial . washing it. chemicals, heat in the oven . that lume is solid. and for the price being less then a 10th of the price its worth it