Hmm. Just me then. Tried him Wednesday and today with no answer.Only 2 days for me

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

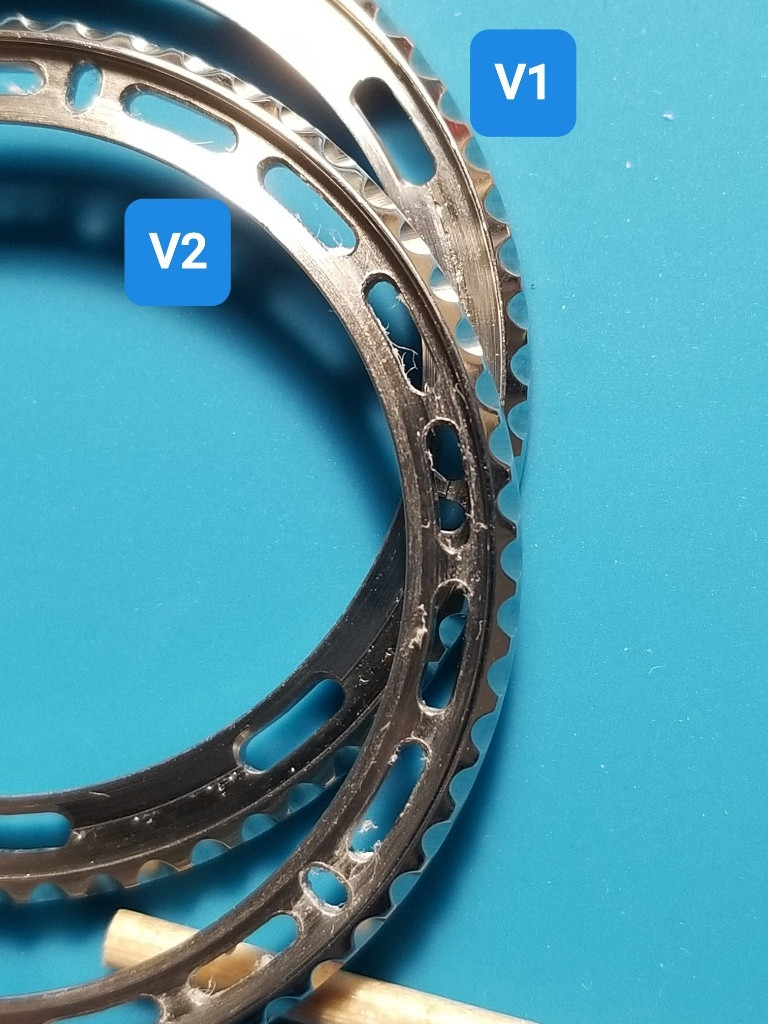

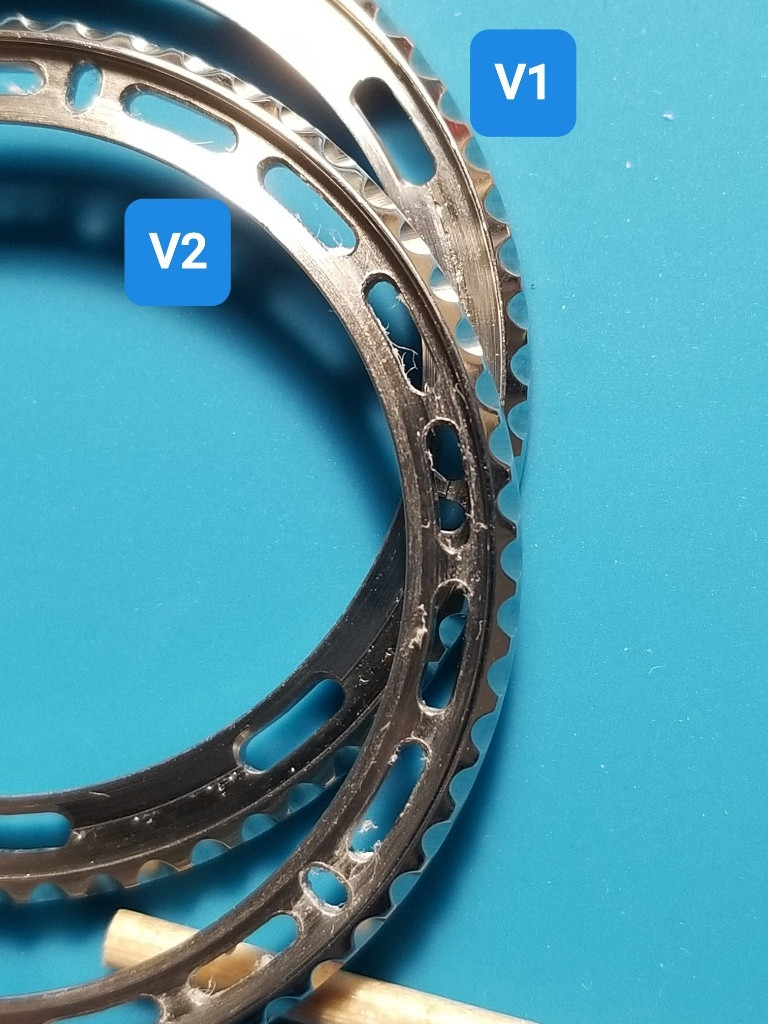

Pepsi bezel insert battle CF vs Xing_Patrick: A photo comparison

- Thread starter JustFou

- Start date

- 27/5/22

- 4,434

- 6,558

- 113

China is on holiday right now.Red looks amazing. Definitely less reflective than Gen. I think.

How long does QC take from Patrick? Been waiting a week with no response.

This week. But not last week, right?China is on holiday right now.

- 27/5/22

- 4,434

- 6,558

- 113

Chinese like to take extended holidays.This week. But not last week, right?

Manuelito108

Known Member

Mine should arrive next 3-4 days, you suggest me to fix with 3m tape or put inside ring without adesive?

- 12/3/18

- 37,519

- 80,120

- 113

It won't stay without adhesive.Mine should arrive next 3-4 days, you suggest me to fix with 3m tape or put inside ring without adesive?

- 12/3/18

- 37,519

- 80,120

- 113

If you aren't going to be getting it wet regularly, the 3M adhesive rings are bulletproof.Can you recommend one?

If you plan on submerging it regularly, I would use something permanent like slow cure epoxy so you can adjust it to a perfect position. It can be released later if necessary by soaking in acetone (Goof Off) in a shallow tray where the acetone does not contact the marker fill. The tray needs to be placed in an airtight environment (zip lock bag) as acetone evaporates quickly.

What’s regularly? I swim occasionally. Have you seen them come off in water?If you aren't going to be getting it wet regularly, the 3M adhesive rings are bulletproof.

If you plan on submerging it regularly, I would use something permanent like slow cure epoxy so you can adjust it to a perfect position. It can be released later if necessary by soaking in acetone (Goof Off) in a shallow tray where the acetone does not contact the marker fill. The tray needs to be placed in an airtight environment (zip lock bag) as acetone evaporates quickly.

I’d go epoxy, but don’t think Xing is best bezel we’ll ever get. And I’d be too afraid of acetone on the engravings (and maybe any of the ceramic).

I can skip swimming with this one if it’s a danger.

- 12/3/18

- 37,519

- 80,120

- 113

If it were me I wouldn't ever get a 3M tape ring wet - I don't get any of my watches wet, not even splash from hand washing. Water soaking is a method to soften a tape ring to make removal easier. I have read about members losing an insert from swimming with one taped on. I do not recommend it.

There is absolutely no way to damage ceramic with acetone, and it's very easy to fill a small shallow tray to a level that doesn't cover the top of the insert. Besides, it really should never have to come off. Obviously with a GMT bezel you would need to be careful about putting glue blobs on parts of the bezel well away from the perpendicular slots where the click ring pins fit so they retain their movability.

There is absolutely no way to damage ceramic with acetone, and it's very easy to fill a small shallow tray to a level that doesn't cover the top of the insert. Besides, it really should never have to come off. Obviously with a GMT bezel you would need to be careful about putting glue blobs on parts of the bezel well away from the perpendicular slots where the click ring pins fit so they retain their movability.

- 13/3/16

- 1,307

- 2,060

- 113

And I’d be too afraid of acetone on the engravings (and maybe any of the ceramic).

I tested a Xing insert by wiping the engraving with acetone and nothing happened. So I assume it’s either plated or sputter coated. I’ve used acetone to remove painted inserts and it removes the silver paint pretty quickly. Xing is doing it right…whatever it is.

Brave of you, but awesome to know it was unaffected by acetone. Good job Xing. Just need Patrick to ship my insert now!I tested a Xing insert by wiping the engraving with acetone and nothing happened. So I assume it’s either plated or sputter coated. I’ve used acetone to remove painted inserts and it removes the silver paint pretty quickly. Xing is doing it right…whatever it is.

- 13/3/16

- 1,307

- 2,060

- 113

Brave of you, but awesome to know it was unaffected by acetone. Good job Xing. Just need Patrick to ship my insert now!

I also did the acetone test on a VSF 126 Starbucks insert and it passed. It looks like the days of enamel paint in ceramic inserts is becoming a thing of the past. At least with the top tier insert manufacturers.

- 16/4/22

- 482

- 546

- 93

thanks nice to know this was really tested. Curious are Clean bezels painted or are they plated too.I tested a Xing insert by wiping the engraving with acetone and nothing happened. So I assume it’s either plated or sputter coated. I’ve used acetone to remove painted inserts and it removes the silver paint pretty quickly. Xing is doing it right…whatever it is.

Xing did state it in their vendor posting that they plate it. https://forum.replica-watch.info/threads/update-xing-bezel-4-0.10941259/#post-11254769

Double layer of Platinum plating (same electroplating factory that is producing our new DJ41 bezels) The numbers are brighter and more uniform.

- 12/3/18

- 37,519

- 80,120

- 113

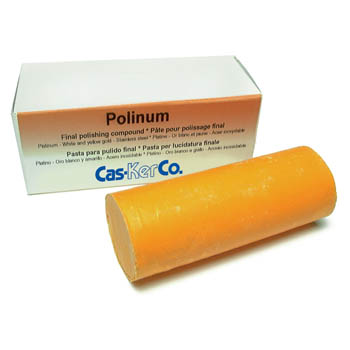

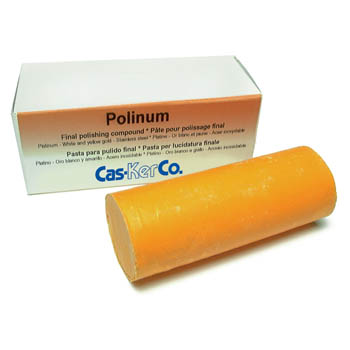

I haven't tried to polish a ceramic insert but I have both sanded and polished SS Daytona bezels to remove scratches. So if I were going to try polishing a ceramic insert I think the same approach is viable.Anyone have any ideas on how to polish the ceramic further for more gloss?

On the SS bezel I used 7000 grit sandpaper, which is the same I use for final sanding on cases, bracelets, etc. It's fine enough that one could almost mistake the finish as having already been polished. Obviously sanding isn't needed (or feasible really) on ceramic but I described it for context.

Next comes the polishing. I use a dremel, mounted in a vice. Any buffer or drill, etc. will also work. I use two main types of buffing wheels - solid felt and stacked cloth layers. I use the stacked cloth layers more often, though they are not as uniform in diameter and can develop stringers and loose threads that could dig into a bezel / insert engraving. So for this task a sold felt wheel is better.

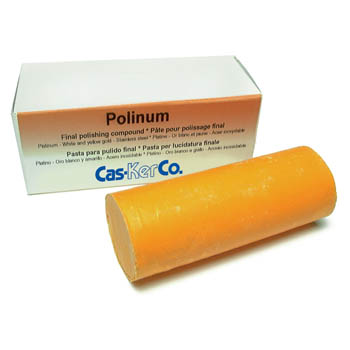

For the utmost mirror finish on SS I haven't found anything better than Polinum. The stuff is just awesome.

Polinum Polishing Compound for Platinum

Jewelers and watchmakers trust Cas-Ker for quality products like polinum and other fine metal polishes. Find this and other professional jeweler and watchmaker supplies at Cas-Ker Jewelers Supplies, your trusted and timely source since 1927.

www.jewelerssupplies.com

On an bezel with engravings, I just barely touch the Polinum laden wheel to the surface and I didn't hurt the black markings a bit. And those markings are quite shallow with the fill nearly flush to the surface.

So I would try this technique. Test it on the backside, not near a joint just to be safest. Really a shame this even has to be a concern but we might be surprised with a solution.

Last edited:

- 13/3/16

- 1,307

- 2,060

- 113

I haven't tried to polish a ceramic insert but I have both sanded and polished SS Daytona bezels to remove scratches. So if I were going to try polishing a ceramic insert I think the same approach is viable.

On the SS bezel I used 7000 grit sandpaper, which is the same I use for final sanding on cases, bracelets, etc. It's fine enough that one could almost mistake the finish as having already been polished. Obviously sanding isn't needed (or feasible really) on ceramic but I described it for context.

Next comes the polishing. I use a dremel, mounted in a vice. Any buffer or drill, etc. will also work. I use two main types of buffing wheels - solid felt and stacked cloth layers. I use the stacked cloth layers more often, though they are not as uniform in diameter and can develop stringers and loose threads that could dig into a bezel / insert engraving. So for this task a sold felt wheel is better.

For the utmost mirror finish on SS I haven't found anything better than Polinum. The stuff is just awesome.

Polinum Polishing Compound for Platinum

Jewelers and watchmakers trust Cas-Ker for quality products like polinum and other fine metal polishes. Find this and other professional jeweler and watchmaker supplies at Cas-Ker Jewelers Supplies, your trusted and timely source since 1927.www.jewelerssupplies.com

On an bezel with engravings, I just barely touch the Polinum laden wheel to the surface and I didn't hurt the black markings a bit. And those markings are quite shallow with the fill nearly flush to the surface.

So I would try this technique. Test it on the backside, not near a joint just to be safest. Really a shame this even has to be a concern but we might be surprised with a solution.

I‘ve seen many dozens of ceramic inserts but don’t recall ever seeing one that needed polishing. They’ve all had mirror-like finishes. Maybe there’s some bad ones I haven’t seen.

That Polinum sounds really good. I’ll grab some with my next order. Thanks for the tip!

Have you ever tried the blue and yellow abrasive wheels? Insanely great shapers and polishers but very small so they have to be used carefully and are probably not a good choice for larger surfaces.

I‘ve seen many dozens of ceramic inserts but don’t recall ever seeing one that needed polishing. They’ve all had mirror-like finishes.

Patrick seems open to feedback. Hopefully he can a future version mirror like like most ceramic bezels.

If someone ever does this. Please post the results here or on rwi!I haven't tried to polish a ceramic insert but I have both sanded and polished SS Daytona bezels to remove scratches. So if I were going to try polishing a ceramic insert I think the same approach is viable.

On the SS bezel I used 7000 grit sandpaper, which is the same I use for final sanding on cases, bracelets, etc. It's fine enough that one could almost mistake the finish as having already been polished. Obviously sanding isn't needed (or feasible really) on ceramic but I described it for context.

Next comes the polishing. I use a dremel, mounted in a vice. Any buffer or drill, etc. will also work. I use two main types of buffing wheels - solid felt and stacked cloth layers. I use the stacked cloth layers more often, though they are not as uniform in diameter and can develop stringers and loose threads that could dig into a bezel / insert engraving. So for this task a sold felt wheel is better.

For the utmost mirror finish on SS I haven't found anything better than Polinum. The stuff is just awesome.

Polinum Polishing Compound for Platinum

Jewelers and watchmakers trust Cas-Ker for quality products like polinum and other fine metal polishes. Find this and other professional jeweler and watchmaker supplies at Cas-Ker Jewelers Supplies, your trusted and timely source since 1927.www.jewelerssupplies.com

On an bezel with engravings, I just barely touch the Polinum laden wheel to the surface and I didn't hurt the black markings a bit. And those markings are quite shallow with the fill nearly flush to the surface.

So I would try this technique. Test it on the backside, not near a joint just to be safest. Really a shame this even has to be a concern but we might be surprised with a solution.