Ok, some very rough instructions on the saltwater etching. The process needs a lot of fine tuning, but this is more or less it.The design is transferred to the case, like an iron on t-shirt. Once it's on the case, it resists current. Then you use a small current to etch the metal.

The current follows the path of least resistance, who it bypasses everywhere that's black on the print, and goes straight to the white part, if that makes any sense.

Playing with it now, I'll snap some photos so it'll be more clear.

This is the first piece of metal I came across, it's smooth and clean and flat, so an easy palette, lol. When the bugs are worked out, this will be happening between the lugs of a Raffles (or other) case:

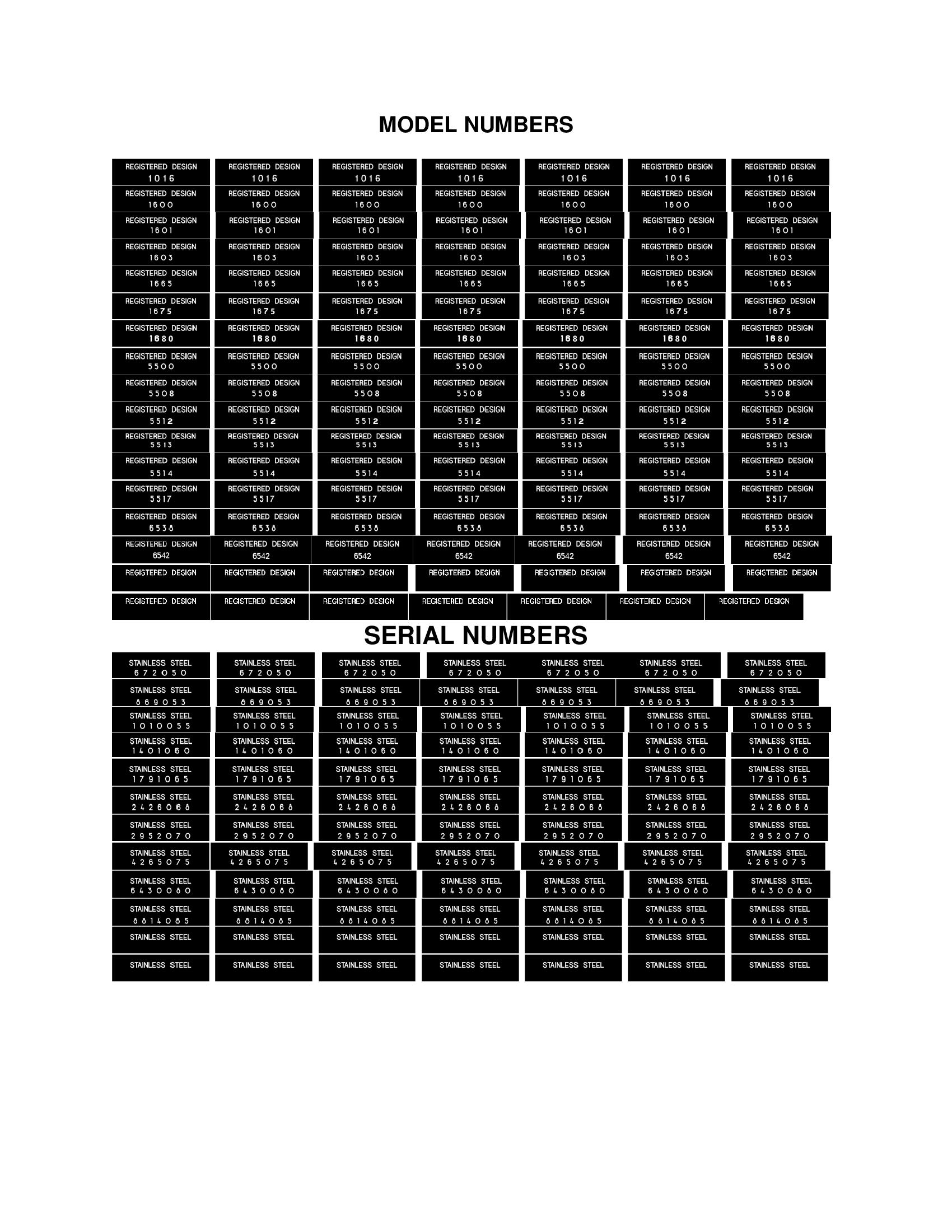

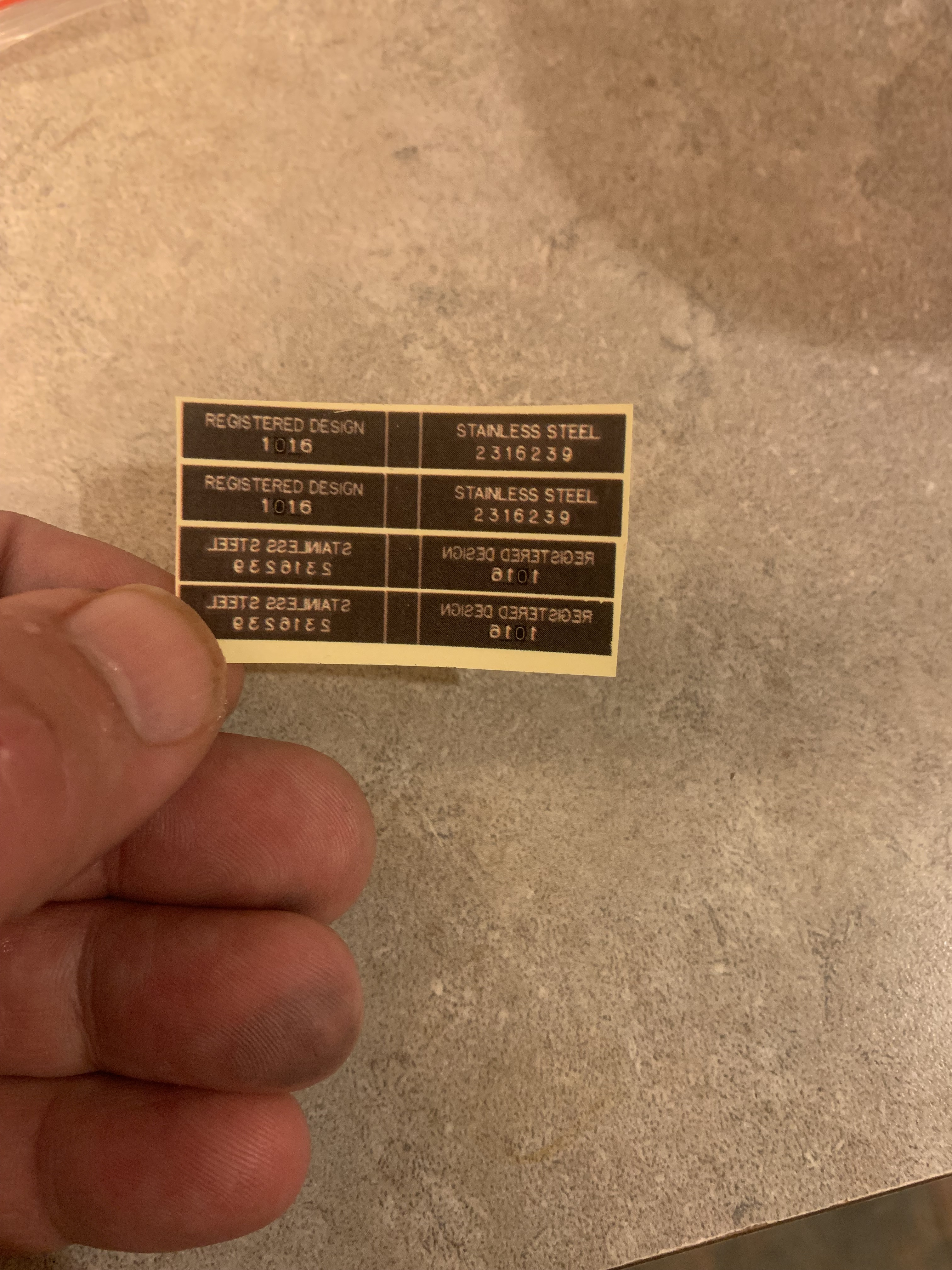

Some quick prints on electronic circuit board heat transfer paper. Every little rectangle should fit perfectly between the lugs of a watch when cut out:

