-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

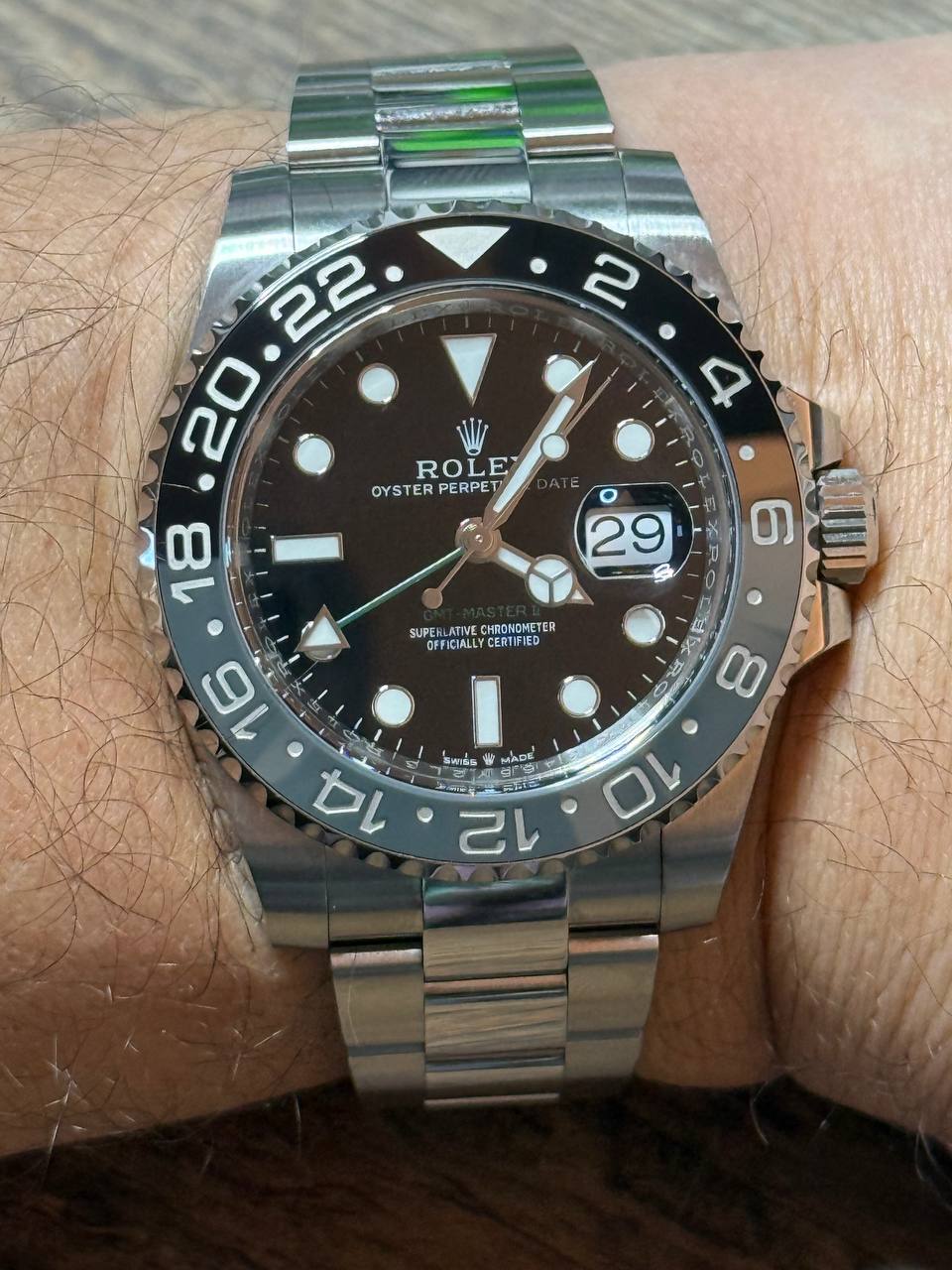

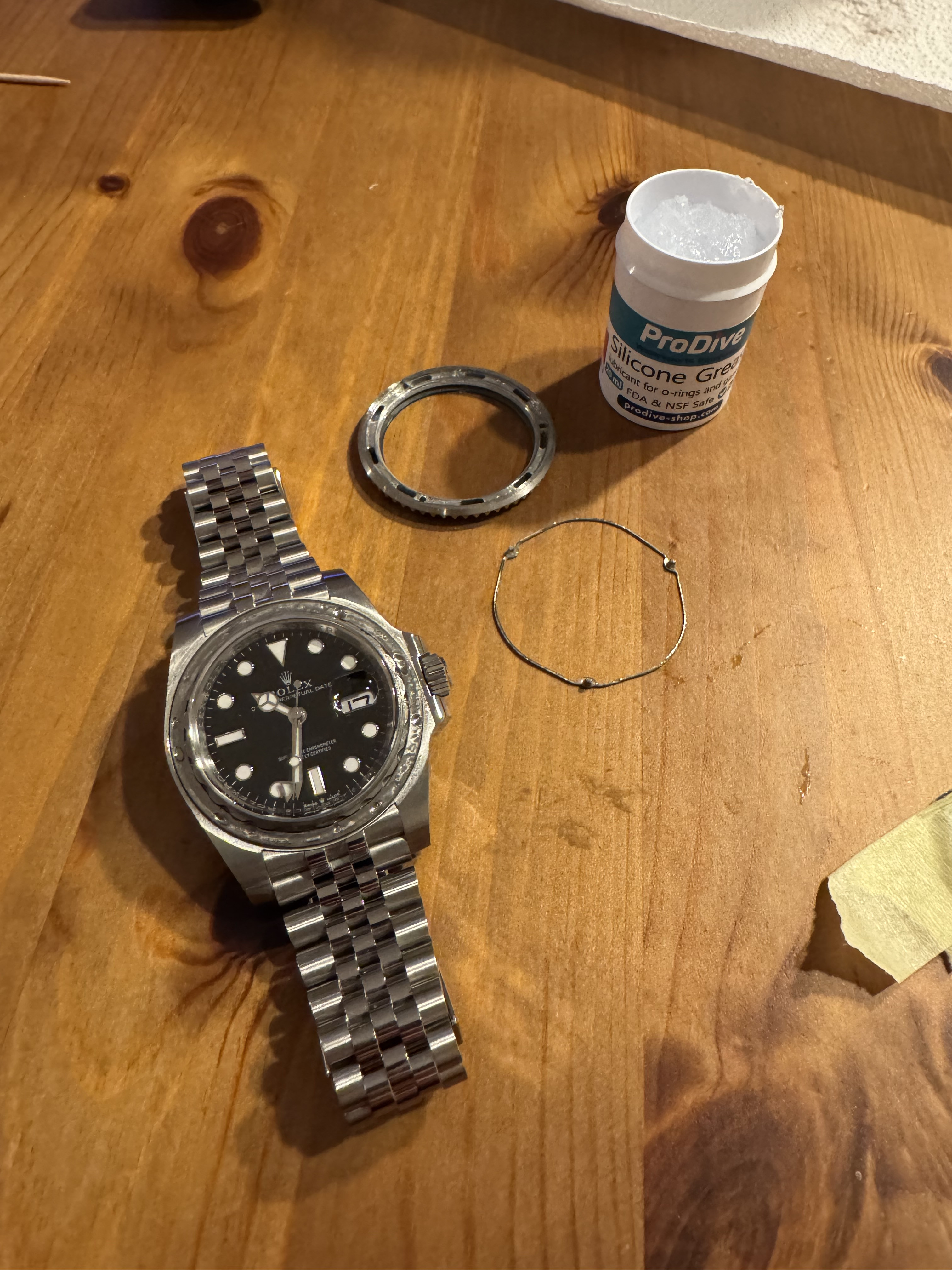

Tutorial: How to fix the Bezel on a CLEAN GMT Master 2

- Thread starter derjenigewelcher

- Start date

Hogge

Getting To Know The Place

- 29/3/21

- 29

- 34

- 13

Hogge

Getting To Know The Place

- 29/3/21

- 29

- 34

- 13

*ed

I have a brand new CLEAN GMT Master 2 Pepsi on the way to me.

I am thinking about makeing a A-Z Video from this mod to explain it with a video.

If you are interested in this, just like this post.

I am thinking about makeing a A-Z Video from this mod to explain it with a video.

If you are interested in this, just like this post.

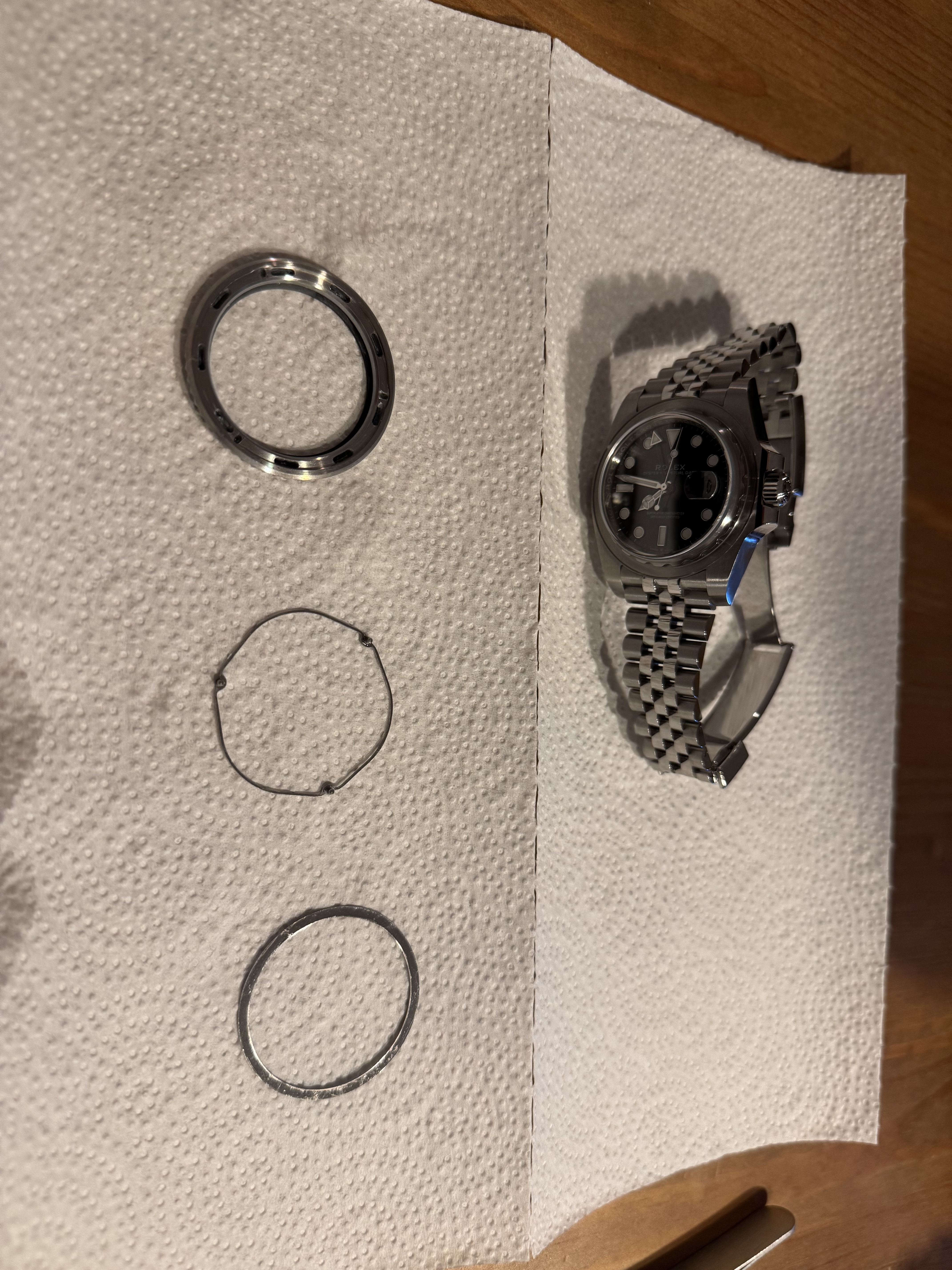

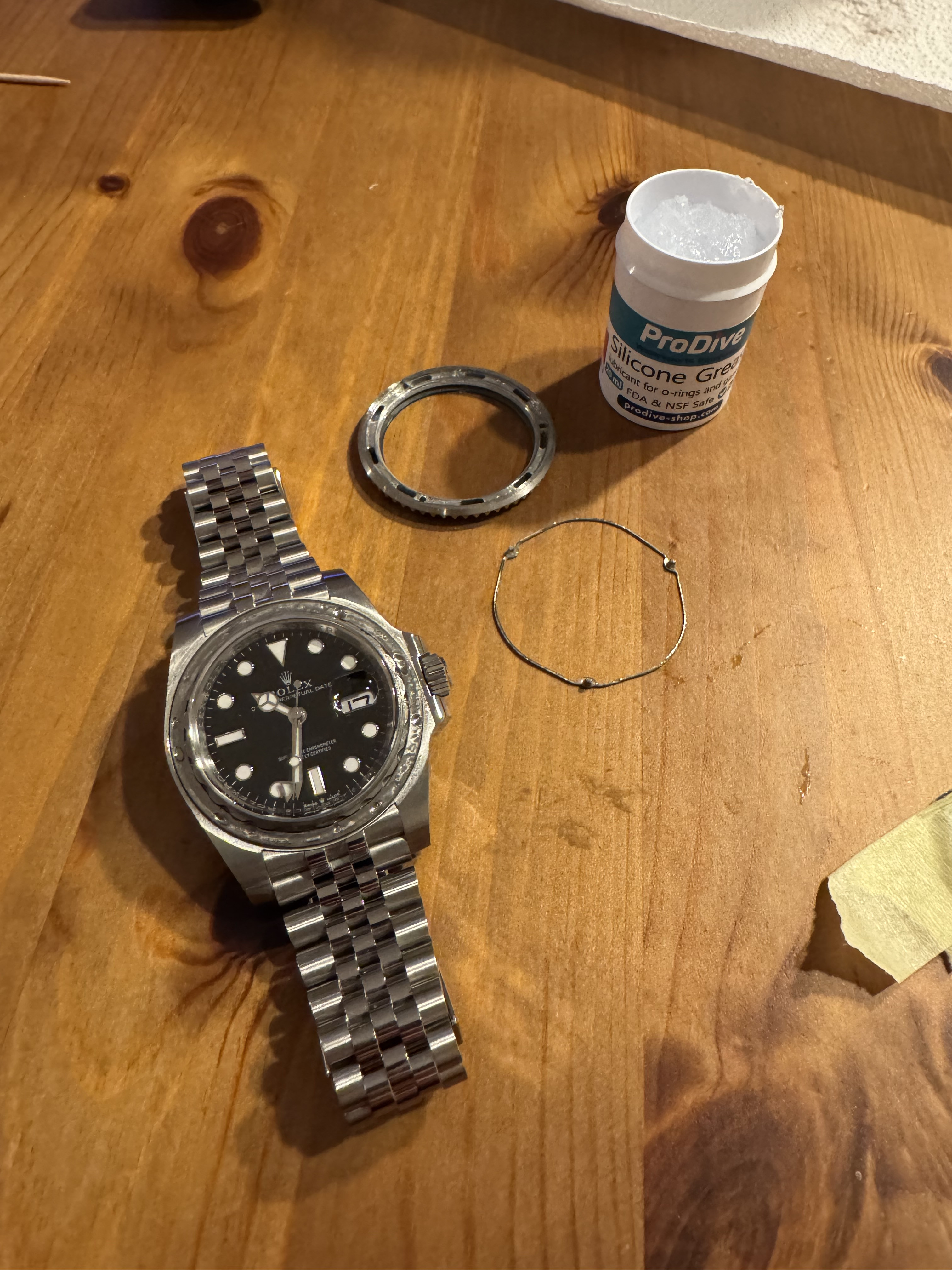

I have a Problem now. I did exactly as said in the instructions. I genlty popped the bezel off and degreased most of the grease. I then applied this silicone grease and reapplied the bezel. But the bezel turns way too hard and harsh. The click spring and the other Parts Are Not damaged. Can anyone help?

Hi mateI have a Problem now. I did exactly as said in the instructions. I genlty popped the bezel off and degreased most of the grease. I then applied this silicone grease and reapplied the bezel. But the bezel turns way too hard and harsh. The click spring and the other Parts Are Not damaged. Can anyone help?

Did you maybe damage the hyrtel ring?

Is the flat washer not 100% on the case, so it has tension vertical wise?

Did you pull out the spring to much? Those are the ideas I have.

