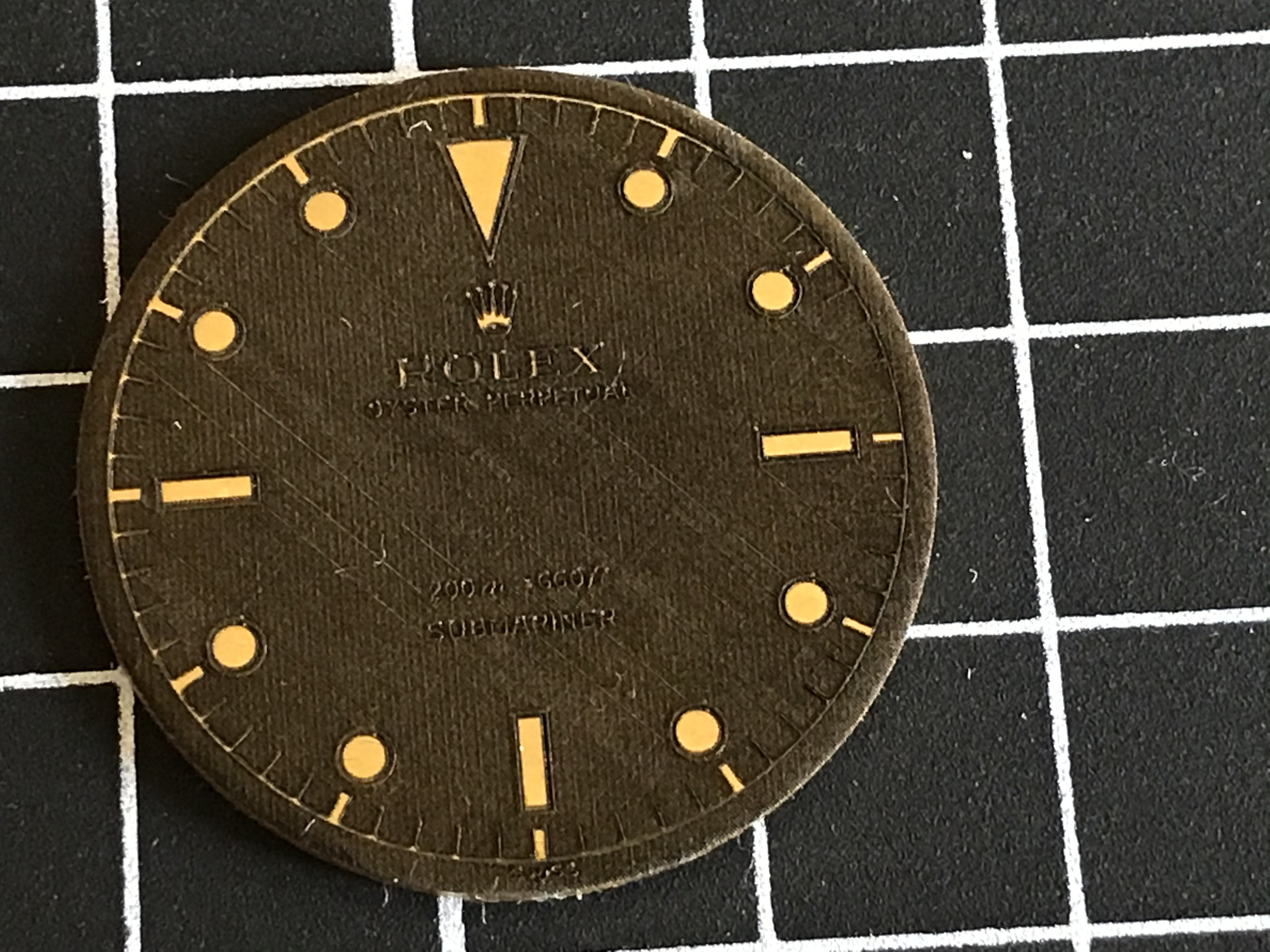

First attempt at using a fibre laser, a little to much power I think.

First attempt at using a fibre laser, a little to much power I think.

Nice! My 3D stamp should be in early next week and I’m hoping for a nice crisp mask.

since the dial is being plated with the black finish, would polishing the blank beforehand yield a glossy finish in the black even before applying any sort of lacquer or clearcoat afterwards?

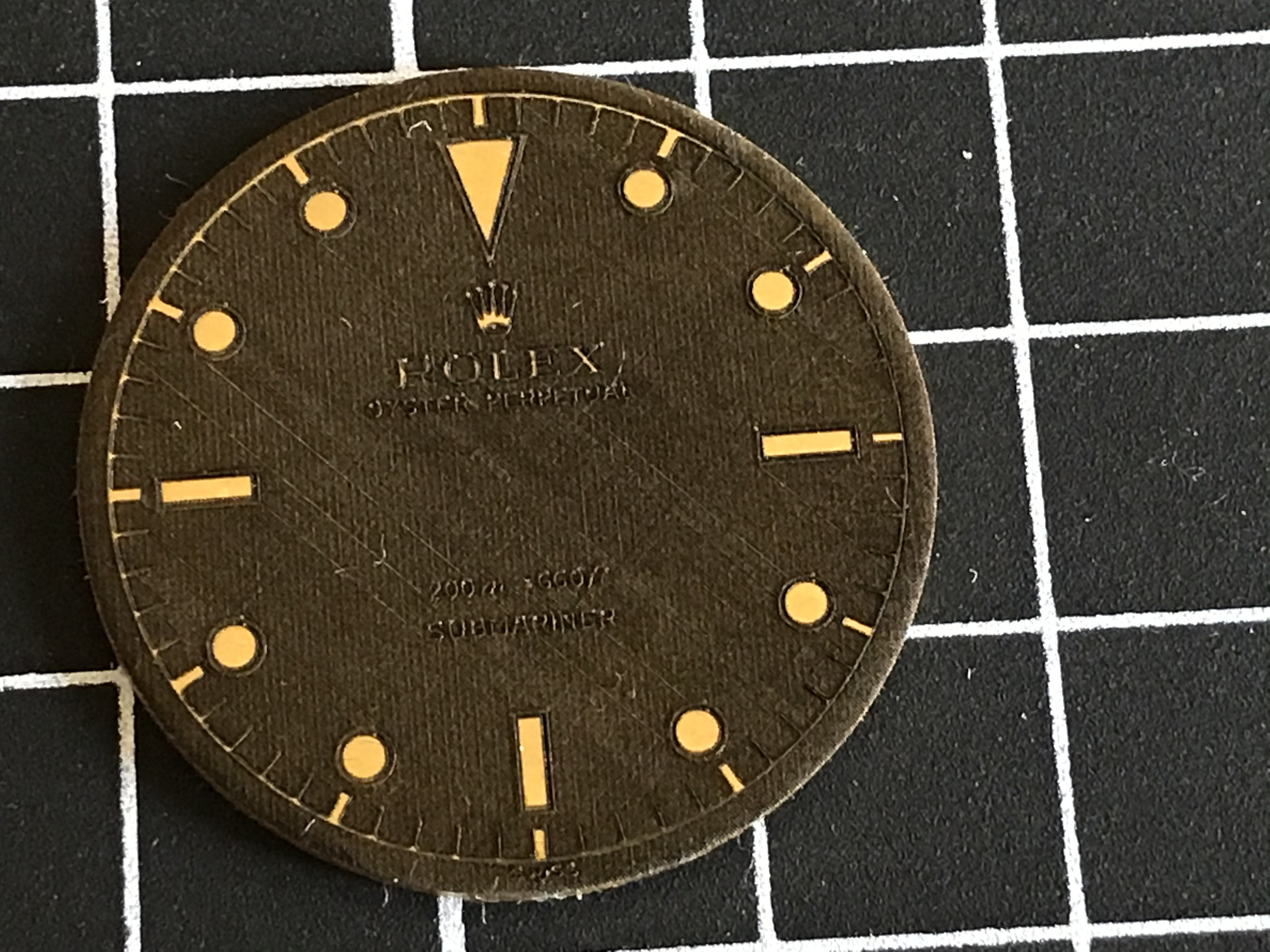

Here is my first real attempt with the stamp. The print is more crisp. Learning lessons here are the dial needs to be anchored down to something prior to being stamped to enable uniform pressure. Since my stamp wasnt anchored down I didn’t capture the full stamp. On paper the stamp looks perfect. I know I can get similar results on the brass as well.

When removing the ink with acetone it does move out the soft outer layer of the black oxide. If anyone is attempting this you will probably need to use steel wool 0000 before removing the ink to make sure all the black oxide is smooth.

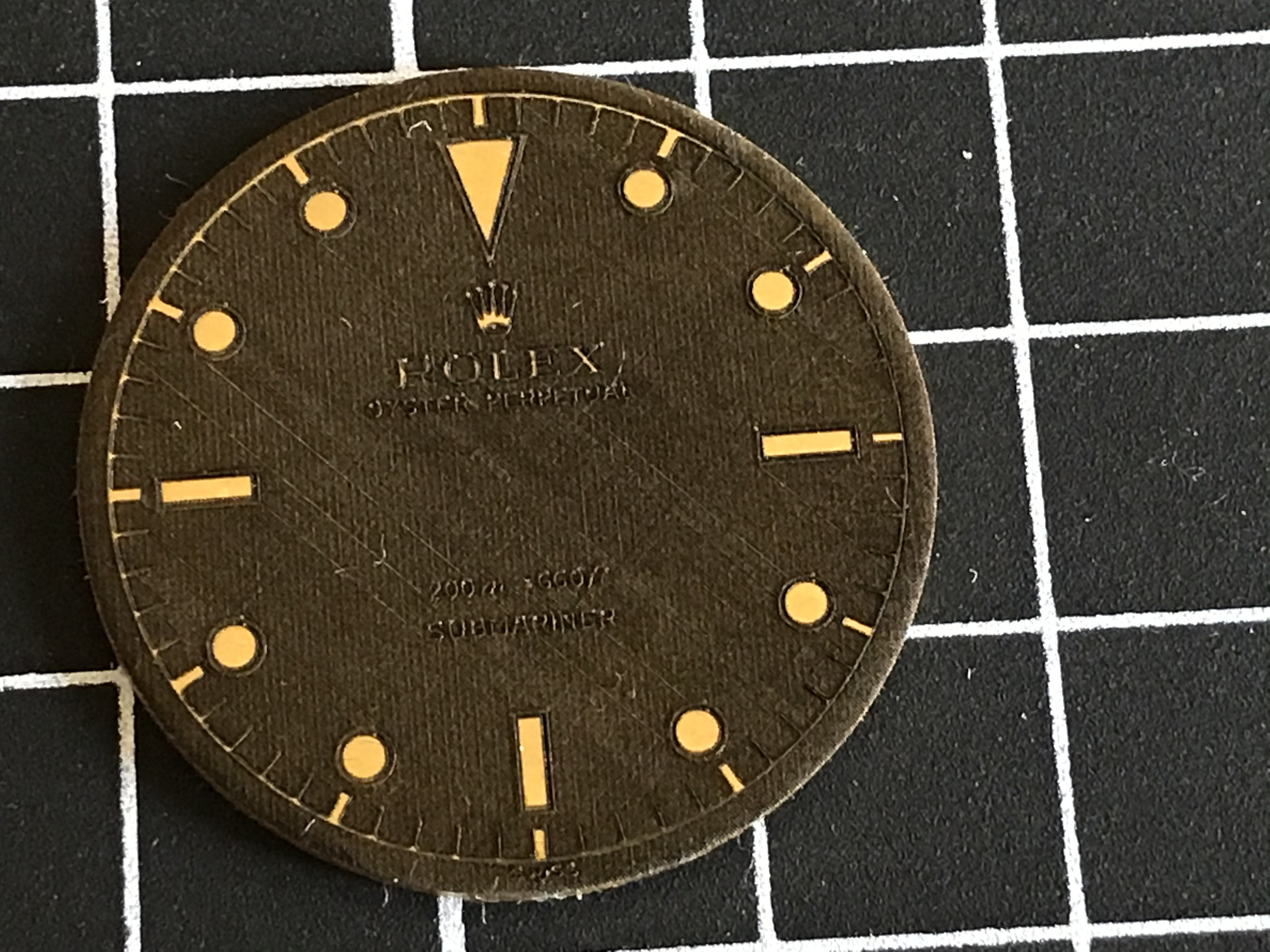

sorry for posting as is progress and not some

Grand reveal. Just excited to share.

that is a lot more high tech than my idea of taping it down or using a finishing nail through a piece of cardboard to hold it down.

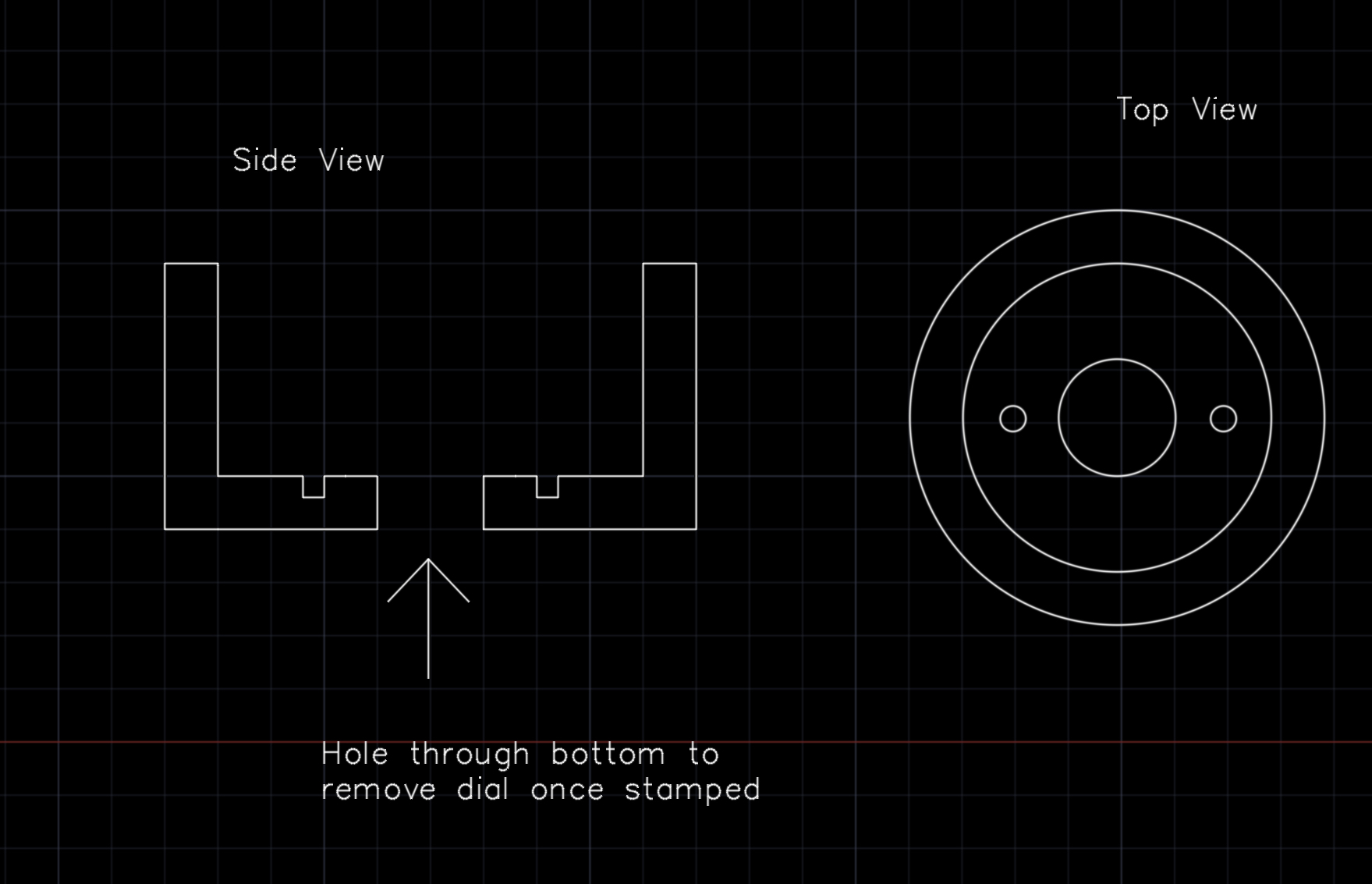

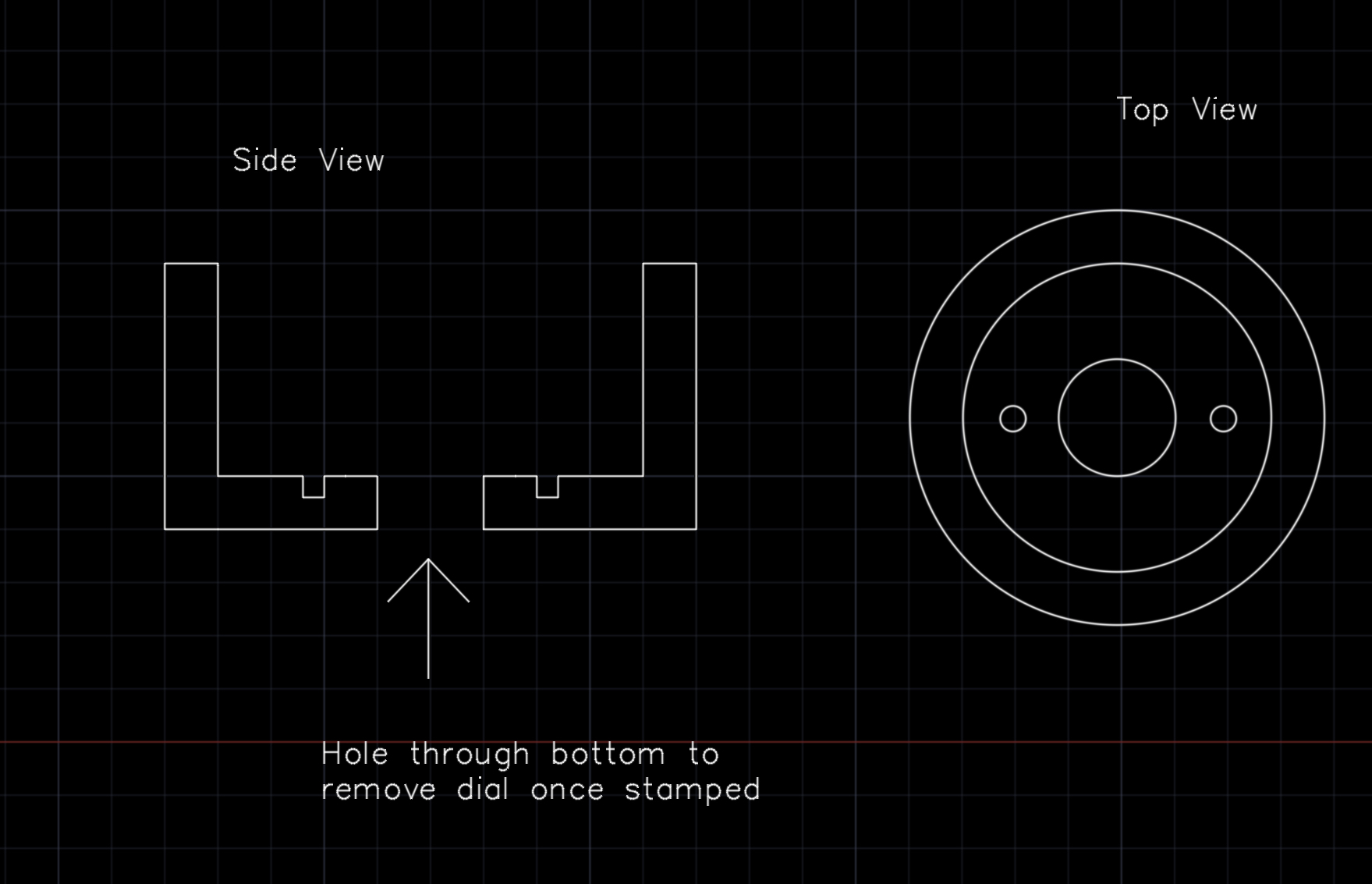

chrome72, could you not have something machined like this to hold your dial in place while you stamp it, it would also help with the uniformity of the stamp.

Sorry for the rough job but it’s obviously not to scale, I just knocked something up quick. The two small holes are for the dial feet.

I just tinkered with duct tape and i got an almost 85% impression. I need to tinker with the amount of ink on the stamp itself to make sure i am not getting globby prints.

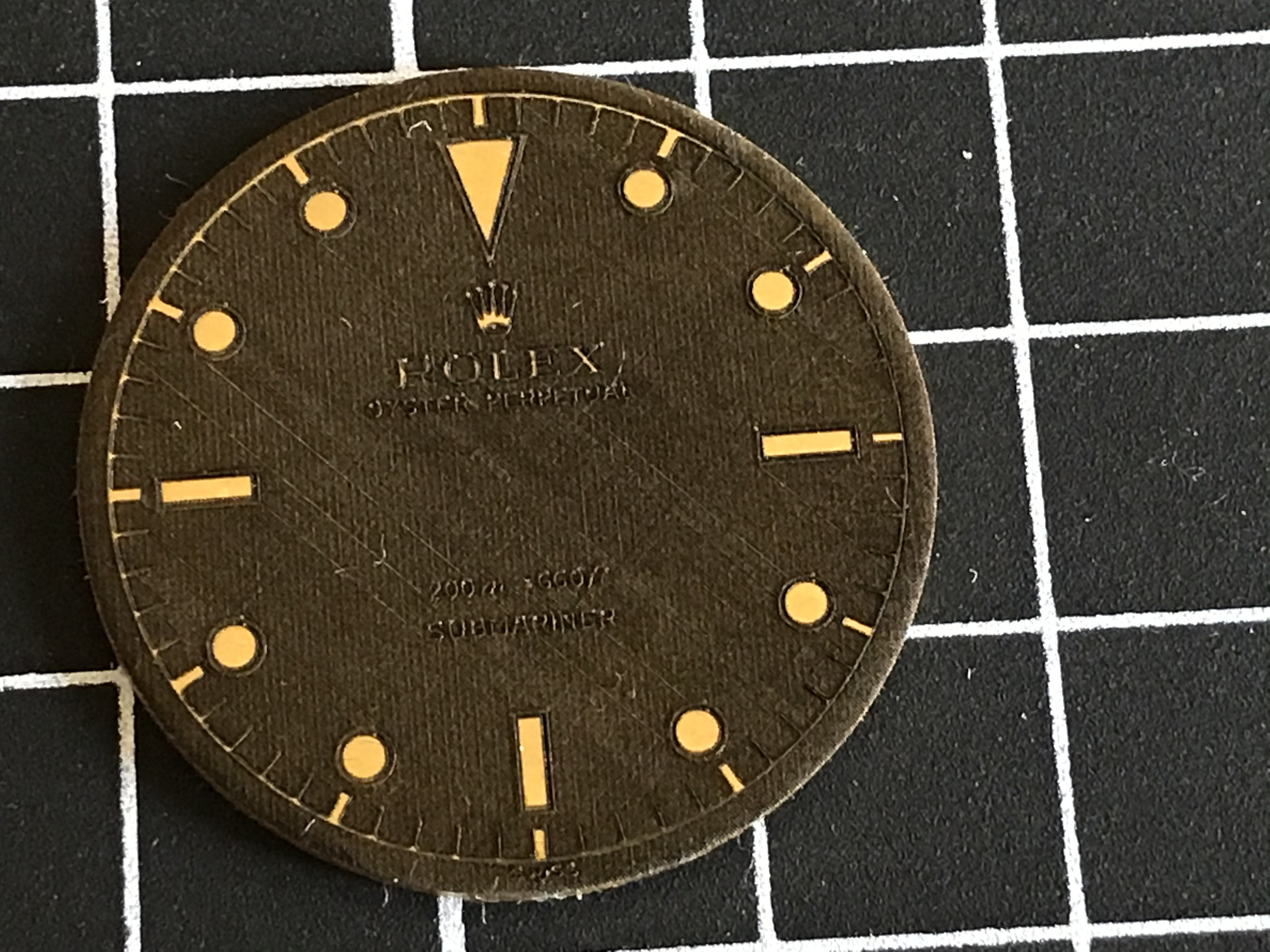

Tinkered with heat press toner transfer for giggle after talking to a guy who ha made pcb boards using this method and got this. Promising but the Rolex crown for some reason came out blobby when removing toner transfer when in the non coated dial it’s clean. Not sure if this has something to do with heat or pressure. Applied 2 quick coats of lacquer.