There are desktop hobbiest diode lasers out there (brands are: Xtool, atomstack, Sculpfun). They specialize in diode lasers which are great at engraving wood, plastic, cardboard etc, but suck at actually engraving metal. They can mark metal which is really annealing the metal. The spot size of lasers are these are sub 1mm (some are .05mm x .08mm which is small but its rectangular). Fiber lasers can cut metal. But fiber lasers are $1.2K+ however they can have almost .01mm x.01mm spot size which is crazy small.

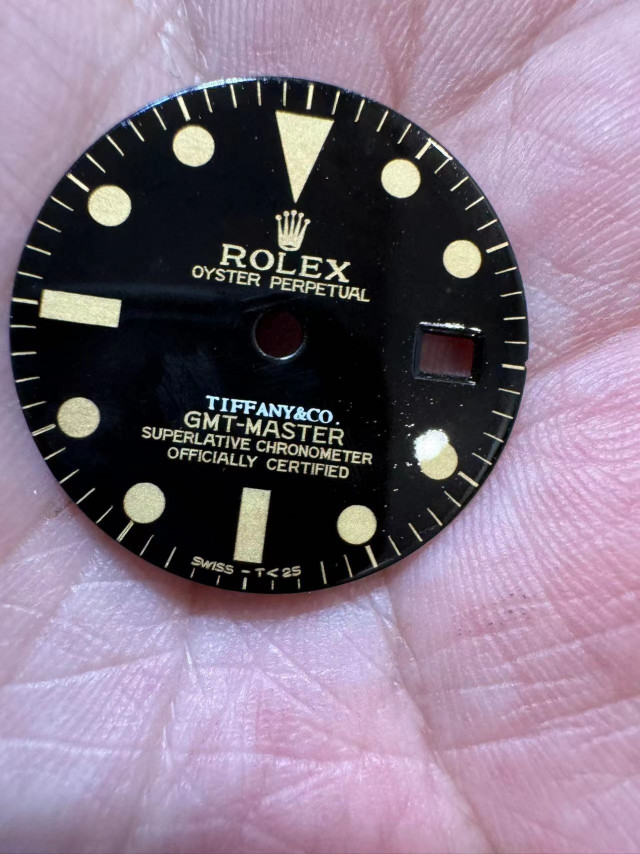

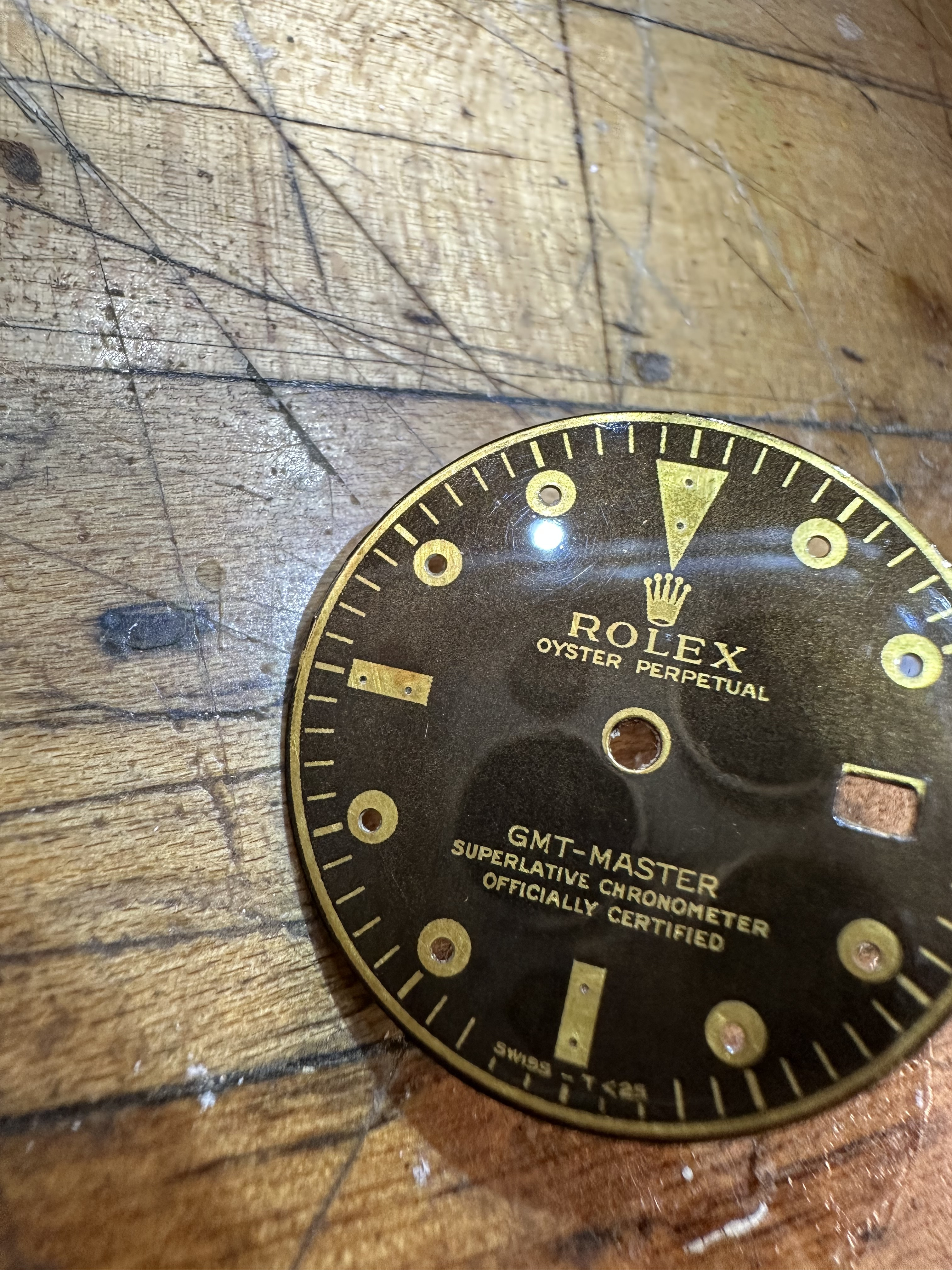

About 1.5 years ago the diode laser market released an infrared laser. This kind of laser has the ability to remove rust from metal. Rust is really oxidation. The infrared lasers also have a spot size of .03mm x .03mm which is super tiny and the size would be great for what we are doing. These machines also have movement accuracy as low as .01mm! So I have a strong suspicion that one of these hobbiest lasers + the infrared laser module could remove the oxidation from the dials (aka the way I have been making my gilt dials for now). It won't be able to actually engrave a metal plated dial (aka it wont be able to engrave black zinc coated brass to reveal the brass).

I know cost is relative but you can buy a used diode laser engrave for $150ish (refurbished on amazon, ebay, or used on facebook market place etc) and buy an infrared laser module for $500ish. So for $650 you could potentially be blasting out tropical dials or even black oxidized dials.

After i wrote all that I remembered someone already did that and and i feel dumb as

this was already mentioned awhile back on a thread i started. The member just needed to dial in his settings. I don't know if he ever followed up on it. You can see in the shine in that specific post and the post above it. I feel dumb for not searching within my own threads for guidance ha.

So you could feasible do this at home for $650ish. You could also use it to laser designs on the caseback too.

[url=https://clickpix.org/image/AB1108EE-3366-47E0-8E6A-656ACA6EC84C.KRGWii]

[url=https://clickpix.org/image/AB1108EE-3366-47E0-8E6A-656ACA6EC84C.KRGWii]