I was going to make a post. I'm so lost on this one. I think I'm doing something in the wrong order and it's making my hair fall out.

Bezel popped out easily, and of course I lost the bearings/springs. I got new ones. I got a new crystal because I shattered the first one, and I shattered that one too.

What I'm doing:

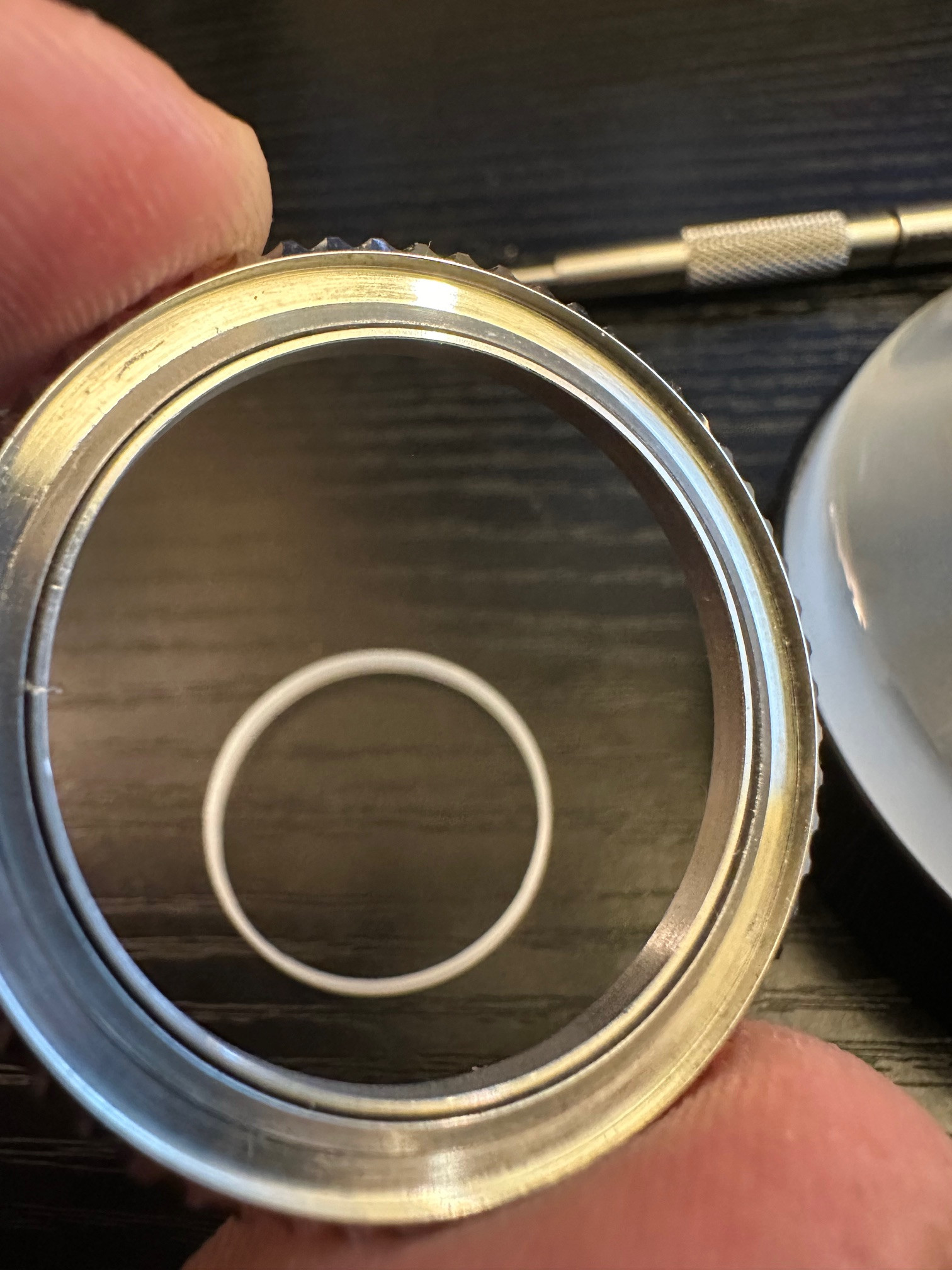

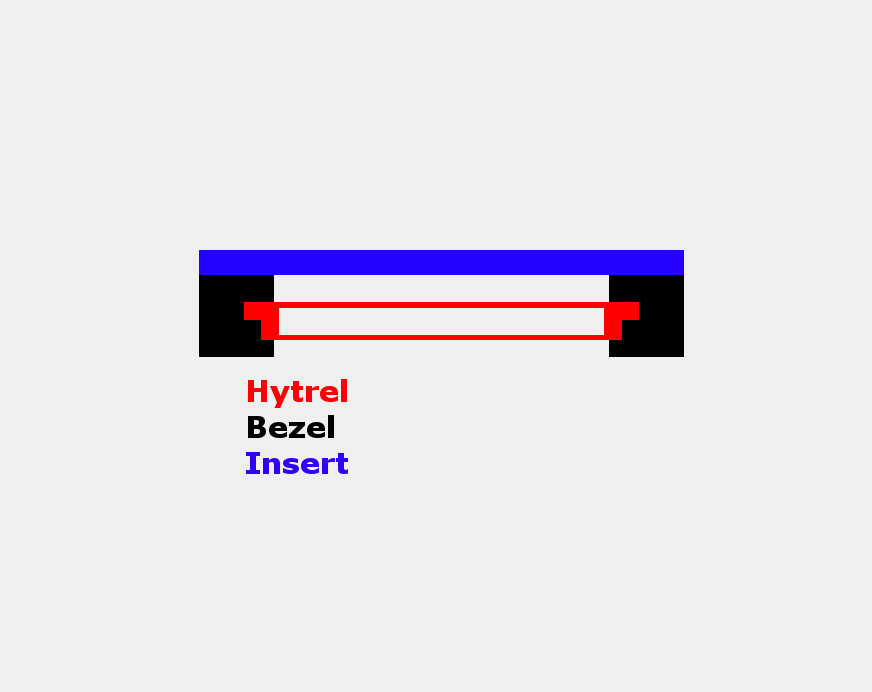

1. I put the crystal gasket around the ring while the bezel is off.

2. I then put the metal retainer on around it after.

3. I set the crystal in, line up the date window and press. I had it once and it seemed all good, but it was a little off, so I removed it again.

4. The time I did have the crystal in "correctly", I lightly pressed the bezel (before putting on the insert), and nothing. Wouldn't spin.

5. Then I broke the bezel insert at 4:00.

6. I have assembled countless Seiko watches with ease (for the most part), but this watch is from hell. 2 sets of hands. I broke the keyworks on the first movement. 2 crystals, now the bezel. I can't win with this one, so I'm convinced I need to learn on this one since it's still nice, but essentially a dumpster fire of a timepiece.

If you could shed some light on what I could be doing wrong, I'd be so unbelievably grateful. It's driving me nuts. I'd also be happy to post any pictures that would lead you to why I'm a complete mess up with this thing...

Thank you so much.