I'm sharing this because you guys are my tribe, like it or not, and I assume that anything I'm excited about will have some impact here, lol.

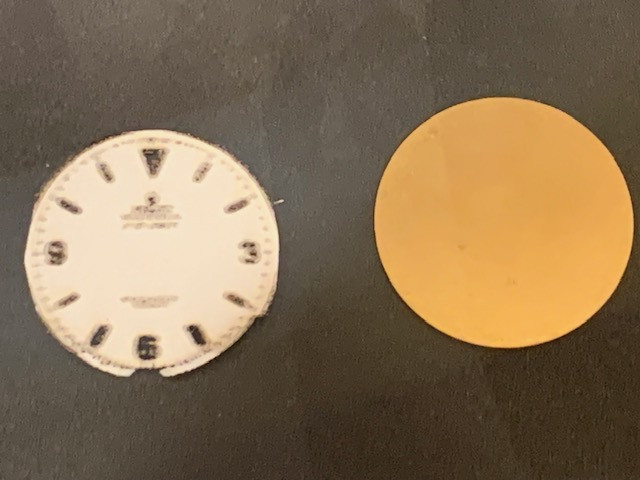

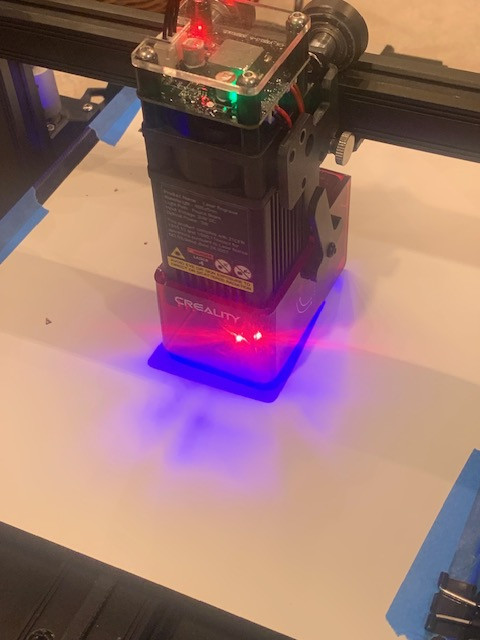

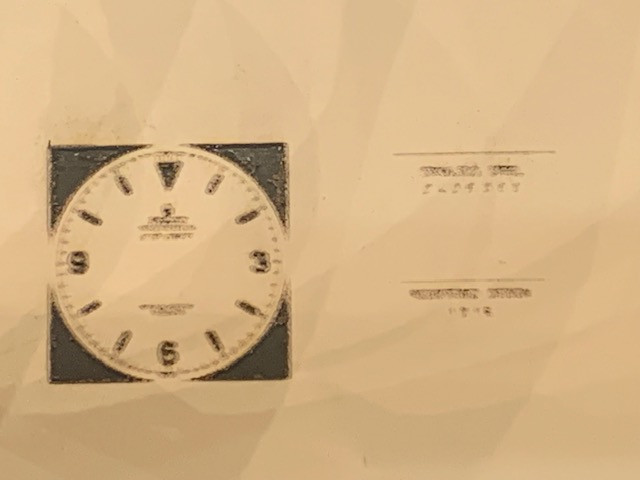

This is VERY EARLY in the process, and requires a LOT of fine tuning, but a pretty nice breakthrough was made in the projects I've been working on. You can see the aborted first attempt (laser set WAY too high, lol) in one of the photos. There will be a lot more failures before success, but as a proof of concept, I think I'm almost there.

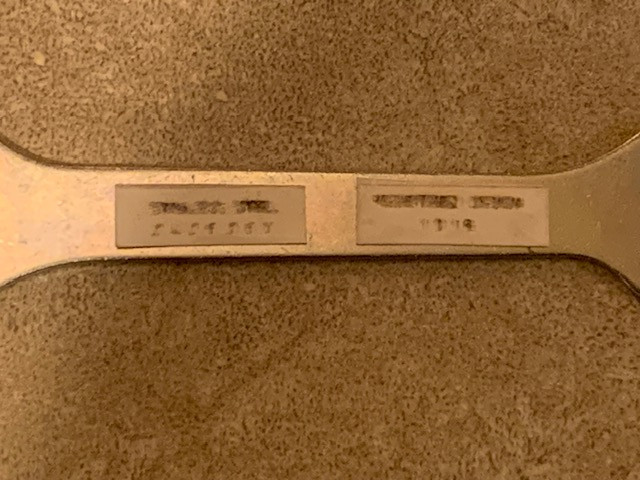

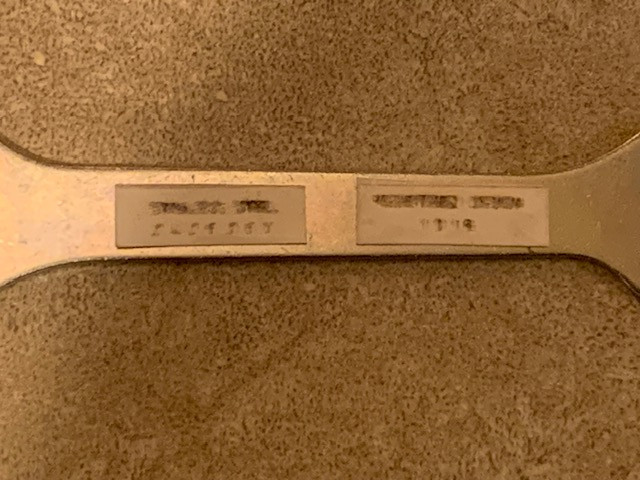

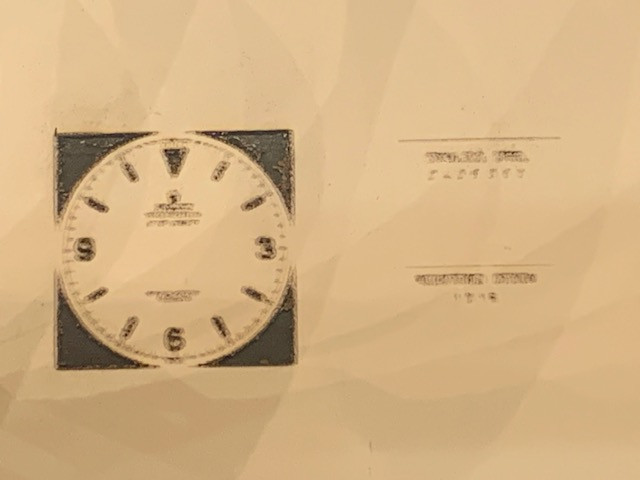

FIRST...TO create a stencil, preferably reusable, for saltwater etching serial number and model numbers between lugs. If it works, it would open up some very reasonable quality lug engraving to anyone with the desire to do it (ie, it won't be OEM, factory new quality, but it will look very much like what a real vintage watch looks like in the wild).

The process should be simple, and very user friendly with a low barrier to entry.

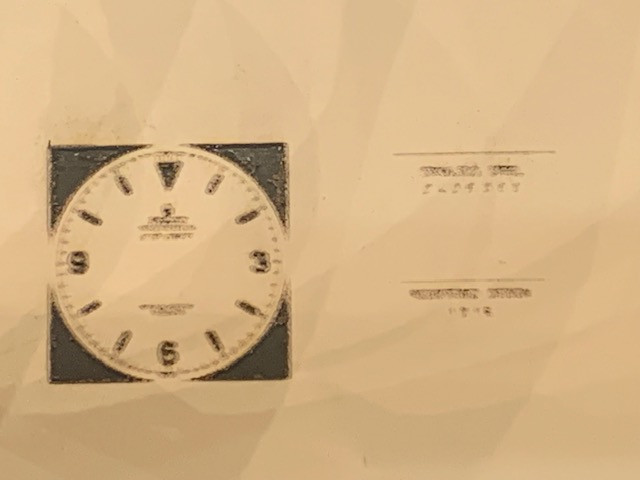

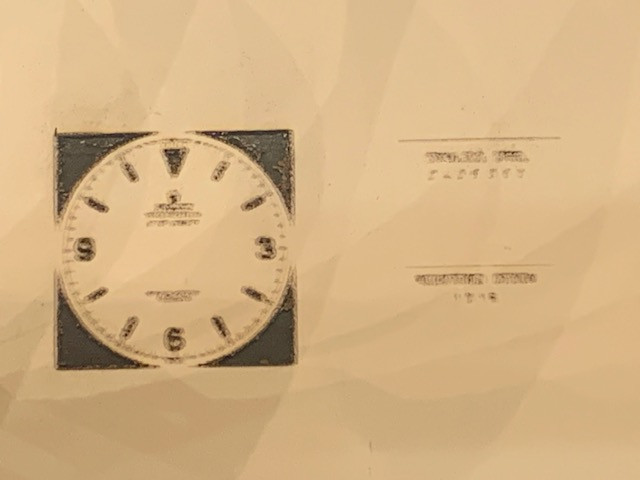

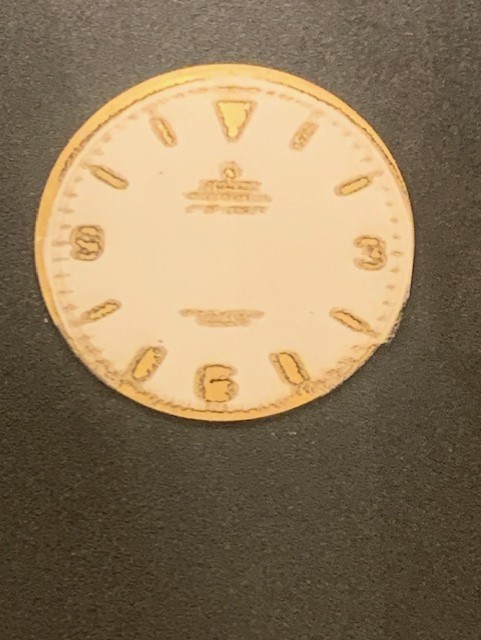

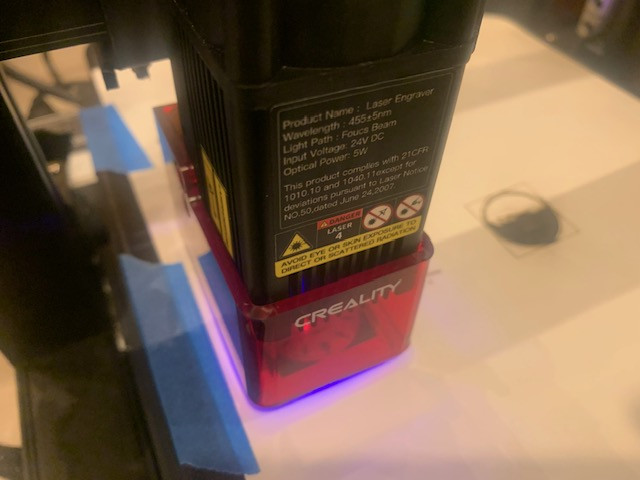

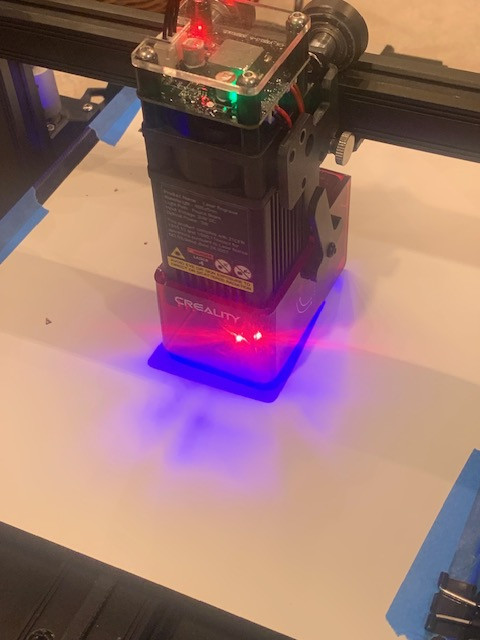

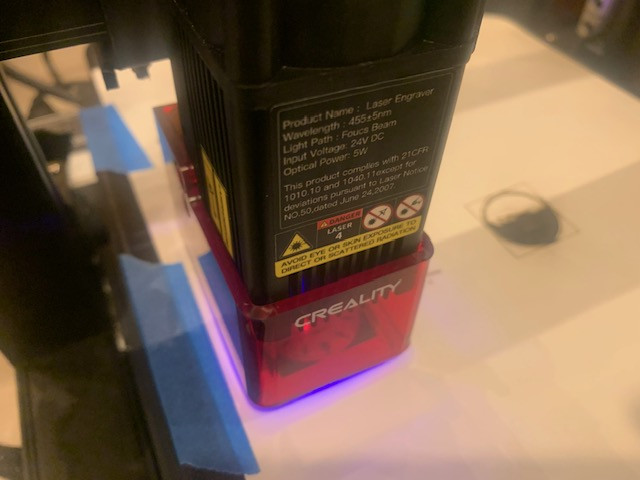

This is a laser cut of vwery cheap sticker paper. The laser settings (focus, speed, etc) need to be fine tuned quite a bit, and I need to find better paper that doesn't burn as easily, but assuming I can do that, I should be able to cut a vinyl sheet with just about every model and serial number (range) that a novice modder could ever want. The "master sheet" is shared publicly, and anyone could download and use it and change the model and serial numbers to their own preference. I posted the proof sheet a few pages back, but this is the first time I've ever been able to print it into something usable. Basically, cut the sticker out with a laser engraver (it might even work with a precision cutter, like a Cricut or Silhouette, I will know in a couple days, I ordered one as a "gift" to the lady friend, lol):

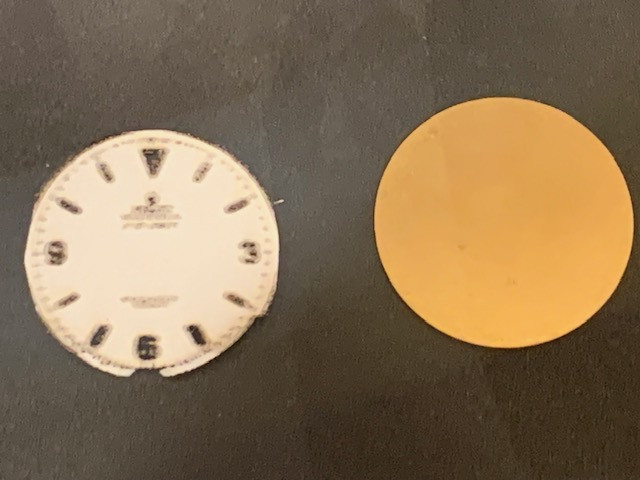

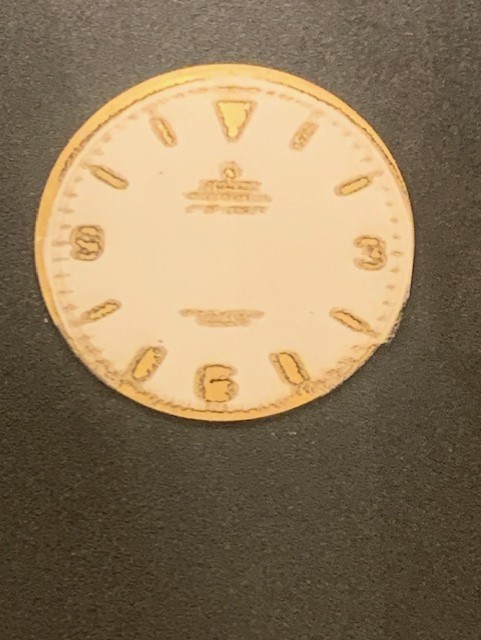

SECOND...to create a "stencil" of sorts to help us who don't have the eyes of a fighter pilot and the hands of a neurosurgeon to lume our dials. Basically, it will be another vinyl sticker that would go over a finished, but unlumed dial, masking off anything that we don't want lume on. So we will be able to lume the indices without "coloring outside the lines." Instead of painstakingly doing it with an oiler or pin, we could actually use a small paintbrush...even spray paint, assuming the mask adheres well. Once the lume is on, the stencil/mask could be peeled off without harming the dial. The sizes of the "masks" could even be tweaked slightly to give the concentric lines in the "nicer" vintage dials.

As said, I have to experiment and tweak the laser settings and the paper/vinyl for the right settings and qualities, but this is a big step towards that.