Stand By for 1800 tonight and your chance to join the coveted "Sunday Night Kitchen Shot Club!"Actually, I cook a lot and I find the rotating bezel very practical for tracking cooking times.

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

That’s bloody lovely that 1016 you’ve done there Karbon.

thank you.That’s bloody lovely that 1016 you’ve done there Karbon.

For my second build ever, I am quite pleased indeed.

This thread is magic.

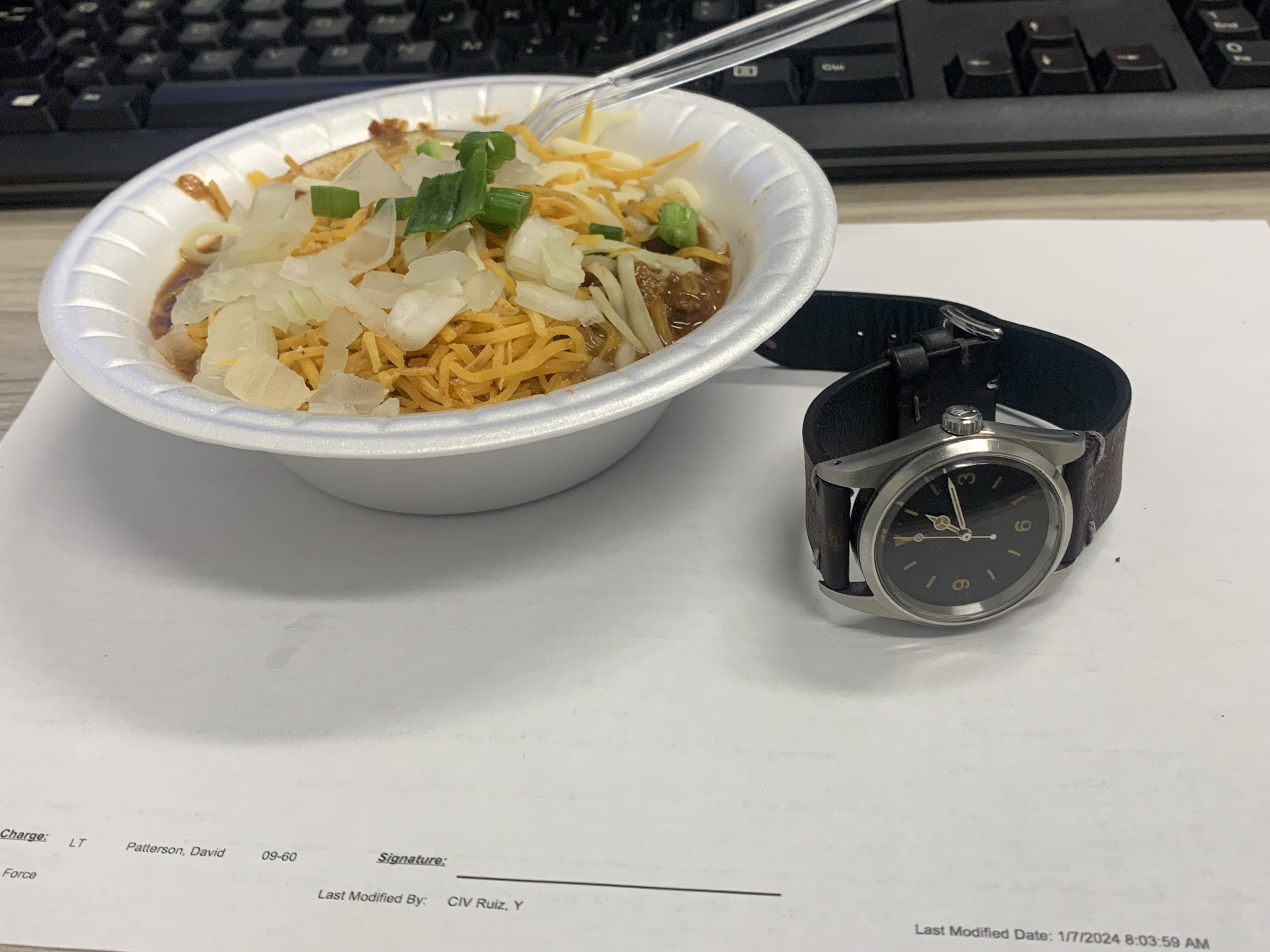

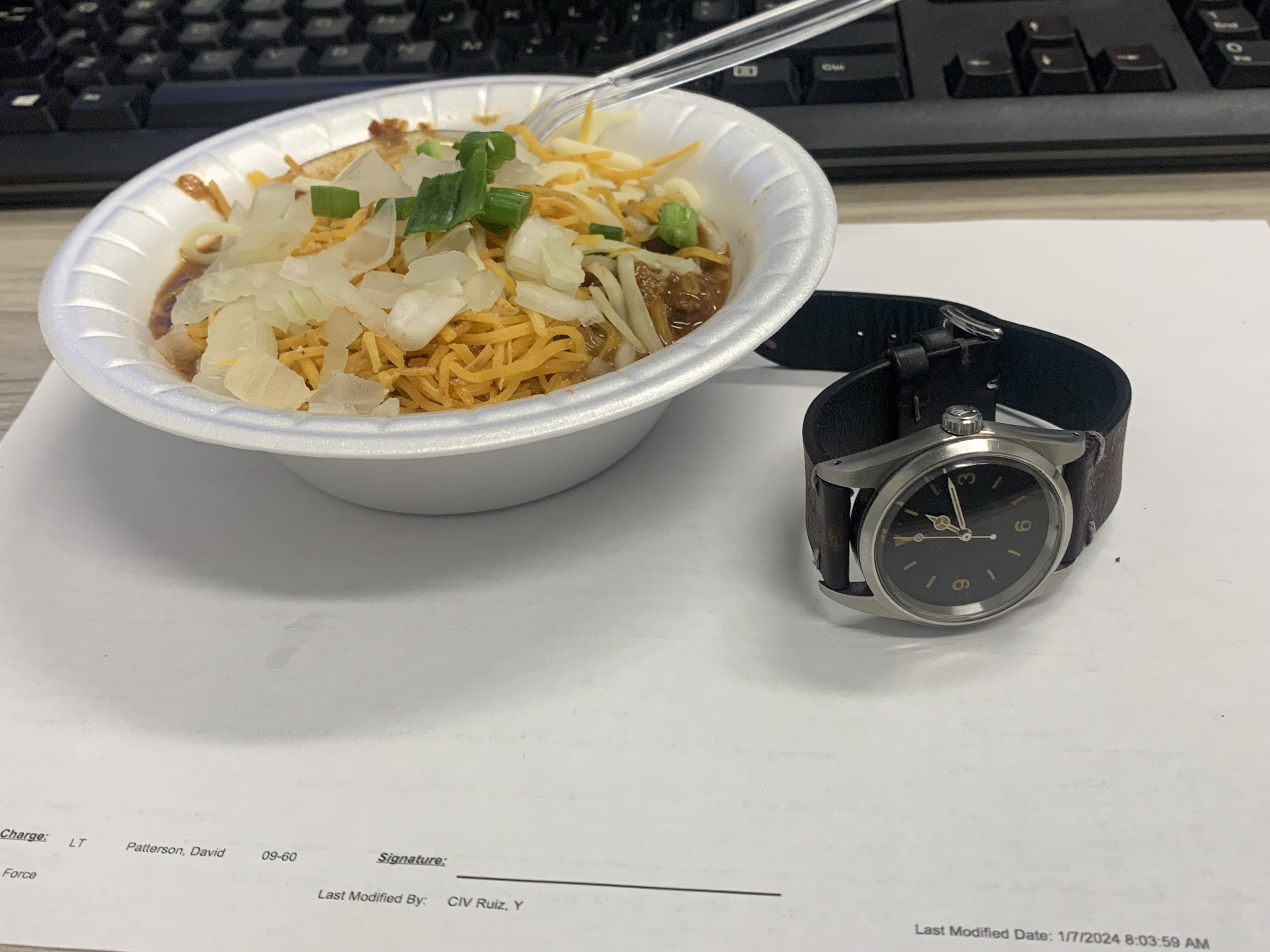

Eating lunch at my desk, this is the best I can do.

