Interesting. That’s a skeletonized Dandong (Peacock) SL-4801 movement. The SL-4801 is Dandong’s “street legal” copy of the Rolex 4130 movement. And by “street legal” I mean they changed enough about it that Rolex stopped suing them for IP infringement.I forgot to say but have you seen this weird skeletonized 4130?

It's been used in some replicas, it's claimed to be a 4130 but some parts are 7750... any thoughts @dogwood ?

New 4130 Movement, different from SA4130, in new skeleton daytona.

There is a new 4130 movement, the shock and wheels are different. But it looks good in this modified skeleton daytona.forum.replica-watch.info

-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Comprehensive Guide to Clone Movements Found in Rolex Reps

- Thread starter dogwood

- Start date

HardyVancity

Do not accept unsolicited offers

The vs3235 is an excellent movement. If your QC pics showed a healthy amplitude (>250 with lift angle set to 55 degrees), then you probably don’t need to get it serviced right away. But you’ll probably want to get it serviced within a couple of years and then every 5-10 years after that — every 5 years if it’s a daily watch, 10 years if it’s a drawer queen.

Great Post! I find myself in a situation concerning my Super Franken Submariner 16610LN. Built by a reputable watchmaker within this community, features a VR3135 movement. However, it's experiencing a decline in its once-robust amplitude. Given that it's my everyday timepiece, I've entrusted it to @dogwood , relying on his expertise to replace the movement with a DD VS3135 : )The vs3235 is an excellent movement. If your QC pics showed a healthy amplitude (>250 with lift angle set to 55 degrees), then you probably don’t need to get it serviced right away. But you’ll probably want to get it serviced within a couple of years and then every 5-10 years after that — every 5 years if it’s a daily watch, 10 years if it’s a drawer queen.

Daniel_AUT

Getting To Know The Place

- 7/1/24

- 68

- 20

- 8

That’s very healthy.So my DD4130 has an amplitude of 283 and 52.0 degrees on the QC videos, I'm curious

I did this and it’s much better, still a little rough when first starting to thread but then smooth after that. Photo is of what came off on the foam swabs from both the stem and case side. I lubed o ring on stem, crown entry on case and case back.The gritty feeling when threading on the crown could be from grit in the threads. Remove the crown (press the release in the winding position). Then use a foam (not cotton) swap to clean the threads both on the crown tube and inside the crown. Then apply a little bit of o-ring lubricant to the o-rings in the tube and the one in the crown.

Nicely done. I’m often shocked by how dirty crown threads are.

I also had to clean the crown on my clean 126500. After applying some oil it´s possible to unscrew and rescrew it very smooth. Sadly the crown itself is a little sharp edgedNicely done. I’m often shocked by how dirty crown threads are.

Any tips on how to make it more smooth?

Wet and dry sandpaper - go gently as these crowns can be surprisingly soft metal.I also had to clean the crown on my clean 126500. After applying some oil it´s possible to unscrew and rescrew it very smooth. Sadly the crown itself is a little sharp edged

Any tips on how to make it more smooth?

Here is an example for you, after taking the crown guards off this Daytona I smoothed and rounded the crown too.

Daniel_AUT

Getting To Know The Place

- 7/1/24

- 68

- 20

- 8

Most people are also worried and immediately do a service/revision that if they get a watch with VS3235, SA4130, DD3285, etc. that the movement is supposedly dirty from the assembly and assembly of the Chinese and the Chinese do not oil these movements properly Far too little, I have no idea whether that's true or notThe vs3235 is an excellent movement. If your QC pics showed a healthy amplitude (>250 with lift angle set to 55 degrees), then you probably don’t need to get it serviced right away. But you’ll probably want to get it serviced within a couple of years and then every 5-10 years after that — every 5 years if it’s a daily watch, 10 years if it’s a drawer queen.

It’s variable. I’ve seen movements from China that were perfectly assembled, clean, and correctly oiled. I’ve seen others which were filthy and over/under oiled. It’s a roll of the dice.Most people are also worried and immediately do a service/revision that if they get a watch with VS3235, SA4130, DD3285, etc. that the movement is supposedly dirty from the assembly and assembly of the Chinese and the Chinese do not oil these movements properly Far too little, I have no idea whether that's true or not

Daniel_AUT

Getting To Know The Place

- 7/1/24

- 68

- 20

- 8

that is absolutely correct!!!!It’s variable. I’ve seen movements from China that were perfectly assembled, clean, and correctly oiled. I’ve seen others which were filthy and over/under oiled. It’s a roll of the dice.

Daniel_AUT

Getting To Know The Place

- 7/1/24

- 68

- 20

- 8

How long any movement lasts is really down to a question of metallurgy and machining tolerances. With most of the parts in a movement being interchangeable - particularly with clones - what you're left with is the baseplate and the bridges. If those have been machined from good brass and then nickel coated and milled from well callibrated machinery then the answer is - it should last a very long time. But if there's slopiness in the workshop/ factory then parts interefere with one another and wear unevenly - the Mainspring Barrel being a prime suspect for slowly eating through it's arbor/ spindle holes - but even those can be remedied to a certain extent. Likewise the Keyless Works - if components in there are sub-standard (yoke, Click Spring, etc) it'll find an excuse to take a bite out of itself at some point.Which would also be interesting, but that's why these clone works haven't been around for that long. There's just a lack of long-term experience here... how long the works last or the material, whether that's comparable to the lifespan of a GEN

Advise given earlier is a good fit - If it's working - shows good Amplitude/ Winding and time setting feel smooth - leave it for a bit.

But if there are any feelings of grinding/ nasty noises - have the thing to pieces and give a full service.

One of the commonest problems seen with these movements and the ETA clones is de-burring not being done on components and that's a sure fir eway of allowing that component to start eating it's neighbour.

Many people who have the original NOOB 4130, which if you bought in 2020 is now 4 years old... no issuesWhich would also be interesting, but that's why these clone works haven't been around for that long. There's just a lack of long-term experience here... how long the works last or the material, whether that's comparable to the lifespan of a GEN

Same with the VS3135... 4 years old ish at this point and still chugging on strong

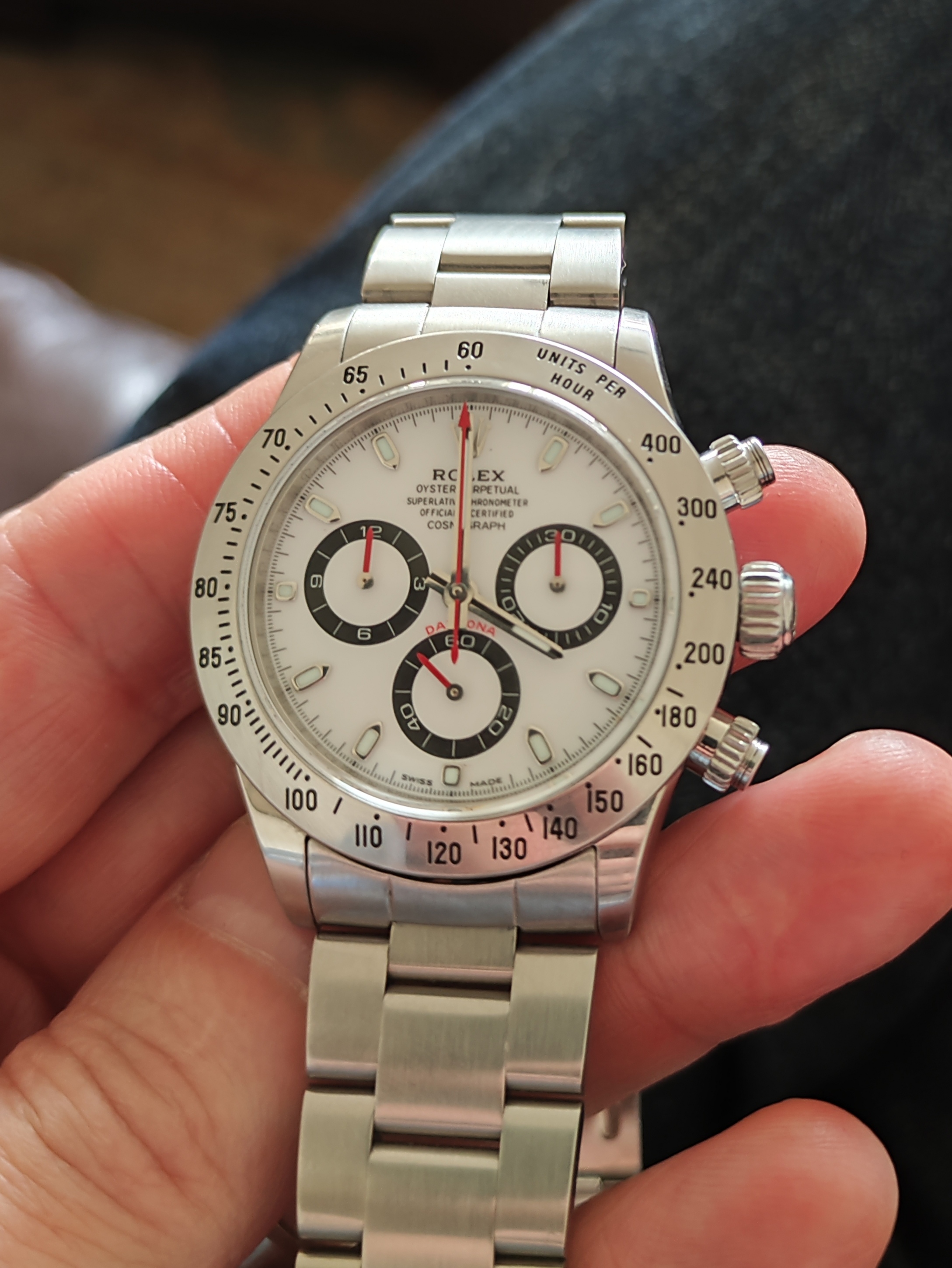

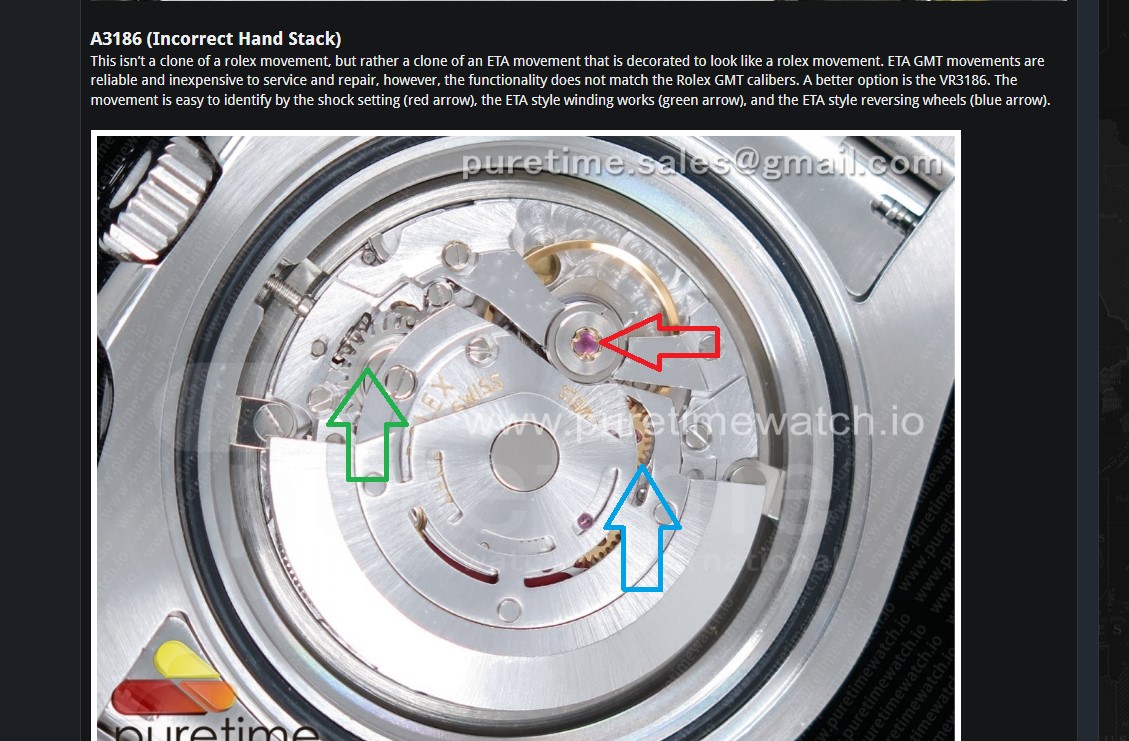

This is the movement in my GMT Pepsi. It of course has stopped working and I am looking for a replacement movement. Is the VR3186 compatible with my case? I have read that it is but I need a movement holder?

Can anyone help me with this? What is the best movement to replace the A3186 movement pictured>

Thanks for the help

Can anyone help me with this? What is the best movement to replace the A3186 movement pictured>

Thanks for the help

This is the movement in my GMT Pepsi. It of course has stopped working and I am looking for a replacement movement. Is the VR3186 compatible with my case? I have read that it is but I need a movement holder?

Can anyone help me with this? What is the best movement to replace the A3186 movement pictured>

Thanks for the help

You should be able to replace this movement with a 2836 eta clone. A vr3187 will not work for you.