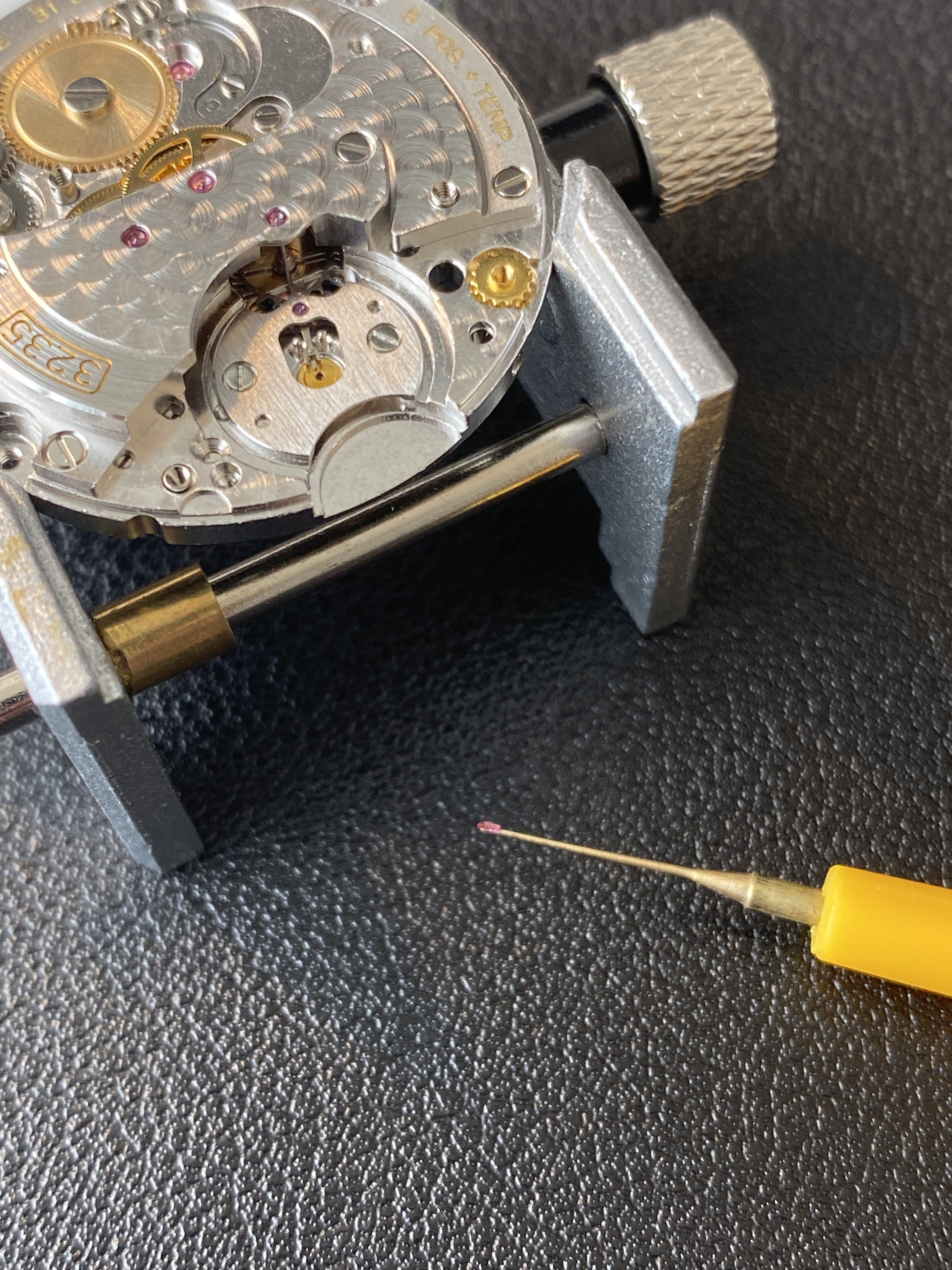

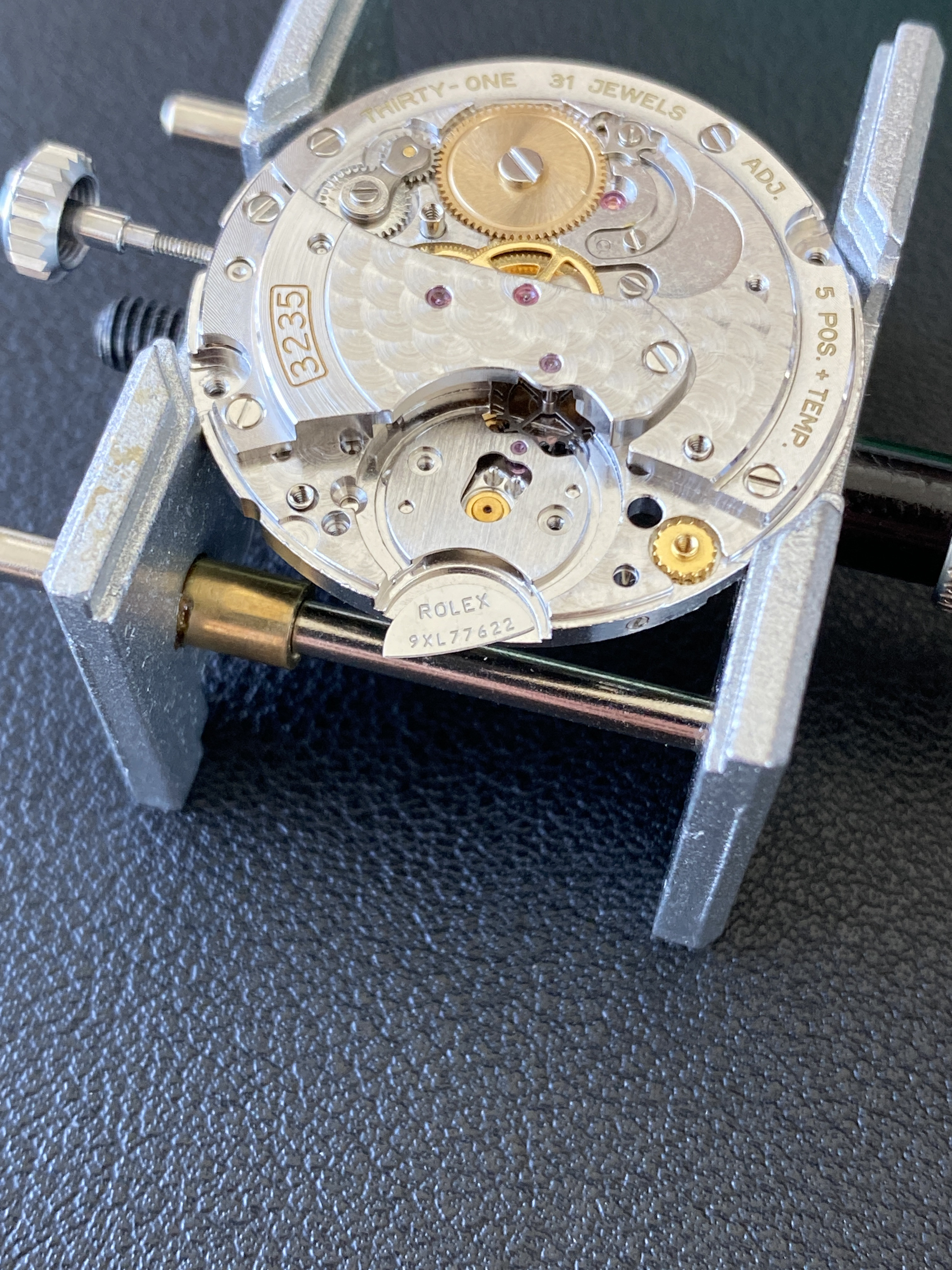

