Thanks, I hadn't thought of that!You can put the original file on a Google Drive or any cloud. Then you can post the link

Sharing what I have for anyone interested in some of these DIY projects:

Gilt Dials (Print on waterslide paper, slide onto blank dial):

Dial layout test.docx

1016? 6538 6538r 6538 2/6 m/f 1675 5500 6610 5512 5513 5512v2 6542 Neg 27mm (34mm case): DATE WHEEL ROLE...

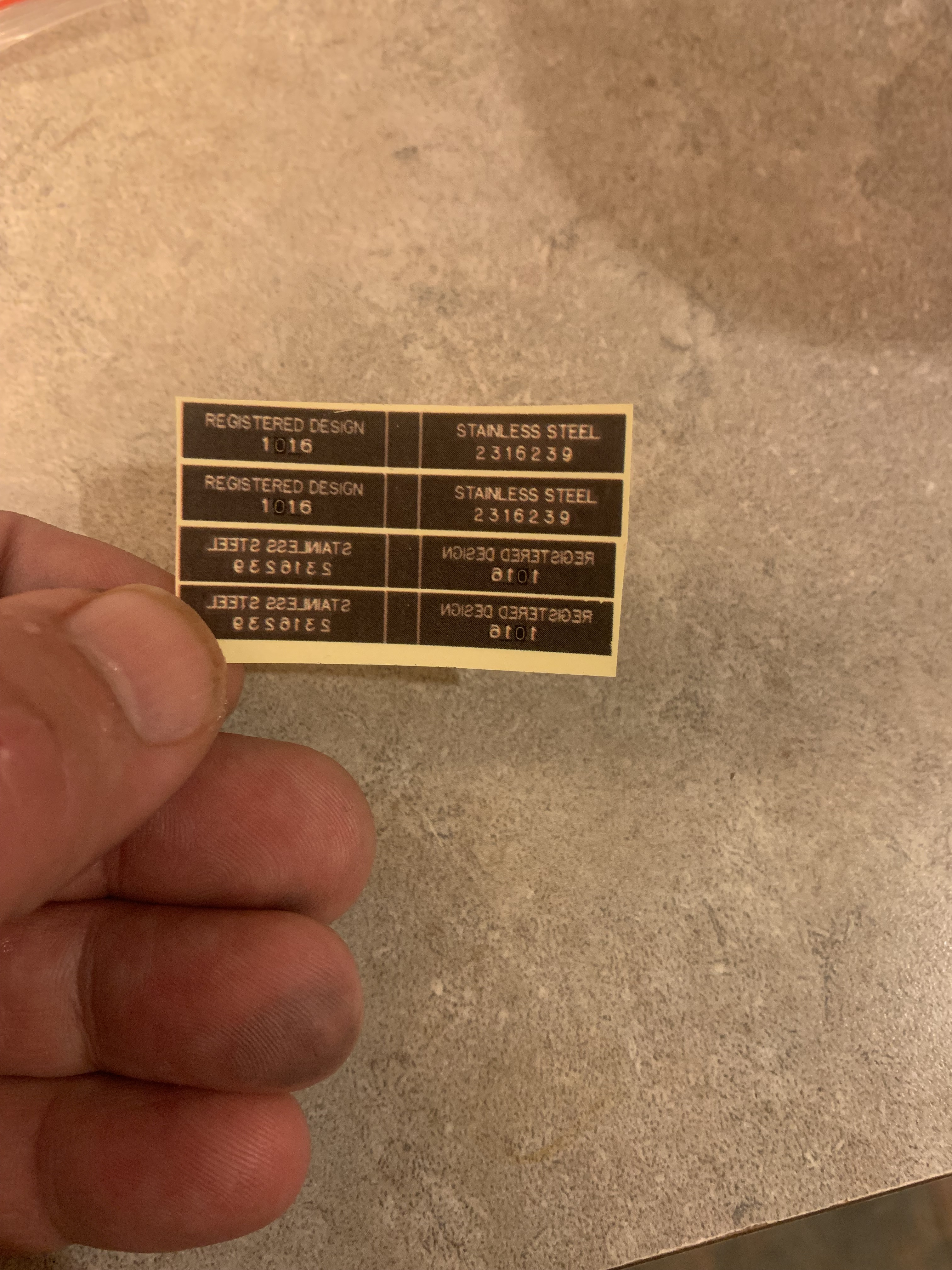

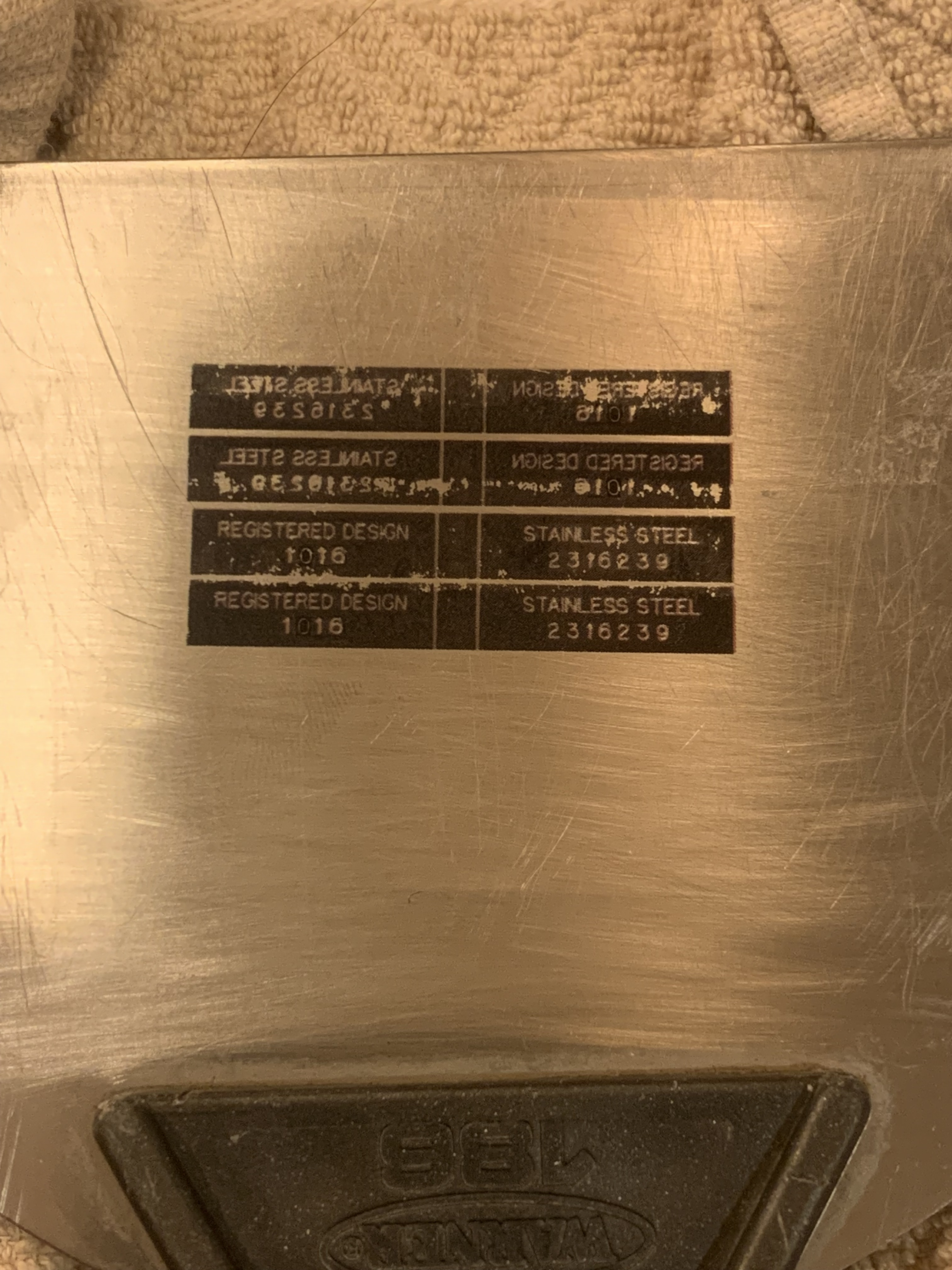

SERIAL NUMBERS FOR ELECT PAPER.docx

5513 and reversed 5517 and reversed 5500 and reversed 1680 and reversed 1016 and reversed 1601 and reversed

FONTS FOR SERIAL NUMBERS

KATOMI 1279 ABCDEFGHIJKLMNOPQRSTUVWXYZ 1234567890 HALFMOON 123690 ABCDEFGHIJKLMNOPQRSTUVWXYZ 1234567890 ROADGEEK B 124 ABCDEFGHIJKLMNOPQRSTUVWXYZ 1234567890 ROADGEEK C 12 4 ABCDEFGHIJKLMNOPQRSTUVWXYZ 1234567890 ROADGEEK D 12 480 ABCDEFGHIJKLMNOPQRSTUVWXYZ 1234567890 ROADGEEK E 12 48 ABCDEFGHIJKLM...

Last edited: