SUCCESS!!!!!!!

It was the geometry of the Clarks pallet fork that was the problem!!!!

So... john doe iii sold me a spare VR3235 movement that he had sitting around, and it arrived today. Unfortunately, the movement had taken a few bumps during shipment and it didn't actually work when I pulled it out of the packaging. NB: I don't think this was John Doe's fault, the movement was packaged in bubble wrap, but it had slid out and was floating around in the box. Initially I was a bit bummed since I wouldn't be able to see a functioning movement to see how the pallet fork engaged / disengaged with the escape wheel. But... I reasoned that it was unlikely that the pallet fork in John's movement had been damaged, so I decided to test simply swapping it out of John's movement and putting it into my movement to replace the Clarks pallet fork which I'd purchased on eBay.

I got John's pallet fork installed and even before I had replaced the pallet bridge, I could tell it looked like it engaged the escape wheel more symmetrically. I put the rest of the balance assembly back into place and gave the crown a bit of a wind... and wouldn't you know it, the balance started swinging. And I mean swinging properly. Not the anemic 90 degrees I was getting before. No... I was getting a nice healthy swagger of a swing.

I put the movement on my timegrapher and it was a thing of beauty! Would you take a look at that:

Three beautiful distinct lumps in both the tick and the tock... and an amplitude of 230 degrees (and that's with very little energy in the mainspring).

