how thick is tolerable for the saltwater etching to work?

I don't think the thickness really matters, as long as it's not so thick to be unusable. The important thing is that the "mask" needs to resist electricity, so the charge follows the path of least resistance to the exposed metal. I believe even a Sharpie or similar ink works to some extent.

Vinyl is a little thicker (but still pretty thin), but I'm mostly focused on that because of the other qualities it has...it's cheap, flexible to cover an irregular surface, and if applied and removed carefully, reusable until it falls apart. A standard letter size piece of vinyl sticker paper could have enough stencils for a lifetime of building replicas.

For this project, I was looking for something that anyone could replicate with simple tools and equipment ( I'd like something that can be peeled off and reused, at least a few times).

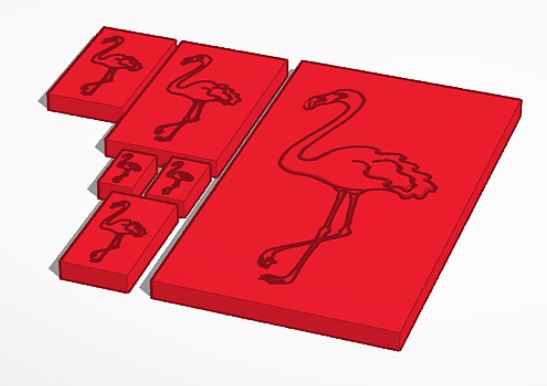

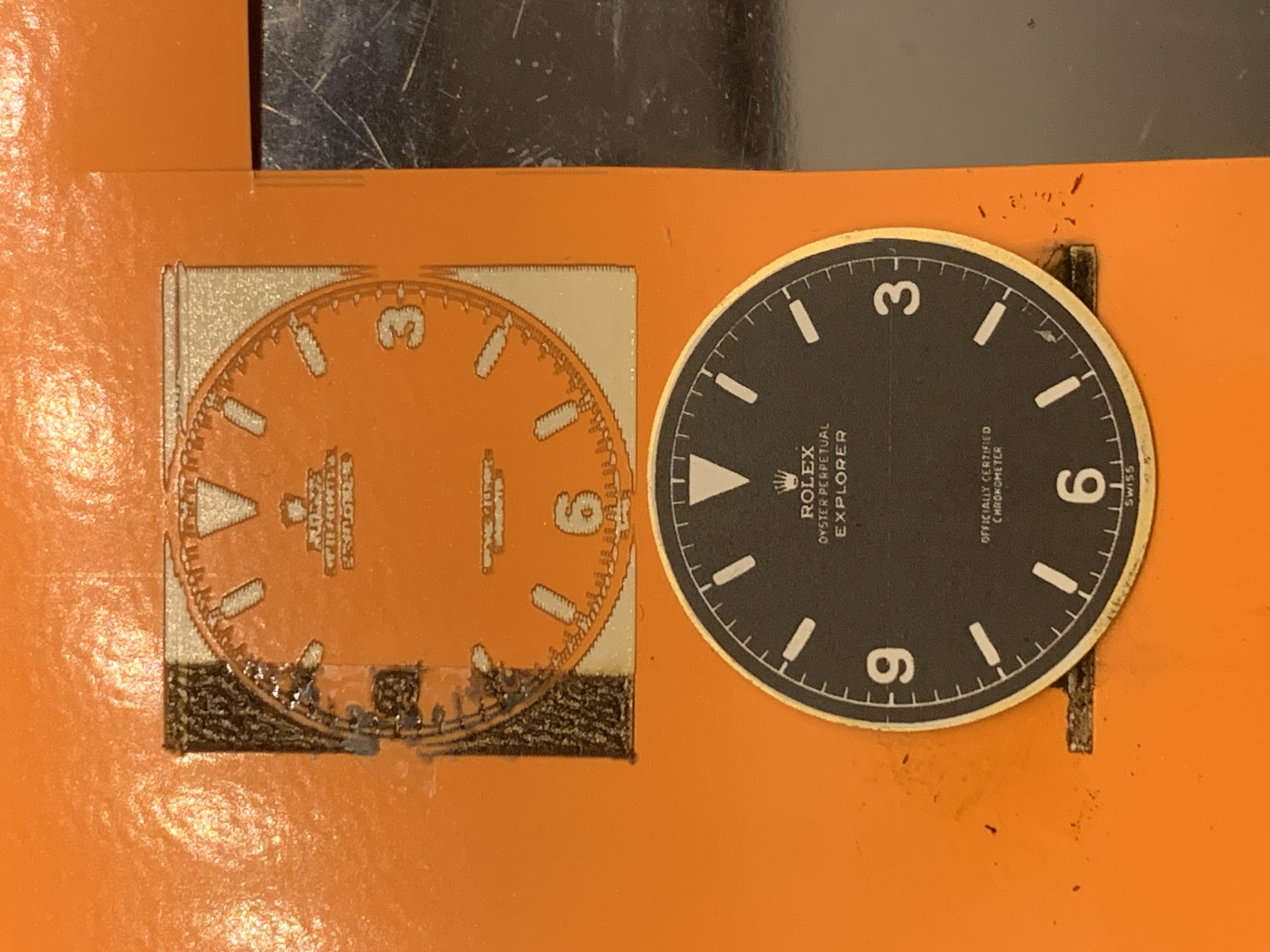

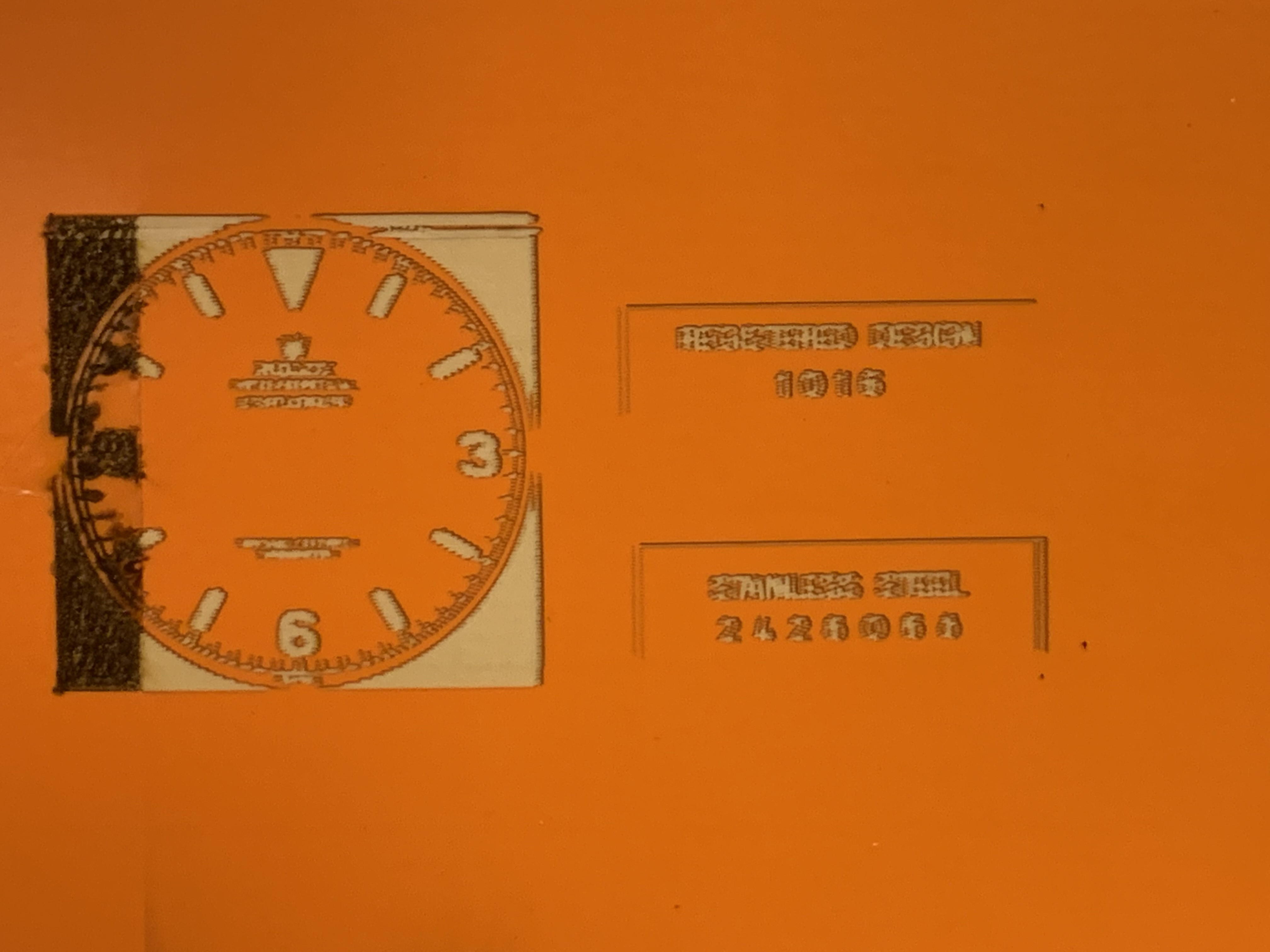

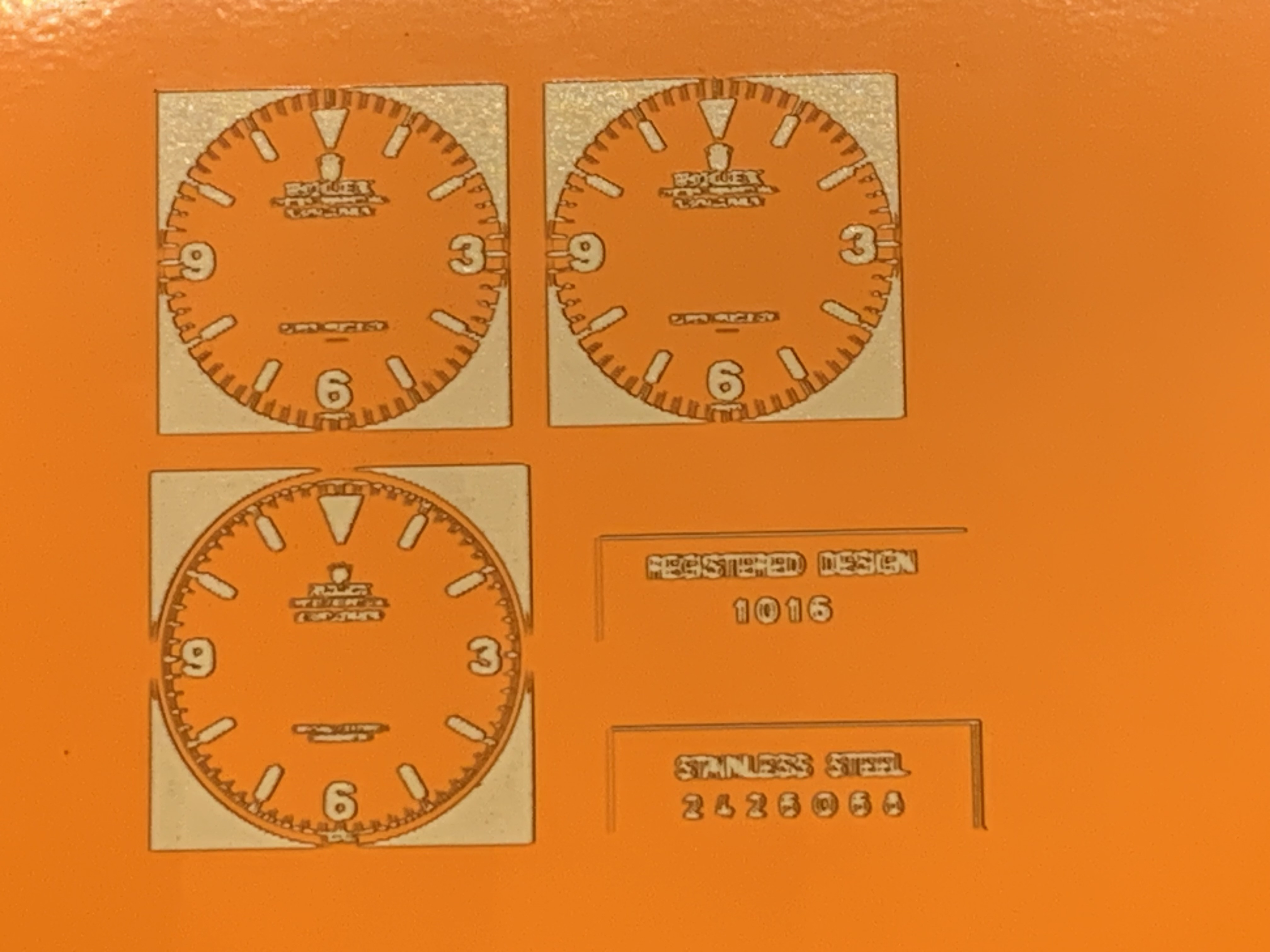

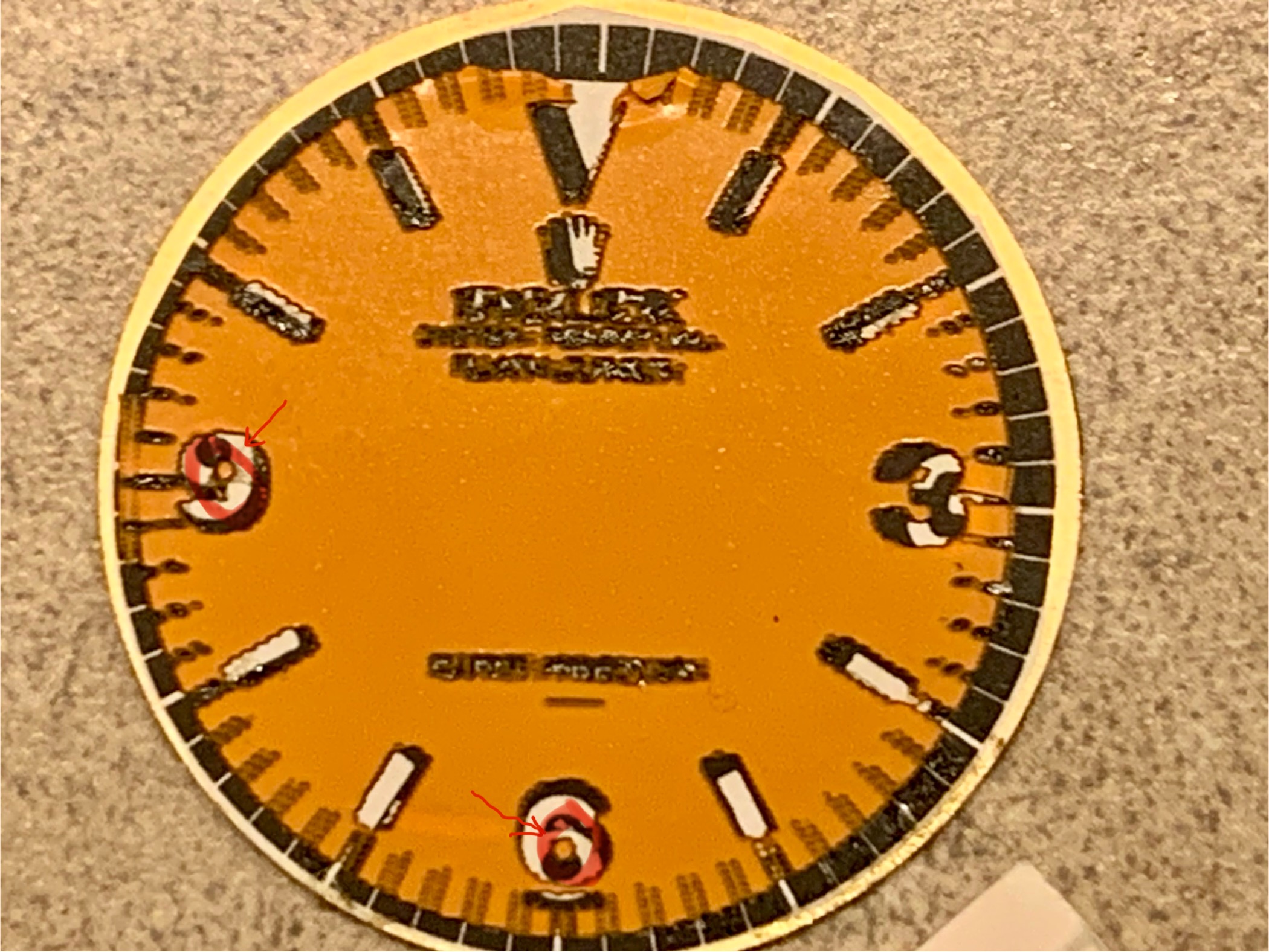

It's almost there with the laser cutter, I think when the files are converted from jpg to svg they'll be much clearer and less pixelated, and the post office is delivering a precision cutter today, which hopefully is another method to get to the same result.

When all the bugs are worked out of the process, I'll do a write up with all the necessary downloadable files so that anyone can do this themselves.

Basically, download the files and "print" them...either by cutting with a laser engraver or a precision cutter (like a Cricut or Silhouette). Then apply to the "target" (either a watch dial for the lume painting masks, or between the lugs for the lug engraving masks). Paint the lume or etch the metal, remove the decal, and if everything goes as expected, save it for the next time you use it.

The tools to do the saltwater engraving itself are easy and cheap...a battery or old phone charger, a Q-tip (or paint brush...really anything would work as long as current can pass through it) and some saltwater.

The tools for the masks would be a bit more difficult...either buy or borrow a laser engraver (or laser engraving attachment for a 3D printer) or go to a printing shop or Kinko's and have them print for you. I can't imagine the expense would be too great, if you're providing the material and files, all they need to do is run it through their machine.