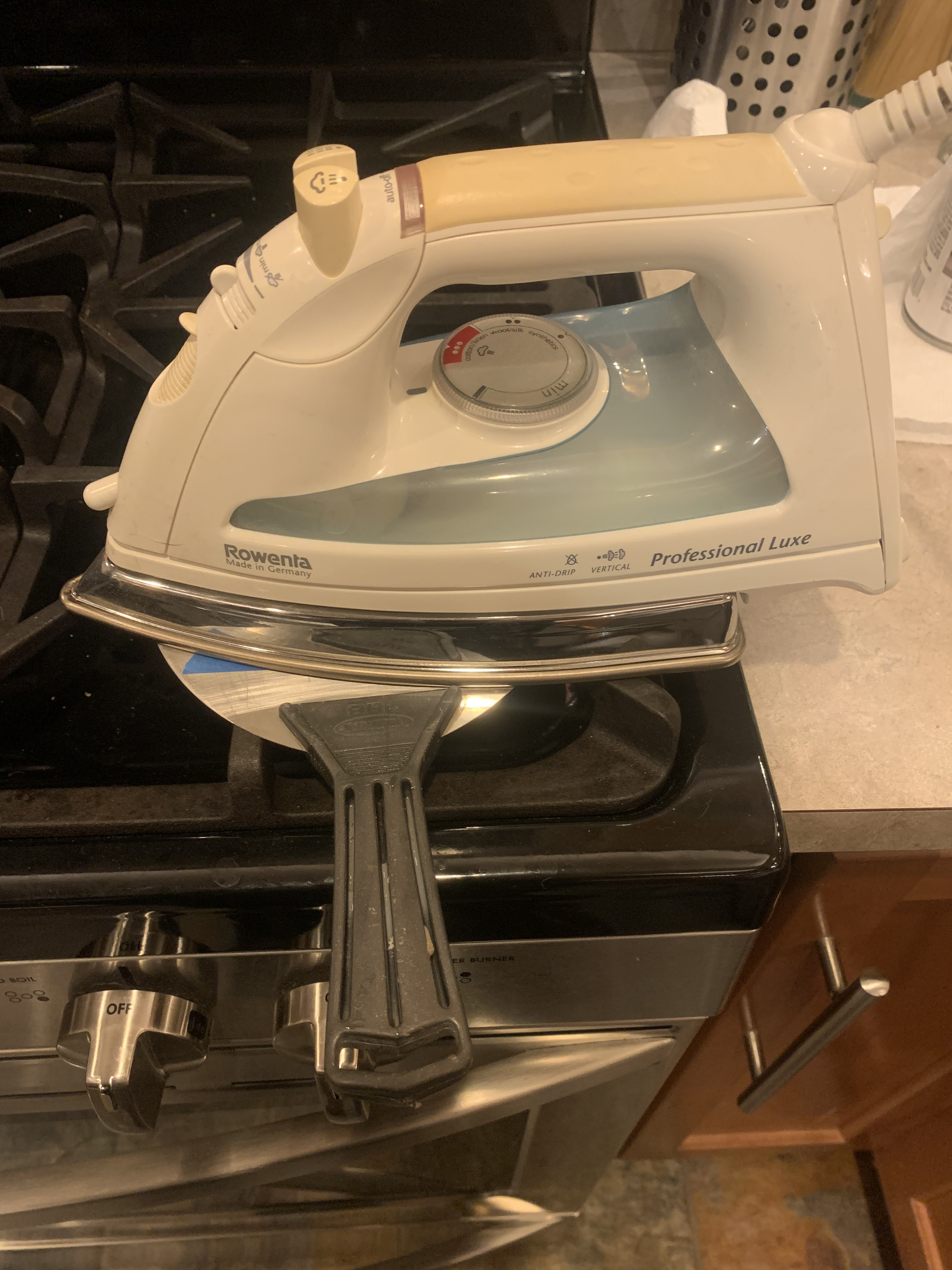

Have to get it perfectly flat, full contact with the metal: Not sure how I'll do it on a watch case, might try adapting a SEL.

Then it's heated, so the ink/toner melts and sticks to the metal. The exact temperature and time heated is one of the things I'll need to work out. To get between the lugs, I'm thinking a pen tip soldering iron might work.

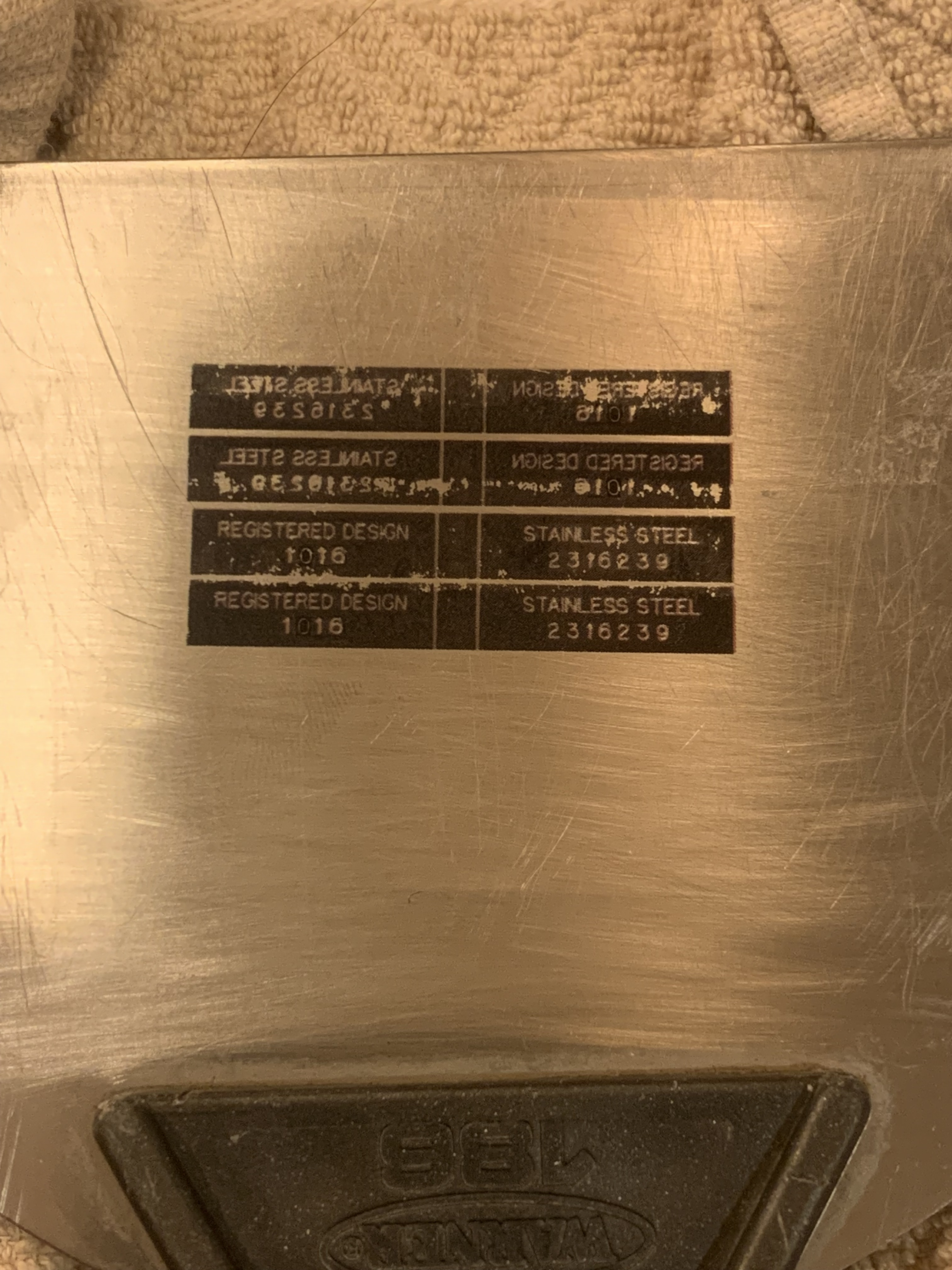

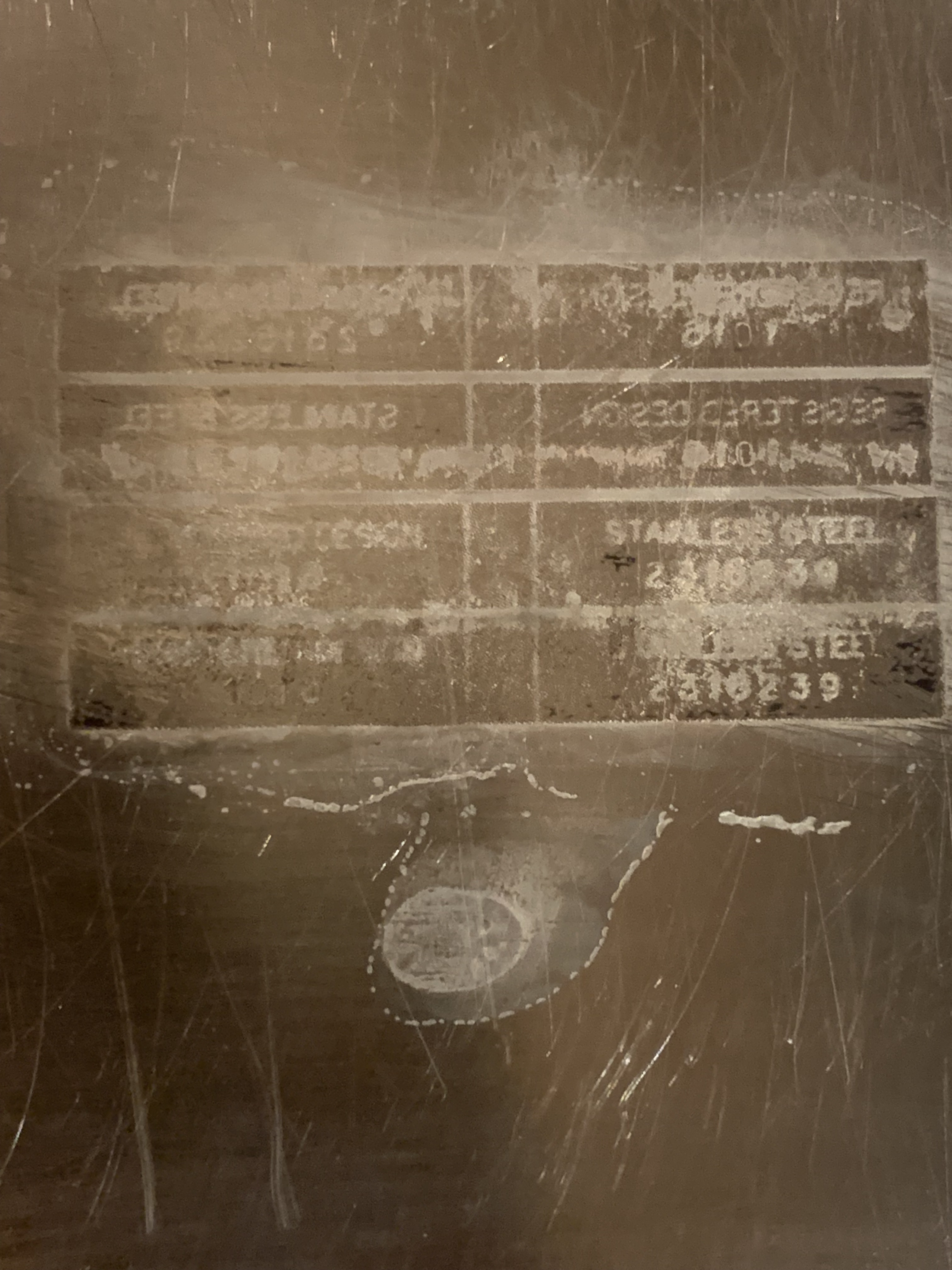

Let everything cool and remove the tape and paper. If the paper sticks, you can rinse the paper away with water. You can be a bit aggressive...if the transfer works, it's pretty well attached. This is not a perfect transfer, but good enough to show the concept.

Now you need to etch the metal. Take a 9v batter or an old phone charger and attach one wire to the metal, the other gets attached to a q-tip that's dipped in salt water. Touch the q-tip to the area you want to etch, and it will attack the metal where it's NOT covered by the decal. The water will bubble and change color...yellow, brown, even blue. You will see a little smoke. You will smell nasty gas (chlorine gas, I think...that's what it smells like...do this in a well ventilated area!). This is normal and not terribly dangerous, although it can be a little scary.

When you're done, clean off the remains of the toner/ink and what's left is etched into the metal. It actually looks pretty good, especially since real vintage Rolexes are usually very worn between the lugs.

Obviously this process needs some tweaking...but for something I threw together in a couple minutes, it's really not bad at all. I figure a few hours of practicing on scrap and I'll be ready for a real watch case.

Last edited: