-

Tired of adverts on RWI? - Subscribe by clicking HERE and PMing Trailboss for instructions and they will magically go away!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The 1016: The Under Appreciated Thread

- Thread starter ebzen02

- Start date

Buy both - 'tis the season to be jolly, tra la la la la, la la, la lahhh.I treated my jkf oyster with an overnight stay in Nivea liquid cream. Perfect outcome. Just did the same with the rivet bracelet. Let's see.

I need to buy some IPA, not the beer version

Afetr all.

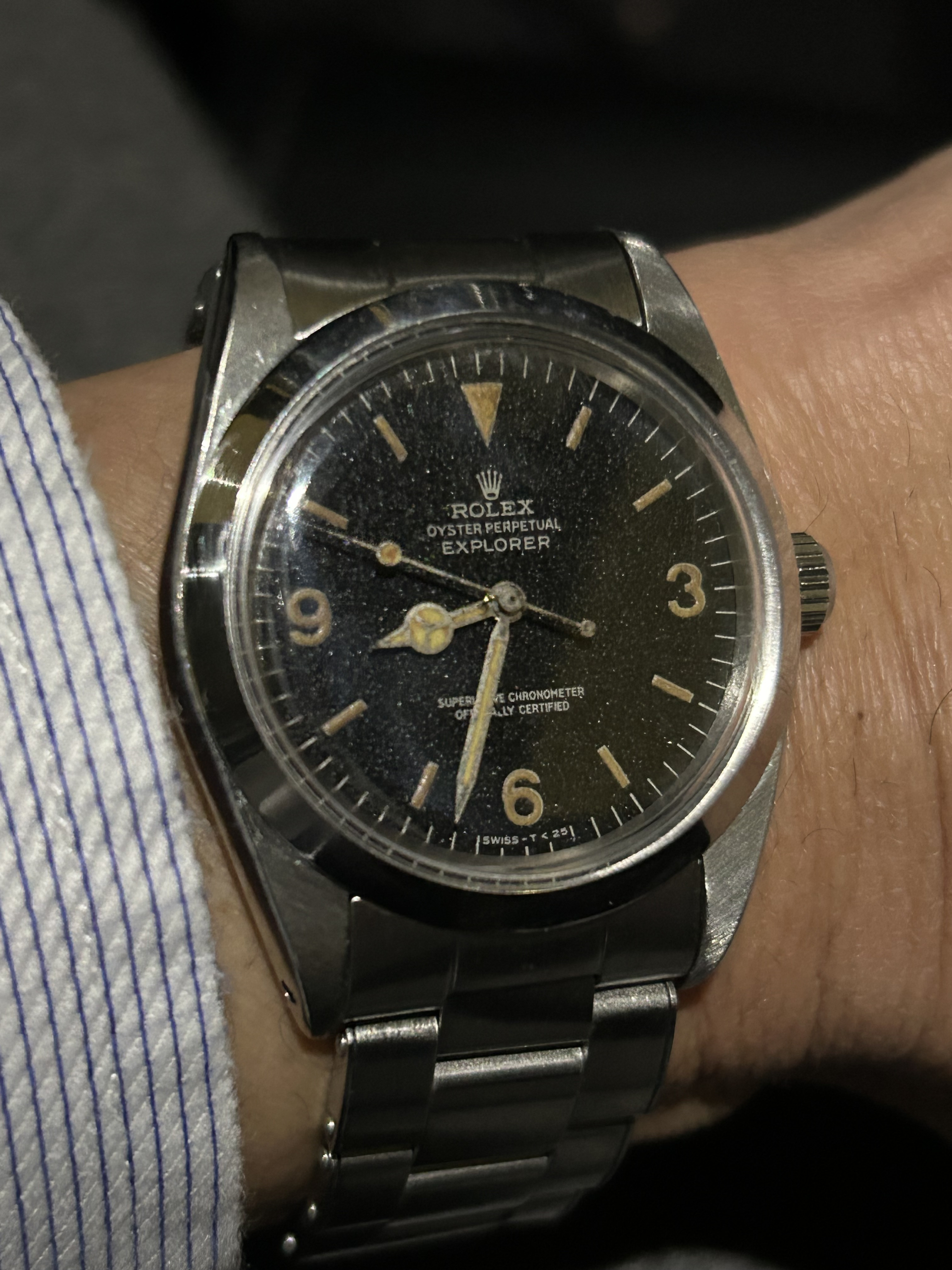

That's a "fat font" dial - on first impression. But you're 100% right - something doesn't look right.

Fat Font Rolex 1016 Explorer I – Hairspring

I know it wasn’t first on top of Everest and I know shouldn’t really consider paying double for a slightly altered dial. Yet, here I am. Ten small years into this hobby and the #rolexero have me convinced that this is a gorgeous practical daily that I must own one day. The force is strong with...

hairspring.com

hairspring.com

hands proportion and their lume colorGen. however something looks off.

the placement of the text....the size of the numerals' ?

what you think?

numerals seem fatter than they should be

?

looks like a botched up restoration

I thought fat font at first as well but the other stick indices are way to thick. It must have been refinished dial because I have yet to see a frogfoot rep dialThat's a "fat font" dial - on first impression. But you're 100% right - something doesn't look right.

Fat Font Rolex 1016 Explorer I – Hairspring

I know it wasn’t first on top of Everest and I know shouldn’t really consider paying double for a slightly altered dial. Yet, here I am. Ten small years into this hobby and the #rolexero have me convinced that this is a gorgeous practical daily that I must own one day. The force is strong with...hairspring.com

Yes. Exactly that. Visually, it erks doesn't it? Fat font still had standard indices and yet, with that one . . . All the alarms are sounding.I thought fat font at first as well but the other stick indices are way to thick. It must have been refinished dial because I have yet to see a frogfoot rep dial

"Fat Font" dial - ultra-rare - someone's got too clever and figured they could 'upgrade' to it and make the extra money.

Oh, well, someone paid extra money for it - and is flexing it.

Somewhat ironic, and ressuring - that we, the brethren of this thread are possibly amongst the best qualified to call a 'fake' when we see it!

Even Sothebys might have missed that one.

so, she completed her Nivea bath.

It's true that the 1016 really shines on a steel bracelet.

with a strap it almost looks dainty. On steel, it looks rugged and "massive"

It's true that the 1016 really shines on a steel bracelet.

with a strap it almost looks dainty. On steel, it looks rugged and "massive"

any thoughts on this laser engraver?

Just found this amazing item on AliExpress. Check it out! US $144.75 43% Off | Wainlux Laser Engraver K6 Mark Printer Cutter Woodworking Machines Plastic 3000mw Bluetooth Mini Laser Engraving Marking Machine

I asked them. It cannot engrave SS directly (you need the 10W version) but it could certainly cut vinyl

Just found this amazing item on AliExpress. Check it out! US $144.75 43% Off | Wainlux Laser Engraver K6 Mark Printer Cutter Woodworking Machines Plastic 3000mw Bluetooth Mini Laser Engraving Marking Machine

I asked them. It cannot engrave SS directly (you need the 10W version) but it could certainly cut vinyl

- 4/10/22

- 538

- 938

- 93

I think you Can use it with a brass black plainted plate, with 3watt you Can easy remove the paint, if you want to use the laser engraving to do gilt dial it could work.any thoughts on this laser engraver?

Just found this amazing item on AliExpress. Check it out! US $144.75 43% Off | Wainlux Laser Engraver K6 Mark Printer Cutter Woodworking Machines Plastic 3000mw Bluetooth Mini Laser Engraving Marking Machine

I asked them. It cannot engrave SS directly (you need the 10W version) but it could certainly cut vinyl

Interesting ideas for engraving.

As far as the case engravings go, I'm curious if one of the lower end engravers would be able to etch the curved surface between the lugs.

Because it seems like painting it with cheap paint (to resist the electrochemical reaction), laser engraving the paint away (to leave the bare metal exposed in the shape of the engravings/numbers), then saltwater etching the exposed metal would be a very simple process...but it all comes down to whether or not the laser etching will work on a curved surface.

As far as the case engravings go, I'm curious if one of the lower end engravers would be able to etch the curved surface between the lugs.

Because it seems like painting it with cheap paint (to resist the electrochemical reaction), laser engraving the paint away (to leave the bare metal exposed in the shape of the engravings/numbers), then saltwater etching the exposed metal would be a very simple process...but it all comes down to whether or not the laser etching will work on a curved surface.

not dial work. I am thinking serialsI think you Can use it with a brass black plainted plate, with 3watt you Can easy remove the paint, if you want to use the laser engraving to do gilt dial it could work.

Now I'm thinking both, lol.not dial work. I am thinking serials

Would be interesting to experiment with gilt dials by removing paint to expose the gold, rather than adding black to hide the brass. The end result should be more or less the same, just wondering which process would yield cleaner lines.

I need to take a vacation from work and deep dive into all these methods, lol. Just found a source for extremely cheap scratch and dent 3D printers, ordered one to set up as a dedicated laser engraver, rather than swapping mine back and forth.

I asked them. They said you need the 10W model which is 3 times more expensiveInteresting ideas for engraving.

As far as the case engravings go, I'm curious if one of the lower end engravers would be able to etch the curved surface between the lugs.

Because it seems like painting it with cheap paint (to resist the electrochemical reaction), laser engraving the paint away (to leave the bare metal exposed in the shape of the engravings/numbers), then saltwater etching the exposed metal would be a very simple process...but it all comes down to whether or not the laser etching will work on a curved surface.

Now I'm thinking both, lol.

Would be interesting to experiment with gilt dials by removing paint to expose the gold, rather than adding black to hide the brass. The end result should be more or less the same, just wondering which process would yield cleaner lines.

I need to take a vacation from work and deep dive into all these methods, lol. Just found a source for extremely cheap scratch and dent 3D printers, ordered one to set up as a dedicated laser engraver, rather than swapping mine back and forth.

I was thinking you can laser engrave the black areas of the dial and leave the brass exposed, but I like your idea better where the dial is painted black and then laser burns off the paint to expose the gilt

Last edited:

10W for metal, but we're only talking about the paint. And for Stainless Steel, I believe you'd need more than 10W. I remember reading that 40W was where the real fun begins with steel, which is a lot more expensive.I asked them. They said you need the 10W model which is 3 times more expensive

Yes, exactly. And having the lower power laser means it wouldn't actually have enough power to affect the metal.I was thinking you can laser engrave the black areas of the dial and leave the brass exposed, but I like your idea better where the dial is painted black and then laser burns off the paint to expose the gilt

So it would more or less be identical to a waterslide decal dial as far as having black pigment and exposed brass gilt. So whichever method gives a cleaner, neater, more detailed "edge" would be better.

TBH, it's potentially a better result than the original gen dials, which I believe were pad printed with ink.

A little bit of a tangent, but I'm now experimenting with white printing, rather than gold gilt dials. I tried using white waterslide decal paper, but the white wasn't bold enough (the paper is a little bit transparent, so the brass underneath kind of undermines the effect). So far, high gloss white paint under the decal (directly on the dial) looks pretty good, I'm going to slightly tweak the reproduction size of the dials to make the font a little bigger so the white "pops" more.

I hate myself for even saying this, but I'm really seriously considering buying a gen 1016 or similar to compare to, lol...which kind of defeats the purpose of chasing a rep, but now I'm kind of determined to see this through...it's like marrying a beautiful actress or supermodel, just so I can raise the quality of the hookers I cheat with...lol

You can only do so much creating something at home, then scouring the internet to find photos for reference. Think how convenient it would be to have the real deal on hand, to compare from identical angles, in identical light, under identical magnification.

Yes, this is a sickness, lol.

Last edited: