-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you want someone done right... (Engraving content)

- Thread starter newest dude on the forum

- Start date

doin it with the Gravograph (but the motorized one/not the diamond cutter)! Hope, we're on the right track & will share the results, soonForgive me for asking a very basic question but how would you go about putting these designs on a caseback? I know solidworks is used for CNC and 3D printing. A CNC machine of some type?

The drag engraver uses a pantograph to copy a design and engrave it into an item...the area between case lugs, or a case back. It's how Rolex actually did it originally (at least between the lugs, possibly elsewhere), so it's the best way to do it to copy the original design.Forgive me for asking a very basic question but how would you go about putting these designs on a caseback? I know solidworks is used for CNC and 3D printing. A CNC machine of some type?

Yes, the letters are "carved" into a plastic block. You'd trace the letters with the pantograph, and the engraver would transfer it to the case back.So the 3D printed design would be used as the "master" for the pantagraph which would just engrave whatever it traces?

The "master" is usually quite a bit bigger than the target, so you can transfer greater detail. The pantograph engraver allows you to reduce the image down from 1:1 to 1:8 size.

Last edited:

Exactly!So the 3D printed design would be used as the "master" for the pantagraph which would just engrave whatever it traces?

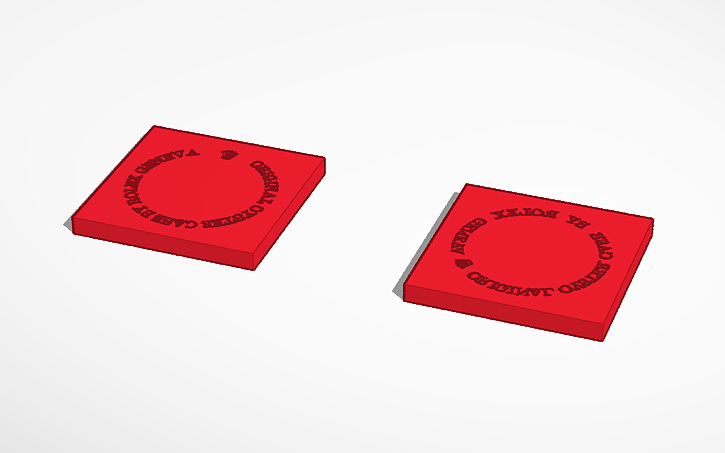

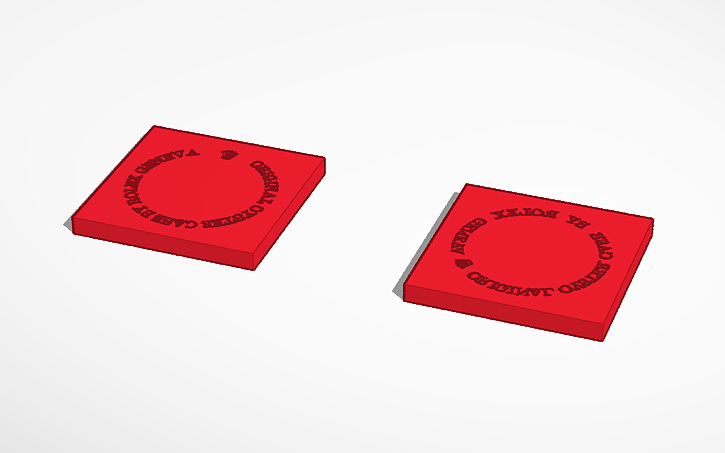

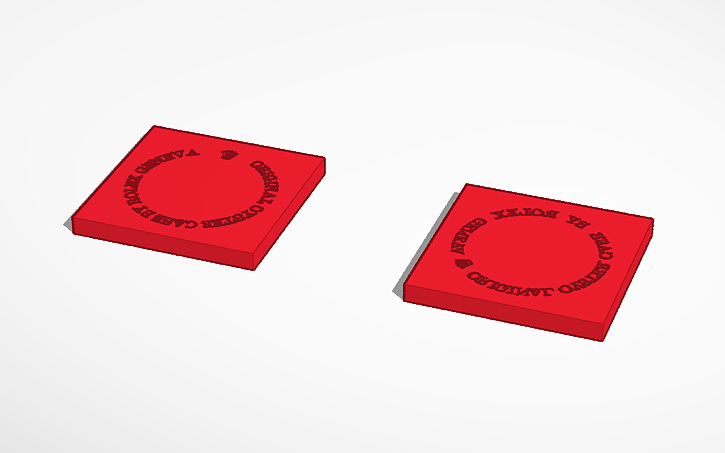

Updated design, with both the original (updated) image from @brekker0 (on the left) and the newer image from @matzemedia on the right.

I reduced the templates to 50mm "blocks" (40mm diameter circle engraed on the block) so the circle on the watch case back could be sized from 40mm (1:1) down to 5mm (1:8). I don't have one in front of me, but I'm guessing the Tudor engraving is about 20mm, give or take(?) so 1:2 reduction in size.

Not sure which of these is more accurate, and Tudor did had a lot of variations on their case backs, so use whichever is closer to what you need.

www.tinkercad.com

www.tinkercad.com

I reduced the templates to 50mm "blocks" (40mm diameter circle engraed on the block) so the circle on the watch case back could be sized from 40mm (1:1) down to 5mm (1:8). I don't have one in front of me, but I'm guessing the Tudor engraving is about 20mm, give or take(?) so 1:2 reduction in size.

Not sure which of these is more accurate, and Tudor did had a lot of variations on their case backs, so use whichever is closer to what you need.

3D design Tudor Case Back - Tinkercad

3D design Tudor Case Back created by David Patterson with Tinkercad

Last edited:

For really good results, the mastercopy's text should at least measure between 8mm to 15mm.... Otherwise the pointer cannot follow the font with its details...Updated design, with both the original (updated) image from @brekker0 (on the left) and the newer image from @matzemedia on the right.

I reduced the templates to 50mm "blocks" (40mm diameter circle engraed on the block) so the circle on the watch case back could be sized from 40mm (1:1) down to 5mm (1:8). I don't have one in front of me, but I'm guessing the Tudor engraving is about 20mm, give or take(?) so 1:2 reduction in size.

3D design Tudor Case Back - Tinkercad

3D design Tudor Case Back created by David Patterson with Tinkercadwww.tinkercad.com

- 9/5/24

- 259

- 110

- 43

Goodluck on this. I could not do this so I just send my case to Phong. He seems to have perfected the vintage lugs engraving.

If the engraving is a 25mm circle, then the CAD drawing can be reduced to 31.25mm to give a 25mm circle engraving.

Or double the drawing to 62.5mm and a 1:2 setting on the engravograph should be the right size.

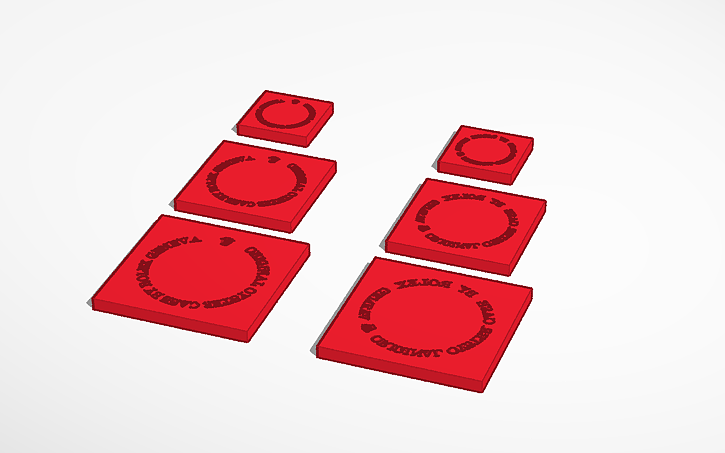

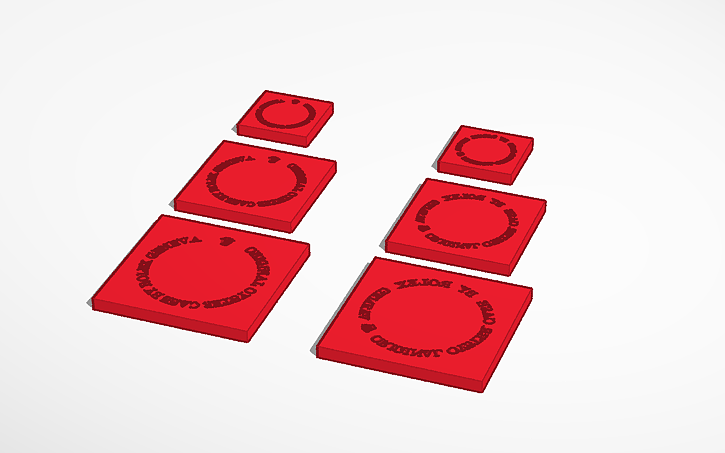

Ok, updated UPDATED CAD file with both versions of the case back art, in original size, plus reduced size (to use 1:1 setting on engraving machine) and enlarged size (to use 1:2 setting on engraving machine). For those who hate math, lol.

Either the reduced at 1:1 or the enlarged at 1:2 should give a 25mm diameter circle on the case back. You don't have to print all 6 templates, it would be a waste of filament/resin, but some might work better than others, so experimentation is encouraged.

www.tinkercad.com

www.tinkercad.com

It also occurred to me that the actual New Hermes fonts and images are beveled on the top and bottom edges, to slide into the tray, which has opposite bevels. I don't remember the size (IIRC, it is 50mm, but I might be wrong), so if wanted, someone could bevel the edges top and bottom, and these templates would slide firmly onto the tray.

Either the reduced at 1:1 or the enlarged at 1:2 should give a 25mm diameter circle on the case back. You don't have to print all 6 templates, it would be a waste of filament/resin, but some might work better than others, so experimentation is encouraged.

3D design Tudor Case Back - Tinkercad

3D design Tudor Case Back created by David Patterson with Tinkercad

It also occurred to me that the actual New Hermes fonts and images are beveled on the top and bottom edges, to slide into the tray, which has opposite bevels. I don't remember the size (IIRC, it is 50mm, but I might be wrong), so if wanted, someone could bevel the edges top and bottom, and these templates would slide firmly onto the tray.

Last edited:

And since I'm looking through my old files (and can't remember if I shared this before) this is one I did a while back for inside the case back. Rolex changed the design over the years, but this is a decent starting point. The 1016 model number could be deleted, and the appropriate number engraved with the brass fonts if need be (ie, for a 5513 or 1675, etc).

Tudor inside casebacks were similar, only "Rolex" was replaced with "Tudor." Other than that, they're pretty much the same...and accuracy here isn't really that important, because anyone looking inside the caseback is probalby going to see more obvious tells than the exact layout of the inside caseback engraving...

www.tinkercad.com

www.tinkercad.com

Tudor inside casebacks were similar, only "Rolex" was replaced with "Tudor." Other than that, they're pretty much the same...and accuracy here isn't really that important, because anyone looking inside the caseback is probalby going to see more obvious tells than the exact layout of the inside caseback engraving...

3D design Case Back Engraving template - Tinkercad

3D design Case Back Engraving template created by David Patterson with Tinkercad

Guys, I really didn't expect, that this thread originated from @newest dude on the forum would take off on that speed! The synergy on this thread is absolutely overwhelming and will push us forward as hell! I can't await, seeing the first results (and of course skyrocketing the prices on old engraving machines....)

The trick is, if you EVER plan to buy an engraving machine, do it sooner, rather than later, lol. The more folks read this thread, the more demand there will be for these obsolete but still fairly common machines.Guys, I really didn't expect, that this thread originated from @newest dude on the forum would take off on that speed! The synergy on this thread is absolutely overwhelming and will push us forward as hell! I can't await, seeing the first results (and of course skyrocketing the prices on old engraving machines....)

I actually picked up one early on, and have snagged another two since that were selling at "too cheap to pass on" prices. The additional machines came with nice fonts and accessories that are usually very expensive to purchase a la carte.

- 9/8/10

- 1,050

- 953

- 113

I'd like to echo the sentiment - awesome to see the forum pull together and bang out this solution so quick! Brilliant stuff!

awesome job on the templates guys...this is massive. Does @newest dude on the forum have a 3d printer or should we send him a set ??

I let myself be driven by the positive energy and have sent another better version to @dpd3672 . Now the typography should be right.