- 23/6/17

- 2,226

- 2,495

- 113

Nice! While McGyver-ing sounds fun, I opted to order a smooth SS 36mm datejust bezel from AliXYou can use any fixed metal bezel that is made to fit a 29.5mm crystal and double as a crystal retaining ring. For example a fluted or smooth bezel from a 36mm datejust or day-date. These can be found on AliExpress.

If you want to make your own, take the retaining ring to a hardware or big box store and find a pipe (thin wall metal or PVC) that has slightly larger inside diameter. Cut off about a 2" piece then cut a slit in it and remove a small perpendicular section. Use a hose clamp or zip ties to close the slit. It can be spot welded or epoxied (if PVC) or just used clamped. A vise is best when using a taller die like this would be.

Nice. That ID has to be off (not uncommon) because the top step of a 29.5mm gen-spec crystal is 30.4mm and the bezel has to clear that plus the gasket thickness.Nice! While McGyver-ing sounds fun, I opted to order a smooth SS 36mm datejust bezel from AliXThe inner diameter is 30.3. Thanks again for the help.

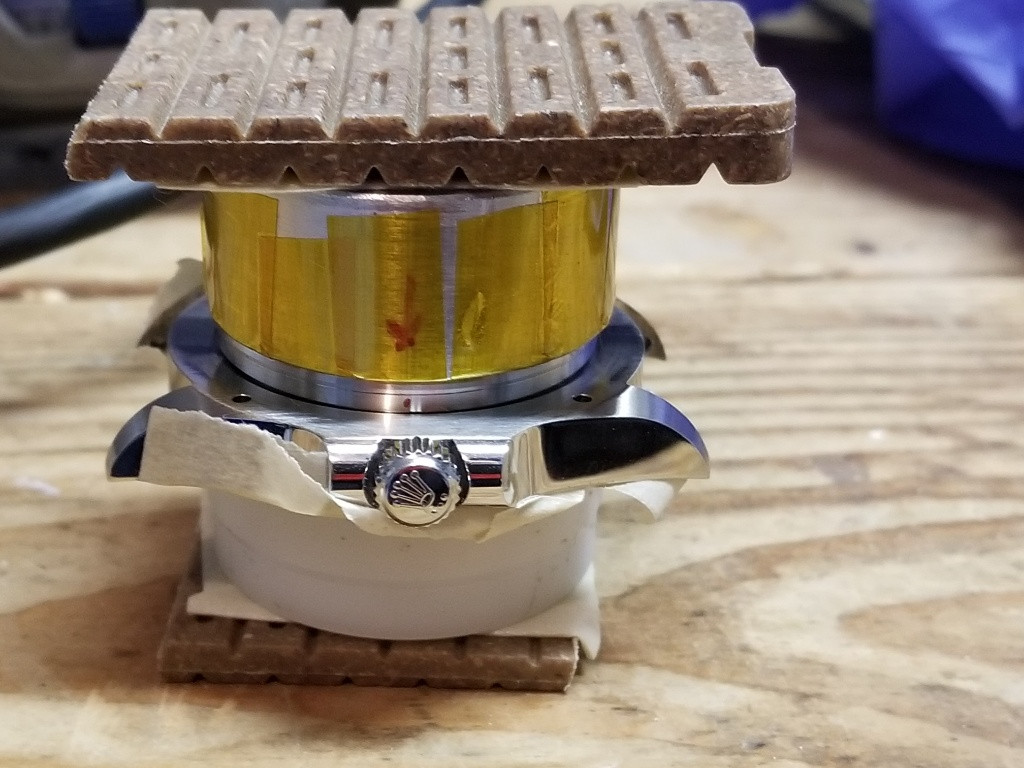

like this Bro?You can use any fixed metal bezel that is made to fit a 29.5mm crystal and double as a crystal retaining ring. For example a fluted or smooth bezel from a 36mm datejust or day-date. These can be found on AliExpress.

If you want to make your own, take the retaining ring to a hardware or big box store and find a pipe (thin wall metal or PVC) that has slightly larger inside diameter. Cut off about a 2" piece then cut a slit in it and remove a small perpendicular section. Use a hose clamp or zip ties to close the slit. It can be spot welded or epoxied (if PVC) or just used clamped.

Alternately two long cuts can be made on opposite sides (cut the pipe in half lengthwise), and material removed by sanding on a flat surface. Then clamp or adhere the halves together. Neatness doesn't count and it's only the inner diameter that matters.

A vise is best when using a taller die like this would be.

That's the one I ordered

More pics with the sunlight of this beauty pleaseRealistic expectations for under 300quid to my door.

Yes that should work. See my comment above about the ID, which has to be stated wrong by the vendor.

Yep those are the ones. I have a BP dial in a JF v2 16610.Agree, BP used to throw great dials.

Here my ARF based franken 16610LV with BP dial.

The R of "Oyster" well placed under the Rolex's R right leg, seems period correct for mid 2000s gen productions as far as I remember.

Yes that should work. See my comment above about the ID, which has to be stated wrong by the vendor.

Peel those Stickers off Bro

You can hand sand the 36mm bezel to increase the ID. Wrap some 320 or 400 grit paper around a small round tool handle, place it on the material to be removed and turn it around and around like a hand crank. I use this technique often to increase various ID's.I just read the reviews and there's someone complaining that it doesn't fit a DJ 36

Anyway... I'll know when it gets here.

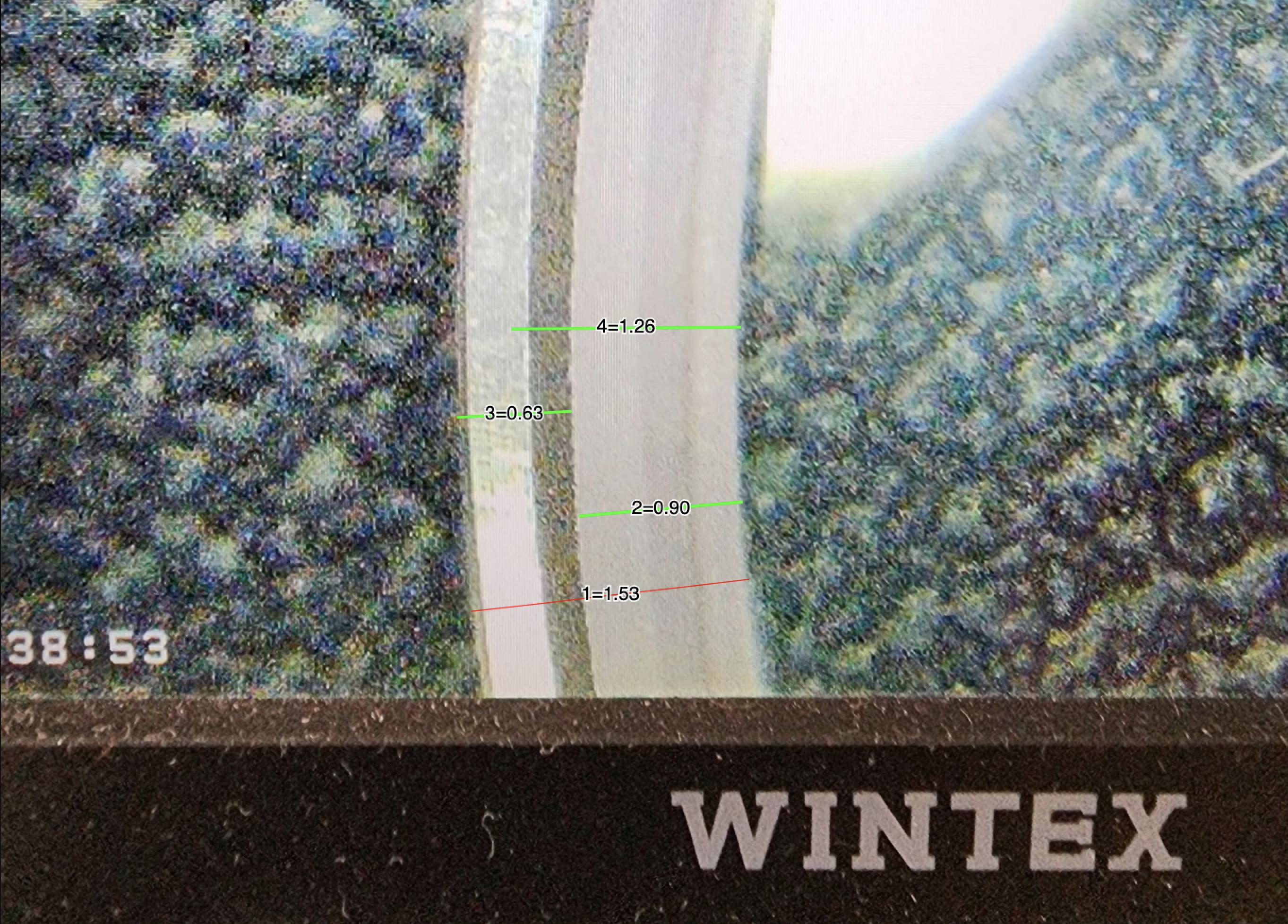

In the mean time I measured the retaining ring outer diameter and it's 31.93. The gen crystal is 30.4 so that means that the ring + gasket is 1.53.

I took a pic of the assembled crystal + gasket + ring under the microscope and did some measuring.

I think the sweet spot for the ring die would be 31.65ish (30.4 + 1.25) so we are pressing in the center of the retaining ring. I think it should be simple enough to 3D print this too.

I hope I don't have to hammer this back in haha, at least judging by how easy it came off together with the bezel.You can hand sand the 36mm bezel to increase the ID. Wrap some 320 or 400 grit paper around a small round tool handle, place it on the material to be removed and turn it around and around like a hand crank. I use this technique often to increase various ID's.

A die really needs to metal or thick PVC for most retaining ring re-presses. I think a 3D printed one may not cut it. Would be great if it does but I've had a few that required beating on the vise arm with a 4 lb sledge hammer to close the final 1mm gap between the retaining ring and the case.

Scenarios like that arise sometimes when using gen gaskets which are usually thicker and always more dense that the cheap rep gaskets. Gen gaskets (or even Clark's gaskets which are also thicker) sometimes need to be thinned until they can can be force fit. I routinely thin any new Daytona crystal gasket when replacing a ceramic bezel. It reduces the pucker factor a few notches, haha.

Crystal gasket shave - DIY

I’m way behind on this, sorry.

For a stock/OOTB 16610ln, ARF or BP?

i would choose BP for the LN.I’m way behind on this, sorry.

For a stock/OOTB 16610ln, ARF or BP?