(Coworker brought in chili, which is perfect on a cold, Michigan winter day)

My first build, actually. A simple 1016 that I “over aged” a bit unintentionally, but has now become my daily driver. Plan to revisit the dial eventually and undo some of the patina, but can’t bring myself to open it up just yet.

(Coworker brought in chili, which is perfect on a cold, Michigan winter day)

My first build, actually. A simple 1016 that I “over aged” a bit unintentionally, but has now become my daily driver. Plan to revisit the dial eventually and undo some of the patina, but can’t bring myself to open it up just yet.

Well done DPD - Loving the classic leather look - love that understated look, great for a Sunday - anyway, you're in.

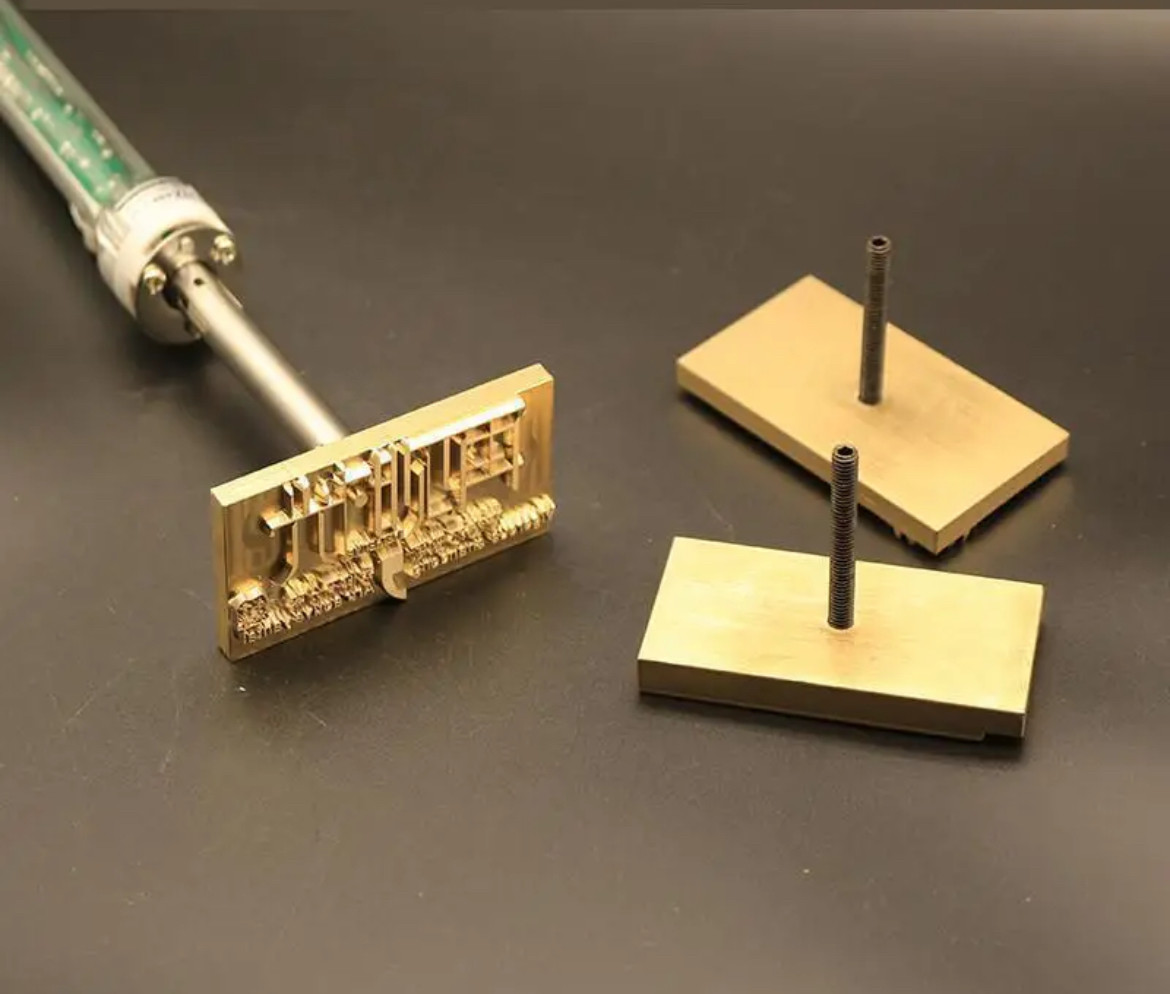

the only thing preventing me from moving to leather is the lack of engravings

this is driving me bonkers

I am ordering the PCB photosensitive film this week

this is driving me bonkers

I am ordering the PCB photosensitive film this week

Yep, same here. Got a nice strap waiting but the lack of engravings stops me.the only thing preventing me from moving to leather is the lack of engravings

this is driving me bonkers

I am ordering the PCB photosensitive film this week

I haven't updated the progress on the lug engraving because I hate clogging up this thread, but I don't have enough progress to start a stand alone thread.the only thing preventing me from moving to leather is the lack of engravings

this is driving me bonkers

I am ordering the PCB photosensitive film this week

That said, a quick update...I got the precision cutter on Friday. It's a Silhouette Cameo 4 if anyone is curious or knows these machines. I got it because it was on sale, not really knowing if it's even good or bad for the purposes here.

Early results are VERY positive, although I won't know for sure until I spend some time tweaking the settings, and I'm waiting on the .svg files (clean, straight lines) before I start. I know almost nothing about these machines, so it's a starting from scratch proposition, but just a quick test print using .jpg (lots of little pixels) files came out pretty well, both for the lug engraving stencils and the dial luming stencils.

It might have some potential for actually creating dials, in the same manner as waterslide decals to, and opens up some possibilites for different colors and finishes than basic black on gilt, but there's a long way to go with experimenting on that.

I should have some time tonight, though, to revisit the thermal paper and see if acetone transfers better than heat. If it does, I'll post results tonight. The thermal/photo paper looks to have the most potential, but I haven't had much luck transferring the toner to the watch case so far using heat. It's hard to apply the heat between the lugs evenly and consistently and the transfer is usually not cleanly done. The watch case itself is a small type of "heat sink," so it's hard to keep the heat focused on the small area between the lugs and not having it transfer to the whole case, and it's hard to keep the heat consistent at a precise temperature required for the thermal transfer.

If it works, it will be the easiest and cheapest way to do lug engraving, something that any DIYer should be able to do, and for a very trivial investment (literally, less than $20 and you can engrave cases for the rest of your life, lol), although the results might fall somewhere between laser engraving the case directly and drag engraving it (which is the correct, Rolex Factory way).

To my eye, the saltwater etching looks pretty much the same as a vintage Rolex case...a little less than perfect, but that's just how they look IRL. Drag engraving looks almost TOO perfect for a vintage case, and would probably benefit from a little patina itself.

I do, but they did lose a little bit of detail in the conversion. Still, they're pretty close to the original, and for something as small as the area between the lugs, there's not a ton of minute detail required. Let me see if I can share the documents. Google docs doesn't let me upload .svg files for some reason.@dpd3672 do you have the serials sheets on vector yet?

also, how do you make sure it prints to scale?

Microsoft OneDrive

The contents are:

1) Model Numbers in .jpg form...pretty much every model I could think of that hobbyists of our level might decide to build And a blank one for customization

2) Model Numbers reversed image, for prints that have to be done backwards (stickers would use the first, thermal transfers would use reversed images)

3) Model Numbers in svg format...cleaner lines, but some of the numbers look weird.

4) Serial Numbers in jpg form...I picked a serial number from every 5 years so we can date our builds plus 1953 (a big year for Rolex) 1968 (my birth year) and 1987 (HS graduation, lol). Plus a blank one for customization

5) Serial Numbers reversed

6) Serial Numbers in svg format.

7) a Microsoft Word document that's printable with pretty much everything above. One print should give you enough to practice with for quite a while. Also, the fonts I used that looked as close to gen as I could find, with the specific characters after the font name that were particularly close to gen. So the fonts are first, you really don't need to print those, they're just reference. After the font name, I added the numbers in black that looked particularly good withint that font, and in red when they were the best for that specific character.

For printing to scale...the Word document pretty much comes out correct, if printed on standard paper. You can also tweak the sizes in the Word settings (I just make the little black labels 20mm wide...there's some wiggle room) or in the printer settings. I have yet to actually measure the font on an actual watch case...an obvious step I seem to keep forgetting to do while I focus on the process, lol.

So you can print the entire document (minus page 1, which is just for reference) and have a bunch on hand, or just open up the file you want to print in Word, copy and paste the item you want to print, adjust the size to ~20mm wide, copy again and paste a BUNCH of times (might as well fill up the paper, you'll make mistakes and have ones come out bad). Then print. It works best on a printer capable of 1200 dpi, most home printers don't do this, but most people's work have higher end printers, or public libraries, or the local Kinkos or print center.

It will make more sense once you actually do it once. Cut out the little stencils with scissors and attach them to the case however you can (this is where the process needs the most work). Etch with electricity in saltwater and admire the results!

Please let me know if you stumble onto any improvements or tricks to make this work. Once we dial in the process, I'll do a big "how to" write up so that anyone can do this.

Last edited:

I tried a soldering iron, but don't have a tip that's wide enough to do something like that. But it's an idea worth exploring (I kill me, lol).

The issue I have is that the case itself distributes the heat, so it pulls the heat away from the lug area, and ambient air is working against the heat to cool it. It might be possible in an oven, but not sure how to apply pressure to the paper to keep it in contact with the case. A metal, lug shaped piece clamped on (like a modified solid end link) would work, but haven't really experimented with that yet, and most SELs I've seen aren't really solid, there's a gap in them.

Stop!Wait, are we going to start branding "1016" on ourselves now?

Asking for a friend.

I'm already looking at tattoo guns!

automatico

Known Member

- 5/10/11

- 104

- 212

- 43

"the only thing preventing me from moving to leather is the lack of engravings"

Yep, me too, on more than one project watch.

I bought a couple sets of 20mm Riyi end pieces on eBay to use with straps and it cured the no numbers problem (for me). The catch is stuffing the strap with the spring bars into the lug holes with the end pieces in place.

The method?

I use a sharpened wooden 'popsicle stick' to shove the strap (with the spring bars in the strap) under the Riyi 'hoods'. The wooden stick will not scratch anything, and you can shove the strap over to get the spring bars and strap between the lugs with the sharpened end.

It has worked fine so far. Might also need to narrow the stick down a little bit.

Yep, me too, on more than one project watch.

I bought a couple sets of 20mm Riyi end pieces on eBay to use with straps and it cured the no numbers problem (for me). The catch is stuffing the strap with the spring bars into the lug holes with the end pieces in place.

The method?

I use a sharpened wooden 'popsicle stick' to shove the strap (with the spring bars in the strap) under the Riyi 'hoods'. The wooden stick will not scratch anything, and you can shove the strap over to get the spring bars and strap between the lugs with the sharpened end.

It has worked fine so far. Might also need to narrow the stick down a little bit.