WatchSmith.US

I'm Pretty Popular

- 13/3/16

- 1,307

- 2,062

- 113

Turning the brass nut clockwise lowers the bridge, and turning it anti clockwise raises it. IIRC it’s 0.1mm per tooth on the nut which you can turn with a screwdriver tip.

Turning the brass nut clockwise lowers the bridge, and turning it anti clockwise raises it. IIRC it’s 0.1mm per tooth on the nut which you can turn with a screwdriver tip.

Assuming it’s a real nut, it should turn fairly easily.

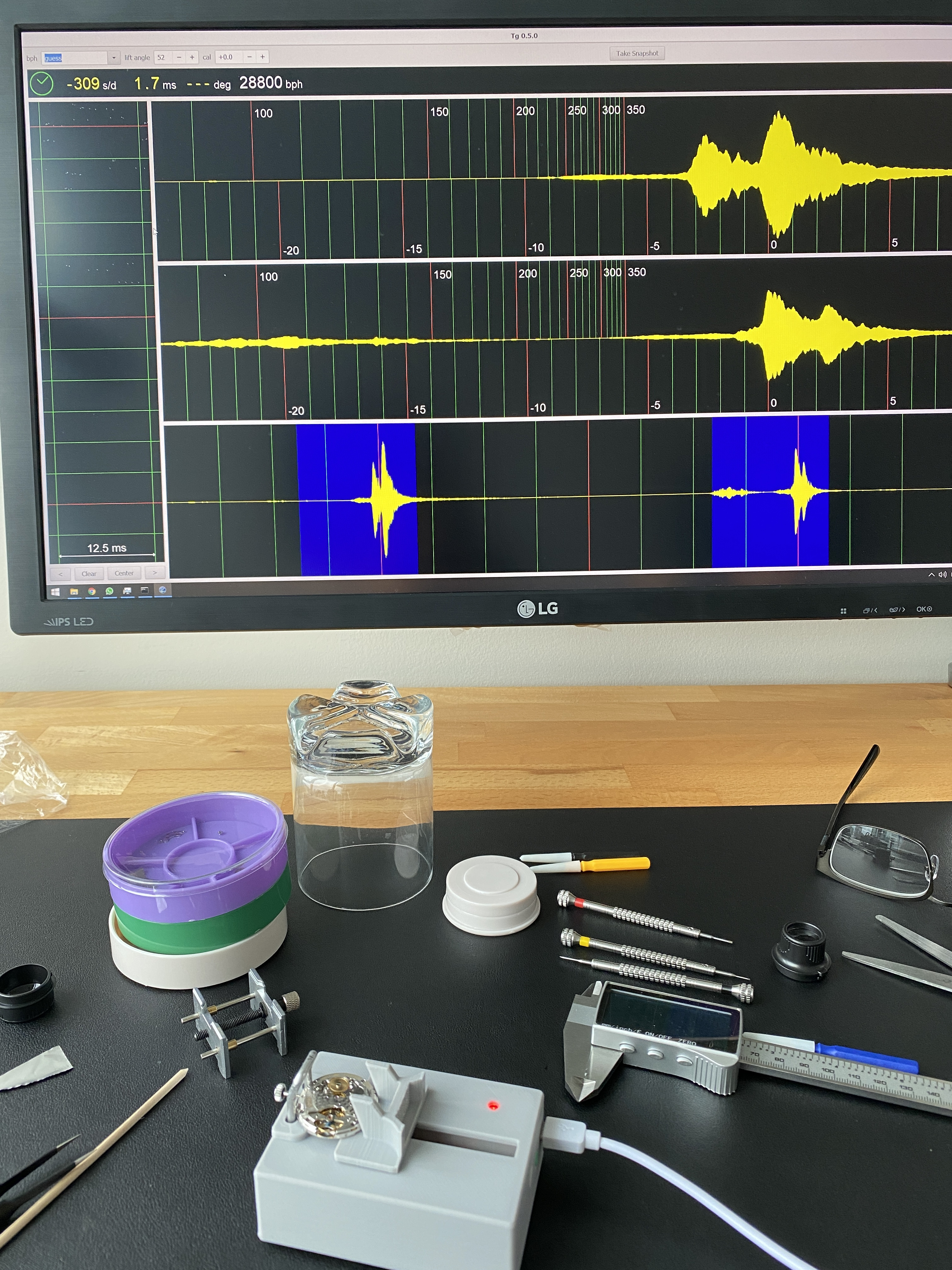

Without a timegrapher I would be shooting in the dark as far as amplitude. I suppose a slomo video could work but accuracy is the name of the game.

I wish I had better suggestions for you.

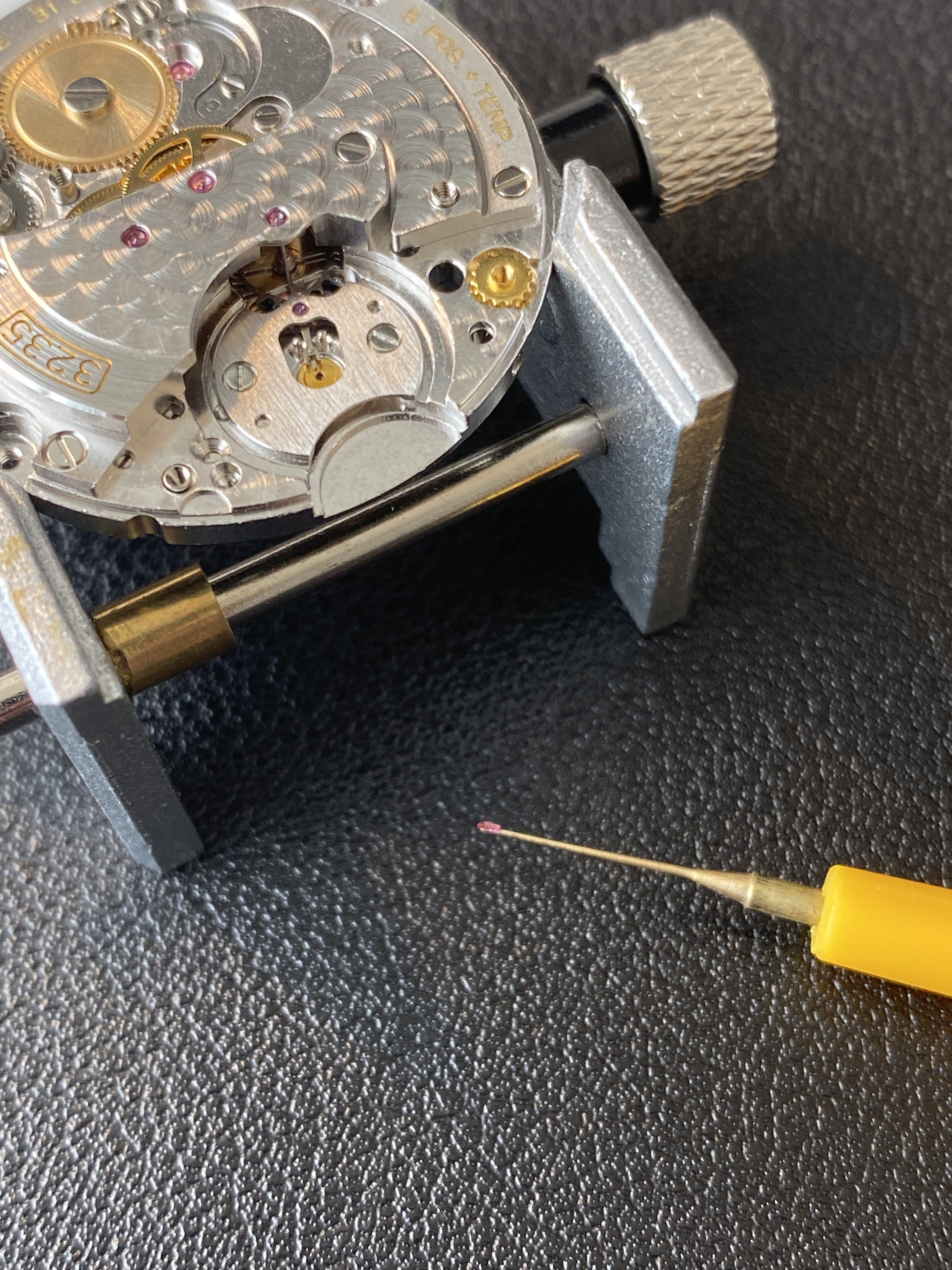

Oh boy... update... One of the pallet stones came out when I was trying to apply Moebius 9415 grease to it. I literally just touched the stone with the oiler and the stone stuck to the oiler when I pulled it away. This tells me either the shellac was weak from the start, or I did something to degrade the shellac as part of my cleaning. My cleaning procedure was 10 minutes in the ultrasonic cleaner in a bath of naphtha (lighter fluid), then drying the parts, then another 10 minute bath in a fresh solution of naphtha in the ultrasonic cleaner. Then I removed the pallet fork and balance (the two parts with shellac secured jewels), and placed the dried parts into a 99.9% alcohol solution for another 10 minutes in the ultrasonic bath. I was pretty sure that naphtha was safe for shellac, but maybe not for that duration? Or was it the length of time I left it in the ultrasonic cleaner? Or did I just get a poorly secured pallet stone?

Some pics:

Here's the pallet fork before cleaning (I don't have a pic showing the shellac side)

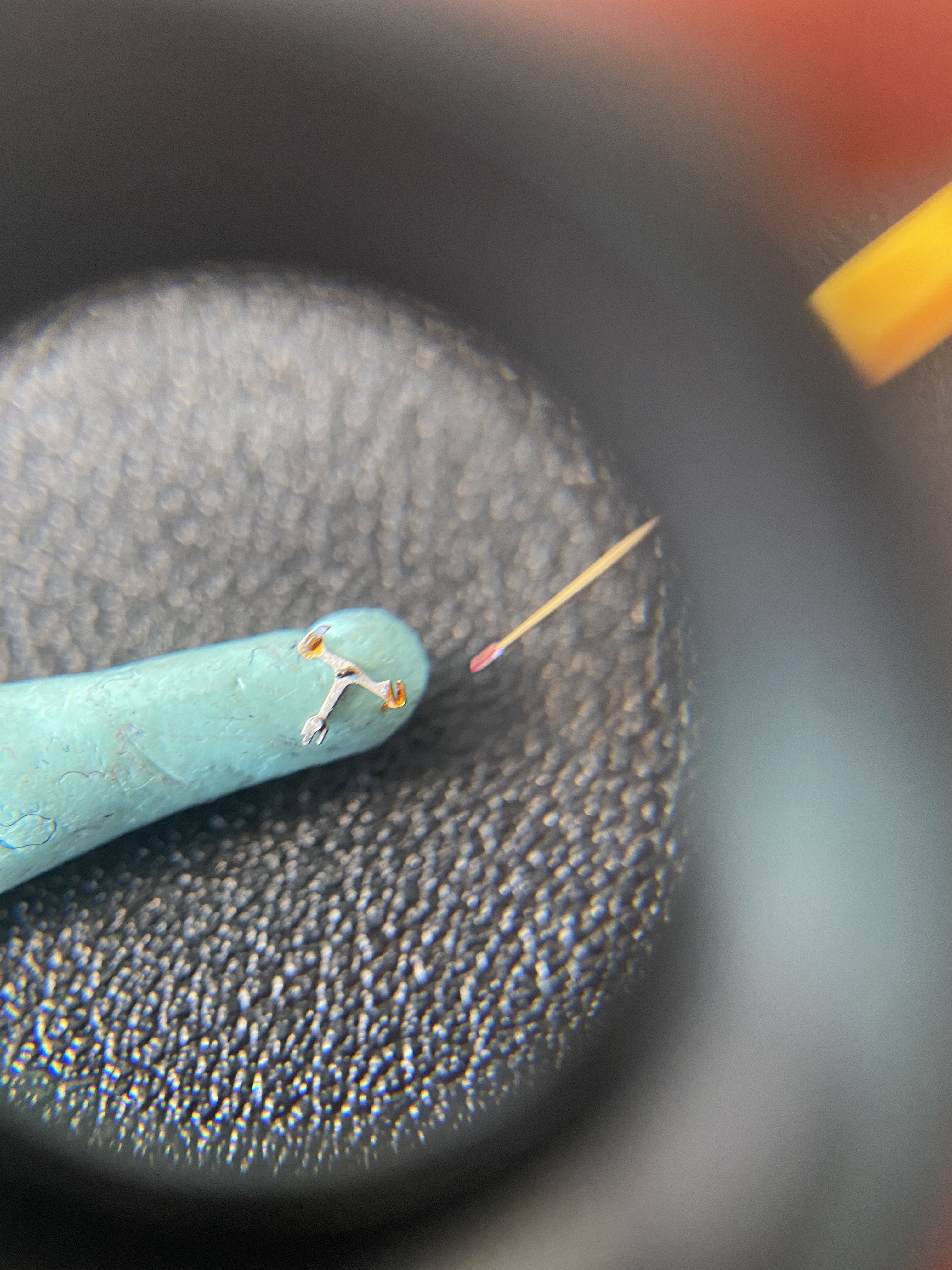

Here's the pallet stone that came away stuck to the oiler:

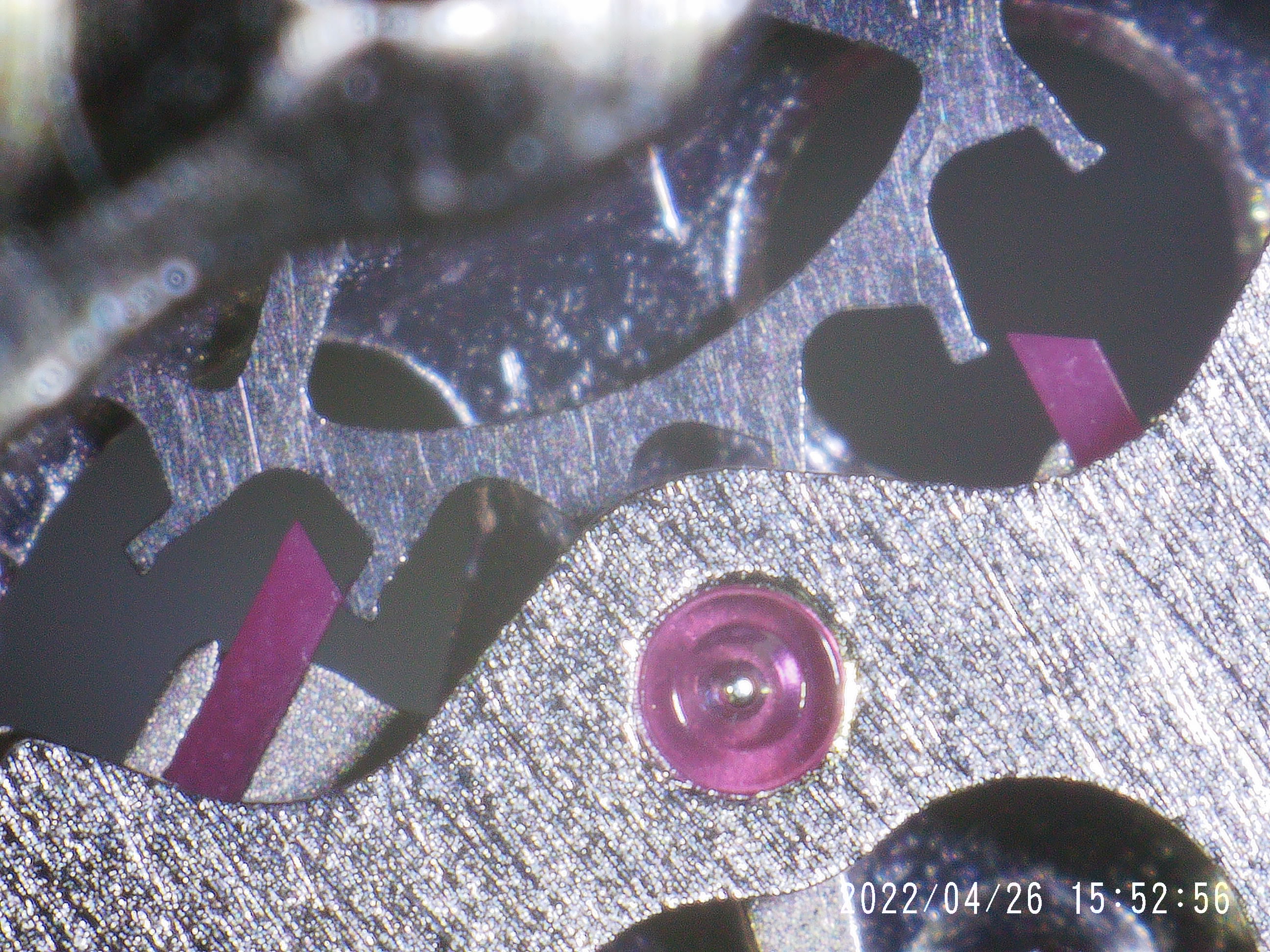

A close up of the pallet fork showing the shellac... does the colour seem right? Or does this look like my washing solution destroyed the shellac?

Acetone, Shellite, Butane, Battery contact cleaner, Lighter fluid, are very high on hydrogen amongst hydrocarbons. They can strip the carbon material off many things e.g. oils, shellac, varnish, superglue, grease, oils etc… so these chems are a no-no on anything that burns or melts with heat easily.

Ever noticed how your greasy hands will suddenly become dry if you wash with liduid butane or lighter fluid? That’s the Hydrogen pulling the carbon from oils and evaporating it.

You can reapply shellac but will need a hot laser or a magnifying glass on a bright sunny day to melt it. It would be easier to get a replacement pallet fork if you don’t mind waiting.

Did you notice the VR3235 is a modified 3135 on the date seating side and 3235 on the rotor side? With just an extra setting wheel to change the hand sweep direction when you twist the crown?

Btw these rhinestone pickers work really well picking up watch hands and small parts and they don’t leave marks. Helps a lot if your tweezer game is off and much easier to maneuver than Rodico.

Just make sure to check the brass tip for burs before using on hands. I usually polish them before loading the tip w/ polyurethane goo.

Good luck! Its great to see someone go through the same learning experience.

Did you disassemble the barrel and the main spring? At full wind the amplitude reaches up to 300+ if the mainspring is anchored on the barrel groove, otherwise, you would have lost significant amplitude by the time it unravels half-way.

Here is a video and at 11:50 minute mark he re-installs the main spring. Curious if you did the same.

https://youtu.be/N9ee6qqyPhg

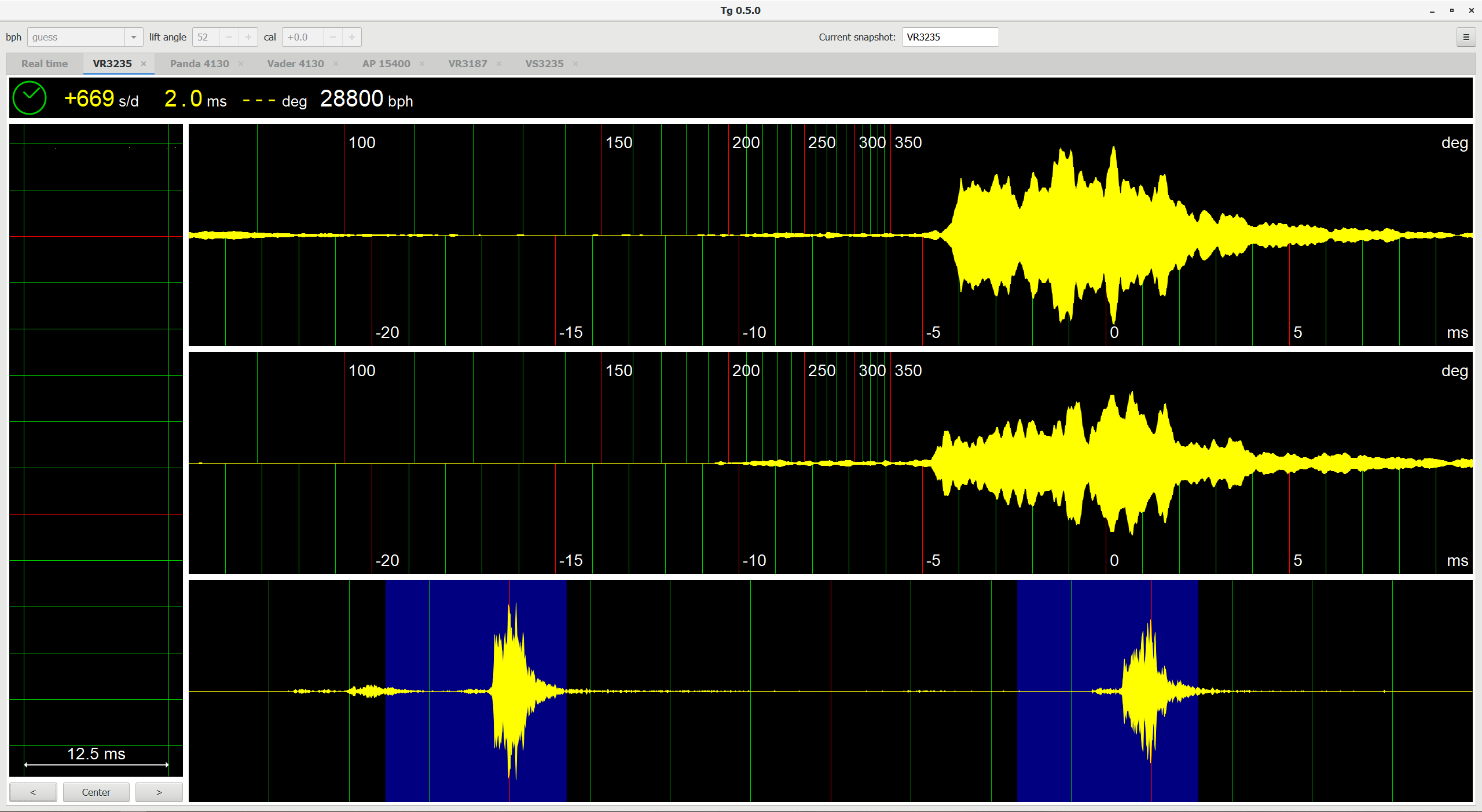

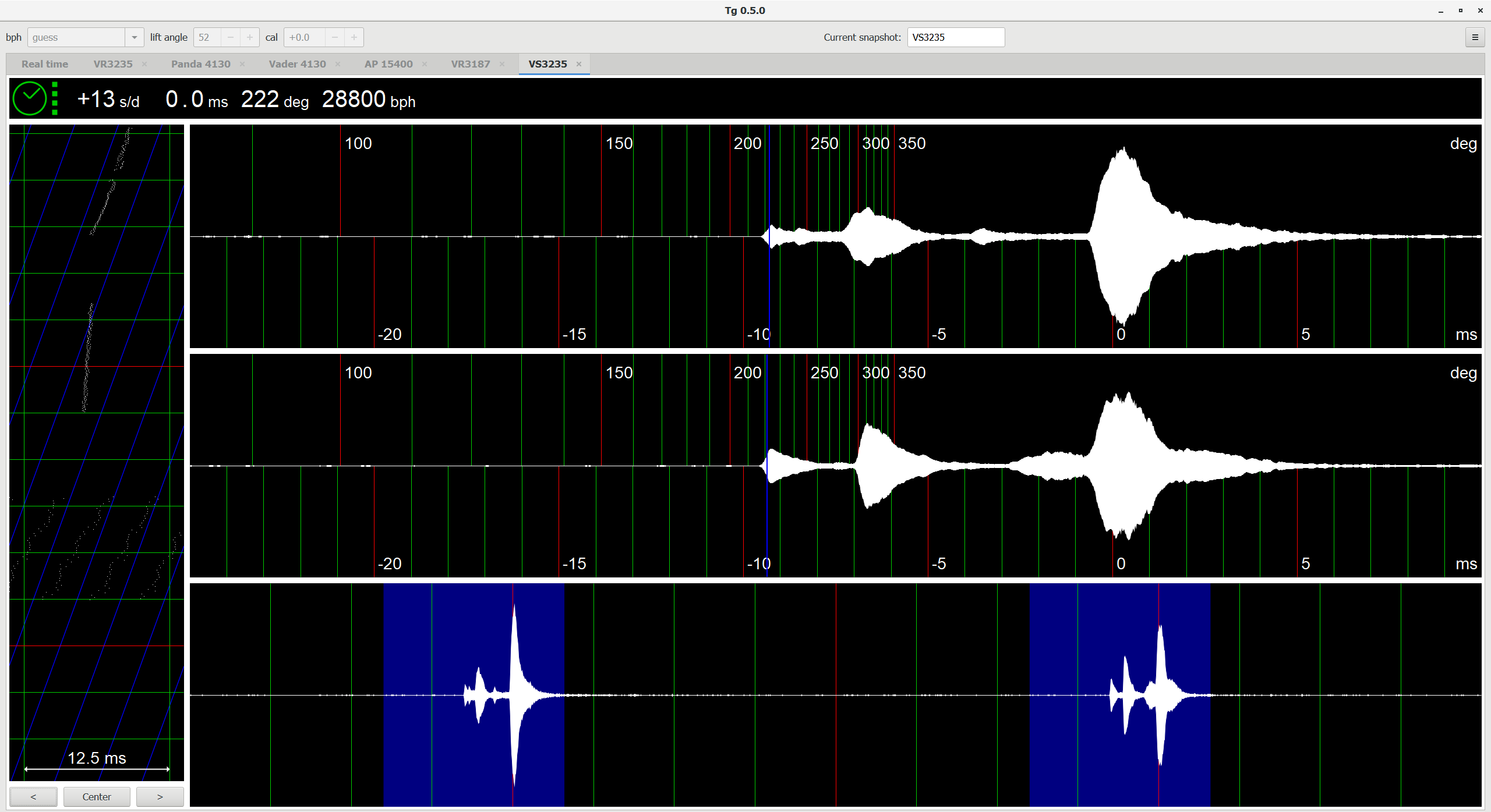

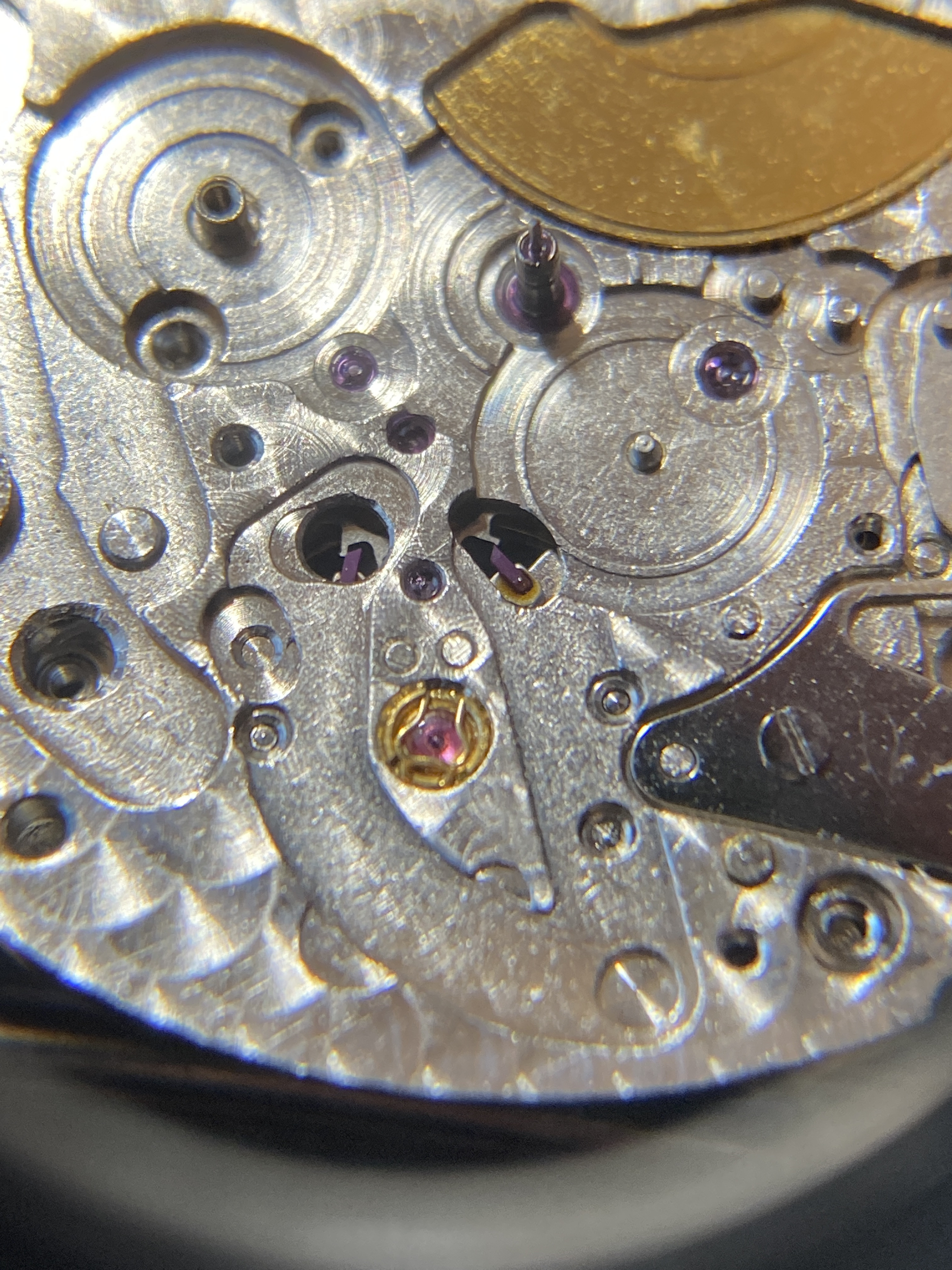

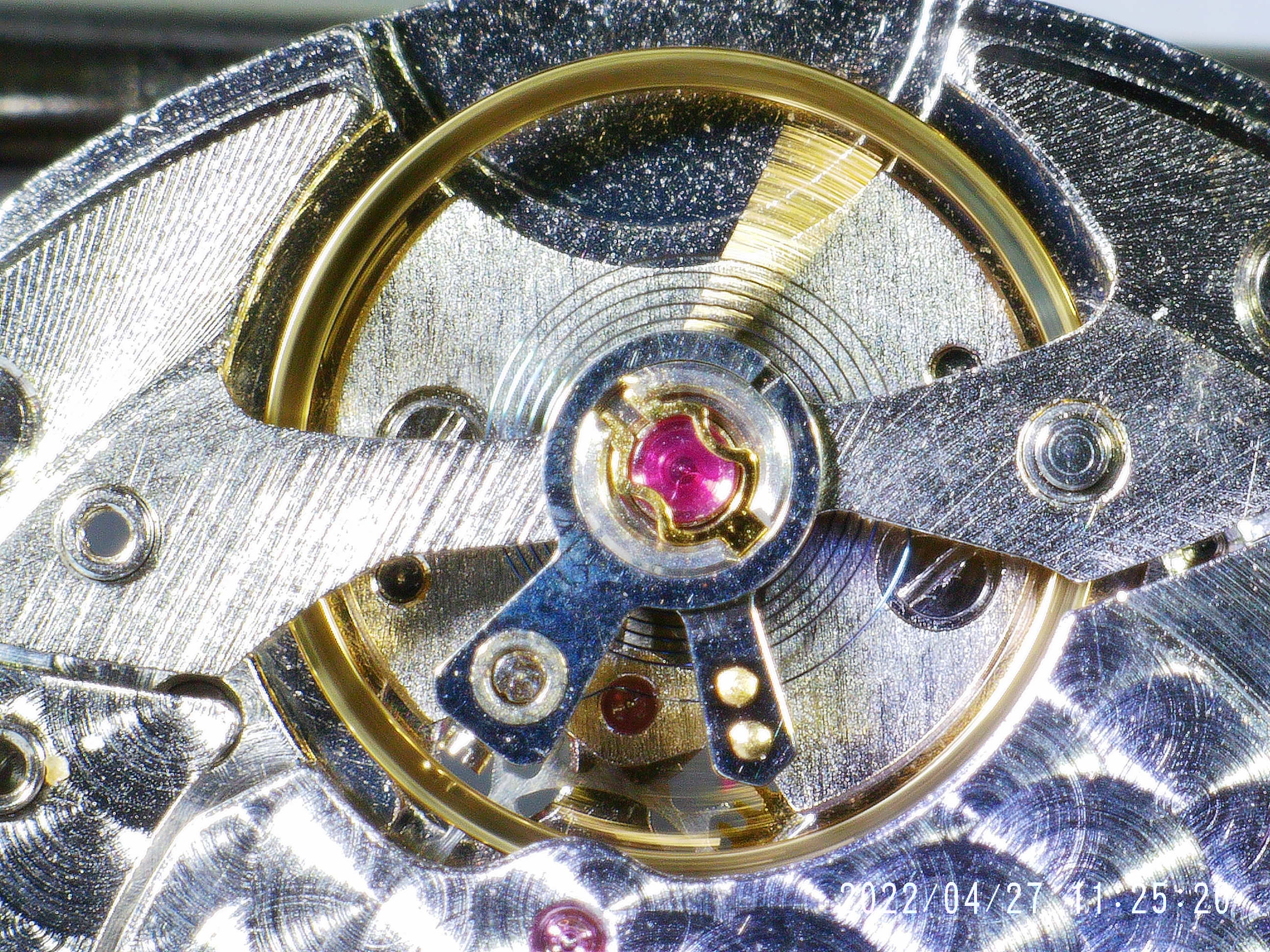

Update: I haven't made any real progress, but I have discovered something that I *think* might be causing my amplitude problem. I think there's some kind of mismatch between my Clark pallet fork and my VR escape wheel. The reason for this is that I'm getting inconsistent locking distance on the entry stone (see pics). I remember in Mark Lovik's course he mentioned a rule of thumb that the locking distance should be about 1/6th of the impulse face width. So based on the pics below, it appears that my locking distance on the entry stone is too big most of the time, but is also very small about 10% of the time.

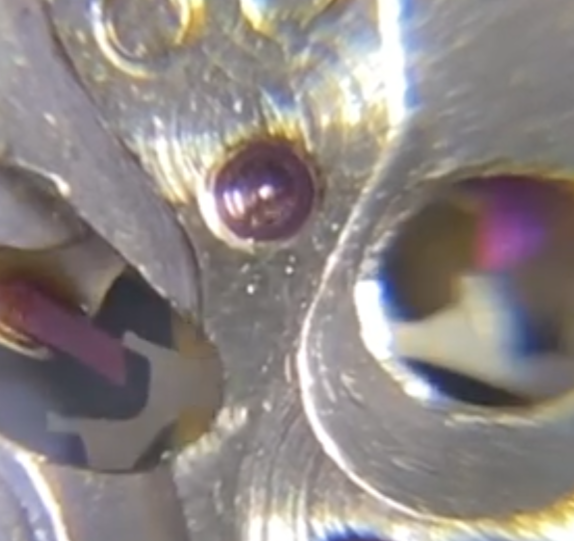

These pics were both single frames from a slo-mo video that I shot. The first pic shows the "normal" locking distance on the entry stone. It kinda looks like my locking distance is closer to 1/4 of even 1/3 of the impulse face width. Could this explain my low amplitude? Perhaps too much energy is being expended by the balance wheel to "unlock" the entry stone?

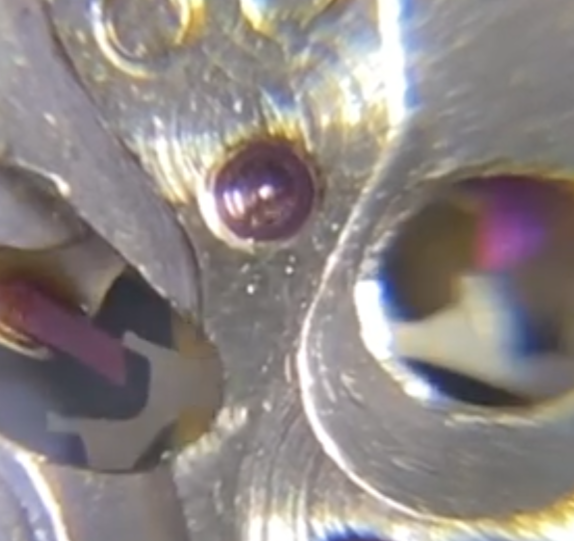

This second picture shows the amount of locking distance I'm getting about 10% of the time (perhaps this is due to a few teeth on the escape wheel having slightly different geometry and I'm only seeing it each time the escape wheel makes a complete revolution. Interestingly, there are also parts of the slo-mo video where the entry stone locks in this position, and then after a pause slides into the position shown in the image above.

Here's a pic of the exit stone (I flipped the movement 180 degrees, to get better light on this stone)... but interestingly it looks like the escape wheel tooth isn't even locking on the locking face, it looks like it kind of just jams on the corner of the impulse face of the exit jewel.

I kinda wish I had another VR3235 movement on hand so I could check to see what a "healthy" VR3235 movement's pallet fork / escape wheel locking behaviour looks like. At the moment, I' only have VS3235 and N4130 movements in the rest of my reps. I'm kinda tempted to order a VR3235 from AliExpress (C$200) just to see what this looks like. However, before I pull the trigger on a spare movement, are there any watchsmiths with more experience than me (i.e. everyone) that could chime in on the pics above?

It does not need service. Its all about beeing a nerd and wanna improve skillsHow old is the watch that it needed servicing already?

In some clone movements I have serviced the oil under the cap jewel doesn’t always make a uniform circle. Oftentimes it disperses unevenly which I attribute to slight inaccuracies in manufacturing. I have not experienced this in genuine movements or jewels. As long as the pivot sits in oil you should be ok, but the service interval might be sooner than normal.