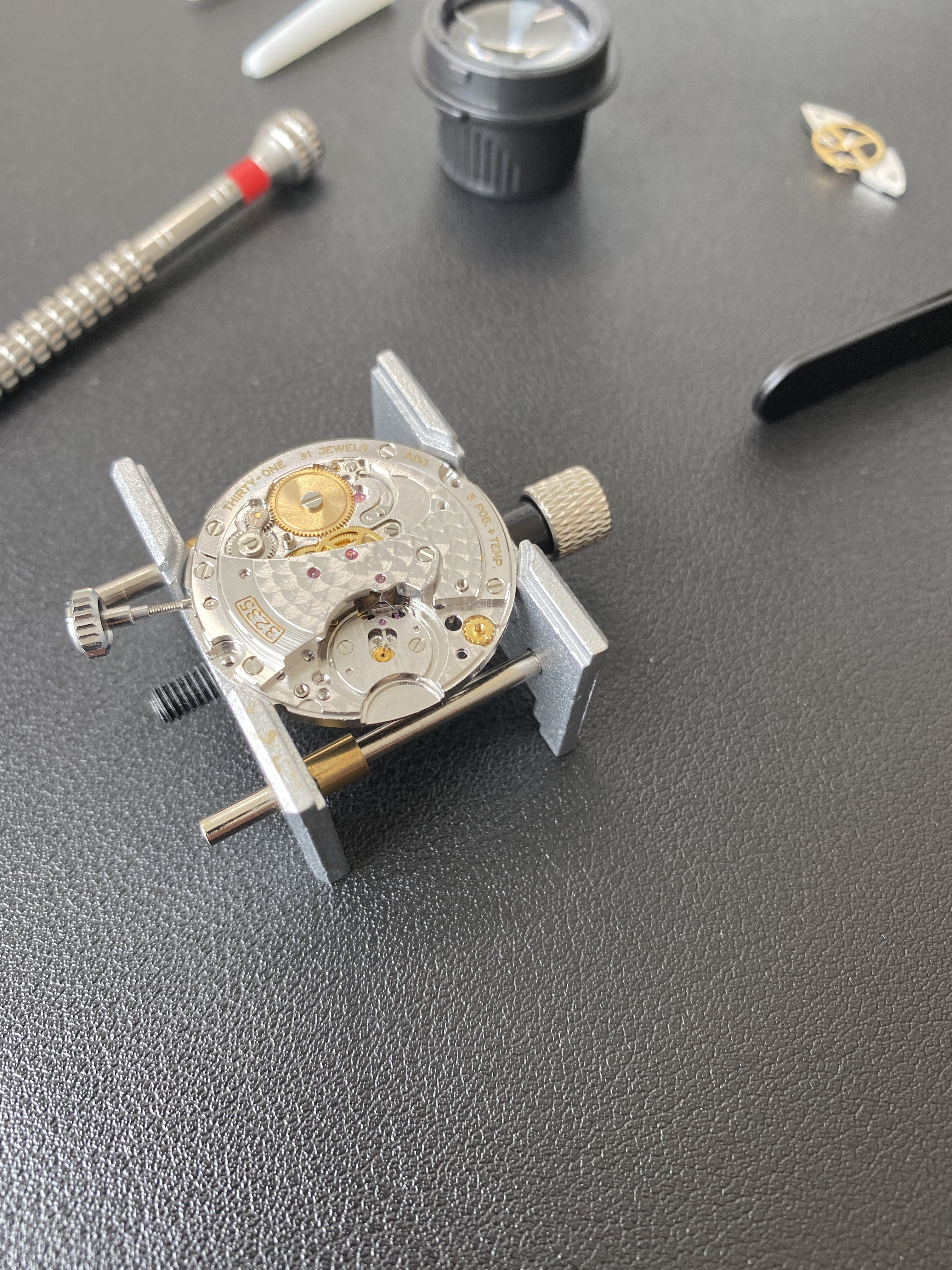

i finally got this bastard re-assembled. It only took several hours, but I think I have a method that’s repeatable.

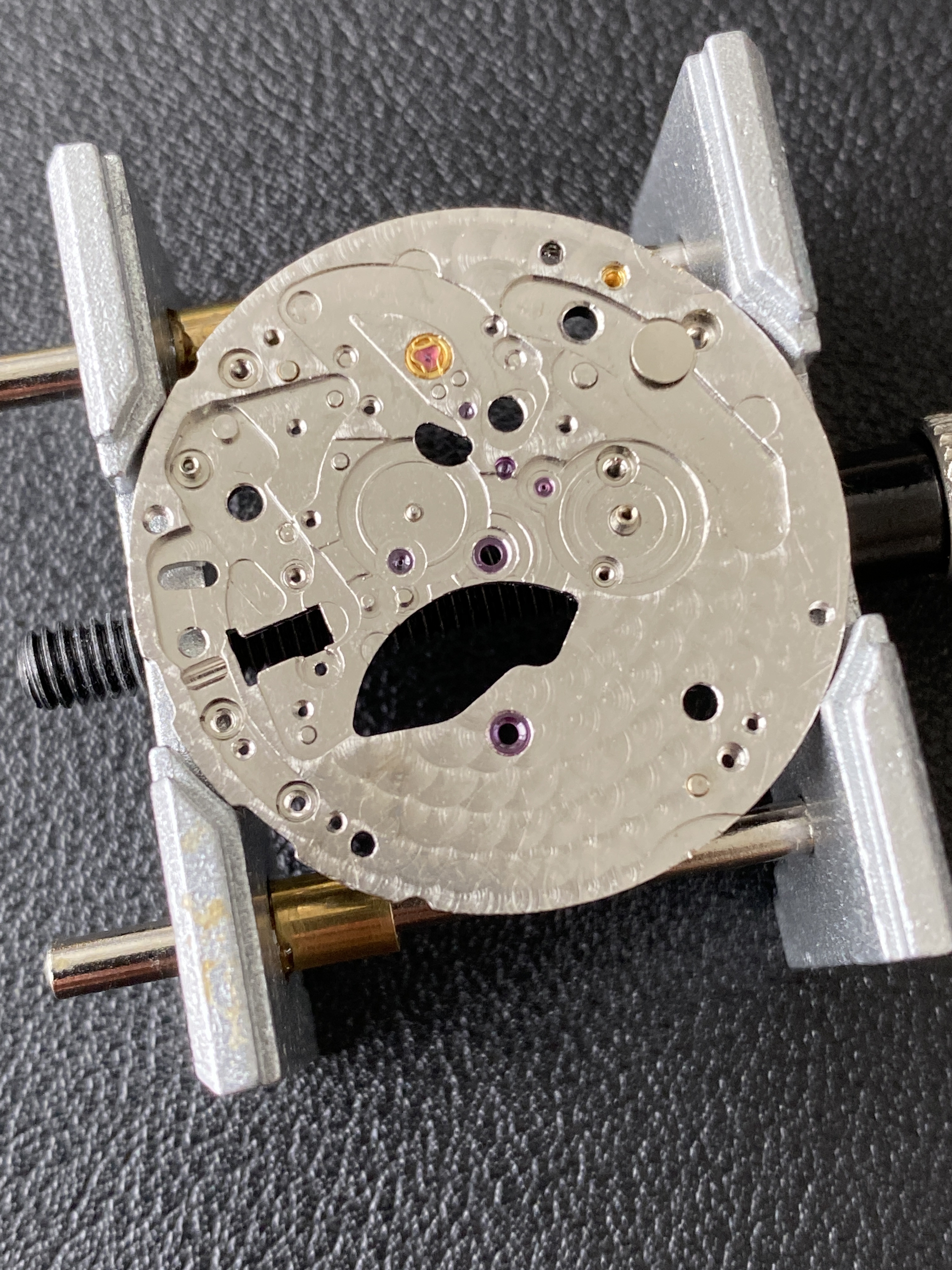

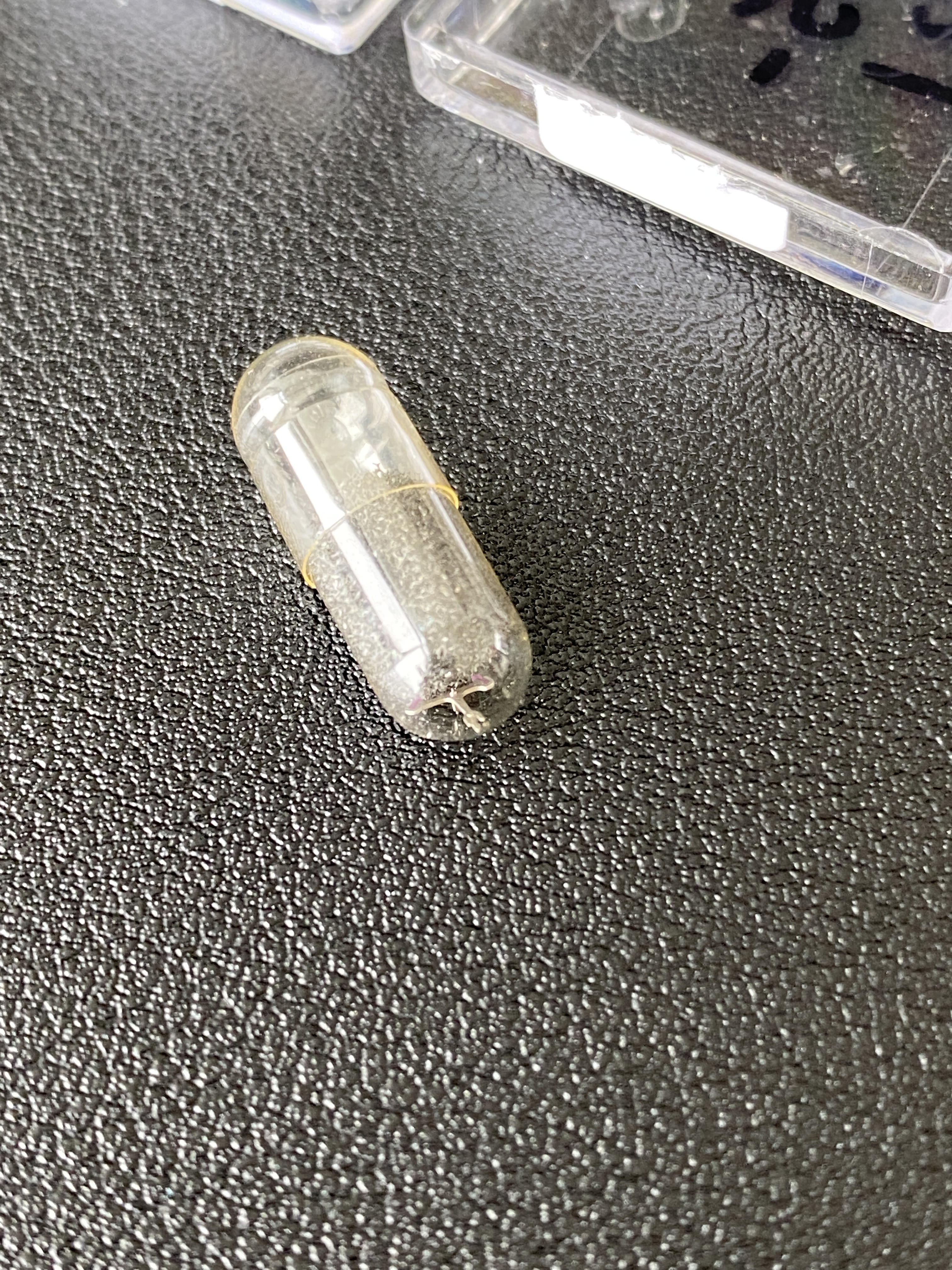

- put the bottom Jewel with the hole through it into the brass insert in the main plate.

- apply a little bit of lubrication to the hole in the jewel.

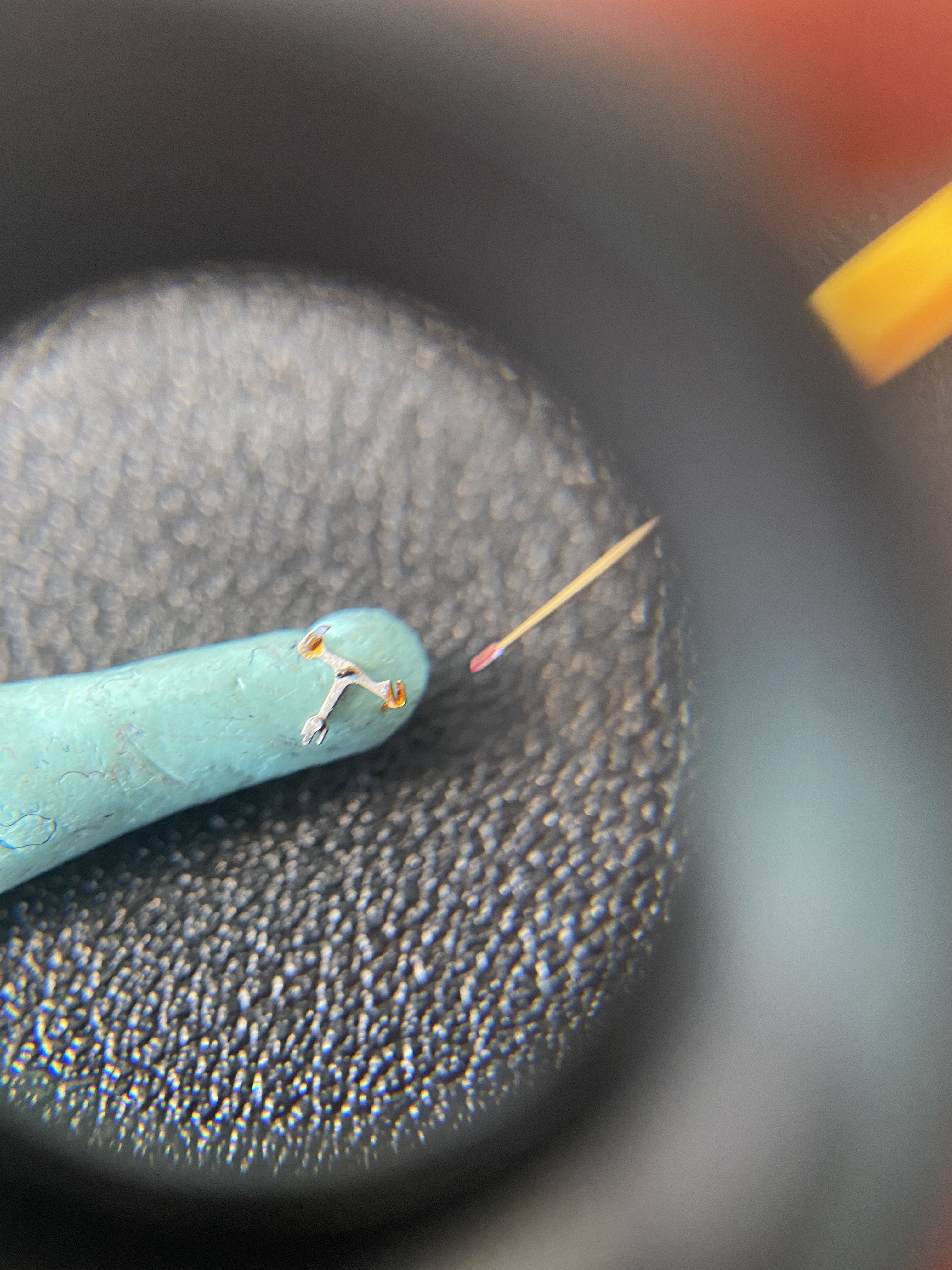

- muse rodico (because my skills with tweezers are lacking) to move the cap stone jewel into position and then use an oiler to push it into position on top of the oiled hole jewel.

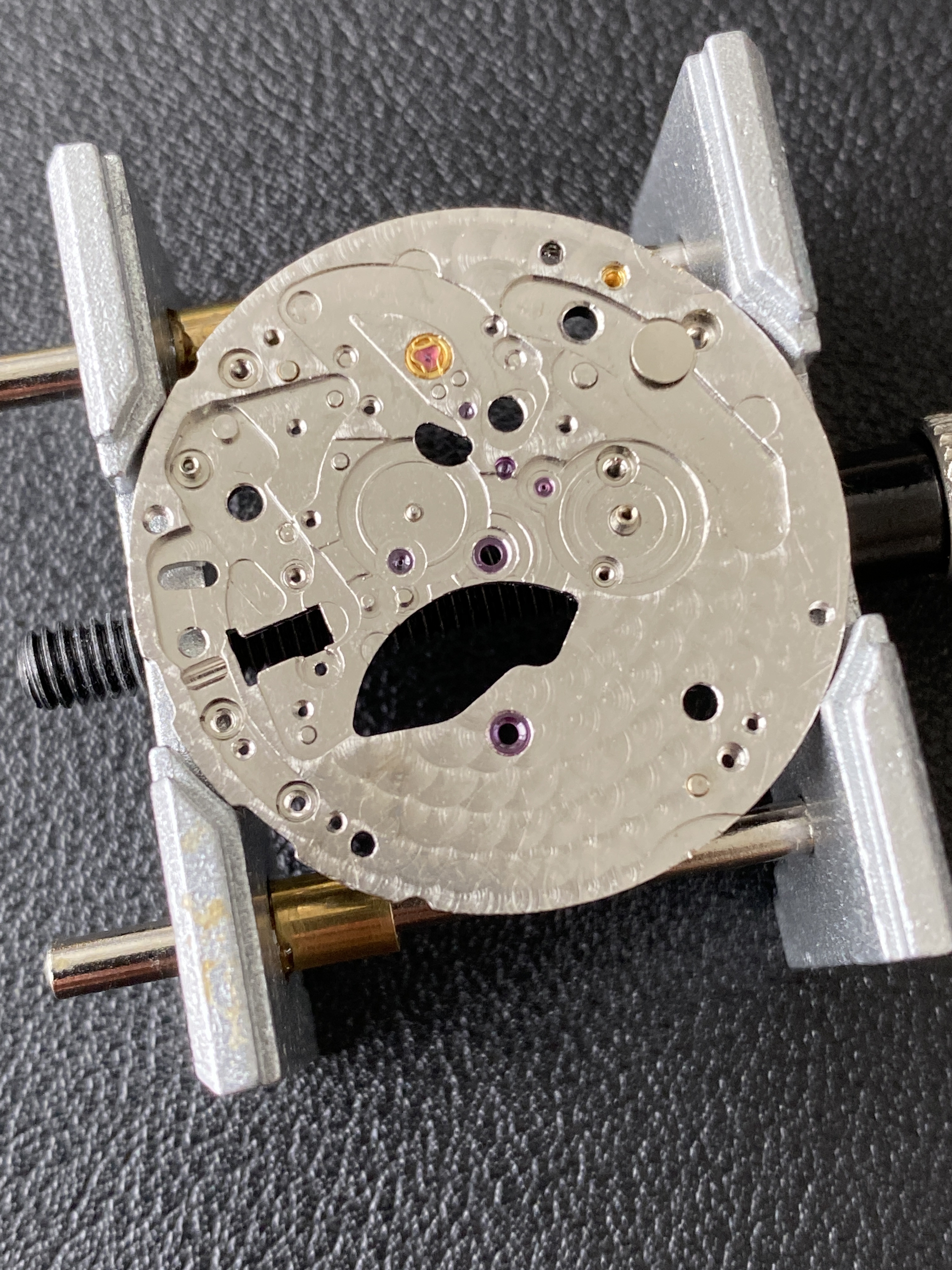

- Use rodico to move the spring from the parts tray to the movement.

- cover the movement with cling wrap and use Pegwood and an oiler poked through the film to maneuver the spring into place. This part takes many iterations to get it to work. Take breaks. Remember to breathe. Shake out your arms if they’re getting tired.

- once the back of the spring / pivot end is as close as possible to where it should be, use the Pegwood to hold it in place and the oiler to get one arm and then the other to hook onto the brass rim of the setting.