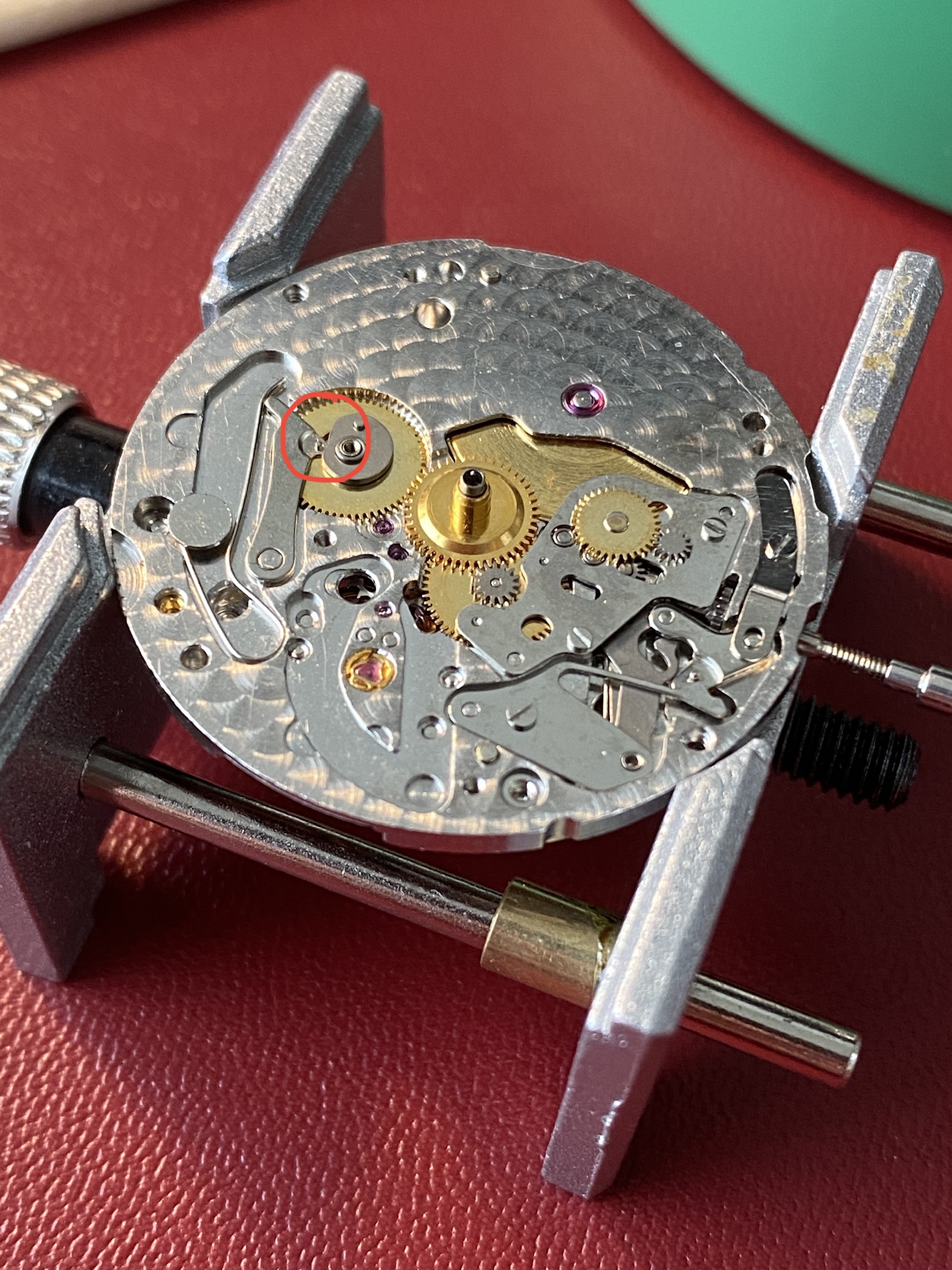

I put the movement under the digital microscope and took a few pics to see just how the pallet stones were locking compared to before, and sure enough, both of the stones were now engaging the escape wheel nicely on the locking faces.

So now I have a still somewhat disassembled (but nonetheless working) movement!!! I couldn't be happier. But not just happy because I have a working movement... hell for the price of the tools and parts I've purchased to "service" my movement, I could have bought three new movements... I'm happy because I've learned a ton! And, I had a hunch that it was the pallet fork geometry that was messing up the movement, and I strongly suspected it was the Clarks pallet fork; and wouldn't you know it, that hunch turned out to be right.

So, now I just need to re-assemble the rest of the movement and get it cased back up. Happy times ahead!!!

Thanks everybody for coming along for the ride and for all the help along the way!

It was the geometry of the Clarks pallet fork that was the problem!!!!

So... john doe iii sold me a spare VR3235 movement that he had sitting around, and it arrived today. Unfortunately, the movement had taken a few bumps during shipment and it didn't actually work when I pulled it out of the packaging. NB: I don't think this was John Doe's fault, the movement was packaged in bubble wrap, but it had slid out and was floating around in the box. Initially I was a bit bummed since I wouldn't be able to see a functioning movement to see how the pallet fork engaged / disengaged with the escape wheel. But... I reasoned that it was unlikely that the pallet fork in John's movement had been damaged, so I decided to test simply swapping it out of John's movement and putting it into my movement to replace the Clarks pallet fork which I'd purchased on eBay.

I got John's pallet fork installed and even before I had replaced the pallet bridge, I could tell it looked like it engaged the escape wheel more symmetrically. I put the rest of the balance assembly back into place and gave the crown a bit of a wind... and wouldn't you know it, the balance started swinging. And I mean swinging properly. Not the anemic 90 degrees I was getting before. No... I was getting a nice healthy swagger of a swing.

I put the movement on my timegrapher and it was a thing of beauty! Would you take a look at that:

Three beautiful distinct lumps in both the tick and the tock... and an amplitude of 230 degrees (and that's with very little energy in the mainspring).

I put the movement under the digital microscope and took a few pics to see just how the pallet stones were locking compared to before, and sure enough, both of the stones were now engaging the escape wheel nicely on the locking faces.

So now I have a still somewhat disassembled (but nonetheless working) movement!!! I couldn't be happier. But not just happy because I have a working movement... hell for the price of the tools and parts I've purchased to "service" my movement, I could have bought three new movements... I'm happy because I've learned a ton! And, I had a hunch that it was the pallet fork geometry that was messing up the movement, and I strongly suspected it was the Clarks pallet fork; and wouldn't you know it, that hunch turned out to be right.

So, now I just need to re-assemble the rest of the movement and get it cased back up. Happy times ahead!!!

Thanks everybody for coming along for the ride and for all the help along the way!

Last edited: