-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

haha yeah it was so cold outside and i was too lazy to go out hahah my wife wasn't happy that i turned on the drill yesterday at 10pm... there was just some trouble hahahaYou freehand the lugholes

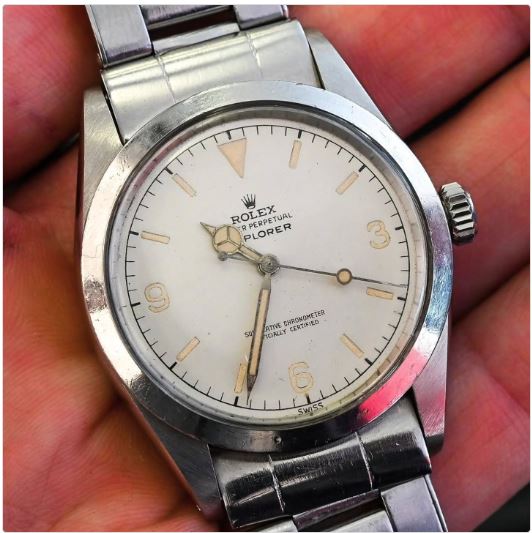

GEN mid 60's fat font frog foot

Extremely fat holy molyGEN mid 60's fat font frog foot

Now this one reminds me of a failed 5513 dial from that dodgy @Karbon74

I wish I sucked that bad ...

automatico

Known Member

- 5/10/11

- 122

- 246

- 43

I use a dremel and its workstation.

I've had good luck with a relatively low cost ($90) Harbor Freight bench type drill press.

Also have a Sherline miniature milling machine but with the screw feed, it is hard to tell how the bit is cutting (it has no 'feel') and this leads to 'crowding the bit'. 'Crowding the bit' leads to overheating/breaking.

For blind (no hole) rounded case sides like later DJ etc. I use a 'ball nose' end mill cutter to start the holes because the rounded end does not 'walk' on rounded surfaces like a regular drill bit. After the hole is started, I go with a regular drill bit.

Example of a 'ball nose' end mill cutter...eBay item number: 395664379799

I've had good luck with a relatively low cost ($90) Harbor Freight bench type drill press.

Also have a Sherline miniature milling machine but with the screw feed, it is hard to tell how the bit is cutting (it has no 'feel') and this leads to 'crowding the bit'. 'Crowding the bit' leads to overheating/breaking.

For blind (no hole) rounded case sides like later DJ etc. I use a 'ball nose' end mill cutter to start the holes because the rounded end does not 'walk' on rounded surfaces like a regular drill bit. After the hole is started, I go with a regular drill bit.

Example of a 'ball nose' end mill cutter...eBay item number: 395664379799

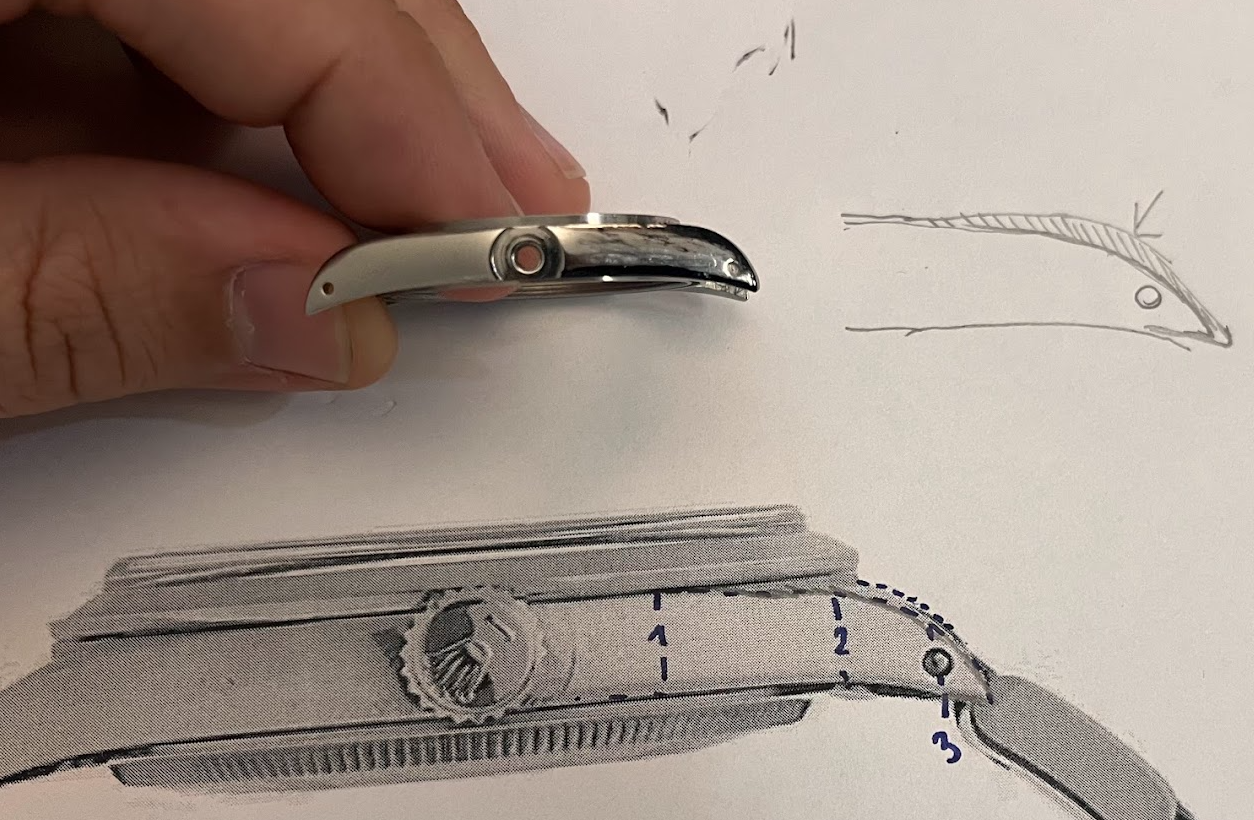

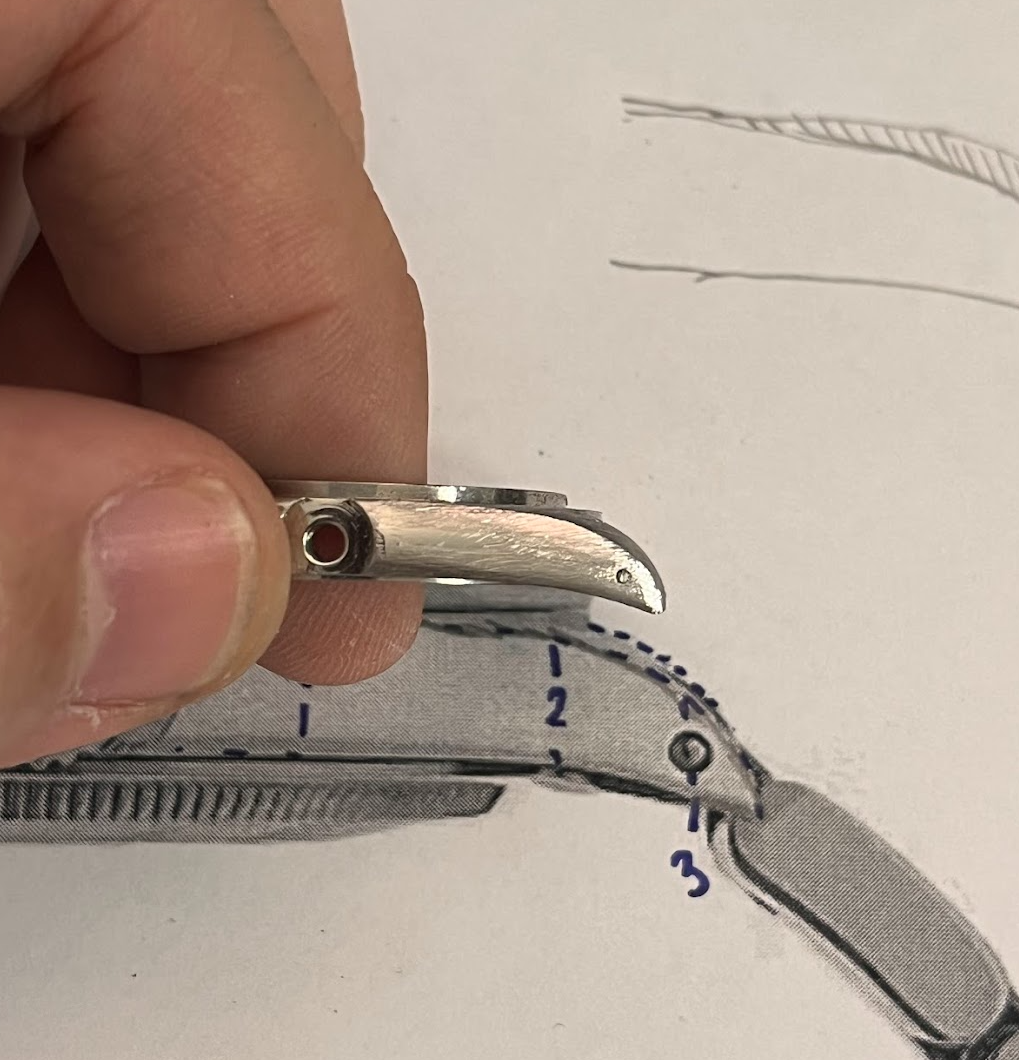

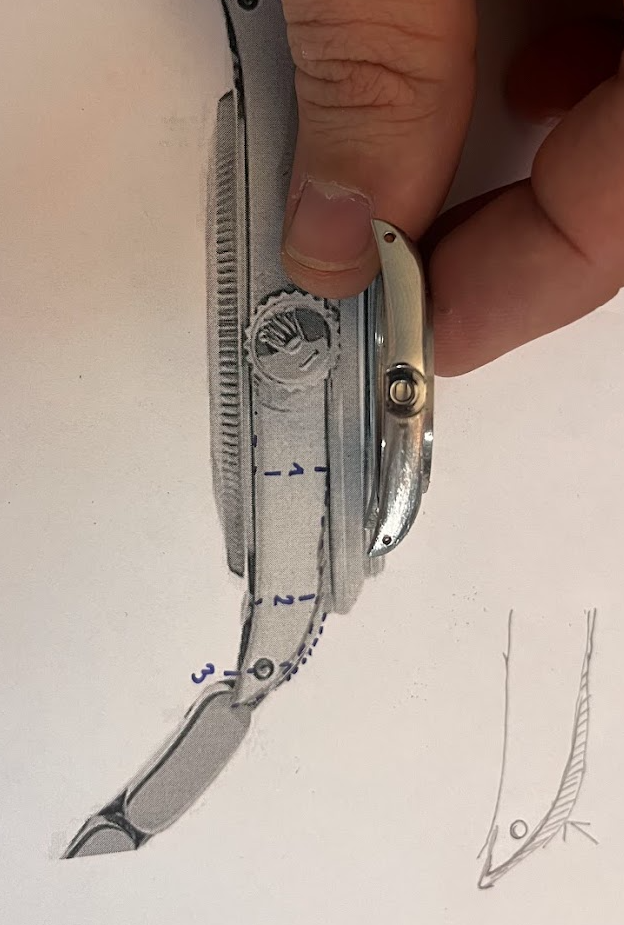

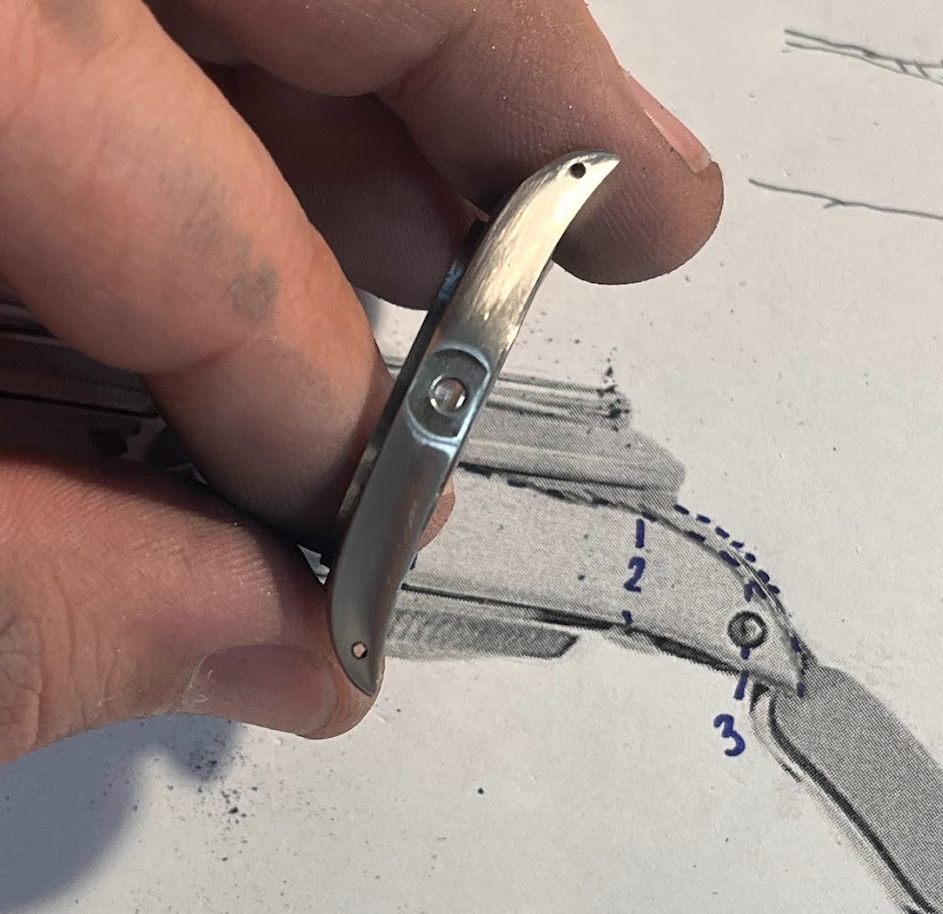

That is how I do it as well. But I also remove material at the top with a lathe. Postion 1 is to high for a 1016 and the crown is out of the middle. Better use your 16000 as base for a 1016. There the dimension looks more correct.

But anyhow: nice work and beautiful result!

I think the 1016 is thicker as my 16000 case. Anyway it would be a good base without any work. Will try it out someday.That is how I do it as well. But I also remove material at the top with a lathe. Postion 1 is to high for a 1016 and the crown is out of the middle. Better use your 16000 as base for a 1016. There the dimension looks more correct.

But anyhow: nice work and beautiful result!