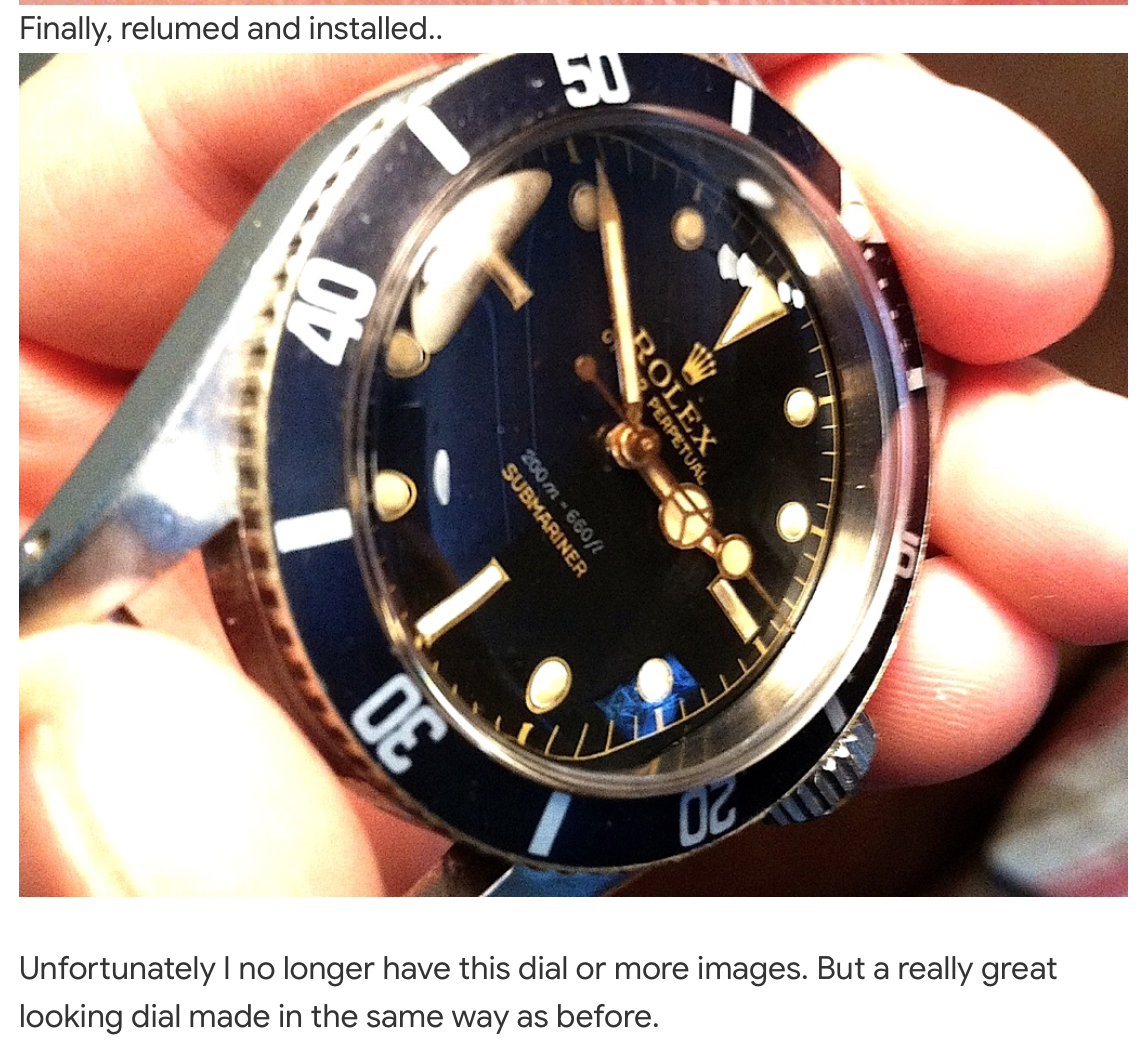

deadpan

Active Member

On the original Rolex dials, or TDL’s ... or both?

Surely if TDL is using original Rolex pads to print his dials, then the originals would have been printed as well? Or am I missing something?

On the original Rolex dials, or TDL’s ... or both?

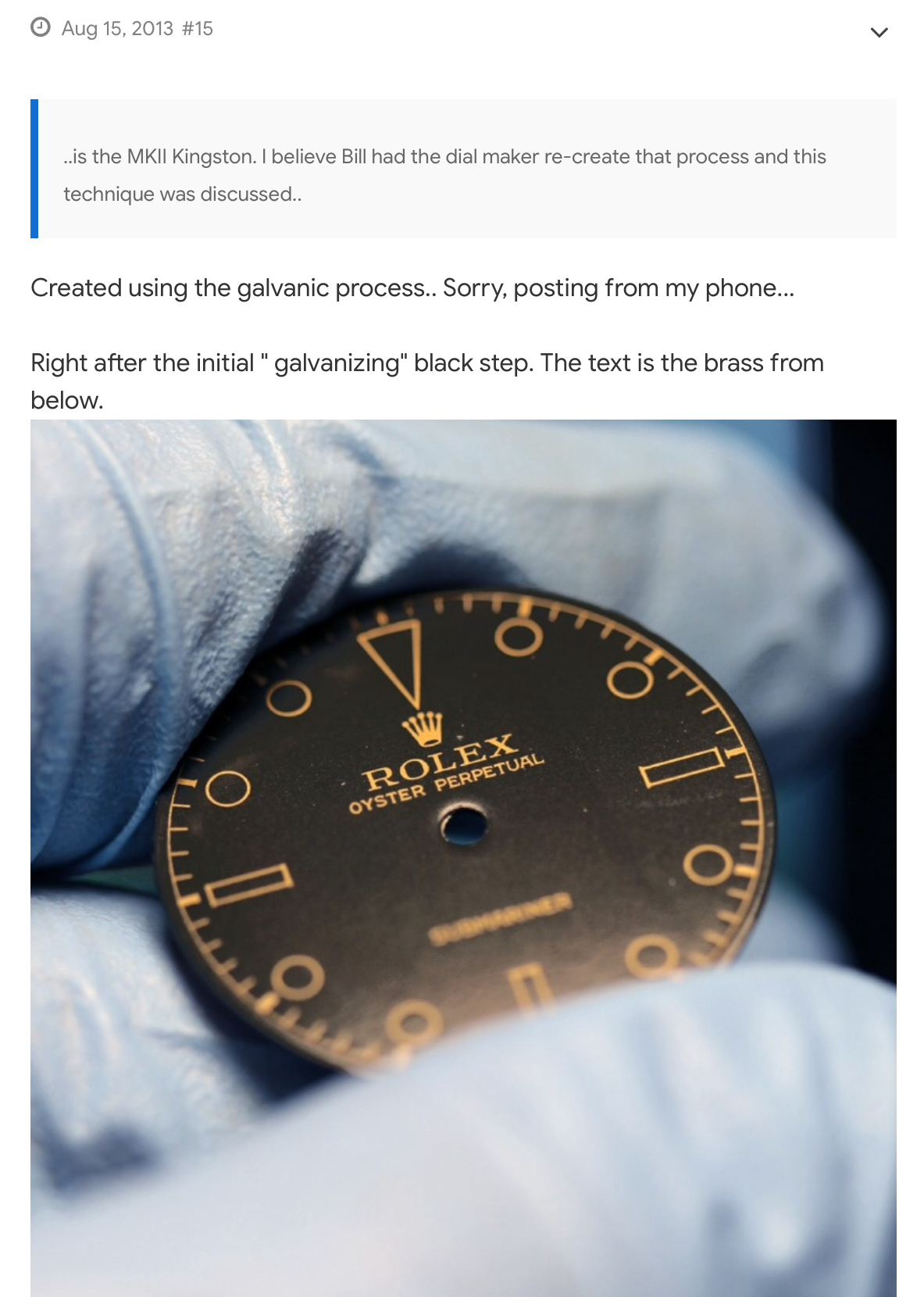

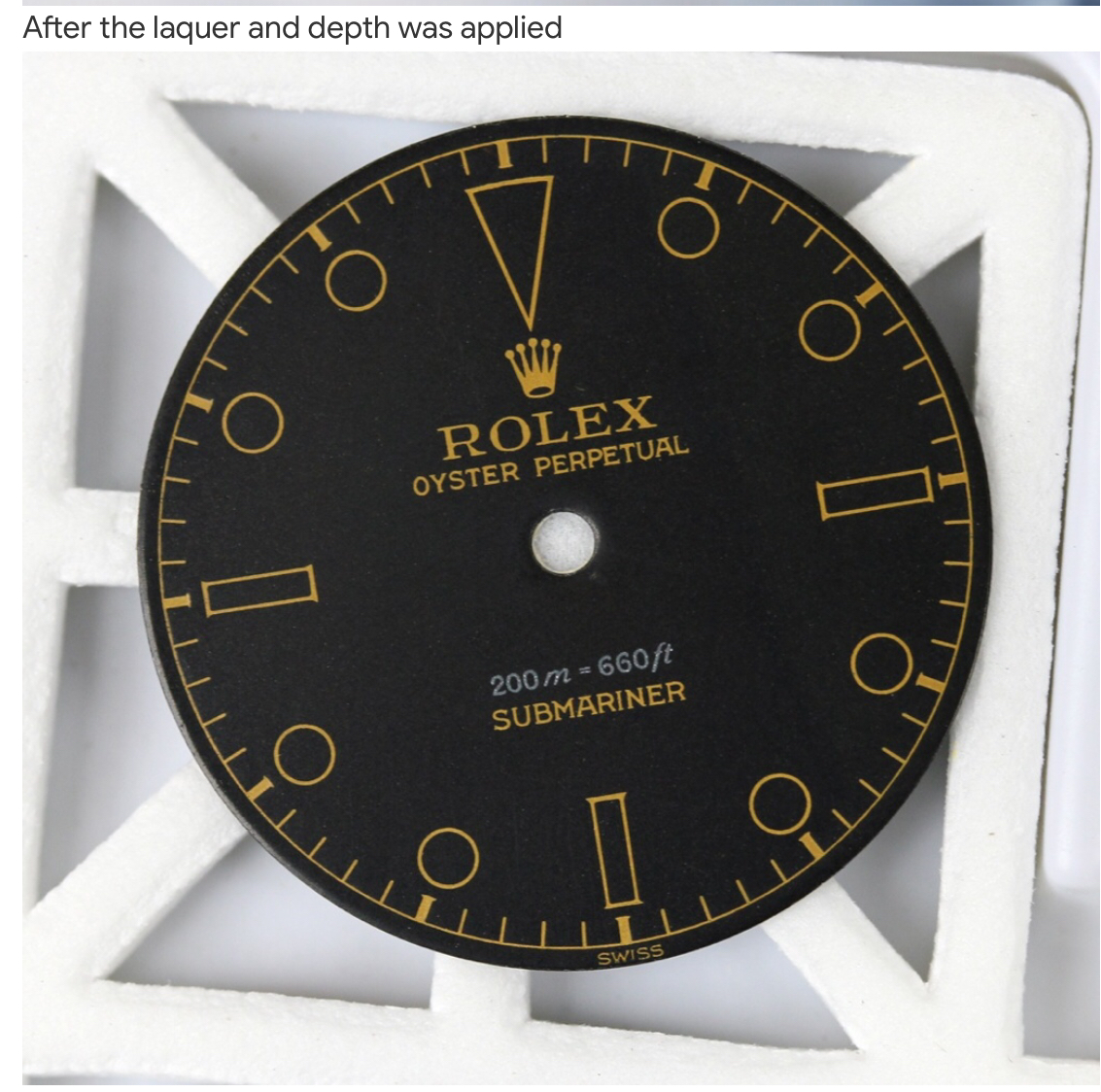

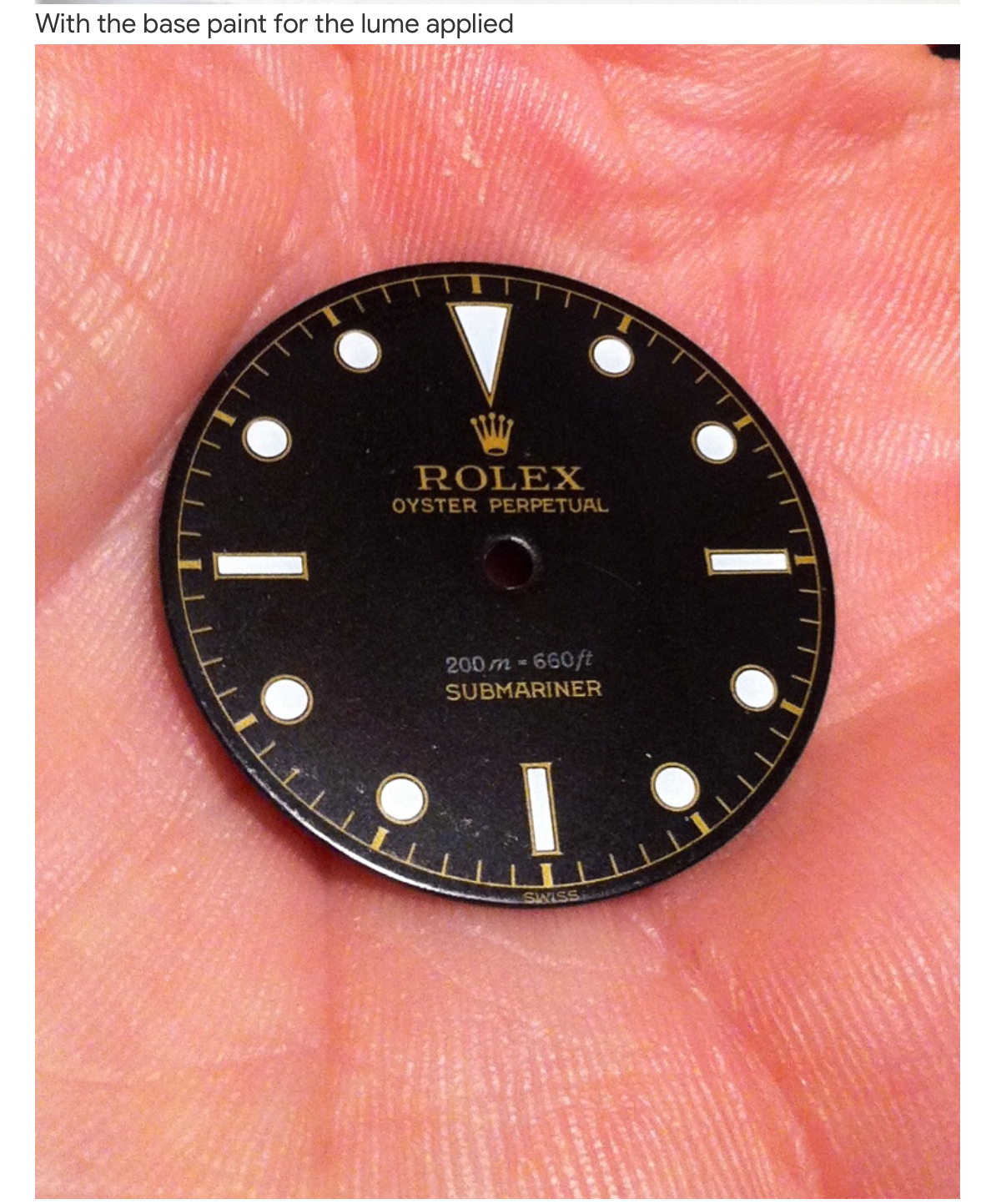

In early gilt dials, a negative mask containing the letters and numbers was applied over the black primer. The dial was then etched. After cleaning the dial, the numbers etched on the dial were gilded with gold leaf or silvered with silver leaf. When examined with a microscope, older gilt dials show that the letters have ”

I don’t know if this is any help but I found a patent from the 1940’s which I think is explaining the process, to be honest it’s all a bit technical for me and went straight over my head.

https://www.freepatentsonline.com/3989603.html

i found that one too which led me to searching patents for various terms. The patent you posted is dealing with aluminum which is a different beast than brass in terms what you can do. Aluminum has more things you can do like anodizing.

So found a brief description of the patent and it is this: dial is galvanically coated then varnished. Then the dial is stamped to provide the negative relief and then it mentions the stamped images’s varnish is removed I’m assuming through the stamping process. Then the dial is coated again with this time I am assuming gold or brass so that it fills in the negative relief stamped areas. Totally different way than other articles have mentioned.

It seems that there is a few different ways to do the dials, I honestly think that unless you intend of going down the route of making them as a business it’s going to be too costly due to the amount of specialist equipment and chemicals you need. Once my car is back on the road I’m going to go to my friends workshop and try doing it with his fibre laser, brass black marks easily and with a quick fine sanding and some lacquer I think you will get decent results.

I’m actually doing that this week but with toner transfer design and some dicropan t-4 which blackens brass then remove the toner transfer with acetone. Some of my test dials for blackness aren’t too bad and if I add a few more coats should look pretty unfit on black

It will be interesting to see how that turns out, is there any chance that the acetone interferes with the blueing?

What are you expecting the thickness of the blueing to be and do you think you will have to use several coatings?