@KJ2020 may have more

- 12/3/18

- 37,544

- 80,345

- 113

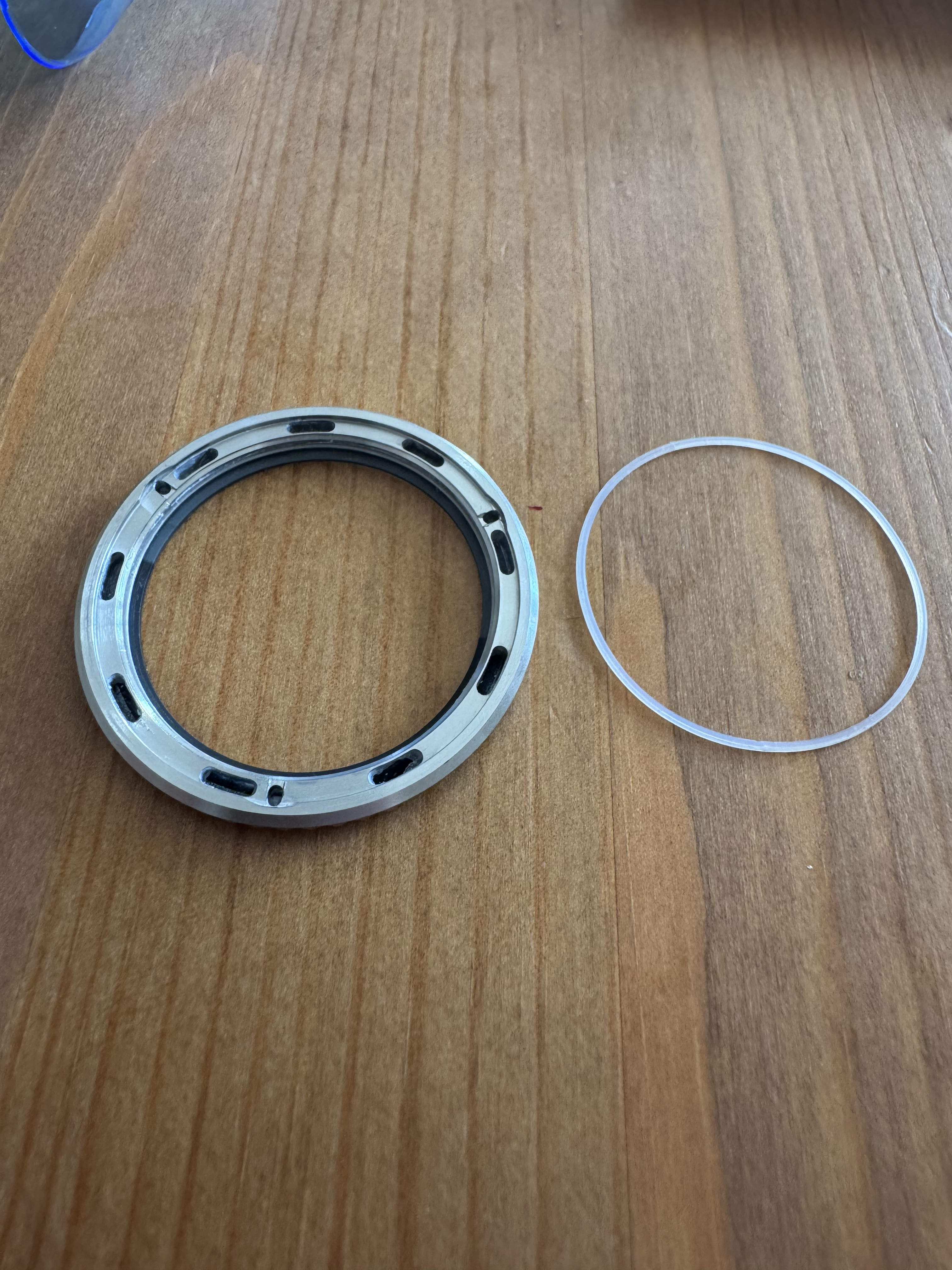

Try carefully removing the bezel gasket (hytrel ring) and then install all the rest of the parts normally. If the bezel rotates freely, then you can suspect the bezel gasket and we will go from there.I have a Problem now. I did exactly as said in the instructions. I genlty popped the bezel off and degreased most of the grease. I then applied this silicone grease and reapplied the bezel. But the bezel turns way too hard and harsh. The click spring and the other Parts Are Not damaged. Can anyone help?

If it still is tight, you've may have the click spring too tight. Sometimes a section of the spring between 2 pins can catch on a retaining ring tooth if it's too tight. Also make sure all the pins can move freely within their slots. I had one slot last week that needed some light sanding to open it up a little. It actually broke a pin off after it was caught up. I was able to epoxy the pin back into its base on the click ring.

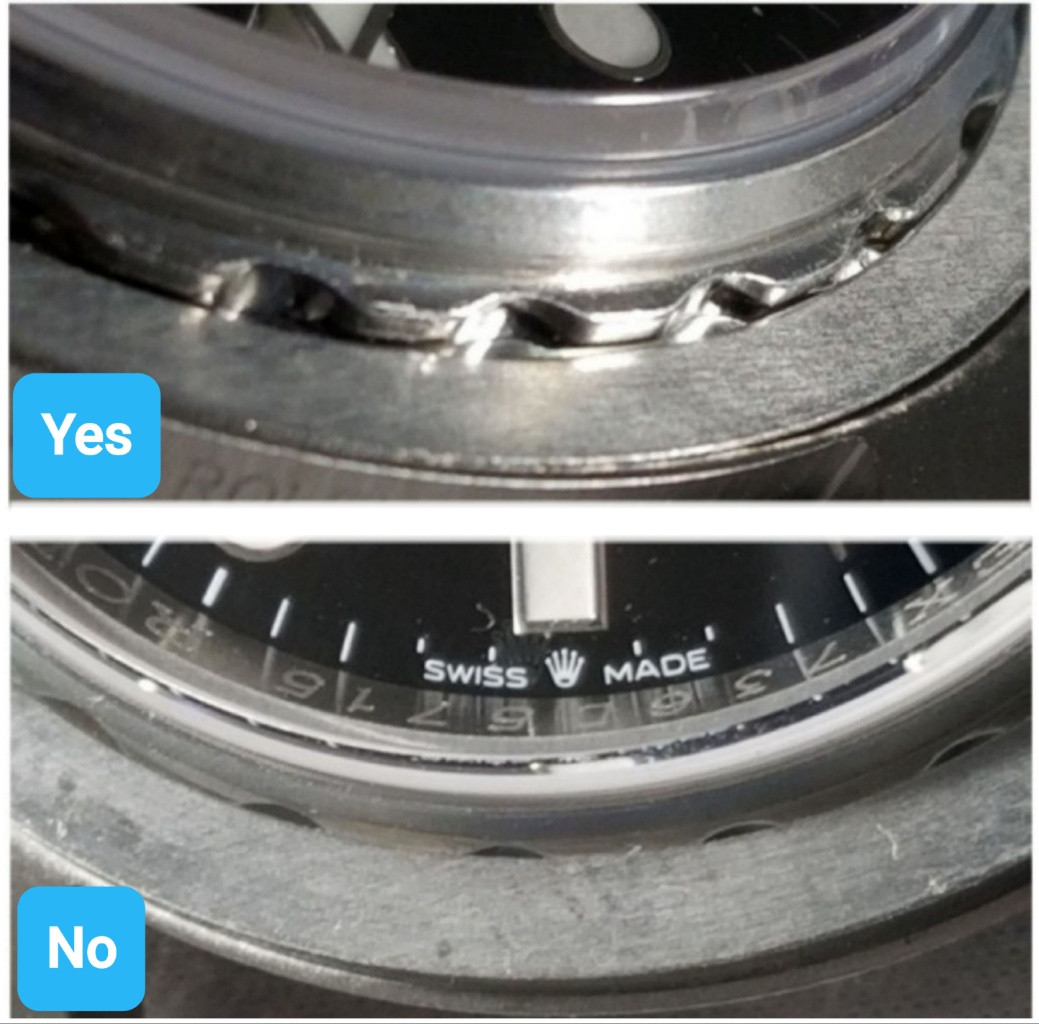

To loosen the click ring a little, flatten out the curve between each set of 2 pins a bit. Then place the click on top of the washer and assess its shape. All 3 of the pin bases should snugly contact a scallop (indent between teeth) on the retaining ring but no part of the spring between the pins should contact any of the teeth.

Once you have optimal bends in the 3 parts of the spring between the pins, place the no gasket bezel on the click ring and test its rotation. If the rotation is tight, loosen the click ring more (flatten the curves between pins). If the rotation is loose, increase the curves between the pins. Keep adjusting til it gets closest to satisfactory. A good way to increase the curve between pins is to use a round object about 1/2" in diameter, like a round tool handle, a small vial, a dowel stick, etc. Place the round object inside the ring, inside a curve and gently bend the spring around the object. This will put a nice curved bend in it. Once you have satisfactory rotation, put the bezel gasket back in and reseat the bezel.

If all the click spring bending doesn't help, take a close look at your washer. There is a small step in the case surrounding the retaining ring teeth that part of the washer's inner perimeter can get stuck on making it sit higher at that location. The washer should fit entirely outside of that step so you may need to sand its interior and or its exterior so it fits entirely inside the case detent.

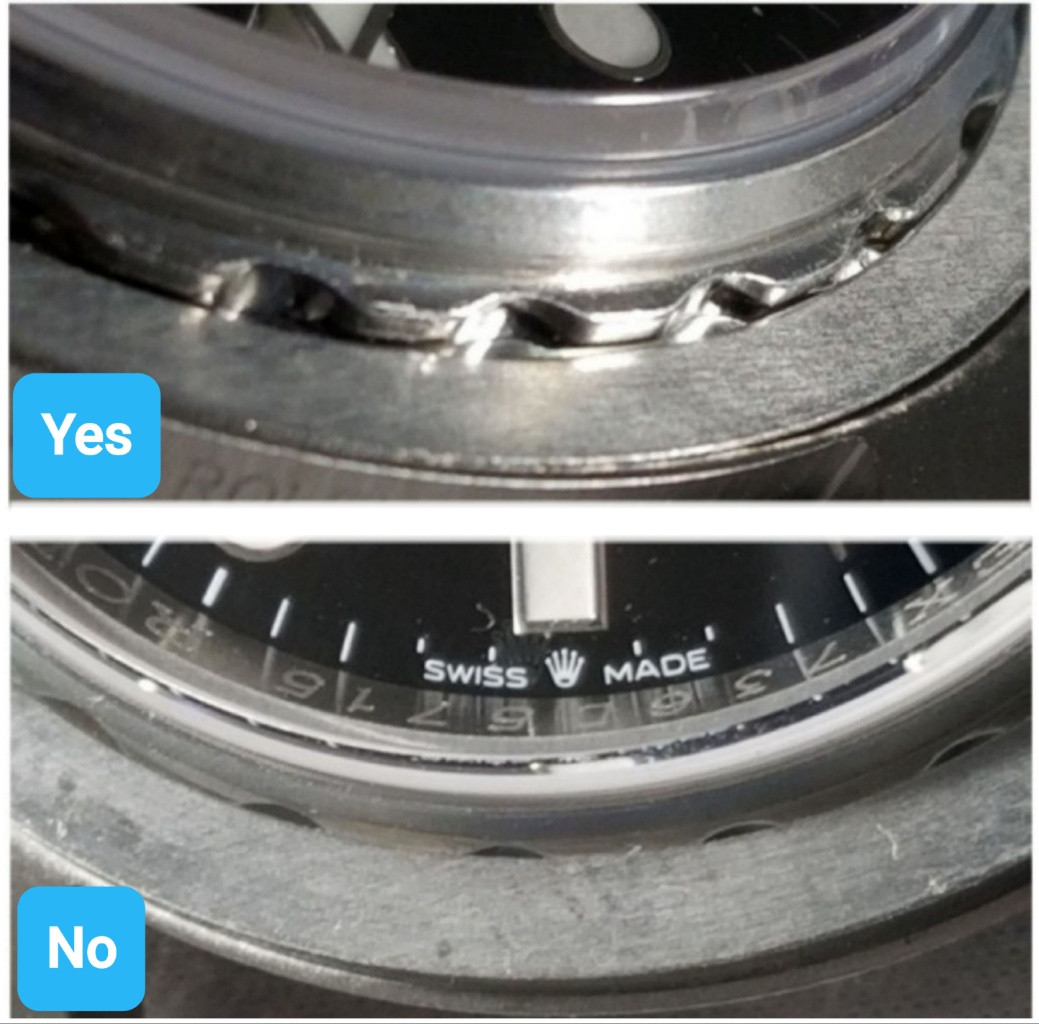

Red arrow looks OK, blue arrow not so much

Last edited:

Thats What i thought but i cannot Remove it somehow. You think it is damaged?Its inserted under the bezel, S M A L L and THIN gasket ring, i can see it on youe photos

If you cannot tell if it is, it probably is. Its a very thin gasket and gets damaged most of rhe times. Remove with tweezers and insert fishing lineThats What i thought but i cannot Remove it somehow. You think it is damaged?

You may read the whole thread. All is detailed explained. Its enough that the gasket is minir squeezed to fail function after removing. Plus i dont see in this scale if its inserted the corect side or 180 fals

- 12/3/18

- 37,544

- 80,345

- 113

Re-read my last post. You've completed Step 1. Proceed with the rest of the suggestions. The hytrel ring goes back in the bezel groove from where you took it out but not until later in your troubleshooting. It does not look damaged and should be OK to reuse.

Try carefully removing the bezel gasket (hytrel ring) and then install all the rest of the parts normally. If the bezel rotates freely, then you can suspect the bezel gasket and we will go from there.

If it still is tight, you've may have the click spring too tight. Sometimes a section of the spring between 2 pins can catch on a retaining ring tooth if it's too tight. Also make sure all the pins can move freely within their slots. I had one slot last week that needed some light sanding to open it up a little. It actually broke a pin off after it was caught up. I was able to epoxy the pin back into its base on the click ring.

To loosen the click ring a little, flatten out the curve between each set of 2 pins a bit. Then place the click on top of the washer and assess its shape. All 3 of the pin bases should snugly contact a scallop (indent between teeth) on the retaining ring but no part of the spring between the pins should contact any of the teeth.

Once you have optimal bends in the 3 parts of the spring between the pins, place the no gasket bezel on the click ring and test its rotation. If the rotation is tight, loosen the click ring more (flatten the curves between pins). If the rotation is loose, increase the curves between the pins. Keep adjusting til it gets closest to satisfactory. A good way to increase the curve between pins is to use a round object about 1/2" in diameter, like a round tool handle, a small vial, a dowel stick, etc. Place the round object inside the ring, inside a curve and gently bend the spring around the object. This will put a nice curved bend in it. Once you have satisfactory rotation, put the bezel gasket back in and reseat the bezel.

If all the click spring bending doesn't help, take a close look at your washer. There is a small step in the case surrounding the retaining ring teeth that part of the washer's inner perimeter can get stuck on making it sit higher at that location. The washer should fit entirely outside of that step so you may need to sand its interior and or its exterior so it fits entirely inside the case detent.

Red arrow looks OK, blue arrow not so much

Thank you very much! Here is the Update: I carefully removed the hyrtel ring and installed the bezel without it. I was able to move the bezel (still felt Rough when Moving), but the bezel had a lot more play an popped off super easy. Now i sanded down the immer diameter of the metal ring. I measured everything and Now my metal ring diameter is wide enough to sit flush in the Groove. I popped the bezel back on (with hyrtel ring) and in the beginning it felt better, but After a Full Rotation it got worse again and it was super hard to move the bezel. I am having a breakdown atmRe-read my last post. You've completed Step 1. Proceed with the rest of the suggestions. The hytrel ring goes back in the bezel groove from where you took it out but not until later in your troubleshooting. It does not look damaged and should be OK to reuse.

- 12/3/18

- 37,544

- 80,345

- 113

Did you assess the shape of the click ring and its fit around the retaining ring?Thank you very much! Here is the Update: I carefully removed the hyrtel ring and installed the bezel without it. I was able to move the bezel (still felt Rough when Moving), but the bezel had a lot more play an popped off super easy. Now i sanded down the immer diameter of the metal ring. I measured everything and Now my metal ring diameter is wide enough to sit flush in the Groove. I popped the bezel back on (with hyrtel ring) and in the beginning it felt better, but After a Full Rotation it got worse again and it was super hard to move the bezel. I am having a breakdown atm

Yes. The Click Ring fits perfectly in my opinion. The parts between the pins dont touch the bezel, i can spin freelyDid you assess the shape of the click ring and its fit around the retaining ring?

- 19/12/24

- 85

- 48

- 18

If you opened up the ID of the washer/spacer that sits under the spring, make sure there aren't any burs on it. I taped mine down to a flat surface and polished each side. I also took the 3 pin spring, put it upside down into some hard foam and polished the back of that as well. Made everything silky smooth when it went back together.

You also want to make sure to re-apply some kind of grease to each part. Just not as much as Clean uses.

You also want to make sure to re-apply some kind of grease to each part. Just not as much as Clean uses.

Last edited: